Concrete is perhaps the most widely used construction material, encompassing qualities of strength, durability, and versatility. However, one major drawback of concrete lies in tensile strength; it does not offer sufficient resistance to tensile stresses. This is where rebar becomes indispensable. Rebar is designed to confer tensile strength to concrete, so it needs to resist tensile stresses, leading to the stability and longevity of tall skyscrapers and intricate bridges. This article examines the properties of rebar, its applications in modern construction, and some scientific explanations for the conversion of concrete into a robust and reliable building material through the use of rebar. With some knowledge about the world of rebar, structural engineers, construction professionals, or someone simply curious about design basics, will undoubtedly gain some valuable insights.

Definition and Purpose of Rebar

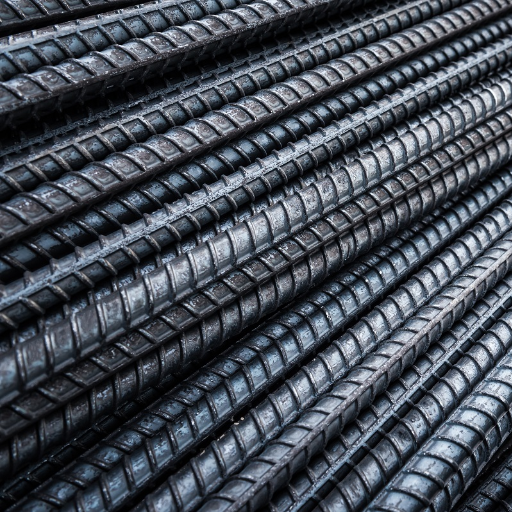

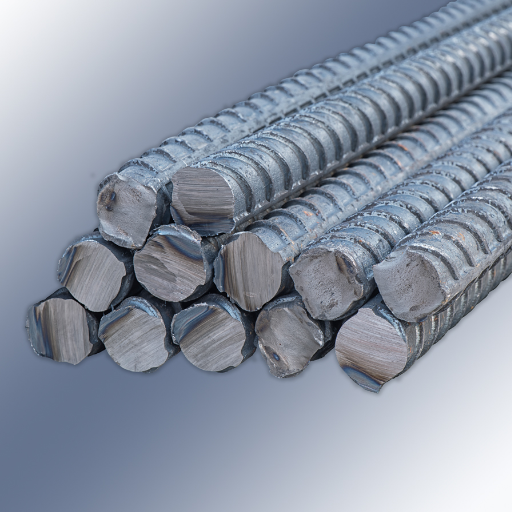

Rebar, being an abbreviation for reinforcing bar, is a steel rod used to strengthen and support concrete in construction. Concrete is strong by nature in compression but being weak in tension limits its full utilization; rebar is placed to provide that tensile strength to resist stretching and bending forces. During construction, rebars are embedded within the concrete to form a composite that enhances the concrete properties in durability, stability, and load carrying. A carbon steel bar, rebar, has surface deformations created by ridges that maximize the bond between it and concrete to guarantee that the reinforcement system will work effectively.

What is Rebar?

Rebar, an abbreviation for reinforcing bar, has been a key construction component, primarily used for strengthening and stabilizing concrete structures. It enhances concrete’s tensile capacity, intrinsically strong under compression forces but weak under tensile ones. Recent advances in rebar manufacturing techniques have led to its production by a variety of materials, including stainless steel, epoxy-coated steel, and even fiber-reinforced polymers, each one selected for the particular demands of any project. Rebars are classified by their grades and diameters when considering material specifications, with ASTM A615 and ASTM A706 being typical standards for physical and mechanical properties. The ridges or deformations on the rebar surface, everything against the concrete bond, greatly aid the stress transfer mechanism and prevent cracking of the concrete or, in some cases, failure of the structure due to stress being transferred through cracks. This material finds its way into everything from a neighborhood home to a highway bridge, a high-rise building, and a tunnel. Correct identification, type, and placement of rebar shall be responsible for the structural strength and life of the reinforced concrete system.

The Role of Rebar in Reinforcing Concrete

Different types of rebar cater to all structural and environmental requirements for specific project reinforcements. Carbon steel rebar is the most commonly used type and provides great tensile strength and is very economically priced under general construction applications. On the other hand, epoxy coating is meant to resist corrosion; hence, it is preferable in projects where such environments like high moisture or marine environments, such as seawalls and offshore structures, are involved. A stainless steel rebar exhibits the highest corrosion resistance and durability, but is often applied to projects where resistance to corrosion and durability are given a lower priority, really due to cost considerations. Since it is light and non-corrosive, glass fiber-reinforced polymer (GFRP) rebar is generally used where little magnetic interference is desired, such as in electromagnetic-sensitive facilities.

It is truly the proper choice of rebar type and its adequate application that optimizes structural performance, addresses environmental challenges, and places modern building codes that are increasingly emphasizing durability and sustainability.

Why Rebar is Necessary in Construction

As reinforcement bars or rebars in the usage, they precisely lend tensile strength to concrete, where tensile forces are being exerted by nature but hold pressure well in erection. Concrete structures are embedded with rebars to resist stresses, including cracking and bending, from external loads, seismic activity, thermal gradients, etc. It is evident from our studies that conventional reinforced concrete projects can last above 50 years, depending on the application conditions, which reinforces the status of reinforced concrete as the most cost-effective and durable infrastructural product. Extra protection like epoxy-coated steel-type rebars or GFRP is incorporated at locations with very high risk, electromagnetic interference, etc., to run away from adequate and excellent structural integrity as a permanent solution. Generally, rebar is strategically used and is indispensable in terms of safety standards, material performance, and modern design requirements.

Types of Rebar Available

- Carbon Steel Rebar

Most commonly used rebar for its versatility and strength, along with its cost-effectiveness. Useful in an extensive range of uses for common construction projects.

- Epoxy-Coated Rebar

These are used in cases where corrosion risk is high, most notably in coastal or marine-type projects. This coating is a safeguard against rusting and damage from environmental factors.

- Galvanized Rebar

It is more durable in an environment compared to the usual carbon steel rebar and is used when the environment requires long-term durability.

- Stainless Steel Rebar

While it is more expensive, it is preferable for major constructions subjected to adverse conditions, especially where corrosion poses a vital threat.

- Glass Fiber Reinforced Polymer (GFRP) Rebar

A lightweight yet non-corrosive variety is best suited for problematic buildings, where electromagnetic interference could cause issues; examples include medical or research facilities.

- Welded Wire Fabric (WWF)

Prefabricated steel wire meshes are used to reinforce slabs and walls to provide increased strength and stability.

Compare The Most Common Type of Steel Rebar

|

Type of Rebar |

Strength |

Corrosion Resistance |

Cost |

Typical Uses |

Weight |

|---|---|---|---|---|---|

|

Carbon Steel Rebar (Black Bar) |

High tensile strength |

Low, prone to rusting |

Low (most affordable) |

General construction, including bridges, buildings |

Heavy |

|

Epoxy-Coated Rebar |

Moderate, coating ensures durability |

High, resistant to corrosion |

Moderate |

Marine, highways, and high-moisture environments |

Heavy with coating |

|

Stainless Steel Rebar |

Very high, long-lasting |

Very high, extremely resistant |

Very expensive |

Critical structures, coastal and chemical environments |

Heavy |

|

Galvanized Rebar |

High, due to zinc coating |

Good, slower rusting rate |

Higher than carbon steel |

Construction in wet or corrosive conditions |

Heavy |

|

Glass Fiber Rebar (GFRP) |

High, non-metallic composition |

Excellent, will not corrode |

Expensive |

Medical facilities, research labs, or electromagnetic exposure |

Lightweight |

|

Welded Wire Fabric (WWF) |

Dependable strength when used in grids |

Low to moderate, steel base |

Varies depending on size |

Slabs, walls, and structural reinforcements |

Varies by density |

Epoxy-Coated Rebar: Corrosion Resistance

This type of rebar, also known as epoxy-coated reinforcing steel, is perhaps the most famous corrosion protection measure for reinforced concrete structures. The exterior layer of epoxy forms an impervious barrier protecting the steel from moisture, chlorides, and other corrosive elements present in marine circumstances, bridges, industrial plants, etc. Studies filtering to epoxy-coated rebars indicate the extended longevity of concrete structures, thereby minimizing the rate of deterioration due to corrosion of the reinforcement.

A primary factor in its performance is the adhesion of the epoxy to the reinforcing steel and its durability. Modern technology confers an even adherence to the coating with an assurance of fulfillment of protective requirements. Consolidated with laboratory tests and practical experiences, confirming that the epoxy layer is highly resistant to cracking and degradation caused by mechanical stresses, this ensures that epoxy-coated rebar can be applied in harsh environmental conditions. Despite the initial cost of epoxy-coated steel being slightly higher than that of uncoated steel, it becomes more economical over time, as it requires less maintenance and repair in areas of harsh weather exposure or those with high chloride content. The use of epoxy coating on reinforcing steel represents a deliberate and proactive step toward increasing the longevity of the structure and sustainable development.

Stainless Steel Rebar: Durability and Longevity

Manufacturing and Fabrication of Rebar

The manufacturing of rebar essentially involves melting raw materials, such as iron ore, scrap steel, and alloys, in a furnace to produce steel billets. These billets are then heated and fed into rolling mills to pass through various finishing stages to get the desired size and shape. The finishing processes include surface finishing or imprinting of deformation patterns to improve binding capacity with concrete. Fabrication typically involves cutting, bending, and welding to adapt the product to meet the specific needs of the project. Manufacturing utilizes advanced machines for precision, and robotic automation enhances efficiency and consistency. Quality management follows throughout manufacturing and fabrication to ensure that the product meets the industry standards in guarantee of performance in actual constructions.

Materials Used to Manufacture Rebar

The primary manufacture of rebars is by steel, keeping in mind the application, witnessing high strength, ductility, and the capacity to bond well with concrete. Usually, the base material consists of recycled steel from scrap, which is then melted down in electric arc furnaces (EAF), depending on the scrap and other specific steel-making processes capable of producing billets or rods, which then serve as precursor materials for the production of rebars. Adding to the steel alloys would prepare the steel to possess desired qualities for the ultimate use; therefore, manganese might be added for impact resistance, chromium for corrosion resistance, or vanadium for tensile strength.

Advanced grades of rebar, such as epoxy-coated and stainless steel compositions, are also manufactured to resist superior in hostile environments prone to moisture or chemical exposure. Microalloyed rebar enlists minimal amounts of niobium or titanium to improve strength without affecting weldability. These material composition variations cater for the ever-varying mechanical and environmental requirements of modern construction works. A close watch coupled with proper, timely technical control of these materials during the entire manufacturing process is paramount to the achievement of a quality rebar measuring up to very stringent engineering standards and codes of safety.

The Process of Rebar Fabrication

Rebar fabrication follows a coordinated and meticulously controlled procedure that assures well-fit durability, strength, and precision demanded by construction standards. The entire process begins by selecting suitable raw materials; typically, low-carbon steel is melted in an electric-arc furnace or a similar facility. Once melted and refined to remove impurities, the steel is brought to the composition required for rebar manufacture. Alloying elements may be introduced at this stage to tailor the particular engineering properties of the steel. For example, manganese, chromium, or vanadium could be added to improve tensile and impact strength or corrosion resistance.

Once the steel is refined, the molten steel is cast into billets and then reheated and fed to a phased rolling line. The rolling mills are designed to progressively shape the billets into elongated bars of uniform diameter and surface finish. This stage is critical because ribbing patterns are applied to the concrete surfaces with precise geometry and spacing of the ribs, as they have a direct bearing on the strength of bonded reinforced concrete.

After rolling and cooling, the rebar undergoes a specific processing technique, known as “thermo-mechanical treatment” (TMT), which results in enhanced mechanical properties. TMT consists of a rapid quenching process to form a high-strength outer surface layer combined with a relatively soft and ductile core. Quality control is bordering measures from tensile strength tests, bend tests, chemical analyses throughout fabrication to ensure adherence to engineering standards, and English certifications.

Benefits of Using Rebar in Construction

- Enhanced Structural Strength

Rebar builds the tensile strength of concrete, which remains weak when subjected to tensile forces. By placing the bars, the concrete can tolerate greater stress so that the structure undergoes durability under static and dynamic loads simultaneously.

- Improved Load-Bearing Capacity

With the reinforcement of concrete using rebar, the structures become capable of carrying more load. Thus, large-scale works requiring huge strength and stability, such as bridges, high-rise buildings, and dams, have become a reality. The studies show that the stress load endured by reinforced concrete is ten times that applied to unreinforced concrete.

- Resistance to Cracking and Deformation

Rebar can ensure that concrete does not shrink, crack, or deform. By dispersing stress uniformly, rebar minimizes localized failure, thereby increasing the structure’s longevity. For example, steel reinforcement can withstand a strain of 0.2%, thus providing both ductility and strength.

- Adaptability and Versatility

The cutting and bending of the rebar can be customized as per the project’s design requirements. Whatever the scope may be, the rebar can be bent from a straight bar to very complex shapes to meet architectural and engineering needs. The most common type of rebar used is Class 60, which refers to its yield strength of 60,000 PSI (pounds per square inch).

- Seismic Performance Improvement

Furthermore, an earthquake-proof structure would see far less damage during an earthquake. These reinforcements will absorb energy that is generated during such causes of release, reducing the chances of catastrophic failure. Statistically, reinforced concrete buildings have been proven to withstand earthquakes better than non-reinforced ones.

- Corrosion Resistance

The need for additional protection arose when it was identified that steel rusts fairly quickly in harsh environments such as coastal regions or in industrial areas with high air moisture. The coating protects the steel, thereby resisting maintenance and extending the material’s lifespan over time.

Enhanced Structural Strength

Modern construction techniques have enhanced structural strength considerably by the application of advances in materials science. Structures composed of high-strength steel rebars and novel concrete mixes sustain heavier loads in greater flexibility under stress. For instance, Ultra-High Performance Concrete (UHPC), which utilizes optimized particle packing and fiber incorporation designs for reinforcement, exhibits compression strengths exceeding 20,000 psi —a significant increase compared to the strength ratings of conventional concrete. Moreover, these systems utilize state-of-the-art modeling software to analyze and solve load balancing problems, ascertaining that the designs fit into stringent safety codes and far exceed conventional benchmarks in real sense. The series of improvements in material characteristics and design principles ensures that modern infrastructure holds up under extreme conditions and maximizes risk reduction and offers greater life expectancy.

Increased Durability of Concrete Structures

The improved durability of concrete structures can largely be attributed to the significant advancements in materials science and construction methods. An example is the use of supplementary cementitious materials (SCMs), such as fly ash, silica fume, or ground-granulated blast-furnace slag, to enhance their chemical resistance and impart better mechanical properties. They help by decreasing permeability, which limits the ingress of water and corrosive chemicals, such as chlorides and sulfates, into the structure, thereby preventing its deterioration.

Recent developments in curing techniques have extended the life expectancy of concrete structures. Internal curing, in terms of innovation, involves the use of lightweight aggregates or pre-soaked material to maintain an internal moisture supply within the concrete matrix during the early stages of hydration. Hence, extrusion cracking is prevented, and the long-term stability and strength of the concrete are greatly enhanced. Among others, temperature curing control has similar effects on large structural pours by reducing its thermal stresses and improving material performance uniformity.

Nanotechnology has also facilitated the advancement of ultra-high-performance concrete (UHPC), which exhibits far higher compressive strengths than ordinary concrete, while also offering the advantages of tensile ductility and durability. For instance, nano-silica particles contribute to microstructural densification, resulting in a reduction of porosity and an increase in the resistance of concrete to both physical and chemical attacks. These improvements addressed problems caused by freeze-thaw cycles and carbonation, ensuring better durability under various climatic conditions.

Common Applications of Rebar

Reinforcing steel, or rebars, is used in construction to increase the tensile strength of concrete, which is very strong in compression but weak in tension. Typical applications for rebars include:

- Foundations: Rebars are needed in concrete footings and slabs to resist load-bearing stresses and the onset of cracking.

- Bridges: It strengthens concrete to resist dynamic loads such as those from traffic and structural stresses imparted by environmental factors.

- Columns and Beams: The rebars are used in these structural members to allow it to resist bending forces and maintain stability when subjected to heavy loads.

- Roadways and Pavements: Ductility of roads increases provided with reinforced concrete, which limits maintenance occasioned by wear and tear from environmental conditions.

- Retaining Walls: It gives the retaining walls extra strength to withstand heavy soil pressure or water.

Applications of rebar demonstrate its essential function in assuring the security, durability, and longevity of concrete structures placed in different environments.

Rebar Used in Building Foundations

Rebar considerably strengthens the building foundations by increasing their capability to resist simultaneous tensile and compressive forces. The foundations should resist extraordinary loads from the superstructures, as these loads are transmitted to them. They should also resist environmental stress from various sources, such as soil movement or upward water pressure. The use of rebar in concrete foundations reduces cracking and enhances the foundation’s strength.

Nowadays, foundation systems primarily use reinforced concrete footings, slabs, and piers to distribute loads over a wide area. Steel reinforcement, for example, is arranged in grids in mat or raft foundations for high-rises to handle complex stress patterns from both vertical loads and lateral forces, such as wind or seismic forces. Research shows that depending on the grade and configuration of steel, rebar may increase the tensile strength of concrete by as much as 25 times.

Meanwhile, epoxy coating or galvanizing methods are used to protect the rebar from corrosion in areas with high moisture or corrosive soils. Safe foundations combined with engineering art and advanced materials shall stand the test of time even in the most adverse conditions.

Reinforcing Bridges and Roads

The strengthening of bridges and roads has become vital in the field of infrastructure engineering to ensure durability and safety, particularly in response to increasing traffic demands. These projects are mainly carried out using reinforced concrete and steel, as both are very strong and resilient materials under tensile and compressive forces. These days, improvements in technology serve the purpose of reinforcement, with fiber-reinforced polymers (FRP) being the most prominent, especially in corrosion-prone or extreme weather conditions.

Reference Sources

1. Corrosion Effect of Stray Currents and Techniques for Evaluating Corrosion of Rebars in Concrete

- Key Findings: This study focuses on the impact of stray currents on the corrosion of steel rebars in concrete. It highlights the susceptibility of steel fibers to stray-current-induced corrosion and evaluates the effectiveness of various corrosion monitoring techniques, such as linear polarization resistance and gravimetric analysis.

- Key Findings: This research compares the reinforcement efficiency in beams and columns using ETABS software versus actual project data. It concludes that ETABS-calculated reinforcements are more economical than those installed in the project, with significant differences in reinforcement percentages (e.g., 60% in beams and 40% in columns).

Frequently Asked Questions (FAQs)

Q: What is the type of rebar used in concrete construction?

A: The type of rebar used in concrete construction is primarily steel bar reinforcing, often made from high-strength steel. Most commonly, grade 60 rebar is utilized due to its minimum yield strength, which ensures durability and performance under load. Rebar is designed to carry tensile loads that concrete alone cannot handle, making it essential for structural integrity. Other types, such as grade 40, may be used for less demanding applications. The properties to concrete improve significantly with the correct type of rebar, enhancing the overall strength of the structures.

Q: Why is rebar necessary in reinforced concrete?

A: Rebar is necessary in reinforced concrete because it provides tensile strength that concrete lacks. Concrete is strong in compression but weak in tension, which is where rebar comes into play. Without rebar, structural members reinforced with steel would be prone to cracking and failure under stress. Additionally, rebar helps control temperature changes and thermal expansion within concrete, minimizing the risk of damage. The inclusion of rebar is vital to ensure the longevity and safety of concrete and masonry structures.

Q: How can I determine the size of rebar I need for my project?

A: Determining the size of rebar you need for your project involves considering the load requirements, spacing, and the structural design. For most concrete structures, the standard rebar sizes, such as #4 and #5, are commonly used, depending on the specific application. You should also take into account the concrete cover required to protect the rebar from environmental factors. Consulting with structural engineers can provide insights into the appropriate bar size needed for safety and compliance with building codes. It’s essential to select the correct size of rebar to ensure the structural integrity of the project.

Q: What are the benefits of placing rebar in concrete?

A: Placing rebar in concrete offers numerous benefits, including enhanced strength and durability. Rebar supports the concrete in carrying tensile loads, which helps prevent cracking and structural failures. Moreover, it improves the resistance of concrete and masonry structures to various stresses, such as thermal expansion and contraction. Proper placement of rebar also contributes to a more stable and reliable concrete structural member reinforced with steel, which is crucial for long-term performance. Overall, the strategic placement of rebar is key to achieving a robust and resilient concrete construction.

Q: How does cutting rebar affect its performance?

A: Cutting rebar must be done carefully to prevent compromising its structural integrity. If rebar is cut improperly, it can lead to weakened areas that may fail under load. Using the correct tools, such as a rebar cutter or grinder, ensures clean cuts that do not introduce stress risers. Additionally, when cutting rebar, it’s important to consider the rebar necessary for maintaining the required tensile strength in the overall structure. Properly cut pieces of rebar should be inspected and placed according to engineering specifications to ensure they will function effectively in the concrete mix.