Because of its wide use in a variety of fields, 4×8 galvanized sheet metal is regarded as a highly versatile, steadfast, and economical option. Its great corrosion resistance and multi-purpose capability makes it essential in construction, manufacturing, and other do-it-yourself activities. This guide has the objective of providing a thorough and technical description of 4×8 galvanized sheet metal, including its ingredient, advantages, typical usage, as well as important factors regarding selection and usage. Thus whether you are a contractor deciding what materials to purchase for your project or a hobbyist looking for reliable makes, this article will assist you with the most vital information to help you make the right choices.

What is 4×8 Galvanized Sheet Metal?

4×8 galvanized sheet metal is simply a galvanized steel sheet given additional care to contain corrosion which is 4 by 8 feet in dimension. Because of its affordability and durability, it is used in roofing and siding, as well as parts for vehicles. In addition to this, it is used in custom ducts and other framing works on account of its moisture resistance and robustness. The zinc coating does more than prevent rusting: it improves the material’s lifespan no matter how much it is used.

Definition and Characteristics of Galvanized Steel

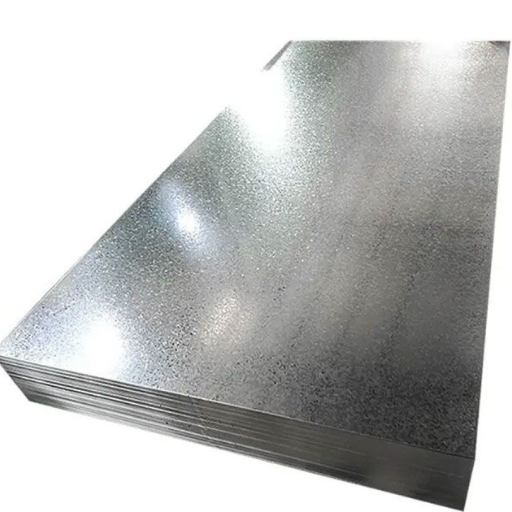

Galvanized steel is steel that has a protective zinc coating done on it to prevent rusting as well as to make sure it can stand the environmental elements. A commonly used technique for this is hot dip galvanization, in which steel is dipped into molten zinc, or slipped into liquid zinc at temperatures about 840°F (449°C). During this Zinc and Steel undergo a metallurgical bond which forms a strong coating that protects against rust and corrosion.

Galvanized steel is best known for the protective shield against moisture, oxygen, and other harmful materials. The zinc coat protect the steel surface directly, but also provides “sacrificial protection.” What this means is, even if the galvanized zinc coating is scratched and damaged, the zinc layer will corrode first before the rusting of the underlying steel.”

Galvanized steel comes at a range grades and finishes which add flexibility for numerous applications. Commonly, they are used in construction as beams, columns, and fasteners. They are also placed in automotive equipment, electrical equipment cases, and farm machines. It has a long life span of over 50 years in rural areas and 20-25 years in extreme industrial or coastal surroundings which makes it a dependable material across industries.

Common Uses of 4×8 Galvanized Sheets

The automobile industry also uses the 4×8 galvanized sheets for underbody and body panels plus reinforcement sections. The low weight of the galvanized sheets along with high tensile strength assures the durability of the vehicle without adding excess weight. Furthermore, these sheets are useful in making storage tanks, air conditioning stock, and ventilation systems because of their long serving and wear resistant properties.

4×8 galvanized sheets benefit the automotive industry too as they are used for underbody sections, body panels and also reinforcement parts. The lightweight nature and high tensile strength ensures vehicle structural integrity while significantly reducing its weight. Moreover, these sheets are used in making storage tanks, HVAC equipment, and ventilation systems due to their wear resistance and ability to perform for a long time.

Silo, trough and fencing is made from galvanized sheets by agricultural parts manufacturers. These sheets are also useful for parts exposed to the outside and electrical enclosures, cable trays, and conduit systems, which increasing touches the environment and needs materials that can protect against rust and corrosion. The industrial and residential needs are covered with the fact that with new advancements in production processes the 4×8 galvanized sheets are practical, inexpensive and durable.

What Are the Different Gauges Available for 4×8 Sheets?

The most common gauges saw for 4×8 galvanized sheets are between 26 to 16, although they do range from 30 gauge (thin) to 7 gauge (thick). 26 and 24 gauges are more common for shingles/siding in residential buildings because they are lightweight. Greater structural strength, like in manufacturing tooling or heavy-duty enclosures, require thicker gauges like 14 or 12 for industrial use. Each application will determine the specific gauge required along the factors of strength, flexibility, and weight.

Understanding Steel Sheet Gauges

Selecting the appropriate gauge of steel sheets requires the evaluation of several factors to determine its performance effectiveness for it’s purpose. The gauge will not only determine the material’s thickness, but also weight, strength, and flexibility of the sheet. For a structural application, thicker gauges will ensure better load bearing capabilities and withstand deformities. Projects that need to minimize used materials will benefit from thinner gauges.

In any case, the kind of steel in use is of equal importance. As an instance, the performance of stainless steel sheets is better than carbon steel ones because the former’s resistance to corrosion, as well as its tensile properties, is stronger, allowing it to hold strength even at thinner gauges. Furthermore, some environmental factors, for example, moisture or chemical exposure, may require a specific gauge and steel grade combination to resist deterioration. More recent research has shown new advancements in coating processes like galvanization and polymer layering which protect thinner steel sheets while maintaining core integrity.

Lastly, adherence to industrial norms and policies is equally important. For instance, ASTM and ISO provide comprehensive procedures on the tolerances of the thickness of sheet steel, which makes sure that uniformity and reliability is achieved across different applications. These standards ease the decision-making burden of engineers and architects when specifying materials for design, aesthetic, or structural purposes, industrial, and more.

Choosing the Right Gauge for Your Project

Carefully analyzing the potential application, material properties, and structure marks the first step to determining the gauge for your project. Different applications may require different gauges, for example for lightweight structures such as interior wall covers, 22 or 24 gauges may be preferable due to their ease of handling and flexibility. On the other hand, load bearing components and industrial machinery may require thicker gauges such as 12 or 14 for added strength and durability.

Using a material’s tensile yield and ultimate tensile strength provides insight on how a particular gauge of steel will fulfill various demands. кон Industry databases and material property charts prepare precise equations to determine load bearing capacity, thermal expansion, and long term wear. In addition to these, external conditions like environment, humidity, temperature changes and exposure to corrosive material also has to be taken into account. Adopting industry best practices allows optimal material selection to achieve economic efficiency as well as structural strength.

How to Purchase 4×8 Galvanized Sheet Metal?

To purchase 4×8 galvanized sheet metal, follow these steps:

- Determine Requirements – Consider the overall project. Identify the required thickness of the metal, if a coating is needed, and the quantity.

- Research Suppliers – Search metal product suppliers or distributors. Look for online vendors, local hardware shops, or dedicated metal supply businesses.

- Compare Prices and Quality – Request quotations from multiple vendors in order to assess pricing, quality, and different delivery options. Check the specifications to determine if the offered products fit the expectations.

- Order and Delivery – Complete an order directly from the supplier’s webpage or call the sales representative. Shipping costs and delivery dates should be agreed upon before finalizing the purchase.

- Inspect Upon Arrival – Once the sheet metal have been delivered, check whether the metal is in a good condition. If there are any issues concerning the quality or damages, the supplier should be contacted immediately.

Completing the listed steps allows for a streamlined process while obtaining the required materials for the specified project.

Where to Buy Galvanized Steel Sheets

Galvanized steel sheets may be purchased from various online and local suppliers. McMaster-Carr, Grainger and OnlineMetals are examples of larger industrial suppliers that sell galvanized steel sheets with differing sizes and thicknesses to suit the needs of any project. Local regional metal distribution centers are also good sellers of the sheets as they provide consultations in person and offer customized cutting for clients.

Such global providers as Metal Supermarkets directly ship to your location, making inventory more accessible for businesses with deadlines. In addition, large-scale businesses make purchases from selective suppliers who specialize in bulk orders. When evaluating potential vendors, verify their product certifications against the manufacturer’s mark of the building clients such as ASTM A653 or A659 which contains the quality standards for galvanized steel to ensure compliance.

For more specialized purposes, businesses may wish to contact manufacturers directly, as they can more easily provide custom galvanized sheet metal cut to size for specific purposes. Still, cost optimization and obtaining materials in time for projects are crucial; therefore, pricing, shipping terms, and availability across multiple suppliers should be compared.

Stock Availability and Ordering Process

To minimize delays and maintain production schedules, consistent stock availability is critical. Buyers must trust suppliers that offer real-time stock level updates and automated reordering features for frequently used items such as galvanized steel sheets. Several suppliers have also integrated user-friendly online systems where customers manage orders, check stock, and create quick quote documents. With the automated order systems, exact timing will depend on the manufacturing schedule and precise order details with delivery windows will need to be provided to ensure on-time delivery.

While looking at stock, think about seasonal demand patterns as well as possible supply chain risks which might affect the availability of materials. In order to improve the procurement process, companies must cultivate relationships with key vendors who provide additional services, including purchase discounts, material storage, and expedited shipment. This approach not only facilitates acquisition of materials but also protects the firm from project delays related to supply vulnerability risks.

How to Cut and Work with 4×8 Galvanized Steel Sheets?

Working with and cutting galvanized steel sheets of 4×8 feet requires proper tool selection given the thickness of the material and the requirements of the project. For thinner sheets, precision cuts can be made using aviation snips, while thicker sheets require an electric shear. For straight cuts, larger cuts can be made using a circular saw fitted with a metal-cutting blade. While cutting, the sheet must be placed over a stable surface. Marking cut lines must be done clearly with markers or chalk. When handling the sheet, care must be taken not to damage the zinc coating used as rust protection. The sheet must be handled with care and excessive force in cutting must be avoided.

PPE in form of gloves, safety goggles and ear protection must be worn when working with the sheets. If shaping or bending is to be done, a bending brake must be used which will ensure clean edges while retaining structural integrity. Every cut edge is to be smoothened with a metal file, sharpening increases the chance of accidents, so this step is necessary. Lastly, check the sheet for scratches and exposed places after cutting in addition to adding zinc-rich paint or primer where protection form corrosion is no longer maintained.

Tools Required for Cutting Galvanized Sheet Metal

While working with galvanized sheet metal, tool selection is required to achieve the cuts precisely while preserving the integrity of the protective zinc coating. Standard tools include:

- Tin Snips – These hand tools excel in small projects allowing for straight, curved, or even very intricate cuts neat and orderly. Pick the right variant based on cuts with different directions and shapes like straight cut, left cut, or right cut, as they are specifically made for different types of cuts.

- Power Shears – Power Shears provide speedy and accurate cuts, making them ideal for large projects. They are useful for professionals tackling highly detailed projects.

- Angle Grinders – Fitted with metal cutting discs, angle grinders are more versatile than the other options when dealing with tougher or thicker sheets. Users need to take extra safety measures when it comes to the excessive heat cause, as it may melt the zinc coating.

- Electric or Manual Nibblers – As these tools permit precise, clean, and distortion-free filters, they are often used for more advanced intricacy. They are useful for thicker sheets because they remove small ‘nibbles’ along the cut line.

- Jigsaws with Metal-Cutting Blades – A jigsaw fitted with a metal-cutting blade can perform more detailed or intricate designs with curves. Set speeds reduce heat accumulation for more intricate cut shapes.

Choosing a tool should align with the dimensions of the sheet metal, the detail required for the cuts, and overall scope of the work. It is recommended to check that tools are properly maintained as well as adhere to the appropriate safety standards to avoid injuries and remain productive.

Safety Precautions When Handling Steel Sheets

Working with steel sheets demands strict safety protocols to prevent injuries and maintain effective workflow. Scissors, safety glasses, and boots are all crucial parts of PPE; workers must don industrial gloves while handling as they can snag and cut on sharp edges, safety goggles to block vision of any flying objects that could damage the eyes, and steel cap boots to protect feet if sheets are dropped. Mechanical devices like hoists or suction lifters need to be used during transport to eliminate potential pose of musculoskeletal strain and on-site transport dynamics.

What Are the Applications of 4×8 Galvanized Sheets?

The 4×8 galvanized sheets are incredibly versatile and sturdy which is why they’re used in so many different applications. Construction activities are the primary users of these sheets for roofing, siding and ductwork as the cased galvanized layer protects from rust and deteriorating weather conditions. The sheets are thoroughly used for outer structures like fences, sheds, and agricultural tools. Plus, they’re needed to help boost component life in vehicles and machines, which makes them useful in automotive and industrial sectors. With such widespread capabilities, they’re useful for added value construction and industrial products.

Use Cases in Construction and Building

Synchronized worksheets are very important in modern constructions because of its low cost and great efficacy. One of the modern examples of its use is as roofs where they serve as strong shields against elements such as rain or humidity that may deteriorate the structure with time. Both residential and business constructions are now employing structural frameworks for beams, trusses, and columns which are made out of galvanized steel as they can carry a hefty weight while preserving their structural integrity for a long periods of time.

Galvanized steel also finds its application in modular construction systems; its innovative construction techniques and lightweight make transportation easier, assembly swift, and overall streamlined. Moreover, galvanized steel components are a fundamental piece to creating vital infrastructures such as bridges, guardrails, and walkways since they serve pedestrians and vehicles consistently while enduring various weather conditions, heavy traffic, and high-usage areas. The sustainability construction industry places value on this material as it requires little maintenance alongside its long life span and constant performance throughout various circumstances.

Industrial Applications of Galvanized Steel Sheets

The outstanding rot resistance, mechanical strength, and adaptability of galvanized steel sheets makes them popular across various industries. In construction, these sheets are used for roofing, cladding, as well as primary structural frameworks which are put through high levels of wear and tear. The automotive industry uses galvanized steel sheets to make body panels, chassis parts, and reinforcements so that the vehicles can withstand harsh environmental factors such as humidity and road salt for a long period of time. The energy industry also uses galvanized steel sheets for the solar mounts, components of wind turbines, and electrical enclosures which need to withstand prolonged exposure to harsh outdoor elements. All of these uses demonstrate the material’s importance to the infrastructure and technological development of the current world.

Reference Sources

-

Characterization of Galvanized Sheet Steel for Automotive Vehicle Bodies

This study focuses on the corrosion resistance, weldability, and performance of galvanized steel sheets in automotive applications. Read more here. -

Investigative Study on Bending and Spring Back of Electro-Galvanized Steel

This research explores the bending and springback behavior of electro-galvanized steel using the “Theory of Plasticity” and experimental methods. Read more here. -

Effect of Process Parameters on the Structure and Properties of Galvanized Sheets

This paper examines how galvanizing parameters influence the microstructure and mechanical properties of galvanized sheets. Read more here.

Frequently Asked Questions (FAQs)

Q: What is a 4 x 8 galvanized sheet metal?

A: A 4 x 8 galvanized sheet metal is a flat panel made of steel that measures 4 feet by 8 feet. It is coated with a layer of zinc to prevent rust and corrosion, making it suitable for various applications.

Q: What are the common thicknesses available for 4 x 8 galvanized sheet metal?

A: The common thicknesses for 4 x 8 galvanized sheet metal include 16 gauge and 26 gauge. The gauge indicates the thickness of the steel, with lower numbers denoting thicker sheets.

Q: Can 4 x 8 galvanized sheet metal be used for roofing?

A: Yes, 4 x 8 galvanized sheet metal can be used for roofing applications due to its durability and resistance to weather elements. It is important to ensure that the thickness is suitable for roofing purposes.

Q: What is the difference between hot rolled and cold rolled steel sheets?

A: Hot rolled steel sheets are produced by rolling steel at high temperatures, resulting in a rough surface. Cold rolled steel sheets, on the other hand, are processed at room temperature, which provides a smoother finish and tighter tolerances.

Q: How does the surface finish of 4 x 8 galvanized sheet metal affect its application?

A: The smooth surface finish of 4 x 8 galvanized sheet metal enhances its aesthetic appeal, making it suitable for visible applications. Additionally, a smooth surface can improve its performance in applications requiring easy cleaning and maintenance.

Q: Is 4 x 8 galvanized sheet metal heavy?

A: The weight of a 4 x 8 galvanized sheet metal depends on its thickness. For instance, a 16 gauge sheet typically weighs more than a 26 gauge sheet due to the difference in thickness.

Q: What are some common applications for 4 x 8 galvanized sheet metal?

A: Common applications for 4 x 8 galvanized sheet metal include roofing, siding, HVAC ductwork, and various construction projects where a durable and corrosion-resistant material is required.

Q: Can 4 x 8 galvanized sheet metal be easily cut or shaped?

A: Yes, 4 x 8 galvanized sheet metal can be cut or shaped using appropriate tools such as tin snips or plasma cutters. However, care should be taken to avoid damaging the galvanized coating during the process.