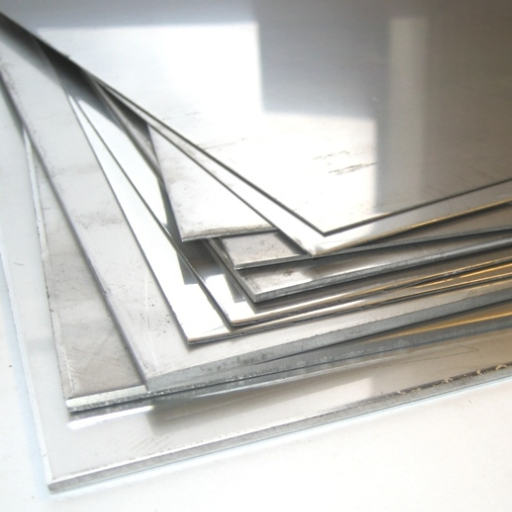

Frequently used across numerous industries, stainless steel plates have been valued and appreciated for their strength, tenacity, and corrosion resistance. This comprehensive guide responds to the needs of experienced industry professionals, researchers, students, and hobbyists to understand stainless steel plates: physical properties, grades, and use in practice.

Key Benefits of Stainless Steel Plates

Outstanding resistance to rust and corrosion, providing excellent service in harsh climatic conditions. This quality ensures longevity and reduces maintenance costs.

Excellent ability to withstand high loads and high temperatures over extended periods, with good corrosion resistance and toughness.

Smooth and non-porous finishes that are easy to clean and maintain, making them perfect for food, pharmaceutical, and medical device industries.

Multiple variations available to meet wide-ranging requirements across construction, automotive, and industrial applications.

100% recyclable with no quality degradation, making it an environmentally responsible choice for modern applications.

Durability and Longevity

Stainless steel plates demonstrate exceptional resilience and endurance, making them a cornerstone material across numerous industries. Their resistance to corrosion, oxidation, and general wear ensures structural integrity even in the harshest environments.

Industrial Applications of Stainless Steel Plates

Primary Industry Applications

- Construction: Structural components, building envelopes, and roofing systems requiring high strength and atmospheric resistance

- Chemical Processing: Storage tanks and transportation systems handling concentrated, aggressive chemicals

- Food and Beverage: Processing equipment, storage solutions, and preparation surfaces requiring hygienic, easy-to-clean materials

- Marine: Offshore platforms and coastal installations requiring superior saltwater corrosion resistance

- Energy and Power: Pressure vessels, boilers, and high-temperature applications in power generation facilities

Construction and Infrastructure

Stainless steel sheets play an irreplaceable role in modern building and infrastructure design. Their popularity stems from exceptional durability and environmental resistance, making them ideal for:

- Bridge construction requiring long-term structural integrity

- High-rise buildings in urban environments

- Architectural facades and curtain wall systems

- Roofing structures in moisture-saturated areas

Types and Grades of Stainless Steel

Austenitic Stainless Steel (300 Series)

High in chromium and nickel content, providing excellent corrosion resistance. Common grades include 304 and 316, widely used in food and chemical industries.

Ferritic Stainless Steel

Higher chromium content with lower nickel, offering excellent weldability and resistance to intergranular corrosion. Grades 409 and 430 are popular in automotive and appliance manufacturing.

Martensitic Stainless Steel

Provides appreciable strength and moderate corrosion resistance. Grades 410 and 420 are commonly used in cutlery and surgical instruments.

Duplex Stainless Steel

Combines austenitic and ferritic properties, offering excellent saltwater resistance and stress-corrosion cracking resistance. Grade 2205 is prevalent in the marine and oil industries.

Precipitation-Hardening (PH) Stainless Steel

Heat-treatable alloys designed for very high tensile strength applications. Type 17-4 PH is important in aerospace and severe chemical environments.

Popular Stainless Steel Grades in Detail

304 Stainless Steel and Its Applications

304 stainless steel, also known as 18/8 due to its approximately 18% chromium and 8% nickel content, represents the most popular stainless steel alloy. Its exceptional combination of properties includes:

- Excellent corrosion resistance

- Outstanding formability and ductility

- Good strength retention across temperature ranges

- Superior weldability

Primary Applications: Food processing equipment, kitchen appliances, architectural structures, handrails, and entrance canopies.

316 Stainless Steel for Enhanced Resistance

316 stainless steel offers superior corrosion resistance, especially in chloride and extreme chemical environments. The addition of molybdenum provides enhanced resistance to pitting and crevice corrosion.

430 Stainless Steel Analysis

430 grade stainless steel belongs to the ferritic family, featuring 16-18% chromium content. It offers excellent corrosion resistance and thermal conductivity while remaining cost-effective.

Mechanical Properties:

- Tensile strength: ~450 MPa

- Yield strength: ~205 MPa

- Thermal shock resistance up to 1500°F (815°C)

Material Comparison Table

| Property | Stainless Steel | Aluminum | Carbon Steel |

|---|---|---|---|

| Density | High | Low | High |

| Strength-to-Weight Ratio | Moderate | High | Low |

| Corrosion Resistance | Excellent | Moderate | Poor |

| Heat Resistance | High | Moderate | Low |

| Electrical Conductivity | Poor | Excellent | Poor |

| Machinability | Moderate | High | Low |

| Cost | High | Moderate | Low |

| Durability | Excellent | Moderate | Moderate |

| Common Applications | Construction, medical tools | Aerospace, electronics | Automotive, pipelines |

Choosing the Right Stainless Steel Plate

Factors to Consider: Thickness and Finish

Selecting the appropriate thickness and surface finish is crucial for optimal performance:

- Thickness Selection: Determines load-bearing capacity and application suitability. Thin plates (18 gauge) offer cost-effectiveness, while heavy gauges provide superior strength

- Surface Finish: Critical for functionality and aesthetics. High-cleanliness environments require polished surfaces, while brushed finishes offer easier maintenance and fingerprint resistance

Understanding Grades and Their Suitability

Grade selection depends on multiple factors including mechanical stress, temperature variations, and chemical exposure. Key considerations include:

- Austenitic grades (304, 316): Excellent corrosion resistance with chromium and nickel content

- Martensitic and duplex grades: High strength applications with good corrosion resistance

- Ferritic grades (430): Cost-effective for decorative and low-corrosion environments

Manufacturing Processes

The production of high-quality stainless steel plates involves sophisticated manufacturing processes:

- Initial Melting: Iron ore, chromium, nickel, and molybdenum are melted in electric arc furnaces

- Refining: Molten steel is refined using argon oxygen decarburization (AOD) to control carbon levels

- Forming: Steel is cast into slabs or ingots based on intended applications

- Rolling: Hot and cold rolling processes achieve specific dimensions and surface qualities

- Heat Treatment: Annealing and acid treatment improve formability and corrosion resistance

- Precision Manufacturing: Advanced techniques including laser cutting and precision machining create complex components

Unique Advantages of Stainless Steel Plates

Corrosion Resistance

Superior corrosion resistance due to chromium content forming a passive oxide layer, making it ideal for moisture, chemical, and marine environments.

Strength and Durability

High hardness and durability rating suitable for high-load and mechanical stress applications, resisting work hardening and abrasion.

Heat Resistance

Excellent performance at elevated temperatures, widely used in energy devices, boilers, heat exchangers, and engine components.

Hygienic Properties

Non-porous surface enabling easy cleaning and disinfection, crucial for pharmaceutical, medical equipment, and food processing industries.

Aesthetic Appeal

Stylish and timeless appearance suitable for architectural and interior design projects, maintaining luster across various environments.

Recyclability

100% recyclable with no quality degradation, supporting sustainable manufacturing goals while reducing environmental impact.

Reference Sources

1. Resistance of Bacterial Biofilms Formed on Stainless Steel Surface to Disinfecting Agent

- Key Findings:

- Biofilms formed on stainless steel surfaces (type 304) in food industry environments showed significant resistance to disinfectants.

- A disinfectant containing hydrogen peroxide and peroxyacetic acid was tested. At operational concentrations (0.5% for 10 minutes), it reduced biofilm cells by only 1–2 log cycles.

2. Roller Straightening Process and FEM Simulation for Stainless Steel Clad Plate

- Key Findings:

- A novel isothermal residual curvature straightening process was developed for stainless steel clad plates.

- The process effectively reduced residual stress and improved plate flatness.

Frequently Asked Questions (FAQs)

Q: What are the benefits of using 304 stainless steel plates in industrial applications?

A: 304 stainless steel plates offer excellent corrosion resistance and formability, making them highly versatile for various applications. They’re commonly used in kitchen appliances and industrial equipment due to their ability to withstand corrosive environments. The lower carbon content in 304L stainless steel further enhances corrosion resistance, especially in intergranular corrosion situations.

Q: How do 316 stainless steel plates compare to 304 stainless steel plates?

A: 316 stainless steel plates offer increased strength and superior corrosion resistance, especially in marine and chemical processing industries. The molybdenum content in 316 stainless steel enhances resistance to pitting and crevice corrosion in aggressive environments, such as those involving sulfuric acid. While 304 is suitable for many applications, 316 excels in harsh environments with corrosive material exposure.

Q: What applications are best suited for stainless steel sheet products?

A: Stainless steel sheets are utilized across architectural components, exhaust systems, and water treatment facilities. Their excellent forming and welding characteristics allow easy fabrication into various shapes. In industrial settings, they’re used for structural components due to their strength and corrosion resistance. They can be polished for aesthetic purposes and perforated for filtration systems.

Q: Can stainless steel plates be customized for specific industrial needs?

A: Yes, stainless steel plates can be customized by cutting to size and shaping according to project requirements. Manufacturers offer extensive inventories that can be tailored for various applications, including finishing options like polished sheets or specific thicknesses for high-temperature environments. This flexibility allows use across diverse industries while meeting stringent manufacturing demands.

Q: What is carbide precipitation and how does it affect stainless steel?

A: Carbide precipitation refers to carbide formation during welding or heat treatment, which can affect overall corrosion resistance. This is particularly significant in 304 stainless steel and can lead to intergranular corrosion if not properly managed. Using appropriate filler materials, maintaining proper heat control, and selecting lower carbon content alloys like 304L can minimize this issue.

Conclusion

Stainless steel plates represent a cornerstone material in modern industry, offering unmatched versatility, durability, and performance across diverse applications. Whether you’re an engineer, purchasing specialist, or business decision-maker, understanding the properties, grades, and applications of stainless steel plates enables informed choices that optimize performance, cost-effectiveness, and long-term reliability.

The combination of corrosion resistance, strength, hygiene properties, and sustainability makes stainless steel plates an invaluable resource for industries ranging from construction and manufacturing to food processing and medical equipment. As technology continues to advance, stainless steel plates will undoubtedly remain essential for achieving operational excellence and meeting the demanding requirements of tomorrow’s applications.