Titanium is often equated with strength. The lightweight, durability, and resilience of titanium make it a go-to selection in the aerospace industry, medical equipment, and industrial machinery. However, did you know that there are other metals which are stronger than titanium in certain aspects? This article explores some of the most intriguing phenomena in metallurgy — materials which defy expectations and transcend our understanding of strength and performance in metals. From advanced alloys to naturally occurring elements, these extraordinary materials not only challenge Titanium’s mythology but also revolutionize modern engineering. Get ready to uncover the science behind these metals and the metals that stand precedence in the hierarchy of strength.

What is the strongest metal in the world?

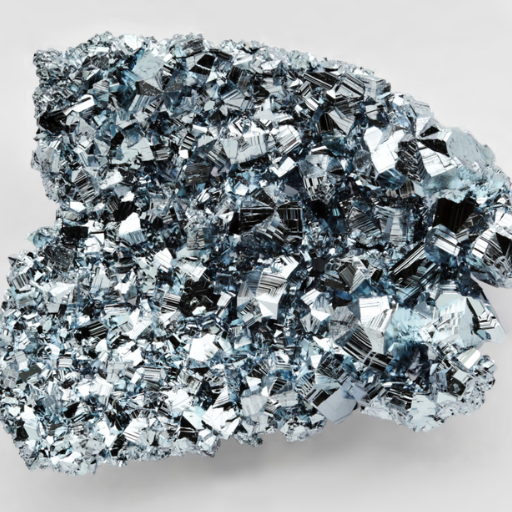

Widely believed to be the strongest metal in the world, tungsten’s status as a naturally occurring metal is undeniable. Benefiting from arcane tensile strength of roughly 1510 megapascals (MPa), tungsten holds the claim over being the strongest naturally occurring metal. Furthermore, he is unmatched in melting point, possessing a remarkable sub 3422°C (6192°F) the highest of any metal. Extracted from extreme conditions before, these characteristics reward him in armor, aerospace components, and industrial tools.

Understanding tensile strength and yield strength

Tensile and yield strength are two parameters in material science that calibrate the mechanical performance of a material with deforming forces exerted on it. As the name indicates, tensile strength is the maximum stress a material is able to withstand while being stretched or pulled before it fails. This is generally given in megapascals (MPa) or pounds per square inch (psi). It is the upper value of a material’s load bearing limit. Yield strength is the stress at which a material exhibits strain in terms of permanent deformation. After this point, a material will no longer revert to its original shape.

Take for example, alloys of exceptionally high performance titanium. Alloys of titanium perform exceptionally well whilst having a tensile strength of around 1000 MPa and yield strength of approximately 880 MPa. This balance showcases their remarkable strength and formability. Metrics need to be understood in engineering uses to have selected materials that will not fail or even excessively deform under operational stresses. The interplay of yield and tensile strength enables engineers to devise structures and machines optimized for safety, durability, and resource efficiency.

Comparing titanium and steel

Environmental factors, the weight of the materials, and their respective mechanical properties require comparison while looking at steel and titanium. Known for its remarkable strength-to-weight ratio, titanium is almost 45% lighter than steel, and in many instances, works almost as well as steel does. That makes it more suitable for use in the Aerospace industry and other industries where weight is critical. Steel, on the other hand, especially high-strength alloys, have much greater tensile strength, which makes them ideal for use in bearing heavy structures and machinery; some grades are over 2000 MPa.

One other important distinguishing factor in both of the metals is their resistance towards corrosion. Titanium surpasses steel in this regard because it rusts far less easily due to titanium dioxide coating it. This allows titanium to withstand chemical and marine environments. Steel, on the other hand, has some form of durability but relies on coatings to protect it, which is prone to scratching. In terms of cost, steel is a lot more economical because of its ease of procurement and manufacture. The opposite is true for titanium because its extraction and refinement are complex, increasing its cost. This makes him the more expensive option out of the two. Ultimately, the decision comes down to the specific rough application one has in mind, since he has to weigh in dealing with what face he wants most – weight, strength, corrosion resistance, or cost.

Is tungsten stronger than titanium?

Indeed, titanium is far weaker than tungsten in the domains of hardness and tensile strength, as tungsten is the strongest of the four natural metals. He’s more augmented under stressful situations. Regardless, titanium is more versatile as well as lighter and therefore makes it better. Traditionally, someone would have more options if they desired to pick something more flexible and corrosion resistant. Otherwise, he would risk frequent breakage.

Properties of widely used metals

- Aluminum

Aluminum is awash in applications because of its strong resistance to corrosive elements, its mechanical properties like tensile strength that ranges from 70–700 MPa depending on the alloy and heat treatment plus its boiling point melting around 1218 °C, as well as it’s light weight of 2.7 g/cm³. At this density, aluminum is the most commonly used metal after copper. Being a metal, it is a superb conductor of both electricity and heat, copper being the most commonly used in electrical appliances and transmission lines. In appliance and thermal systems, it excels in heat conduction.

- Copper

Copper’s striking features of electricity and thermal conduction renders it as an essential material in all electrical systems such as wiring, transformers and even motors. It has a tensile strength of about 200 MPa, which means it can be alloyed to improve its strength for mechanical purposes. Its ductility and corrosion resistance make it ideal for plumbing and industrial purposes, as well. Lastly, its unique antimicrobial traits are now being put to use in healthcare settings to touch surfaces in order to curb the spread of bacterial infection.

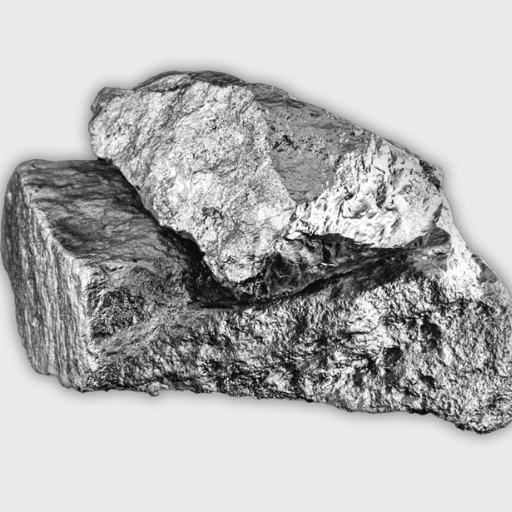

- Steel

Steel is an iron and carbon alloy which offers exceptional versatility alongside structural integrity. The composition and heat treatment of steel will greatly alter its properties. Mild steel has a tensile strength of 400 MPa, while advanced high-strength steels surpass 2000 MPa. This means that steel finished components are shed from construction frameworks to automotive parts. While containing immense strength at low cost, the steel alloy is also prone to further enhanced corrosion resistance by the addition of chromium or galvanization.

- Magnesium

Magnesium is highly reactive, making it prone to corrosion; requiring treatment or coatings for stability in exposed environments. Lower mechanical strength makes him less desirable structurally, with 150 to 300 MPa. Manganese is often alloyed with other elements to increase hardness and durability. This construction makes it useful in the production for easy-to-transport components. With a density two-thirds that of aluminum, magnesium is the lightest among structural metals.

How tungsten carbide compares to titanium

When comparing Titan and Tungsten carbide, the latter trumps the former in almost every category. While titanium is lower in cost, it is much weaker than tungsten which measures 6 on the Morh scale while Tungsten sits high at 9-9.5. This eldos him to have a great strength to weight ratio. Because of this tungsten can be used in almost all mining and cutting tools. Tungsten carbide, however, is much denser than titanium at 15.6 g/cm³, which reduces it’s use in aerospace components on account of weight dependant applications. Titanium’s biocompatibility also surpasses that of tungsten, transferring the preferential use in medical implants, hence more sited tungsten alloys industrial use. The strategic significance of both the materials diverge on account of these reasons.

What are the 10 strongest metals?

- Tungsten – The strongest natural metal, considered the strongest due to it’s exceptional tensile strength and high melting point.

- Titanium – This metal is highly durable and has a lightweight. It is resistant to corrosion and is commonly used in the medical industry and aerospace.

- Chromium – This metal is known for its hardness therefore it finds its way as a coating material for metals when stronger and more durable structures are requested to be made.

- Steel – Steel is primary alloy that is used with carbon and other elements and its features like strength and versatility make it a low cost

- Tantalum – This metal is treated as the most resistant to corrosion and is tough as it gets under extreme conditions. Tantalum finds itself in electronics and in medical apparatus widgets.

- Iron – Iron is fairly weak by itself. However, with alloying, iron becomes much stronger and forms the basis of many industry-strength metals such as steel.

- Nickel – This metal is strong and order resistant. It is also important in the alloy stainless steel.

- Vanadium – Added to metals to improve their strength and toughness, vanadium is used commonly in high strength steel.

- Cobalt – Cobalt is noted for its strength and high-temperature resistance. For this reason, it is used in superalloys for aerospace applications.

- Magnesium Alloys – In magnesium alloys, the strength of the alloy makes up for the low weight of the metal, although they are not as strong as pure metals. Magnesium Alloys are employed in construction and architecture.

Characteristics of the 10 strongest metals

- Tungsten – Boasting the highest tensile strength, at approximately 1510 megapascals (MPa), of any pure metal, tungsten’s unrivaled hardness and strength retention at elevated temperatures makes it useful in the military, metalworking tools and electrical wiring.

- Titanium – Resisting corrosion of salt water and marine environment, titanium has a tensile strength of 1000 MPa with a strength to weight ratio better than all. Consequently, it is used in surgical implants, aerial crafts parts and undersea vehicles.

- Chromium – With its importance in improving the corrosion resistance of stainless steel and existing alloys, chromium has a hardness of 8.5 on the Mohs scale.

- Steel – Steel is more or less an alloy of iron and carbon. Depending on the classification of steel, its tensile strength can reach over 1860 MPa, making it a very sought useful material in construction, automotive sector, infrastructure, and traveling. Steel is widely considered as one of the most useful industrial commodities.

- Osmium – Used where the lowest distance between parts is desired , osmium is famous for extreme density at 22.59 gcm-3 as well as for being incredibly hard and resistant to abrasion. This property nutritious secondary electrical contacts and pivots on delicate instruments.

- Iridium – Also, iridium has accepted features, along with the high melting point of 2446°C and extreme hardness and density, as well as osmium. These features allow use in Ultrapure gas-tight high-temperature crucibles and spark plugs.

- Tantalum – The critical features are high many Tantalum showcases: high tensile strength and ductile material combined with unparalleled resistive power to corrosion even of acidic environments. Tantalum is a must for high-performance resistors and low loss capacitors.

- Vanadium – Its alloys consume tungsten in aerospace structures. Vanadium is most often alloyed with steel, increase tensile strength, ductility, and the resistance to wearing. The alloys containing Vanadium become necessary for the components in automotive, structures in aerospace and tools.

- Cobalt – Cobalt superalloys remain strong and keep their structural integrity at elevated temperatures. Uses include turbine blades, jet engines, and some magnetic components.

- Magnesium Alloys – While not as strong inherently as a pure element, magnesium alloys possess a tensile strength of around 400 MPa while keeping a low density and are therefore advantageous in structural designs for vehicles and aircraft.

How does steel compare to titanium?

Differences in compressive strength

Compressive strength is defined as the maximum load a material can withstand before it buckles or reduces in size. This means that axial loads acting on the material must not exceed its compressive strength; otherwise, it would fail. In simpler terms, the titanium’s strength-to-weight ratios are remarkable, but the pure grade of titanium typically possesses a compressive strength of anywhere between 480 MPa and 1100 MPa. This depends on alloy composition and the processing techniques used. Steel, especially when wrought into high-strength classifications like alloy or carbon steels, can further exceed these figures, with some possessing compressive strength values above 2000 MPa due to certain applications. Therefore. It’s ability to endure sheer material strength under controlled compression makes titanium more advantageous when used in components that require maximum strength for structural load bearing purposes. Even so, the ability of titanium’s sheer superiority in reducing material density along with its extremely mild deformational resistance placed it as the go-to choice in applications wherein weight is a primary design criterion. All factors aside, these two have to be approached from the perspective of saying long-term stability, environmental concerns, and the particular structure under consideration to evaluate effectiveness for compressive stress.

Strength-to-weight ratio of titanium and steel

Titanium is also harder to find and more expensive to process, which elevates its price in comparison to steel. This brings fuel engineers and designers to weigh the performance per cost ratio. The alloy also has its pros and cons due to its weight sitting at 4.5 g/cm³ and holding a tensile strength of 1000 MPa. Steel on the other end weighs 7.8 g/cm³ while housing a tensile strength that sits between 400 MPa and over 2000 MPa. This puts it at greater risk to become harder to work with in more delicate structures that have to take every component into account. In a newly designed S350 m MRI scanner, the combination of titanium hovercraft structures demonstrates its functional use in aerospace, tackling the requirements of engineering standards.

What is the hardness of titanium compared to other metals?

In terms of strength, titanium is softer more common metals like steel and hardens less than tungsten or hardened steel. He measures around six on the Mohs hardness mineral scale while post-process hardened steel surpasses seven and tungsten peaks around 7.5. While the moderate hardness of titanium is appealing, the strongest feature is the resistant to corrosion which makes it an ideal choice for applications that need a low weight but high durability.

Understanding hardness and impact strength

Every material for a project has to have praised selection for each method and impact strength are two opposites that tackle the above one selection. A metarial must have great selection without breaking under various impact strengths. Hardness refers a materials defromation resistance, tools such as mohs scale or Vickers hardness determine these qualities. Whereas impact force is a strength used to determine how much force one can take from the outside without smashing to bits, which is assessed with the Charpy or Izod impact test.

It’s a common trade-off to sacrifice impact strength for resistance to wear and abrasion. Take brittle materials like ceramics. They have superior hardness but are poor at absorbing energy without fracturing. On the other hand, aluminum alloys might possess lower hardness values, however, they have high impact resistance, making these materials ductile and favorable for use in dynamic or shock-loading applications. Complex alloying and heat treatment is usually required to optimize both properties, which is one of the many balancing acts performed on a material to satisfy its operational conditions.

Natural vs. alloyed metals

Naturally occurring metals tend to be pure copper, gold, and silver. These are metals on their own and have atomic properties in multiple grades which speaks to the underlying structure. Take pure copper, for example. It is used in electrical works because of its high conductivity owing to the easy flow of electrons through the lattice structure of the crystal. Reason being, there exists no pure metals, because they usually lack sufficient mechanical strength or durability. Therefore, it cannot be used for high-stress applications.

Reference Sources

-

Alloy Stronger than the Toughest Aerospace Material – Discusses a new superalloy with a composition of aluminum, titanium, niobium, zirconium, and more.

-

10 Strongest Metals in the World – Explores the strongest metals, including steel and tungsten, and their properties.

-

What Are the Strongest and Hardest Metals on Earth? – Compares titanium with steel alloys and other strong metals.

-

MIT Makes Titanium Alloys Tougher and More Flexible – Highlights advancements in titanium alloys that improve strength and ductility.

-

New alloy ‘four times harder than titanium’ – Details a material that is significantly harder than pure titanium, with potential applications in medical implants.

Frequently Asked Questions (FAQs)

Q: What is the strongest metal on Earth compared to titanium?

A: The strongest metal on earth is often considered to be tungsten, as it has an ultimate tensile strength that is higher than that of titanium, making it much harder and more durable in various applications.

Q: How does chromium contribute to the strength of alloys?

A: Chromium is commonly added to stainless steel to enhance its strength and corrosion resistance. This addition helps create a stronger material that can withstand harsher environments compared to pure titanium.

Q: What are the different types of strength when comparing metals?

A: Different types of strength include tensile strength, yield strength, and compressive strength. Tensile strength refers to the resistance of a material to breaking under tension, while yield strength refers to the stress at which a material begins to deform plastically.

Q: Is magnesium alloy stronger than titanium?

A: While magnesium alloys are lightweight and have good strength-to-weight ratios, they are generally not stronger than titanium alloys in terms of overall strength. Titanium metal is often preferred for applications requiring higher strength.

Q: Why is carbon steel often considered stronger than titanium?

A: Carbon steel can have a higher tensile strength than pure titanium due to its composition and heat treatment processes. However, titanium has advantages in corrosion resistance and weight, making it suitable for different applications.

Q: Can stainless steel be considered one of the hardest metals available?

A: Yes, stainless steel is known for its hardness and strength, particularly when alloyed with elements like chromium and nickel. However, it is typically not classified as one of the hardest metals when compared to materials like tungsten or titanium alloys.

Q: What is the significance of titanium grades in determining its strength?

A: Titanium grades indicate the purity and alloying elements in titanium metal, which directly affect its strength and performance characteristics. Higher grades typically have better tensile strength and are used in demanding applications.