Stainless steel gauge thickness charts are instrumental reference tools of a precise nature that professionals use in industries for material specifications. If working with manufacturing, construction, or product design, one must understand gauge measurements and how they correspond to the physical thickness of stainless steel to ensure consistency in results and long-lasting properties. This article becomes a full-fledged guide that demystifies stainless steel gauges: what they mean, how they are measured, and their practical use. By the conclusion, the audience would be more comfortable choosing gauges for their projects and ensuring that everything operates smoothly in any given situation.

Introduction to Gauge Thickness

Gauge thickness refers to standard measurement for thickness in stainless steel and other metals. It follows a numerical scale wherein a thin metal bears a high gauge number and a thick metal a low number. 18-gauge stainless steel is thinner than 14-gauge stainless steel. This system allows manufacturers and workers to maintain consistency and interoperability when making their choices into applications, from kitchen equipment to industrial construction. The right gauge has to be understood and chosen to accommodate strength versus weight and intended application into the projects.

What is Gauge Thickness?

Gauge thickness measurement refers to a thickness measurement system widely used for materials, including steel or aluminum, or for other materials such as wires and plastics. It is a system giving a standardized description for a cross-sectional dimension of any given type of material. It is worth noting that this gauge system is nonlinear, implying that the relationship between the gauge number and the thickness of the material varies, i.e., with an increase in gauge number, the thickness decreases. For example, for steel, a 20-gauge sheet is about 0.036 inches thick, whereas a 10-gauge sheet is approximately 0.134 inches thick.

In determining gauge thickness, the construction, engineering, and manufacturing fields greatly emphasize precision, for their purposes require exact specifications needed for structural integrity and performance. On the other hand, the standards facilitate material selection, cost estimation, and consideration for a perfect fit of the components destined for assembly. It is often the case that gauge numbers, alongside other properties such as tensile strength or material type, are mentioned so that the professionals can make educated choices as to what best suits their particular application.

The Significance of Stainless Steel Gauge

Choosing the proper gauge of stainless steel is an essential item in deciding on its suitability for a wide range of industrial and commercial applications. Higher gauge numbers refer to thinner gauges, and applications using such gauges may require flexibility, light weighting, and ease of fabrication, and hence domestic appliances or cladding systems and decorative finishes might be considered as examples. Thicker gauges with lower gauge numbers provide durability and resistance in structural applications, industrial tanks, pressure vessels, or load-bearing situations.

With recent developments in manufacturing technologies, very advanced manufacturing technologies have rendered possible very precise control of stainless steel gauge, optimizing material performance and simultaneously reducing waste and cost. An example will be strict gauge tolerances in the food processing and medical industries, guaranteeing that equipment meets hygiene and safety standards. The architecture sector benefits from gauge tolerances to maintain design integrity by preventing deformation due to stress.

Often, the gauge is combined with allied properties such as grade, surface finish, and corrosion resistance to ensure the reliable performance of stainless steel components in the environment and under the operational stresses specific to their applications. This underlies how the function of gauge is intertwined with material selection, quality assurance, and product lifecycle management.

Importance of Gauge Thickness in Stainless Steel

The right gauge thickness is essential in achieving a desirable performance in stainless steel applications. Thin gauges fit only in lightweight constructions or decorations because of their flexibility and comparatively lesser use of materials, thus lowering the costs. Thick gauges are more durable and resist impacts more readily; hence, they are suitable for heavy applications and high-stress set-ups. Correct gauge choice means increased reliability and good use of materials with fewer wastes that promote sustainable projects.

Impact on Strength and Durability

Choosing the gauge of a material plays quite an important role in determining the strength and durability of a structure. Thin gauges will be less able to bear loads in applications where more flexibility is needed, more able to resist forces such as wind or mechanical impacts, and less costly. On the contrary, thicker gauges provide great tensile strength and resist deformation, making them better suited for rigorous applications involving infrastructure, transportation, or industrial equipment. Research shows that applying an appropriate gauge thickness that caters to the needs of a particular project leads to better output in performance, while also reducing a great deal of overdesign and usage of materials. This act of optimization guarantees the ideal balance between structural integrity and material efficiency needed for the sustenance of both functionality and sustainability.

Performance Characteristics of Different Gauges

|

Gauge (Thickness) |

Key Characteristics |

Typical Applications |

Material Weight Impact |

|---|---|---|---|

|

8 Gauge (~4.19mm) |

Extremely thick, robust, and durable |

Heavy-duty industrial equipment |

Very heavy |

|

10 Gauge (~3.41mm) |

High structural strength, corrosion-resistant |

Restaurant kitchen counters, sinks |

Heavy |

|

12 Gauge (~2.77mm) |

Balanced strength and flexibility |

Structural framing, vehicles |

Moderately heavy |

|

14 Gauge (~1.98mm) |

Versatile, ideal for general applications |

Countertops, moderate industrial use |

Medium-weight |

|

16 Gauge (~1.59mm) |

Strong yet lightweight for most uses |

Residential sinks, counters |

Light-medium |

|

18 Gauge (~1.27mm) |

Affordable, flexible, easy to fabricate |

Decorative trim, light-duty sinks |

Light |

|

20 Gauge (~0.95mm) |

Thin, lightweight, suited for small-scale items |

Light fixtures, appliances |

Very light |

|

22 Gauge (~0.79mm) |

Minimal strength, highly bendable |

Electrical enclosures, small kitchen tools |

Extremely light |

Common Misconceptions about Gauge Thickness

Another prevalent misconception is that higher versus lower gauge numbers always mean more excellent strength and durability. Yet gauge thickness is dismissed in such a way: high gauge numbers mean thin and mostly less rigid materials. A metal sheet of 22 gauge (roughly 0.79mm thick) is much less sturdy than a sheet of 16 gauge (approximately 1.59mm thick).

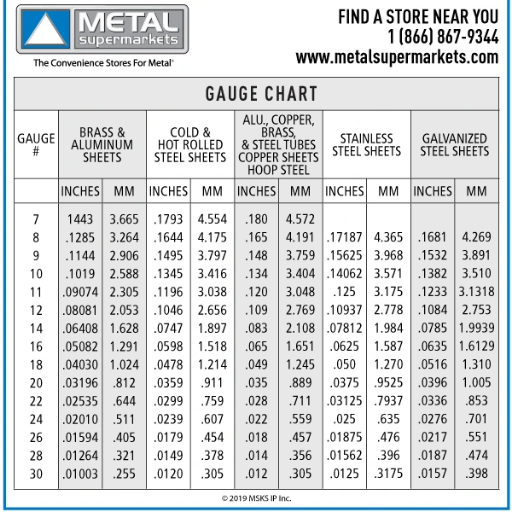

The other misconception is that all gauge thickness standards are universally adhered to across various materials. Otherwise, the gauge system would vary with material composition; steel would have one, aluminum another, and other metals a third. This inconsistency calls for an importance to refer to material-specific charts in making gauge assessments suitable for given applications.

The last set of considerations are those pertaining to the cost of materials. Some people consider thinner gauges as always more affordable due to less volume of the material; this is generally true. However, price may also vary according to how difficult the material is to fabricate, cost of transport, and type of material. One must factor these intricacies into project planning if they want to hit the balance of budget and performance requirements.

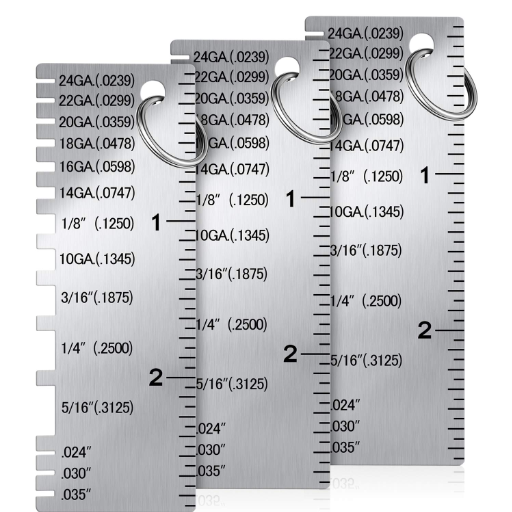

How to Read and Interpret a Gauge Chart?

In an attempt to read and interpret a gauge chart correctly, consider the following:

- Identify the Material Type: Gauge charts are material-specific. Always check that the chart you are consulting is intended for the material you are analyzing, be it steel, aluminum, or copper.

- Locate the Gauge Number: Numbers can be found along with ascending and descending orders. Find your gauge number of application.

- Refer to the Thickness Value: Each gauge number corresponds to a certain value for thickness, generally given in inches or millimeters. The actual thickness of the material is determined by this value.

- Cross-Check Standards: Make sure your chart matches the standardized measurements within your region because gauge standards can change (for example, American Wire Gauge versus Birmingham Gauge).

- Verify Suitability for the Application: Value to check with your project requirements for suitability, including factors for strength, weight, and durability.

Following the above steps systematically would allow you to use a gauge chart that will aid you in making informed decisions relevant to your requirements.

Understanding Gauge Measurements

Gauge measurements are utmost essential for manufacturing and engineering as they provide the required standardization for assessing material thickness and suitability. Where precision, strength integrity, and material performance are concerned, it becomes all the more important such as building, aerospace, or automotive engineering. For example, in metalworking, knowledge of the gauge versus material types (e.g. steel versus aluminum) is needed since a certain gauge number stands for different thicknesses, depending on the material. Quality sources and tools for gauge data allow professionals to shortlist materials that qualify load-bearing, weight, and durability criteria for their respective applications. These days, with advancements in the field of digital tools and data availability, gauge standards are better integrated into computational design systems, thus increasing efficiency and accuracy in workflows.

Examples of Reading a Gauge Chart

Consider the practical application of reading a gauge chart: the designer is tasked with making a lightweight yet strong metal component. Referring to the gauge chart for stainless steel, this designer sees that 16-gauge steel has a thickness of approximately 0.0625 inches (1.59 mm). On the other hand, for the same 16 gauge aluminum corresponds roughly to 0.0508 inches (1.29 mm). This difference in thickness is a good example of why one needs to beware of gauge values for different materials and always cross-reference the thickness values given.

Another example may concern a construction expert who wants to select 22-gauge sheet metal for roof panels. From the gauge chart, the construction expert finds that Galvanized Steel at 22-gauge is about 0.0299 inches (0.76 mm) thick. Together with material strengths, withstanding weather propaganda, the expert will go ahead with their choice, weighing all factors. Using such prevailing knowledge gained from the gauge chart will enable the most appropriate choices to be made in varying engineering and construction situations.

Visual Aids for Better Interpretation

Applications of Stainless Steel Gauge Thickness

- Architectural and Structural Design

18 gauge (0.0478 inches or 1.21 mm) granite stainless steel sheet is generally employed in architectural cladding and roofing. This thickness represents the best compromise between stiffness and flexibility, carrying enough strength to withstand environmental stress while being too light to carry.

- Automotive Manufacturing

Thinner gauges of stainless steel, such as 22-gauge (0.0299 inches or 0.76 mm), are applied in vehicle body panels and trims. The automotive engineers use it so that there are reductions in weight, which offers increased fuel efficiency without compromising the durability and corrosion resistance of the exterior.

- Food and Beverage Industry Equipment

Heavy gauge stainless steels, such as no. 14, provide greater strength and are used for the fabrication of industrial kitchen equipment such as countertops, sinks, and storage units. Its additional thickness offers increased support capacity and service life in impact environments.

- Medical and Pharmaceutical Industries

The thinner stainless steel materials, like 20-gauge (0.0359 inches or 0.91 mm), find extensive application in the manufacture of sterilization trays, surgical instruments, and medical storage units. It allows for very precise machining and at the same time is tough and easy to clean.

- Aerospace and Aviation Components

For thin stainless steel applications that require an excellent strength-to-weight ratio, 24-gauge (0.0239 inches or 0.61 mm) is used in non-structural aircraft components. Weight reduction contributes to fuel efficiency, whereas resistance to temperature variation and corrosion in thin stainless steel controls further variable factors.

- Industrial Machinery and Equipment

Construction Industry Uses

Because of its high strength and resistance against corrosion and great looks, stainless steel is at the heart of modern construction. Stainless steel constructions are more common in structural construction in structural members such as beams, columns, and reinforcements, especially in humid or pollutant environments. For instance, stainless steel façades and cladding employing 16-gauge stainless steel (0.0625 inches or 1.59 mm) will perform for a long time when under environmental stresses and will also stand out in their elegant and modern look. Stainless steel rebars are used for reinforcing concrete in bridging and highway infrastructure, improving longevity and preventing corrosion-based failures. Resistant to fires and earthquakes, it is chosen for important construction projects. New fabrication technologies, in particular laser welding and laser cutting, have raised the efficiency and flexibility of stainless steel in architectural and structural design.

Automotive Applications

- Chassis and Frame Construction

Depending on the tensile strength and durability characteristics serving to any design-fit chassis and frame, reinforced steel is the primary material for manufacturing vehicle chassis and frames. Lightweight steel alloys are used in modern automotive designs to reduce vehicle weight without compromising safety. Research shows that AHSS can increase the crash performance of a frame while at the same time achieving a 25% reduction in the frame weight of the vehicle.

- Suspension Systems

Considered reinforced steel application areas include suspension control arms, stabilizer bars, and springs. All such components receive cyclical bending and stress, where reinforced steel can provide the strength and durability demanded by the steel.

- Body Panels and Impact Zones

Advanced grades of steel are becoming widely used in the manufacturing of automotive body panels and crumple zones as absorbers of energy in collisions. Doors, hoods, and fenders are mostly manufactured with dual-phase and martensitic steel, which improves protection in crash scenarios. It has been demonstrated through research studies that developments in the steel used for impact resistance reduce occupant deaths by 20%.

- Powertrain Components

Being used in engine blocks, transmission gears, and drive shafts, reinforced steel stands out due to its heat resistance and wear characteristics that are very suitable for heat and mechanical stress conditions in the powertrain.

- Exhaust Systems

Kitchenware and Household Items

Considered the most durable, most hygienic, corrosion-resistant material, stainless steel is best for kitchenware and household items. Secondary-grade or lower-grade pots and pans are used in both industrial and domestic applications of stainless steel; therefore, the heat is not distributed properly, and they could be damaged if not taken care of properly. The non-porous surface of stainless steel does not allow the settlement of bacterial deposits, making it very much safe and easy to clean with. Stainless steel finish is also applied to fridges, dishwashers, and ovens that are popular for being fingerprint resistant and wear-resistant all at the same time. Studies further summarize that strength and recyclability features of stainless steel are avenues for sustainability in terms of reducing waste and improving resource efficiency in household applications.

Practical Tips for Selecting the Right Stainless Steel Thickness

- Determine the Purpose of Use

Thickness selection should be governed by the application intended. The thinner stainless steel (20-24 gauge) will be used for applications lighter than backsplash or decorative panels, whereas the heavier steel (14-18 gauge) will be useful in higher-stress applications such as countertops and heavy-duty sinks.

- Consider Durability Requirements

Thicker stainless steel shall be able to withstand heavy duty impacts and resist dents and warping. For areas of constant impact or weight loads, choose a suitable gauge that will ensure operational efficiency to resist wear through a lifetime.

- Balance Cost and Performance

Thicker materials tend to be costlier. If price tag is of consideration, weigh if a mid-range thickness meets your needs without sacrificing performance or beauty.

- Match to Industry Standards

Check industrial recommendations for the application in question, as certain contexts (for instance, commercial kitchen) might have governance on stainless steel thickness as regards safety, hygiene, or durability standards.

- Test for Compatibility

Functionality Considerations

In the analysis of an assigned function, an observation with respect to its mechanical properties concerning the proposed use must be introduced. Thickness influences load resistance, deflection, and durability over time. For example, thinner sheets may serve their purpose in decoration but fail under any structural application that goes heavy on stress or impact. Then again, the corrosion resistance and temperature tolerance of the sheets must fit well with what the operational environment expects of them. After all, the operational environment also weighs heavily on cleansing standards. Extensions and insights from recent published work and industrial resources emphasize that performance and service life can be greatly enhanced if standardized grades of material with suitable surface finishes are used, more so when in rigorous applications such as the food processing or medical industry.

Intended Usage and Project Requirements

A major consideration is industry standards and compliance. For instance, materials ensuring hygienic standards above industry expectations are to be used in the pharmaceutical or food processing industries. Such materials should withstand pitting within sanitary environments, such as 316L stainless steel. The inclusion of information on temperature is vital in cases dealing with extreme heat or cryogenic applications, where the selection of alloys such as those-warrior Inconel or Hastelloy would be most apt.

Reference Sources

-

Heat Input Effect on Microstructural Transformation and Mechanical Properties in GTAW Welds of 409L Ferritic Stainless Steel

- Key Findings: This study examines the effects of gas tungsten arc welding (GTAW) on 4 mm thick stainless steel. It highlights superior mechanical properties in the weld metal and dilution zones.

- Read more

-

Microstructure and Mechanical Properties of Pulse Laser Welded Stainless Steel and Aluminum Alloys for Lithium-Ion Cell Casings

- Key Findings: The study explores the welding of 0.5 mm thick stainless steel (SS 316L) with aluminum alloys, focusing on microstructural changes and mechanical properties.

- Read more

-

Ratcheting-Fatigue Behavior of Harmonic-Structure-Designed SUS316L Stainless Steel

- Key Findings: Investigates the fatigue properties of austenitic stainless steel under axial loading, emphasizing the role of harmonic structures.

- Read more

Frequently Asked Questions (FAQs)

Q: What is a Gauge Thickness Chart?

A: A gauge thickness chart is a useful reference tool that indicates the thickness of various materials, primarily sheet metal. This chart typically includes standard steel and metal gauge thickness, helping users understand the measurements corresponding to different gauge numbers. In the U.S., lower gauge numbers indicate thicker materials, while higher numbers represent thinner materials. The chart can cover a variety of metals, including brass, aluminum, and zinc, making it versatile for various applications. By consulting a gauge thickness chart, you can specify the appropriate sheet metal gauge size for your project.

Q: How Does the Sheet Metal Gauge Chart Work?

A: The sheet metal gauge chart works by providing a list of gauge numbers alongside their corresponding thickness in inches and millimeters. For instance, a standard steel gauge may vary in thickness based on the gauge number; lower numbers correspond to thicker sheets. Each entry in the chart serves as a conversion reference, facilitating the selection of the right sheet metal gauge for different applications. It’s commonly used in industries like construction and manufacturing to ensure accurate measurements. Understanding how to read this chart can help prevent errors in material selection.

Q: What are the Commonly Used Metal Gauge Sizes?

A: The commonly used metal gauge sizes vary based on the type of material and its application. In sheet metal, gauge numbers typically range from 3 to 30, with thicker materials represented by lower gauge numbers. For example, a 10-gauge steel sheet is approximately 0.135 inches thick, while a 30-gauge sheet is only about 0.012 inches thick. These sizes can differ significantly among different metals, such as aluminum and brass, which may have their own set of gauge standards. Knowing these specifications helps in selecting the right size for any project.

Q: What is the Significance of the Gauge Chart for Sheet Metal?

A: The gauge chart for sheet metal is significant because it provides a standardized reference for thickness that is crucial in various industries. It allows manufacturers and fabricators to ensure consistency in their products, which is essential for structural integrity and performance. The thickness indicated on the gauge chart can affect the material’s strength, weight, and formability, making it imperative to choose the correct gauge. Additionally, the chart helps in converting measurements and understanding how different gauge numbers can affect the overall design of a project. Familiarity with this chart can lead to more efficient and effective material usage.

Q: How Do Gauge Numbers Differ Between Metals?

A: Gauge numbers can differ between metals due to variations in density and material properties. For instance, a 16-gauge steel sheet may be thicker than a 16-gauge aluminum sheet because of the differences in their densities. This is important when selecting materials for specific applications, as the properties of steel, brass, and other metals can influence the final product’s performance. Understanding these differences helps in making informed decisions about material selection. A gauge thickness chart typically includes this information, aiding users in comparing the gauge thickness across various materials.