Metals are essential materials for manufacturing, construction, and a number of other sectors. It is worth mentioning that not all metals are alike. Also, the main difference among various types of metals concerns the presence of iron; generally, this factor has yielded performance and other utilization issues for the metal. However, for the case of stainless steel as thin films which are commonly known for their rust resistance and protection against other damages. Is it ferrous or non-ferrous? This paper will thus try to highlight the features that separate ferrous from non-ferrous metals and where stainless steel, in fact, belongs in the sphere of metals. Ultimately, you will have gained insight into some metallurgical principles that enable the clear demarcation of the mentioned categories and their practical application in various settings.

Introduction to Ferrous and Non-Ferrous Metals

Ferrous metals are materials whose principal compound is iron, sometimes alloyed with carbon and other constituents to improve firmness, hardness or pliability. Some of the common examples include steels, cast irons, etc These metals are magnetic in nature and tend to rust or corrode if exposed to moisture, with the exception of some materials, such as stainless steel, which does not corrode due to the presence of chromium.

Non-ferrous metals, on the other hand, do not have iron as an element. Examples of such metals are aluminum, copper, and zinc. These are generally lighter, more flexible and resistant to corrosion than their non-ferrous metal counterparts making such metals suitable for electrical wiring, aerospace devices, and buildings, among others. When it comes to these issues, it is of great importance that attention is paid to the choice of a material that is most suitable for a particular purpose.

Definition of Ferrous Metals

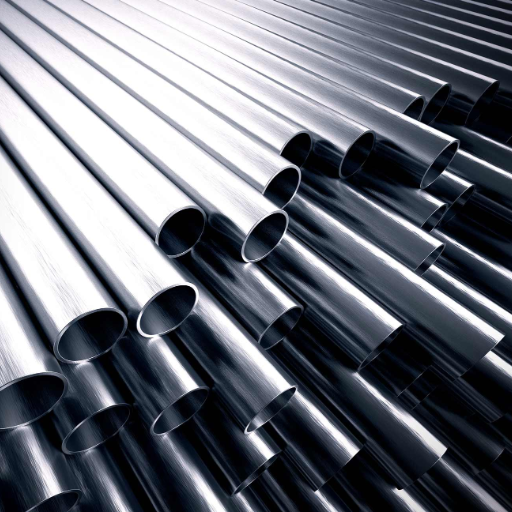

The category of the metals that consist in the forest is viewed as ferrous metals, which is a predominant composition of iron and its most common set of alloys, that is said to be steel and cast iron. What substantiates these metals is the reasons they came to be known as metals in the first place, that is, they have high levels of iron, and it is not surprising that they often have high levels of strength, durability, and magnetism. Due to this fact, they are often used in construction, automobile, and manufacturing and characterized by high tensile strength. However, ferrous metals like cast iron and steel have an innate ability to rust and corrode in the ambient atmosphere, unless they are processed or enough measures are put in place to counteract the forces, such as stainless steel, which has a thin base layer of the easily attacked element. The vast number of uses, such as construction and fabrication, to which they can be put indicates the structural relevance of the materials in the industry.

Definition of Non-Ferrous Metals

Non-ferrous metals are metals and their alloys, of course, but do not contain any noticeable amount of iron. Such metals as aluminum, copper, lead, zinc, and tin, among others, are identified because of their lack of most chemical tendencies, including corrosion, as well as some lightweight and conductive properties. Because of their lack of foreign magnetic properties and how pliable they are, the non-ferrous metals find significant use in various industrial applications like electric, aerospace, and electronics. Resistance comes in the form of other properties and characteristics. For instance, aluminium is valued for its strength-to-weight ratio, while copper is useful because of its high thermal and electrical conductivity for wiring and heat exchangers. The extraction and processing of non-ferrous metals is a more complex set of gauging measurements over ordinary refining processes and recycling techniques have made them even environmentally friendly. These materials possess certain properties that make them essential components in advanced technology and industry.

Key Differences Between Ferrous and Non-Ferrous Metals

|

Parameter |

Ferrous Metals |

Non-Ferrous Metals |

|---|---|---|

|

Iron Content |

Contains iron |

Does not contain iron |

|

Corrosion Resistance |

Prone to rust and corrosion |

Highly corrosion-resistant |

|

Strength |

Generally stronger |

Typically less strong |

|

Weight |

Denser and heavier |

Lightweight |

|

Magnetic Properties |

Magnetic |

Non-magnetic |

|

Electrical Conductivity |

Lower conductivity |

High conductivity |

|

Thermal Conductivity |

Less efficient |

Highly efficient |

|

Cost |

Relatively cheaper |

Generally more expensive |

|

Recycling |

Easily recyclable |

Recyclable with advanced methods |

|

Common Examples |

Steel, cast iron |

Copper, aluminum, lead |

|

Industrial Use |

Construction, tools, transportation |

Wiring, electronics, aircraft |

Properties of Stainless Steel

Stainless steel, in the first place, is a material that stands out for its peculiar characteristics and is in great demand in numerous industries. The main from these attributes are the following:

- Corrosion Protection: Among stainless steel’s complex of properties is its capacity to resist rust and staining due to its high content of chromium, which makes it suitable for use in other submerged or salt, acid wet settings.

- Mechanical strength Ability to Resist Shock: It has commendable mechanical strength characteristics, hence it can take a high degree of punishment and withstand a wide variety of load fluctuations without breaking it as proven after doing some tests on the already corroded metal.

- Thermal Insulating Value: Streamlined and thin, adopted stainless steel found in its more advanced capacities, where even, on direct exposure to fire, it has been found to have little effect on its structure.

- Sanitary Design Considerations: One particular feature about the surfaced stainless steel is its easily washable, water-resistant stainless steel, which is why up to today it remains applicable in various industries such as food services and hospital sectors.

- Aesthetics: In architecture and consumer products, stainless steel is used due to its glossy and long-lasting look, making it remain in style.

Corrosion Resistance of Stainless Steel

One of the most important resistance characteristic of stainless steel is the corrosion resistance which can be majorly be related to the chromium content in the alloy which forms an oxide layer on the surface referred to as a passive. This film, which is both adherent and very thin, provides a barrier to the more active ions. Chromium in the stainless steel can range from a minimum of 10.5% to some 30% depending on the stainless steel and application. Some, for instance, the duplex or super austenitic types of stainless steel, contain molybdenum for more corrosion protection and nitrogen for better repulsion of pitting, crevice corrosion, and types of chloride-induced corrosion, most of all common in seawater and chemical atmosphere.

Environmental conditions, humidity, temperature, and the presence of impurities are all commonly accommodated in the activities in which stainless steel is involved, which are the reasons why such materials are used. For example, stainless steel in grades SS316 and SS316L performs extremely well in corrosive chlorides and is often used in industries where high corrosion, like chemical processing and desalination, occurs. Besides, the lack of proper procedures in cleaning operations or exposures to harsh chemicals for prolonged periods can cause the passivated layer to fail and initiate corrosion. In the absence of necessary strategies, regular intervals of maintaining the equipment would reduce the usable life in the case of stainless steel.

Impact of Iron and Chromium in Stainless Steel

Stainless steel is made of iron and chromium mainly, and these are its main constituents, especially as far as corrosion resistance and strength are concerned. Efficient and sturdy iron allows for various applications, while at the same time, the presence of chromium on the surface is essential for active corrosion control. This layer sustains broken and prevents renewed corrosion in the metal. The resisting ability lies in its content of at least 10.5% of chromium by weight, which is the part of the steel that remains after smelting and is responsible for the harsh environments and surgical devices.

Is Stainless Steel Ferrous or Non-Ferrous?

Moreover, since stainless steel contains the basic element iron, it is considered a ferrous metal. Sometimes, due to the presence of certain amounts of aluminum and other elements, corrosion resistance and durability over standard ferrous metals are increased. Despite such unusual attributes, its value as a ferrous material is as a result of the existence of iron in the steel.

Classification of Stainless Steel as Ferrous

However, this perspective on stainless steel as a ferrous metal is not baseless but is well founded in its primary composition which contains a substantial proportion of iron—in most cases more than 50% by weight. This iron component makes it a ferrous metal, which is part of the larger group referred to as ferrous metals since the term ‘ferrous’ itself means ‘iron’. Outside this element, chromium is one of the main additives in such steels, usually in the range of between 10.5% and 30%, which helps in creating a protective film of chromium oxide in inorganic form, which provides resistance to oxidation and corrosive particles in the presence of moisture in the air.

Besides, other beneficial elements such as nickel, molybdenum and manganese may be added to stainless steel so that tensile strength, weldability, and resistance to heat and chemicals can be improved – once such aspects have been enhanced, the alloy retains its characteristic identity as stainless steel. Being a metal alloy with a certain amount of iron in the structure, most of the mechanical and magnetic properties of stainless steel are due to the iron matri,x which makes the base and the nucleation elements added to it.

Why Stainless Steel is Considered a Ferrous Metal

Stainless steel, innately, thanks to the presence of iron, primarily, chromium or other materials, which serve as an enhancer, is referred to a ferrous metal. The word ‘ferrous’ has its origin in the Latin word ferro, meaning iron, as one of the most essential constituents of such products. While being included, the corrosion resisting elements of chromium, nickel, molybdenum, and other elements also significantly increase the mechanical properties and durability of stainless steel, these properties are only experienced as a function of ferrous content. In addition, many stainless steels exhibit magnetic behaviour as well, which is typical for ferrous materials, yet there is some variation in that even such grades as austenitic may show much reduced magnetism if the crystal lattice is manipulated to do so, also magnetism is greatly reduced following the processing of the material. It is thanks to the high iron content that it falls into this category, and also explains why it is a critical resource for manufacturing and construction that is eco-friendly.

Common Types of Stainless Steel

- Austenitic Stainless Steel

These compositions make up the largest group containing stainless steel which is recognizable by the average person due to its corrosion resistance and anti-magnetism. It contains a significant amount of both chromium and nickel, it is easy to work with and yet is very durable.

- Ferritic Stainless Steel

Ferritic stainless steel is another category of stainless steel, which is magnetic with a lower nickel level and higher chromium content. Also, it is tougher than pliable, offers good corrosion resistance, and is frequently used in automobile and industrial applications.

- Martensitic Stainless Steel

As a form of stainless steel that is widely recognized for its superior strength and toughness, martensitic stainless steel is magnetic. It falls under the ‘adequate’ chromium category and has low nickel content, making it ideal for use in tools and knives because it resists abrasion.

- Duplex Stainless Steel

Austenitic Stainless Steel

Austenitic stainless steels can be referred to as the most common group of stainless steels. The contituent of chromium and nickel are very much in this type of steel and a lot resistance of its elevated areas together with malleability. This kind of steel usually consists of 16-26% chromium, 6-22% nickel, and minor quantities of nitrogen to reinforce its resistance and resistance to pitting, in addition to nitrogen. So-called soft iron because of its stable structure upon cooling in any part, it keeps its qualities at the level of cryogenic distances and very high temperatures. For example, 304 and 316 are found in almost everything from food production to the manufacture of chemical technologies and buildings to medical equipment. Their physical features of anti-corrosive ability and standing up to the worst climatic conditions prove how important these steel materials are in the markets.

Common Types: 304 and 316 Stainless Steel

Among relatively cheap and entry-level classes of steel, 304 stainless steel has gained unprecedented popularity due to its hygienic and easy-to-clean surfaces. It contains higher levels of chromium and nickel, namely up to 8-10.5%. This imparts sufficient corrosion resistance properties to this alloy. This material is very resistant to the effects of very high temperatures, which makes it quite suitable for use in surfaces related to food industries, equipment used in most kitchens, and various fittings. This prevents general rusting of the veneer; however, the prominent drawback of 304 stainless steel is the fact that it performs somewhat poorly in moderate engineering applications involving chloride complex and crevice-free locations.

316 stainless steel, a material mainly used for its improved anti-corrosion properties, contains 16 to 18 % chromium, 10 to 14 % nickel, and 2 to 3 % molybdenum. The resistance to pitting and corrosion benefits from adding in molybdenum most particularly in areas where salt or chloride is high like marine and chemical processing and even healthcare. And this is why people desiring excellence over cheap materials choose it the most, where challenging environmental conditions exist. In fields such as pharmaceuticals and healthcare, it is appreciated for its strong structure because of its high temperature capability and potential to withstand processes of sterilization.

Comparison of Different Stainless Steel Grades

|

Stainless Steel Grade |

Key Features |

Common Applications |

Corrosion Resistance |

Strength and Durability |

Cost |

|---|---|---|---|---|---|

|

304 |

Standard, widely used |

Kitchenware, automotive, building |

Good; general environments |

High tensile strength |

Moderate |

|

316 |

Molybdenum-enhanced for harsh conditions |

Marine, chemical, medical fields |

Excellent; chlorides/salt-rich |

Strong, sterilization capable |

Higher than 304 |

|

303 |

High machinability, not weldable |

Fasteners, fittings, gears |

Moderate; mild environments |

Adequate, less than 304/316 |

Moderate |

|

430 |

Basic, lower cost |

Appliances, decorative trim |

Limited; interior use |

Moderate; less ductile |

Low |

|

2205 |

Duplex, high strength and corrosion |

Oil, gas, marine applications |

Very high; aggressive settings |

Superior to austenitic grades |

High |

|

410 |

Heat-treatable, strong |

Cutlery, turbine blades |

Limited; non-chemical area |

High after heat treatment |

Low to moderate |

|

201 |

Cost-effective alternative to 304 |

Cooking utensils, sinks, trims |

Moderate; low alloy content |

Good; less than 304 |

Low |

|

317 |

Superior corrosion to 316 |

Pulp/paper, chemical processing |

Very high; intense chloride |

High durability, robust |

Higher than 316 |

|

2207 |

Super duplex, extreme conditions |

Offshore, petrochemical, desalination |

Excellent; extreme environments |

Exceptional strength |

Very high |

Applications of Stainless Steel in Various Industries

Many varying stainless steels are extremely useful in many fields of industry because of their resistance to corrosion, longevity, and strength. Some fields where they are used are given below:

- Construction Industry

Stainless steel is often used in building structures, walls, as well as roofing and cladding due to the durability of the material and its ability to withstand external conditions.

- Food and Beverage Industry

It may be in use in catering equipments and food processing industries due to the mentioned features to consider hygienic elements when dealing with food.

- Medical Field

The durability and resistance to heat properties make stainless steel an ideal choice for the construction of port instruments and lab devices.

- Automotive and Transportation

Motors, blowers, ejectors, and many other components within respective silencer systems contain stainless steel materials as well in order to minimize maintenance costs and prolong their useful life.

- Energy Sector

Functional parts and containment walls within VVER-type reactors are fabricated from stainless steels on account of the materials’ resistance to high temperatures and corrosion.

Use of Stainless Steel in Everyday Products

Specifically in connection with its exceptional sturdiness, ability to resist rust, and its attractiveness, Stainless Steel is seminally important in the fabrication and operation of a significant number of items of daily use. Materials such as stainless steel are popular in the interiors of some heavy home equipment devices, such as fridges, ovens, and dishwashers, because they are easy to clean and are also resistant to heat and other factors like moisture. Cookware usually comes in the form of pans and other cookware and is also typically manufactured from stainless steel as it is tough and withstands cooking, ensuring good distribution of heat.

Outside the stricture of use in kitchen and home designs and appliances, stainless steel plays a significant role in most hygiene arrangements, both personal and public. Bath accessories such as taps, sinks, and showers are manufactured in such a way that they will not corrode, with the steel staying free from rust around the taps, sinks, and showers, maintaining the looks. Equally, more and more food and drink containers, as well as bottles, have a stainless steel body as the consumer prefers these due to their health and environmental safety aspects of not using plastics.

The way the product is employed goes further into household and trendily smart phones, digital cameras, and other devices, where the stainless steel is used in the shells of the products as protection from wear and tear, which also makes metal an attractive material of use. The utility of stainless steel in everyday gadgets and products is greatly contributed to by the fact that this kind of material is strong, versatile, and earth-friendly.

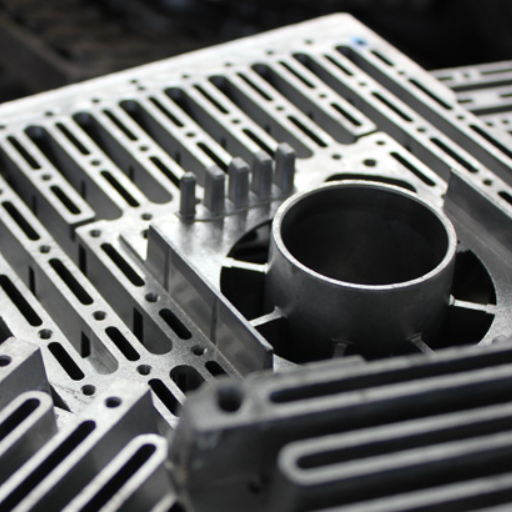

Industrial Applications of Stainless Steel

This graceful and very essential material, stainless steel, serves the needs of many industrial sectors due to its enhanced chemical resistance, malleability, and longevity. In addition, the use of stainless steel within the civil engineering sector is not limited to this material, as it is utilized in brickwork, cladding, and roofing to provide confidence that structural items will last long in the intended environment without deterioration. The same applies to the petrochemical and chemical engineering industries, where the use of stainless steel for pipelines, vessels, and heat exchangers is popular due to its resistance to most chemical attacks and its suitability for use at high temperatures.

The same characteristics of being hygienic and easy to clean with stainless steel have made it an excellent material to adopt in the food and beverage industry, where it is often used for equipment, storage tanks, and many other surfaces that come into contact with food. Additionally, in most cases, stainless steel is quite dominant in the manufacture of silencers, body shell parts, and railway carriages, as it is essential for resisting corrosion and high-temperature exhaust gases.

Besides, modernizing manufacturing advancements in eco-friendly technologies is further incorporating the use of stainless steel in applications such as wind turbines, solar panels, and geothermal systems, where its mechanical characteristics of stability and natural resistance are efficient and can clearly help decrease the installation requirements to enhance performance. In summary, its versatility in the industry, coupled with advancements in fabrication processes, has made stainless steel vital to both traditional and innovative production techniques.

Reference Sources

1. Stainless Steel and Corrosion:

- Key Findings: This study focuses on the corrosion resistance of stainless steel, emphasizing its passivity due to chromium content. The passive layer, a chromium-rich oxide film, is critical for corrosion resistance. The study highlights various forms of corrosion (e.g., pitting, crevice, and stress corrosion cracking) and the importance of maintaining the passive layer through proper cleaning and passivation.

2. Effect of Cryogenic Treatment on the Wear Behavior of Additive Manufactured 316L Stainless Steel:

- Key Findings: Cryogenic treatment significantly improves the wear resistance and hardness of additive-manufactured 316L stainless steel. The treatment reduces porosity, increases compressive residual stress, and induces strain-induced martensite formation, enhancing the material’s mechanical properties.

3. The Effect of Solution Annealing on the Property of Passivated Surface in CF8 Stainless Steel:

- Key Findings: Solution annealing and optimized chemical passivation significantly enhance the corrosion resistance of CF8 stainless steel. The study found that the surface roughness and reflectivity of the passive film are critical factors in improving corrosion resistance.

Frequently Asked Questions (FAQs)

Q: Is stainless steel a ferrous metal?

A: Stainless steel is generally classified as a ferrous metal because it contains iron as one of its primary components. However, it is important to note that stainless steel also includes significant amounts of alloying elements like nickel and chromium, which enhance its corrosion resistance. While standard carbon steel is a ferrous material composed primarily of iron and carbon, stainless steel’s unique composition gives it different properties, such as being less vulnerable to rust. The presence of these alloying elements helps to create a protective layer on the surface, making stainless steel more suitable for various applications in the steel industry.

Q: What are the common types of stainless steel?

A: The common types of stainless steel include 304 and 316 grades, both of which have distinct properties and uses. 304 stainless steel is the most widely used grade, known for its good corrosion resistance and formability, while 316 stainless steel offers enhanced corrosion resistance due to the presence of molybdenum. These grades are categorized under austenitic stainless steels, which are typically non-magnetic and have a high nickel content. Understanding the differences between these types of stainless steel is crucial for alloy selection in different applications, such as architectural structures or food processing equipment.

Q: Are stainless steels non-ferrous metals?

A: While stainless steels are primarily classified as ferrous due to their iron content, they can exhibit characteristics of non-ferrous metals depending on their specific alloying elements. For instance, the presence of nickel and chromium helps prevent rust, which is a characteristic of non-ferrous metals. Additionally, some grades of stainless steel may be considered non-ferrous in certain contexts, particularly when discussing their corrosion resistance and magnetic properties. Overall, stainless steel has both ferrous and non-ferrous attributes, making it a versatile material in metallurgy.

Q: What are the types of ferrous metals?

A: Types of ferrous metals include carbon steel, alloy steel, and cast iron, among others. These metals contain iron and are known for their strength and durability. Carbon steel, which is a common type of ferrous metal, primarily consists of iron combined with a small percentage of carbon, while alloy steel is enhanced with additional elements like vanadium or nickel. Understanding the various types of ferrous metals is essential for specific applications, as their mechanical properties can vary significantly based on their composition and processing methods.

Q: Can stainless steel be processed to produce specific properties?

A: Yes, stainless steel can be processed to produce specific properties through various methods, including heat treatment and alloy selection. Different types of heat treatment can enhance the mechanical strength or corrosion resistance of stainless steel, allowing it to be tailored for specific applications. For example, super duplex stainless steel is a highly alloyed grade that exhibits excellent strength and resistance to pitting corrosion, making it suitable for harsh environments. Metallurgists often assess the carbon content and other alloying elements to ensure that the stainless steel meets the required specifications for its intended use.