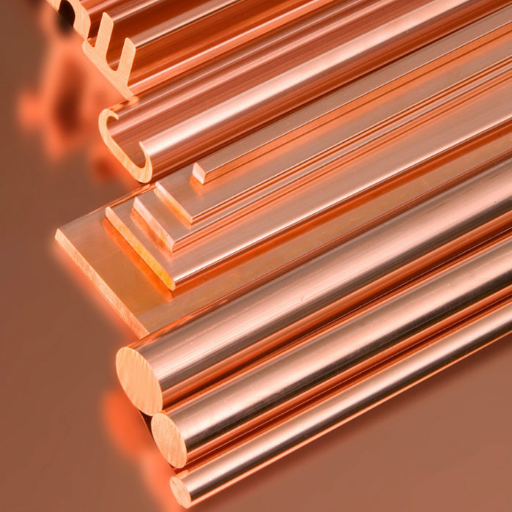

Copper, a malleable metal used for numerous purposes, finds dual applications in the U.S. construction and electronic industries. Due to its striking melting points, copper plays a crucial role in several important applications, including metallic surface modification, casting, alloying, and thermal applications, among others. The melting point of copper is thus not something only metallurgists and engineers should be concerned about, but also those for whom performance and durability in their products are important considerations. This article examines the scientific realities surrounding copper’s melting point, the factors that influence it, and its relevance to various applications, enabling readers to gain both technical insight and context about its uses.

Introduction to Melting Points of Metals

A metal has a characteristically determined melting point, which is determined by its atomic structure and bonding properties. A melting point stands for the temperature at which a metal changes from a solid state to a liquid state under one atmospheric pressure. Higher bond strength, atomic size, and nature of the crystal system can all influence this factor. For example, tungsten, with stronger metallic bonds, will have a much higher melting point compared to lead, which has weaker bonds. The knowledge of melting points is applied in casting, welding, and alloy-related activities; therefore, matrices must be used where melting points ensure the physical integrity and functionality of the material.

Definition of Melting Point

The melting point of any given substance corresponds to the heat and temperature at which that substance, under the standard atmospheric pressure, converts from a perfect solid to the liquid state. This melting process is thermally dynamic, creating a thermal equilibrium whereby the kinetic energy of the particles increases beyond the resistance forces holding them together in a rigid crystalline structure. Melting points serve to be a fundamental characteristic of pure substances and thus are used in identifying and verifying the purity of materials. For instance, the melting point of pure gold is 1,064°C (1,947°F), whereas the presence of impurities in gold would drastically lower this point of conversion into the liquid phase. Measurements of melting points, if trustworthy, provide the backbone to the applications of materials in material science for observing their respective features, in thermodynamics for serving as the precious jewels of temperature when calls arise for variable temperature experiments, and industrial applications for providing the important data required for selecting materials and processing them under given thermal conditions.

Importance of Melting Points in Metallurgy

Utilized in metallurgy, melting points are of the utmost importance for the principal selection and processing of metals and alloys. It gives engineers the knowledge of suitable thermal processes for metals or alloys, such as casting, welding, and heat treatment. For example, stainless steel has a melting range of approximately 1,370°C to 1,530°C (2,500°F to 2,786°F) and is utilized in high-temperature applications, such as the production of reactors and turbine components. The melting point also has implications in the formation of alloys, as the addition of alloying elements can increase or decrease the melting temperature, which subsequently affects the mechanical strength of the metal, for example, by hardening or improving corrosion resistance. Additionally, according to melting point data, the more advanced methods of metallurgy can best optimize the energy spent during smelting, thus reducing waste and simultaneously preserving the integrity and performance of the product.

Overview of Different Metals and Their Melting Points

Metals possess properties that impart melting points spanning virtually all conceivable temperatures, depending on their atomic structures, bond characterizations, and spatial arrangements of electrons within the atoms. For instance, tungsten has the highest melting point recorded for any pure metal, being approximately 3422°C (or 6192°F). This quality places it in situations where there is a significant need for thermal resistance, such as in the aerospace and electrical industries. Aluminium, on the other hand, melts at about 660°C (1220°F), is lightweight, and has the best thermal conductivity properties, which make it well-suited for the automotive and construction sectors.

At 1538°C (2800°F), iron serves as the fundamental element for the production of steel, its melting behavior being altered by the addition of carbon and other alloying elements. Copper melts at 1085°C (1985°F) and conducts heat and electricity, making it ideal for applications where it is utilized. Lead has a melting point of 327.5°C (621.5°F), and at the lower end of the range, such a lull in melting points allows applications for batteries and radiation shielding.

The melting points of metals provide a better understanding of their processing and usage, ensuring that materials are adequately selected to meet the operating conditions, particularly in extreme temperatures. This concept is widely used in metallurgical engineering to design precise alloying and heat-treating processes.

Melting Point of Copper

Copper melts at 1,085 °C (1,984 °F). Its melting temperature thus makes it suitable for use in applications requiring high wear and thermal resistance, with wiring, plumbing, and heat exchangers being typical categories. Its ability to withstand extreme temperatures without loss of structural integrity is ironically the main factor for its huge demand in many industrial and engineering applications.

What is the Melting Point of Pure Copper?

The melting temperature of pure copper is exactly 1,085°C (1,984°F). The melting point is a basic thermal property of copper as an elemental metal and is particularly interesting in industrial applications where high temperatures are involved. Such exact knowledge of the melting temperature becomes an essential parameter in industry, metallurgy, manufacture, and material sciences, where copper finds frequent application, either in pure or alloyed form. Due to its well-defined melting point, it can serve as a standard for calibrating a thermal measurement system in scientific studies. From heat processing requirements, this constant property ensures that copper remains the preferred metal.

Comparison with Other Common Metals

|

Metal |

Melting Point (°C) |

Density (g/cm³) |

Electrical Conductivity |

Primary Applications |

|---|---|---|---|---|

|

Copper |

1085 |

8.96 |

Excellent |

Electrical wiring, heat exchangers |

|

Aluminum |

660 |

2.70 |

Good |

Aerospace, packaging, electronics |

|

Iron |

1538 |

7.87 |

Moderate |

Construction, automotive, machinery |

|

Gold |

1064 |

19.32 |

Excellent |

Jewelry, electronics, currency |

|

Silver |

961 |

10.49 |

Excellent |

Jewelry, electrical components |

|

Titanium |

1668 |

4.51 |

Good |

Aerospace, medical implants |

|

Nickel |

1455 |

8.90 |

Moderate |

Alloys, batteries, plating |

|

Lead |

327 |

11.34 |

Poor |

Batteries, radiation shielding |

Factors Affecting the Melting Point of Copper

- Purity of Copper

Melting temperature alteration by impurities is one of the main factors. Being pure copper has a definite melting point, the addition of foreign substances or alloying with other metals (for example, tin and zinc) may lower the melting point. The melting temperature for brass, which is an alloy of copper and zinc, is less than that of pure copper.

- Atmospheric Pressure

The melting point of copper is affected by external pressure. Copper melts at 1085°C under normal atmospheric pressure. However, while subjected to high pressures, its melting point is said to slightly increase due to the maintainable constraint on the atomic structure. The opposite effect on the melting point may be observed from lower pressures, such as those in vacuum conditions.

- Grain Size and Microstructure

The grain structure of the microstructure of copper affects thermal properties; fine-grained copper melts at somewhat different conditions than coarse-grained copper, mainly because thermal conductivity and the distribution of energy through grain boundaries change.

- Heat Treatment and Work Hardening

Curing mechanisms, such as annealing, give rise to changes in copper crystal structure, as could also be done by quenching or cold-working. These might induce minor changes in the melting behavior, provided the atomic arrangement is altered.

- Alloying Elements

Metal Melting Processes

Methods to Melt Copper

An induction furnace is one of the most common methods for melting copper. This type of furnace uses electromagnetic induction for heating purposes. It is highly efficient and offers precise temperature control while minimizing energy loss. Induction furnaces are the preferred choice for melting copper because non-contact heating minimizes contamination from outside sources.

Another effective method would be to use a crucible furnace. These furnaces contain copper within a refractory-lined container as heating occurs, either through gas burners, resistance coils, or coke as a fuel source. Crucible furnaces are versatile enough to accommodate small to medium-scale operations, making them well-suited to various industrial requirements.

Electric arc furnaces (EAF) are also widely used in large-scale melting operations. In these furnaces, high-voltage electric arcs produce temperatures sufficiently extreme to melt copper in bulk. This method offers distinct advantages when melting scrap copper for recycling, thanks to its speed and robust capabilities.

While each method has unique benefits concerning required volume, energy efficiency, and degree of purity in the final product, the selection must be made in relation to the specific needs of the operation for those benefits to be optimized.

Welding Techniques and Their Importance

It is an art of welding that includes manufacturing and construction in the present world, wherein metals and other materials are joined quite durably. There are several primary welding processes, each developed to meet specific needs based on material, project dimensions, and environmental conditions.

MIG Welding (Gas Metal Arc Welding, or GMAW): This is the most used welding technique due to its ease of use and increased welding speed. A high-speed continuous wire electrode fed through a welding gun melts to join the materials beneath a shield of inert gas. MIG welding can be fast for applications in steel and aluminium for automotive and aerospace engineering.

TIG Welding (Gas Tungsten Arc Welding, or GTAW): TIG welding facilities offer the ability to weld the finest welds, making it suitable for thin materials that require very strong welds. Welding with a tungsten, non-consumable electrode and shielding gas gives it great control but demands skill and time to do it well.

Stick Welding (Shielded Metal Arc Welding, or SMAW): Typically used during maintenance and repair work, stick welding employs a consumable electrode coated with flux. This method is flexible and can be used in various environments, including outdoors and in remote locations, as it does not rely on an external source of shielding gas.

Laser Beam Welding (LBW): A more advanced procedure using energy concentrated from a laser to join materials with precision. The speed, penetration, and tiny heat-affected zone make laser beam welding attractive to the high-technology industries such as electronics and medical device manufacturing.

Applications of Copper’s Melting Point in Industry

Numerous industries can utilize copper, which has a melting point of approximately 1,984°F (1,085°C), due to its versatility and reliability at high temperatures.

- Electrical Components: The heat and electrical conductivity properties of copper have ensured its use in high-temperature applications, where wiring and circuit components, as well as connectors, are manufactured.

- Alloy Production: With the melting temperature, it combines with other metals such as zinc and tin to form brass and bronze, which are used in the working of mechanical and structural applications.

- Manufacturing Processes: Its relatively high melting point supports manufacturing processes such as casting and molding, where precision and material factors are crucial. The importance of these processes for the automotive and aerospace industries cannot be understated.

Copper in Casting Processes

The essential properties of copper make it the necessary choice for casting in various industries. Its high thermal and electrical conductivity ensures that the temperature is applied evenly during the casting, which can cause defects and improper mold fill. Copper is both workable and ductile, which allows for the intricate and complex geometries required for automotive, aerospace, and marine parts. The recent changes in alloy development, such as copper-nickel and copper-beryllium, have extended the applications of alloys, providing wear resistance over corrosion and durability.

Data from recent investigations show how much copper is starting to dominate in some advanced manufacturing processes, such as continuous casting and die casting. Continuous casting has, for instance, made copper billet, slab, and sheet production more efficient while maintaining a consistent microstructure and minimal inclusions. This aligns well with copper recycling strategies, saving resources and reducing waste generated by large-scale manufacturers. Industries are optimizing casting processes for increased productivity and enhanced component performance through the application of advanced technologies and the exceptional material properties of copper.

Welding Techniques Involving Copper

Due to their intrinsic nature, welding techniques must be adjusted to weld copper and its alloys, given their excellent thermal conductivity and tendency to oxidize. The rapid dissipation of heat typical of copper welding processes necessitates a higher energy input to enable the weld pool to reach full fusion. The most common procedures are Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), and Resistance Welding, each of which is used for different copper alloys and types of applications.

Being a welding process that provides maximum control over heat input and shielding action, GTAW is deemed to be most advantageous for copper. This welding process becomes particularly beneficial when working on thinner sections of copper, as it minimizes distortion. GMAW is suitable for applications demanding higher deposition rates, primarily in joining thicker copper parts. Preheating the copper to approximately 400°F to 750°F (200°C to 400°C) is often recommended for these processes to reduce thermal gradients and enhance weld quality.

Copper Alloys and Their Melting Points

Copper alloys, therefore, are a comprehensive set of materials that vary widely in composition according to the mechanical and thermal properties desired. Of course, melting points vary with composition. As examples:

- Brass (copper and zinc): Melting point range typically between 900°C and 940°C (1652°F–1724°F), depending on zinc content.

- Bronze (copper and tin): Melting point generally around 950°C to 1050°C (1742°F–1922°F).

- Cupronickel (copper and nickel): Melting point approximately 1100°C to 1150°C (2012°F–2102°F), influenced by nickel content.

- Beryllium Copper (copper and beryllium): Melting point near 870°C to 980°C (1598°F–1796°F).

Understanding these ranges is crucial when selecting alloys for high-temperature applications, as it ensures material integrity under operational conditions. For precise values, reference to technical datasheets is recommended.

Effect of Alloying Elements on Melting Temperature

A significant difference is introduced by adding alloying elements to the melting temperature of base metals, often resulting in enhanced performance properties for specialized applications. For instance, the addition of nickel to copper enhances thermal stability and increases the melting temperature, rendering the alloy suitable for resistance at a higher degree of temperature; similarly, chromium, as an element of iron-based alloys, enhances the corrosion resistance and also increases the melting span, thus improving structural performance under thermal stress.

From this point, aluminum tends to lower the melting temperature of copper but enhances its formability and conductivity, which is particularly good for electrical applications. In contrast, alloying tungsten or molybdenum with steel drastically elevates the melting temperature while also providing strength and creep resistance at high temperatures.

Such alterations display how greatly alloying elements aid the operational limits of materials. Materials scientists and engineers must have precise knowledge and control of these interactions to ensure the alloys can meet the specific needs of current industrial and aerospace applications.

Applications of Copper Alloys in Various Industries

- Electrical Industry

Copper alloys, such as brass and bronze, are actively used in the electrical industry for various components, including connectors, switches, and wiring. Utilizing their high electrical conductivity for energy transmission and operation is preferable. For example, 100% IACS (International Annealed Copper Standard) represents the conductivity of pure copper. In contrast, Cu-Be alloys marginally reduce conductivity in exchange for greater hardness, which is necessary in highly stressed applications.

- Aerospace and Defense

Copper alloys form the backbone of applications in aerospace, where corrosion resistance and strength are required under conditions of stress realization. Resistance to seawater corrosion by aluminum bronze lands is deployed for aircraft landing gears and bushings. Nickel-copper alloys (such as Monel) are used in missile components and radar equipment, where durability is a must.

- Automotive Industry

Copper alloys are necessary in automotive heat exchangers, brakes, and fuel injection systems. Brass, for example, is used for radiators and oil coolers because of its good thermal conductivity and ability to resist scaling. Also, phosphor bronze is used on bearing surfaces subject to heavy friction.

- Marine Applications

- Construction Industry

Reference Sources

-

RSI Blog: What is the Melting Point of Metal?: This article explains the concept of melting points, highlighting copper’s melting point at 1084°C (1983°F). It discusses the importance of knowing melting points in welding, smelting, and casting processes. The melting point determines when metals become formable and suitable for specific applications.

-

Metal Supermarkets: The Melting Points of Metals: This resource provides a detailed overview of melting points for various metals, including copper at 1084°C. It emphasizes the significance of melting points in industrial applications, such as manufacturing and high-temperature environments. The article also explains how atomic structures and bond strengths affect melting points and why metals have high melting points.

-

American Elements: Melting Point of Common Metals: This page lists the melting points of metals, including copper at 1084°C. It explains the equilibrium state at the melting point and how pressure and impurities can influence it. The article also provides a comprehensive table of melting points for elements and alloys.

Frequently Asked Questions (FAQs)

Q: What is the melting point of copper?

A: The melting point of copper is approximately 1,984 degrees Fahrenheit (1,085 degrees Celsius). This property makes copper a suitable material for various applications, including electrical wiring and plumbing. The high melting point allows copper to maintain structural integrity under heat, making it ideal for use in high-temperature environments. Factors such as purity and the presence of alloying elements can slightly alter the melting point. Understanding the melting point is essential for processes like casting and welding copper components.

Q: How does the melting point of copper compare to other metals?

A: Compared to other common metals, the melting point of copper is relatively high. For instance, aluminum melts at 1,221 degrees Fahrenheit (660 degrees Celsius), while iron has a melting point of about 2,800 degrees Fahrenheit (1,538 degrees Celsius). This places copper in a unique position, offering both strength and ductility at elevated temperatures. Metals like lead have much lower melting points, making them easier to work with but less suitable for high-temperature applications. Understanding these differences is crucial for choosing the right metal for specific industrial processes.

Q: What factors can affect the melting point of copper?

A: Several factors can influence the melting point of copper, including its purity and the presence of alloys. Pure copper has a specific melting point, but when mixed with other elements, such as zinc to form brass or tin to create bronze, the melting point can change significantly. Impurities often lower the melting point, making the material easier to melt and work with. Additionally, the rate of heating can also impact how copper behaves as it approaches its melting point. Knowing these factors is important for metallurgists and engineers when designing metal components.

Q: Why is the melting point of copper important in industrial applications?

A: The melting point of copper is crucial in various industrial applications, particularly in metallurgy and manufacturing. It determines how copper can be processed, including casting, welding, and soldering. Understanding its melting point allows engineers to design processes that minimize material waste and ensure quality. In electrical applications, the melting point is important for ensuring safety and reliability, as overheating can lead to failure. Furthermore, applications in electronics require precise control over melting and solidification, highlighting the significance of knowing copper’s melting point.

Q: Can the melting point of copper be measured accurately?

A: Yes, the melting point of copper can be measured accurately using several methods, including differential thermal analysis and pyrometry. These techniques allow scientists and engineers to determine the precise temperature at which copper transitions from solid to liquid. Advanced equipment can provide highly accurate measurements, essential for research and industrial applications. Moreover, understanding the melting point in different environments, such as vacuum or inert atmospheres, can further refine accuracy. Accurate melting point measurements are vital for quality control in metal production and processing.