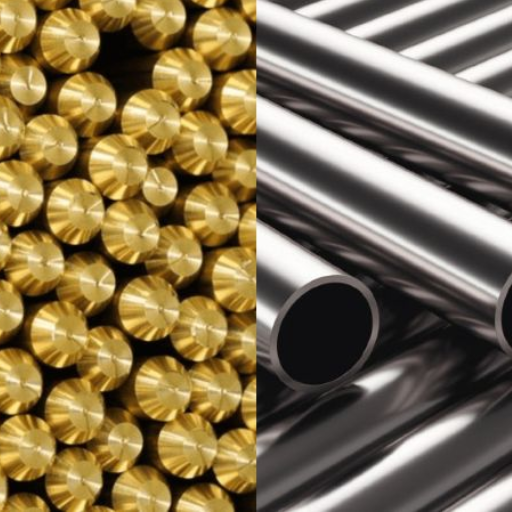

An example that fits the very nature of material evolution is brass plated with stainless steel, where utility and beauty are combined into one flexible solution for all occasions. Depending on the industry it serves, from manufacturing to interiors, it carries that sort of appeal of stainless steel, which boasts a smooth and corrosion-resistant face, with that of strength and machinability on the part of brass. In more detail, this guide shall talk about stainless steel plated brass, its composition, and chief advantages, along with its uses and care. This system will fill the gap for engineers looking into some options in their material supplies and designers who perhaps want to consider more durable and elegant finishes. So let us begin unfolding the wonders of this material and try to understand why it is now widely sought after for industrial and aesthetic uses.

Understanding Stainless Steel Plated Brass

The composition of stainless steel plated brass consists of brass as a core material with a surface layer of chromium-containing steel. The brass core provides strength, durability, and machinability for goods; meanwhile, the stainless steel plating provides a life under harsh corrosive systems and proudly presents its appearance through reflection and surface hardness. With these characteristic features, it becomes a fairly easy material to go through and apply for the practical or decorative needs of industries, including plumbing, manufacturing, and interior design.

What is Stainless Steel Plated Brass?

Stainless steel plated brass enjoys a unique blend of properties bestowed by its core and plating materials. The brass core provides excellent thermal and electrical conductivity, rendering it appropriate in applications calling for efficient energy transfer. In addition, brass is highly machinable and formable, enabling the fine manufacturing of perhaps complex components. Through its plating, stainless steel offers resistance towards oxidation, staining, and corrosion, thereby facilitating an increased life span even in harsh environmental conditions. The protective layer also follows about its wear resistance properties, contributing to a nice, polished, smooth surface finish. Owing to these capabilities, stainless steel plated brass has found its way into sectors ranging from medical to automotive, electronic, and architectural fields wherein it is imperative to have the right pairing of strength, longevity, and beauty.

Properties of Stainless Steel and Brass

Properties of Stainless Steel:

- Corrosion Resistance: Stainless steel, by virtue of at least 10.5% chromium content, forms a chromium oxide layer that gets passive upon exposure to the atmosphere and hence affords rust- and corrosion-protection.

- Tensile Strength: The stainless steel has good tensile strength, commonly between 515 MPa and over 1,200 MPa, depending on its grade.

- Thermal Resistance: At the temperature of greater than 800°C (1,472°F), it is used in applications that depend on the grade of the alloy; whereas, heat resistance.

- Hygiene and Ease of Cleaning: It gets rid of bacterial growth since it is a smooth surface, conforming to sanitation requirements in food and the health sector.

- Recyclability: A recyclable material with ever close to 88% of the stainless steel recycled back into new stainless steel products.

Properties of Brass:

- Corrosion Resistance: Brass provides excellent corrosion resistance, especially in low to moderate moisture conditions, so it should be used in marine and outdoor applications.

- Malleability and Ductility: The material is easily mechanically worked into complex shapes without loss of structural integrity, thereby providing the best shape for artistic and industrial use.

- Acoustic Properties: Brass has a good resonance characteristic and is, therefore, extensively used in the manufacture of musical instruments.

- Aesthetic Appearance: With a brilliant sheen and a golden hue, it is considered highly desirable for architectural decorating.

Process of Brass Plating with Stainless Steel

The brass plating of stainless steel is a highly precise and subtle operation involving electrochemical techniques and consequential preparation to give an impervious and uniform coating. Following excellent surface preparation which is crucial for good adhesion, the stainless steel substrate would be cleaned to render it devoid of any contamination, like grease, oils, or oxides. Mostly alkaline or acidic cleaning solutions are employed. Mechanical means of abrasion may also be used to roughen the surface slightly, which improves the bonding of the brass coating. Finally, the early brass deposition operation may proceed in earnest, either by the electrodeposition route or by immersion.

Benefits of Stainless Steel Plating

- Corrosion Resistance

Brass-plated stainless steel, technically, should definitely be kept from environmental degradation. While the alloy layer prevents moisture, chemicals, or oxidation from penetrating through to the substrate below, studies indicate that brass plating could enhance the corrosion resistance of stainless steel by 50% plus vis-à-vis the unplated surface under similar conditions.

- Enhanced Durability

The layer of brass plating is very hard and resistant to wear and mechanical damage. Ideal for applications where the surface is subject to frequent handling or exposure to abrasive situations, it forms a durable barrier against any physical stress.

- Improved Aesthetic Appeal

The brass-plated finish with its shiny golden color adds to the aesthetic value of stainless steel by bestowing a high-grade decorative finish. Surfaces of this kind are abundantly used in architecture, interior design, and jewellery where visual excellence is of utmost importance.

- Electrical Conductivity

A brass plating layer also serves to enhance electrical conductivity and hence finds applications in various aspects of the electronics industry. The presence of zinc and copper ions improves the current flow, which is essential for items such as connectors and terminals.

- Cost Efficiency

Through the application of a thin, highly controlled layer of brass onto stainless steel surfaces, manufacturers are able to obtain critically engineered performance with the use of limited solid brass materials. The key for brass plating stands for reducing costs while maximizing the properties of the material.

Corrosion Resistance

Brass-plated stainless steel offers superb corrosion resistance, making it ideal wherever moisture, oxidation, and chemical exposure are a reality. This resistance arises from the formation, during the electroplating process, of a very powerful protection layer that prevents direct contact of the underlying stainless steel with corrosive agents. In addition, the intrinsic qualities of brass lend an additional layer of protection against the possibility of its deterioration through time. Furthermore, the alloys with high zinc content are proven by various studies to provide an excellent corrosion barrier, especially in marine or industrial atmospheres. This guarantees a durable function and reliability even in a hostile environment-meaning the material finds relevance in applications ranging anywhere from architectural ventures to precision engineering components.

Enhanced Durability

Apart from being highly corrosion resistant, brass offers great manufacturability. In contributing strength to an application, brass will also provide the ease of machining, making it the prime choice for automotive, plumbing, and electrical fields. Metallurgy developments in recent times have brought further improvement to the behavior of brass alloys; such optimized compositions can offer an improvement in both tensile strength and ductility. For example, some grades of brass have been modified to have increased wear resistance, thus proving efficient against high-friction applications such as gears, bearings, and valve parts. Thereby, such developments attest to brass’s ability to evolve in meeting the demands of present engineering and industrial systems.

Sleek and Modern Appearance

Apart from being valued for the performance properties of brass, it has a legendary reputation for aesthetic value and is thus a major player in contemporary design and architectural framework. Brass lends a warm, golden hue that locates itself somewhere between a noble classic and a modern design language, while cute surface treatments like polishing, lacquering, or patination ensure that brass can fit into any application and stylistic requirement at custom levels. Brass can be seen everywhere from decorative hardware to lighting fixtures to bold interior accents of the present day-unifying utility and beauty. New methods of finishing have given rise to finishes that resist corrosion and require minimal maintenance, maintaining the sleek, contemporary appearance of brass for years to come. Because brass can be a recycled material and can in turn further sustainable manufacturing processes, more and more brass is being recognized as a green material.

Applications of Stainless Steel Plated Brass

- Plumbing Fixtures

The greatest producers and consumers of stainless steel plated brass are the plumbing industry, where the elemental use is for down-faucets, valves, and connectors. Water corrosion-resistant and long-term reliability are guaranteed for the material while it holds on to a suave contemporary look. Also, its antimicrobial properties make it ideal for water-handling systems.

- Architectural Hardware

The material is used for architectural elements which include door handles, hinges, and decorative lookout. The finish on stainless steel offers a perspective in-finish modern while the brass core allows ease of manufacture. These elements retain their classy looks till much long so they can be used along coasts and humid surroundings.

- Lighting Fixtures

The material retains the high shine for a very long time, which allows its use in premium lighting applications. The suitable stainless steel plated brass finishes lighting fixtures that reflect light in a sophisticated manner; thus, adding to the ambiance of both residential and commercial places.

- Automotive Components

Parts such as fittings, trims, and connectors in an automobile are usually put to use with stainless steel plated brass as it is capable of withstanding exposure to different environmental conditions and extreme temperatures. Being lightweight compared to solid stainless steel, it increases a vehicle’s efficiency while upholding grandeur.

- Marine Applications

Because of its high corrosion resistance against saltwater, stainless steel plated brass is a preferred material choice for marine hardware such as cleats, fasteners, and rail fittings. The need for strength to withstand harsh marine environments has, however, earlier been compromised with stainless steel plated brass avoiding premature degradation.

Applications in Automotive Industry

- Exhaust Systems

Due to the resistance to high temperature and corrosive media like exhaust gases and moisture, stainless steel plated brass can be used in exhaust systems. This allows for longer service life and enhanced performance in contrast to cheap materials.

- Brake Systems

Loftier in strength and corrosion resistance, the material can aptly be employed for brake fittings and valves. Assessments show that stainless steel plated brass used in brake systems could increase the lifespan of the components by as much as 30% in corrosive environments.

- Fuel Lines and Connectors

Fuel systems greatly profit from the impermeability of stainless steel plated brass to fuel and from its resistance to chemical corrosion. This ensures the integrity of the fuel delivery systems, therefore lessening the prospects of occurrences of leakages and failures.

- Interior Trim and Decorative Components

For interiors, stainless steel plated brass can offer a disarming high-end aesthetic finish that is also durable. It is principally used for trim pieces and knobs, alongside other decorative components that offer that high-end appearance without compromise on structural integrity.

- Cooling Systems

The resistance to thermal expansion and the ability to counteract the corrosive properties of the coolant make it a reliable option for heat exchangers, connectors, and the rest of the cooling system.

Home Decor and Manufacturing Uses

Stainless steel plated brass, a hybridized version combining properties of a stronger material with resistance and aesthetic appeal, has grown popular for home decor and manufacturing applications. In home decor, it often finds its way into fixtures such as faucet handles, cabinet hardware, and light fixture parts, corrosion resistance ensuring that they function for a long time even in moisture-heavy conditions: high grabbing humidity of kitchen or bath areas. This anti-corrosive character, combined with reflective rests on the surface of the stainless steel plating, imparts extra beauty to it, making it an apt choice for modern, industrial, or even minimalist design concepts.

The stainless steel plated brass finds itself appreciated in manufacturing because of its machinability and corrosion resistance. Custom applications are made out of it; gear-like and precise parts, such as gears, bushings, and valves, especially in an industry where it is always a requirement for the material to be reliable when put under mechanical stress. Another name came from brass for malleability and stainless steel for typhoon in stainless steel plating into a material that can keep a shining surface with a shape-holding property and wear resistance in rigorous operational conditions. Its continuing use in both fields serves to underscore its versatility and efficiency as a material.

Comparing Stainless Steel Plated Brass to Other Materials

A final alteration is in stainless steel plating: brass is a special composition offering corrosion resistance, strength, and malleability, with none of these being present in other similar materials such as pure stainless steel, aluminum, and conventional brass. In this respect, stainless steel plated brass would be considered an import from the old world since a pure stainless steel would be rather heavy and very rigid in nature. The aluminum does not withstand great strength and wear, so in applications requiring long-term reliability, stainless steel plated brass can stand up to the task. While workability is considered the forte of traditional brass, the lack of stainless steel plating also causes it to lack any additional corrosion-resistant properties, and thus, it finds limits in the areas of high humidity or chemical attack. In general, satin finish stainless steel plated brass, in essence, provides a balance of strength, resilience, and versatility, and far outperforms either of the materials in those applications where durability and environmental resistance become critical.

Plated Brass vs Gold-Plated Options

|

Key Point |

Plated Brass |

Gold-Plated Options |

|---|---|---|

|

Corrosion Resistance |

High, especially with stainless steel plating |

Moderate, may tarnish over time |

|

Conductivity |

Moderate |

Excellent |

|

Cost |

Affordable |

Expensive |

|

Durability |

Resistant to wear and damage |

Softer, prone to scratches |

|

Appearance |

Industrial or functional aesthetic |

Luxurious, shiny finish |

|

Maintenance Requirements |

Low |

Requires regular polishing |

|

Environmental Resistance |

High in harsh conditions |

Sensitive to extreme conditions |

|

Application Suitability |

Structural and practical use |

Decorative and conductive uses |

|

Weight |

Heavier due to brass base |

Lightweight |

|

Lifespan |

Long-lasting |

Shorter with frequent use |

Brass vs Gold Plated Stainless Steel

|

Key Point |

Brass |

Gold Plated Stainless Steel |

|---|---|---|

|

Composition |

Alloy of copper and zinc |

Stainless steel with gold layer |

|

Corrosion Resistance |

Moderate |

High resistance with proper coating |

|

Durability |

Long-lasting with tough structure |

May wear off over time |

|

Scratch Resistance |

Moderate |

Low, prone to scratches |

|

Maintenance |

Minimal care needed |

Requires routine polishing |

|

Strength |

High tensile strength |

Lower, depends on base material |

|

Conductivity |

Moderate electrical conductivity |

Low conductivity |

|

Aesthetic Appeal |

Warm, natural tones |

Luxurious, shiny gold appearance |

|

Weight |

Heavier due to alloy composition |

Lightweight |

|

Environmental Impact |

Can be recycled |

Gold plating adds to waste |

|

Application |

Functional and structural uses |

Mostly decorative |

|

Lifespan |

Long-lasting with care |

Shorter with frequent wear |

|

Cost |

Moderate price |

Higher due to gold plating |

Cost-Effectiveness and Versatility

The best things to always consider are the cost and versatility of any material for industrial and decorative applications. Stainless steel plated brass is an inexpensive material due to the prolonged durability and low maintenance costs. Because of its corrosion and wear resistance properties, replacement and repair are reduced, and thus it is suitable in dealing with high demand in use. It can be plated with any kind of finishing—chrome, nickel—to make it adaptable in industries from plumbing to luxury goods.

Practical Tips for Choosing Stainless Steel Plated Brass Products

- Assess Corrosion Resistance Requirements

Consideration of the environment in which this product will be used is essential. For the situations that have high moisture or high corrosion risks, do make sure the plating of this stainless steel can offer adequate protection and sustain itself over a considerable period.

- Evaluate Intended Application

Determine whether the product requires the good looks or mechanical strength as a priority. Stainless steel plating provides elegance to the finish while resisting wear.

- Check Compatibility with Usage Conditions

For a product that will encounter frequent handling or abrasive actions, consideration must also be given to the thickness of plating and standards of adhesion so that the product will not be worn down prematurely.

- Verify Maintenance Needs

Select the low-maintenance finish if cleaning and upkeep may present a challenge in some areas. Stainless steel plating is generally easy to clean, but surface treatments may vary.

- Choose Reputable Manufacturers or Suppliers

Endow your trust to manufacturers who observe quality standards for stainless steel plated brass products’ durability and performances. Where feasible, check for relevant certificates; otherwise, go through customer reviews to make adequate judgments on their credibility.

Assessing Specific Needs and Applications

Maintenance Tips for Longevity

- Regular Inspections

Carrying out regular check-ups every three to six months will allow you to spot any signs of wear, corrosion, or mechanical failure at its early stage. Non-destructive testing (NDT) methods, including ultrasonic thickness measurements or dye-penetrant testing, can be used to examine these instances for an accurate assessment.

- Cleaning Protocols

Cleaning should be done according to the dose of environmental exposures that the system suffers. For example, use solutions acceptable to the trade to clean dust, dirt, and any possible contaminant like chlorides or sulfates in the coastal or industrial environment. The cleaning agents should be chosen in such a manner that they will not chemically degrade the materials.

- Lubrication and Friction Management

Apply good lubricants to the moving parts or exposed surfaces under frictional contacts, with a specification meant for the operational loads and thermal form of the lubricant, such as high-temperature synthetic ones under operating temperatures over 150°F (65°C).

- Protective Coatings and Treatments

Renew protective coatings including anti-corrosive paints, sealants, or galvanic plating every 2–5 years, subject to the level of exposure and suggestions of manufacturers. Go for the ones that have passed the salt spray test rating for no less than 1000 hours if tested in a highly corrosive environment.

- Environmental Monitoring

Reference Sources

-

Corrosion of Aluminum, Copper, Brass, and Stainless Steel 304 in Tequila: This study analyzed the corrosion rates of various metals, including brass and stainless steel 304, in tequila. Stainless steel 304 exhibited the lowest corrosion rate (0.28 pm/s), making it the most stable among the tested materials. Brass showed moderate corrosion resistance compared to aluminum and copper.

-

Optimization of Brass Plating Conditions for Patented Steel Wire: The study focused on improving brass plating for steel wires used in rubber reinforcement. Optimal conditions included a free cyanide concentration of 5 g/L, a voltage of 1.5–2 V, and a pH of 11. The ideal coating thickness was 2–3 μm, which enhanced drawability and adhesion strength (∼7.3 MPa).

Frequently Asked Questions (FAQs)

Q: What are the advantages of stainless steel with brass?

A: The advantages of stainless steel with brass are numerous, as this combination leverages the strengths of both materials. Brass is a versatile material known for its malleability and corrosion resistance, while stainless steel offers superior durability and rust resistance. By plating brass with a thin layer of stainless steel, you can enhance the overall longevity of the product, making it a popular choice for various applications. This combination not only provides aesthetic appeal but also improves the mechanical properties of the brass. Furthermore, the stainless steel layer provides an additional barrier against tarnishing, ensuring that the brass surface remains attractive over time. Overall, this pairing exemplifies cost-effectiveness and machinability while maintaining a sleek appearance.

Q: How does gold plated brass vs gold compare in terms of durability?

A: When comparing gold plated brass vs gold, the durability of each material varies significantly. Gold plated brass typically features a thin layer of gold applied over a brass substrate, making it more affordable than solid gold. However, gold plated brass can tarnish over time, especially in humid or acidic environments, which can detract from its appearance. In contrast, solid gold does not tarnish and is more resistant to wear and tear, making it a more durable choice overall. Although gold plated jewelry can provide a similar look to solid gold, the longevity and resistance to corrosion of solid gold far exceed that of plated brass. Thus, for those seeking a lasting investment, solid gold is the superior choice.

Q: What is the difference between plated brass vs gold plated?

A: The difference between plated brass vs gold plated lies primarily in the base material and the application of the plating. Plated brass refers to a process where a thin layer of another metal is applied to brass, which is an alloy of copper and zinc. Gold plated items, on the other hand, specifically feature a layer of gold over a substrate, which can be brass or other metals. While both processes enhance the appearance of the base material, gold plating typically provides a more luxurious finish and better tarnish resistance than standard plated brass. Moreover, gold plated jewelry is often more sought after due to its aesthetic appeal and value retention. Ultimately, the choice between the two will depend on the desired look and budget considerations.

Q: Is brass or stainless steel better for outdoor use?

A: When deciding whether brass or stainless steel is better for outdoor use, stainless steel generally comes out on top due to its resistance to rust and corrosion. Brass may tarnish when exposed to the elements, especially in coastal areas where saltwater can accelerate deterioration. On the other hand, stainless steel, particularly when treated or coated, provides a solid barrier against environmental factors, ensuring longevity and durability in outdoor applications. While brass can be aesthetically pleasing and versatile, its maintenance requirements may deter some users. Therefore, for outdoor settings where exposure to moisture and temperature fluctuations is common, stainless steel is often the preferred material.

Q: How does comparing gold-plated brass to solid gold impact value?

A: Comparing gold-plated brass to solid gold greatly impacts perceived value, as solid gold holds intrinsic value due to its material composition. Gold-plated brass, while visually appealing, is essentially a brass item coated with a thin layer of gold, which can wear off over time, diminishing its value. In contrast, solid gold offers lasting worth and is not subject to the same wear and tear, making it a more reliable investment. This distinction becomes particularly important in jewelry, where gold-plated options may be more affordable but lack the same level of prestige and longevity. Ultimately, consumers should consider their budget and how they value longevity and material quality when choosing between these two options.