Metals, as the backbone of innumerable industries, do everything from making buildings to cars and everyday household things, to embalming. Somewhat more than this enormous list, the basic distinction between ferrous and nonferrous metals changes applications, properties, and even the recyclability of the metals. But what exactly distinguishes a metal as “ferrous” or “non-ferrous,” and why is this differentiation important? In this blog, we will seek the particular defining parameters of ferrous metals, how they differ from non-ferrous metals, and why this differentiation virtually matters to hot industries worldwide. The guide will be helpful for a materials engineer, a procurement professional, or just anyone interested in metals and what constitutes our world. Dig in for a learning adventure towards their properties, applications, and even the science behind their classification.

Introduction to Ferrous Metals

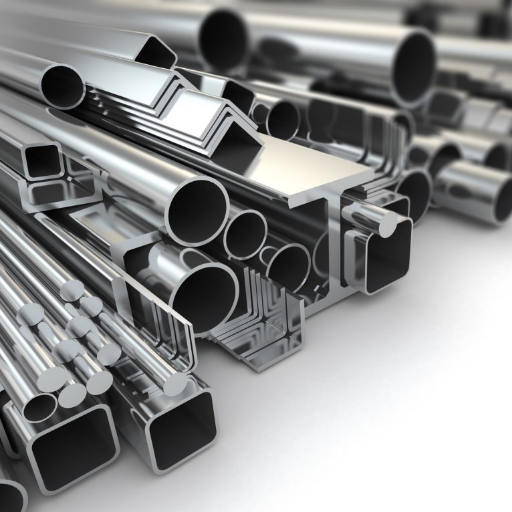

Being the main ingredient, ferrous metals contain iron, thus all of which are durable commodities and susceptible to wide usage in industries. They are mostly described by the magnetic properties and tensile strength they possess. Some common ferrous metals include steel, cast iron, and wrought iron. To build a little bit more varied, these metals find their applications widespread in constructions, automotive productions, tools, and machinery because they are strong, cheap, and easy to work with. A serious drawback, though, is that while ferrous metals rust and corrode on moisture exposure, if they remain untreated or are mixed congenially with other elements such as chromium, they could gain resistance.

Definition of Ferrous Metal

The presence of iron chiefly characterizes ferrous metals as their base component, granting them a peculiar magnetic character and considerable strength. They are capable of versatile applications and may be alloyed with various other elements such as carbon, manganese, or chromium to obtain other attributes such as hardness, wear resistance, and corrosion resistance. For example, the much-used stainless steel is a ferrous alloy that combines iron with carbon and chromium to have excellent resistance against rust and oxidation.

Although commonly used due to their durability and high tensile strength, ferrous metals can be heavy depending on their density. This feature can be a drawback in industries where lightweight materials are preferred. Apart from this, innovative treatments, including galvanization, powder coating, or heat-resistant coatings, have increased the useful life of ferrous metals when used in fields that pose tough conditions. This furthers the adaptability of ferrous metals in varied forms of engineering and manufacturing.

Characteristics of Ferrous Metals

- High Strength and Durability

In connection with their being observed with tensile strength, ferrous metals can pride themselves on properties making their use suitable for heavy-duty applications in construction and infrastructure. For instance, carbon steel values its tensile strength from 400 MPa upward to more than 1,200 MPa, depending on the grade and character of the composition of the ferrous metal.

- Magnetic Properties

Along with the magnetic properties, most of the ferrous metals are used in electrical devices, such as optical transformers, motors, and generators. Research and development produce steels that are improved in magnetic permeability and have less energy loss-ferritic stainless steels, manganese steels, and special electrical grades.

- Corrosion Susceptibility

Being strong, ferrous metals corrode on exposure to water and oxygen. They get oxidized with rust formation, especially in carbon steels. With modern advances, however, chromium-containing stainless steel alloys (above 11%) become highly corrosion-resistant due to the formation of a passive oxide layer on their surface.

- Affordability and Abundance

Iron is the primary element in ferrous metals. Having been one of the most abundant elements in the Earth’s crust, ferrous metals became extremely economical to use on a wide scale in the industries. Being price-efficient in such a manner, they find utility in industries such as automotive, manufacturing, and construction.

- Heat Resistance

Several ferrous metals tend to behave very well at high temperatures, especially alloy steels. For instance, tool steels contain several elements like tungsten, molybdenum, and vanadium, which in turn enhance the strength and stability even at elevated working temperatures.

Properties of Ferrous Metals

- Magnetism

A ferrous metal like iron or steel is magnetic in its natural state and, therefore, finds its place in electrical and electronic applications. For instance, the permeability of iron is so high that it is utilized in the production of transformers, motors, and generators.

- Strength and Durability

Having elemental qualities, tensile strength and durability, ferrous metals are now being considered. Industrial application providing various tensile strength examples, from 400 to 550 MPa, takes carbon steel, for example. Thus, carbon steel can be used in load-bearing structures, such as bridges and skyscrapers.

- Malleability and Ductility

Usually, ferrous metals can be highly malleable and ductile, which properties favor easy processing by bringing them into series of shaping processes such as rolling, forging, and machining. Low-carbon steel, for instance, is very ductile and allows forming complicated detail shapes without suffering from any cracking or breaking.

- Corrosion Resistance

The plain carbon steels and the like of other ferrous metals will rust relatively quickly in the atmosphere unless chromium and nickel are added to improve resistance to corrosion. An example is stainless steel containing 18-20% chromium and 8-10% nickel, which are resistant in corrosive environments.

- Thermal Conductivity

Ferrous metals’ moderate thermal conductivity suits the heat exchange system. Wrought iron measures a thermal conductivity of 80 W/m·K approximately and finds applications in radiator and boiler systems.

- Density

Magnetic Properties

The ferrous metals are known for their innate magnetic property due to their high iron content. These materials show strong magnetic permeability, i.e., they support the creation of a magnetic field efficiently within their structure. Pure iron, for instance, is known to have a relative magnetic permeability of about 200,000 and therefore finds applications, inter alia, in transformers, electric motors, and generators. Moreover, alloys such as silicon steels are engineered to provide ideal magnetic properties with minimum energy loss, an important factor for electrical efficiency. Magnetizing and demagnetizing parameters of ferrous metals are dependent on composition, heat treatment, and processing; for example, soft magnetic materials like annealed iron are quick to respond to a changing magnetic field, while hard magnetic materials resist maintaining their magnetism for a long time. These properties are making ferrous metals indispensable for present-day electromagnetic technologies.

Corrosion Resistance

Corrosion resistance is that property by virtue of which a material withstands its own destruction brought on by an environment containing oxygen, moisture, and certain chemicals. Many ferrous metals, especially higher iron content varieties, rust by oxidation, while this shortcoming is removed in certain alloys like stainless steels, which resist corrosion well due to chromium content. Chromium reacts with oxygen, thereby forming a passive oxide layer that protects the underlying metal from further degradation.

Strength and Durability

Examples and Uses of Ferrous Metals

- Steel

-

- Examples: Carbon steel, stainless steel, tool steel.

- Uses: Widely used in construction (beams, rebar), transportation (automotive and rail components), and manufacturing (tools, machinery, and appliances).

- Cast Iron

-

- Examples: Gray cast iron, ductile cast iron.

- Uses: It goes into pipe making, engine blocks, and machine bases, as well as cookware, because of its durability and heat-retaining capacity.

- Wrought Iron

-

- Examples: Hand-wrought decorative ironwork.

- Uses: Gates, fences, and railings are erected from wrought iron owing to its malleability and resistance to corrosion.

- Alloy Steel

-

- Examples: Chromium steel, manganese steel.

- Uses: As aerospace components, power turbines, and tools with high strength, resistance to wear.

Due to their strength, ductility, and applications, ferrous metals are the backbone of various heavy industries.

Applications in Construction

- Structural Framework

-

- Material: Carbon steel and alloy steel.

- Use Case: Extensively used for structural beams and columns and load-bearing frameworks of buildings and bridges.

- Data: Close to 75% of structural steel produced in the world is used for construction purposes due to its very strong-to-weight ratio and recyclable nature.

- Reinforced Concrete

-

- Material: Mild steel and rebar steel.

- Use Case: Used as a reinforcement material for concrete structures so that the concrete, being brittle in nature, gets subjected to tensile stresses.

- Data: Rebar steel constitutes about 60% of the steel used in construction, owing to its ability to last and resist tensile stress.

- Roofing and Cladding

-

- Material: Galvanized steel and stainless steel.

- Use Case: Installed for metal roofing sheets, cladding, and facades, corrosion resistant, and good looking.

- Data: Stainless steel claddings greatly increase the life span of the building exteriors by reducing maintenance costs by almost 30%.

- Bridges and Infrastructure

-

- Material: High-strength alloy steel.

- Use Case: Suspension cables, trusses, and components of contemporary bridges are constructed using the materials requiring durability and resistance to fatigue.

- Data: By 20%-30%, modern alloy steels have improved the longevity of severely rated infrastructure projects compared to traditional materials.

- Piping Systems

-

- Material: Cast iron and ductile iron.

- Use Case: Fit for installation service of water mains, sewage, and underground pipelines by virtue of its rigidity and corrosion resistance.

- Data: More than 40% of the global municipal piping system employ ductile iron for its strength and longevity.

Use of Ferrous Metals in Manufacturing

Since ferrous metals are rusty when exposed to atmospheric agents, they find broad use in manufacturing industries, while also giving pride of place to durability, versatility, and low cost. These metals find extensive use in automobile manufacturing, such as steels and cast irons, with regard to chassis, engines, and body components. In this regard, advanced high-strength steel (AHSS) has entered widespread adoption to minimize vehicle weight by almost 20% while improving crash safety, as stated in industry reports.

The manufacture of many tools and equipment is another area where ferrous alloys find extensive use, especially high-carbon steels that are used in scenarios that require cutting, drilling, machining, etc., because of their hardness and wear resistance properties. Industrial equipment also makes use of ferrous metals like alloy steels that need to be subjected to higher strength and heat resistance in heavy-duty applications. This machinery includes construction and agricultural apparatuses that require abrasion resistance under extreme working conditions. The assurance of reliability and low maintenance cost makes an easy case for the constant presence of these materials in the manufacturing industries across the globe.

Difference Between Ferrous and Non-Ferrous Metals

Ferrous metals and alloys denote varying combinations of iron as the principal component bearing magnetic properties and having a high-tensile strength. Quite often ferrous metals will rust unless other metal elements like chromium are treated upon or alloyed into them.

Non-ferrous metals, by definition, contain no metals as far as iron is concerned. They are comparatively lighter metals, resistant to corrosion, and are nonmagnetic in nature. Aluminum, copper, and zinc are typical examples. Due to such properties, non-ferrous metals find and enjoy demand in applications where lightweight and durable material is called for, such as aerospace and electrical industries.

Compare the Differences: Ferrous vs Non-Ferrous Metals

|

Key Parameter |

Ferrous Metals |

Non-Ferrous Metals |

|---|---|---|

|

Presence of Iron |

Contains iron |

Does not contain iron |

|

Magnetism |

Generally magnetic |

Non-magnetic |

|

Corrosion Resistance |

Prone to rust and corrosion |

High resistance to corrosion |

|

Weight |

Typically heavier |

Typically lighter |

|

Strength |

High tensile strength |

Lower tensile strength |

|

Conductivity |

Low electrical conductivity |

Excellent electrical conductivity |

|

Cost |

Generally less expensive |

Typically more expensive |

|

Common Examples |

Steel, cast iron, and wrought iron |

Aluminum, copper, zinc, and lead |

|

Applications |

Construction, tools, and automotive parts |

Aerospace, electrical, and wiring |

|

Recycling Potential |

High recyclability |

Also highly recyclable |

Physical Properties

- Density

-

- Ferrous Metals: High density, typically ranging from 7.8 g/cm³ (steel) to 7.87 g/cm³ (cast iron).

- Non-Ferrous Metals: Generally lower density, such as aluminum (2.7 g/cm³), copper (8.96 g/cm³), and zinc (7.14 g/cm³).

- Tensile Strength

-

- Ferrous Metals: High tensile strength, making them ideal for heavy structural applications. For example, structural steel exhibits a tensile strength range of approximately 400-550 MPa.

- Non-ferrous metals have lower tensile strength than ferrous metals. For example, aluminum alloys range from 200 to 400 MPa, depending on type and treatment.

- Thermal Conductivity

-

- Ferrous Metals: Moderate to low thermal conductivity, e.g., carbon steel at ~50 W/m·K.

- Non-Ferrous Metals: High thermal conductivity, with copper being one of the best conductors at ~400 W/m·K.

- Electrical Conductivity

-

- Ferrous Metals: Low electrical conductivity due to higher resistivity.

- Non-Ferrous Metals: Excellent electrical conductivity; copper, for instance, has a conductivity of 59.6 MS/m, making it ideal for wiring.

- Melting Point

-

- Ferrous Metals: High melting points, typically around 1,100–1,500°C, depending on the type of alloy.

- Non-Ferrous Metals: Varying melting points, often lower than ferrous metals. For example, aluminum melts at 660°C, while copper melts at 1,085°C.

- Corrosion Resistance

-

- Ferrous Metals: Susceptible to rust and corrosion unless protected with coatings or alloyed with other elements (e.g., stainless steel).

- Non-Ferrous Metals: Generally more resistant to corrosion; aluminum, for example, naturally forms an oxide layer that prevents further deterioration.

Recycling of Ferrous Metals

Recycling ferrous metals has been a quick, effective, and widely accepted process that lowers landfill waste and conserves natural resources. Ferrous metals, such as steel and iron, have the unique recyclability potential in that they maintain their strength and quality even after being recycled several times. Generally, the recycled metals pass through the following stages: collection, easy sorting or segregation, shredding, melting, and then forming into scrap or semi-finished products. Steel, produced from iron ore, is among the world’s most recycled materials, primarily due to magnetic separation aiding in sorting. Energy use associated with recycling ferrous metals is far less than energy use associated with producing a new metal from the raw ore, and because of that, the environmental impacts, such as greenhouse gas emissions, are reduced significantly.

Process of Recycling Ferrous Metals

Recycling ferrous metals includes a well-established set of multiple steps whose goal is to get maximum efficiency while keeping minimal disturbance to the environment. To begin with, ferrous scrap is collected from a variety of sources, including manufacturing sectors, construction sites, and end-user consumer products. Once gathered, the scrap items are taken to a recycling plant where initial sorting begins. Magnetic sorters and automated systems are applied to differentiate between ferrous and non-ferrous metals and other contaminants by utilizing the magnetic properties of iron and steel.

Post sorting, metals are shredded into smaller pieces to maximize further processing. The shredding increases the surface area, which in turn promotes efficient melting. Afterward, the little pieces are introduced into furnaces to melt them with temperatures maintained well above 2,500°F (1,370°C). Today, steel plants are mostly equipped with electric arc furnaces that are deemed to be relatively energy efficient and emit less in the atmosphere than traditional blast furnaces.

Environmental Benefits

- Reduction in Greenhouse Gas Emissions

- Energy Savings

The energy required in processing recycled steel is much lower than that required for mining and refining iron ore. Supported by studies, it shows a saving of 74% of energy when compared with primary production, meaning a direct reduction in the consumption of fossil fuels.

- Conservation of Natural Resources

The reduction in demand for mining virgin iron ore by the recycling of scrap steel is quite phenomenal. For every ton of recycled steel, it is assumed that over 1,400 pounds of iron ore, 120 pounds of limestone, and 700 pounds of coal are saved.

- Waste Reduction

Recycling ferrous metals greatly reduces waste going into landfills. Recovery of scrap metal decreases general landfill use and potential environmental threats related to solid waste.

- Water and Air Quality Improvement

Reference Sources

-

Ferrous Metal Overview (ScienceDirect): Ferrous metals, primarily iron and steel, are highly recyclable and in demand due to urbanization and commercialization. Steel scrap is almost 100% recyclable and widely used in construction, automotive, and infrastructure.

-

Ferrous Sulphate Market Insights (BusinessWire): The global ferrous sulphate market is analyzed with a focus on its applications, manufacturing technologies, and market trends from 2015 to 2025.

-

Non-Ferrous Metal Recycling Market (GlobeNewswire): The non-ferrous metal recycling market, including aluminum and copper, is projected to grow to $225–$230 billion by 2025. Trends include urban mining, advanced sorting technologies, and e-waste recycling.

Frequently Asked Questions (FAQs)

Q: What are examples of ferrous metals?

A: Examples of ferrous metals include steel, wrought iron, cast iron, and alloy steel. These metals are characterized by their iron content, which typically gives them magnetic properties. Carbon steel is one of the most widely used ferrous metals due to its tensile strength and durability. Wrought iron, while less common today, is known for its malleability and resistance to rust when properly treated. Cast iron is often used in cookware and heavy machinery due to its excellent castability and durability.

Q: What types of scrap metal are ferrous?

A: Ferrous scrap metals include any scrap that contains iron, such as old steel beams, discarded automobile parts, and cast iron cookware. These types of scrap metal are magnetic, making them easy to identify and separate from non-ferrous materials. Recycling ferrous scrap is important as it helps conserve resources and reduces environmental impact. The recycling process involves melting down the scrap to create new products, which can have lower carbon content compared to the original materials.

Q: How do ferrous metals compare to non-ferrous metals?

A: Ferrous metals contain iron, while non-ferrous metals do not. Non-ferrous metals include aluminum, copper, and precious metals like gold and silver. Typically, ferrous metals are more affordable and have higher tensile strength, making them suitable for construction and manufacturing applications. However, non-ferrous metals tend to have a higher resistance to rust and corrosion, which makes them ideal for electrical applications and plumbing.

Q: What are the properties of ferrous materials?

A: Ferrous materials primarily contain iron, which gives them unique properties compared to non-ferrous metals. For instance, many ferrous metals are magnetic, making them suitable for applications where magnetic properties are essential. Additionally, ferrous metals tend to be vulnerable to rust when exposed to moisture and oxygen unless they are treated to prevent corrosion and oxidation. The presence of carbon can significantly influence the mechanical properties and hardness of these metals, with high carbon content resulting in stronger yet less malleable materials.

Q: How do ferrous or non-ferrous metals differ?

A: Ferrous metals contain iron, while non-ferrous metals do not contain iron. This fundamental difference leads to varying properties, such as strength, weight, and susceptibility to rust. Non-ferrous metals, like aluminum, copper, and tin, are generally more resistant to corrosion and are often used in applications where rust when exposed is a concern. Additionally, non-ferrous metals can be recycled more efficiently, making them an environmentally friendly choice.