Galvanized steel coils are prized in multiple industries because of their versatility, corrosion resistance, and durability. These materials are best purchased from suppliers who trace their quality through industry standards to guarantee consistent quality throughout. This document aims to identify leaders in the market for galvanized steel coils, particularly those who focus on construction, automotive, and manufacturing industries to diversify sector demand, markable production quality, and robust fulfillment capability. Reputable suppliers like these rely on precise business decisions which, this document, based on extensive exploration of market leaders, will guide towards meaningful supplier choice reliability and endurance.

What Are Galvanized Steel Coils?

Galvanized steel coils undergo the process of coating sheets of steel with zinc to avoid the steel from undergoing rust and corrosion. The primary method of applying zinc is by galvanization, mainly through the hot dip process where molten zinc submerges the steel. The outcome is a moisture-resistant material which is tough and has a great lifespan. Because of costing less, having high strength, and excellent resistance to corrosion, galvanized steel coils are highly sought after in construction, automotive, and manufacturing industries.

Understanding the Galvanization Process

Galvanization is a multipstep process encompassing important phases which ensure proper coating to seal steel from corrosion damage. Surface preparation comes first, and it is carried out by cleansing the steel’s surface from impurities like: dirty oil, or mill scale. A typical approach involves a series of degreasing, pickling where acidic solutions are used to yank combustion and rust and scale as well as rinsing. Then, the steel is placed into a flux solution bath made of zinc ammonium chloride to stop oxidation from occurring pre-galvanization.

In preparation, steel is placed in a dip of molten zinc at about 840°F (449°C) during the hot dip phase. In this process, zinc reacts chemically with the base steel forming several intermetallic layers. A metallurgical bond is created between the zinc and steel in the form of a bond. This essential bond guarantees the enduring and lasting protection of the galvanized coating.

The step after the steel is removed from the bath is letting the steel cool down. The rest of the zinc is either drained or skimmed off so that the surface of the steel is smooth and uniform. The smooth and uniform finish might require further treatment such as quenching in water or air cooling the steel depending on the desired final characteristics. All these meticulous procedures increase the resistance of galvanized steel to factors such as abrasion and moisture plus chemical attacks, making them useful in many industries.

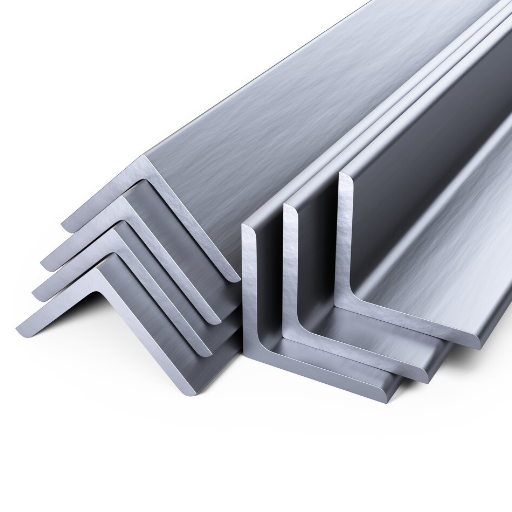

Types of Galvanized Steel Coils

Galvanized steel coils are classified into two major groups based on the galvanization modality and what it will be used for:

- Hot-Dip Galvanized Steel Coils

Steel strands are entrapped hot dip in molten zinc which causes a chemical reaction, which results in a durable and anti-corrosive coat. These coils are broadly applied in construction, automobile industry and agricultural tools and machinery due to their weather resistance. The molten zinc also serves as a protective layer to metal and usually contains between 80 and 275 grams per square meter depending on the necessities of the environment.

- Electro-Galvanized Steel Coils

Zinc is deposited into the surface of the steel using an electric current during Electro-galvanized steel coil production. Compared to zinc hot dip binded into steel, this method provides a more precise coating with lower thickness, typical Zn layer thickness being 20 to 40 grams per square meter. Their smooth surface finish together with the fact that they have a higher aesthetic appeal makes these coils popular in high-end clothes such as household appliances, precision instruments, and electronic products.

Each type of galvanized steel coils is equally important for many industries and are chosen according to the mechanical properties and surface treatments. Factors distinguishing the hot dip and electro galvanized coiled steel is the use of the coil and the exposure to the environment.

Applications of Galvanized Steel Coils

Steel coils are used in various industries because of their durability, ability to withstand corrosion and mechanical adaptability. In the construction industry, these coils are extensively used for roofing, walls, beams, and safety fences because of their ability to endure a great deal of corrosion. Their use in automobiles includes production of body components like floor pans, frame side rails, and undercarriage pieces, providing the vehicle with greater chest longevity and complicating the rusting process. Also, in the domain of electricity these coils are used in manufacturing robust enclosures, cable management trays, or commercial appliances that require lightweight yet strong materials.

Other than that, galvanized steel coils are crucial to fencing, silos, and even farming irrigation systems which are exposed to moisture and chemical agents. This type of steel is used in constructing furniture, lighting, and home appliances because of its above average ability to hold paint, beauty, and consumer goods. Such wide uses demonstrate important flexibility of galvanized steel in industrial and everyday life.

How to Choose the Right Galvanized Steel Coil Supplier?

- Quality Assurance: Verify the supplier has appropriate quality markings like ASTM certification or ISO certification which guarantees the optimal use and life span of the galvanized steel coils.

- Industry Experience: Select a supplier who has an interesting history and experience in serving your business or application with galvanized steel.

- Product Range: Check that the supplier provides the coil with all of the required specifications, for instance: thickness, width, coating type and their quantity.

- Consistent Supply: Check the supplier’s production capacity and their logistics to see if reliable timelines and consistent inventory is available.

- Customer Support: Manufacturer’s technical support for the right product makes prioritized most. Also, responsive and knowledgeable customer care makes prioritizes, too.

- Pricing and Value: Price comparison should be done, but not at the expense of quality, add custom options, and after sales support to overall value. Settling suppliers with low pricing implies poor product value; they should be avoided.

- Reputation and Reviews: Review the customer’s testimonials and provided case studies to determine the trustworthiness, professionalism, and user satisfaction from the vendor.

Covering all these aspects enables you to pick a supplier that meets your operational demands while delivering exceptional galvanized steel coil products.

Trusted Galvanized Steel Suppliers in the Market

While researching reliable suppliers for galvanized steel coils, many trustworthy competing manufacturers universally grab attention because of their quality standards, innovations, and customer dealings. Well known developed steel products such as ArcelorMittal, Nippon Steel Corporation and POSCO have maintained a good market presence around the world as they have high quality galvanized steel products which meets almost all industrial uses and standards. They use modern tests of galvanization and implemented strict quality checks to maintain consistent product strength and longevity.

Moreover, regional market participants are able to meet specific requirements due to their tailored offerings. JFE Steel, Voestalpine, and U.S. Steel are known for their reputable specialized services, compliance with industry standards, and flexible custom tailoring. All these suppliers now practice responsible business policies and adapt their manufacturing processes as well as raw materials to eco-friendly standards.

From this competition, choosing a single dependable supplier requires in-depth scrutiny of their product catalog, technology, and after-sales support to confirm that they will meet the project scope and industry requirements. Following this strategy improves productivity and procures ample reliable supply of quality galvanized steel.

What Are the Benefits of Using Hot-Dipped Galvanized Steel Coils?

The advantages presented by hot-dipped galvanized steel coils make them a preferred selection for different purposes. These include the following:

- Superior Corrosion Resistance: The galvanization process of hot-dipping steel coils in zinc coating protects the steel from rust, and even in the worst conditions, protects against aging.

- Low Maintenance Requirements: The prevention from zinc layer and the upkeep required for galvanized steel coils reduces maintenance costs.

- Cost-Effectiveness: The coils are very cost efficent in the long term. The coils are extremely durable and will weather expensive maintenance repair spending in the long term.

- Versatility: Due to their strength, the galvanized steel coils can support construction, automotive, and agricultural industries.

- Environmental Sustainability: The coils doi galvanization makes them an eco preferred option as opposed to other materials, Providing support in today’s eco centered world.

These factors augment the performance and the carbon footprint cost of a project that involves these coils.

Corrosion Resistance of Hot-Dipped Galvanized Coils

The deduction of the hot-dipped galvanized coils is attributed to the protective zinc coating applied galvanization, tendering to this a shield for the steel against corrosion factors like moisture, oxygen, and other external factors. In addition, the coating zinc works more efficiently, making the rust protection work by sacrificing itself from being corroded, leaving the coil safe and preserving hot-dipped galvanized coils, ensuring extended durability.

More recent innovations in coating thickness control and alloy compositions show promise to improve durability of hot-dip galvanized coatings for more aggressive marine and industrial uses. Various laboratory and field tests show the performance improvement from thicker zinc layers along with small quantities of other elements like aluminium, or magnesium. Coating with magnesium-aluminium-zinc alloy is one of the examples with added resistance to white rust and accelerated salt-spray testing deterioration.

Moreover, the hot dipped galvanized coils can repair scratches or other damages on the surface by migrating zinc ions from the surrounding area. The hot dipped galvanized coils can protect themselves from surface vulnerabilities by sealing the area which makes it possible to avoid uncontrollable damage caused by weather conditions. The ability to self-repair makes hot dipped galvanized coils suitable for harsh engineering structures or equipment.

Cost-Effectiveness of Hot-Dipped Galvanization

Hot-dipped galvanization is universally accepted as one of the most economical methods of ensuring long-term protection of steel and iron from corrosion damage. It is cost-effective owing to a number of reasons; first is the duration of protection it provides which decreases the need for frequent maintenance. Properly galvanized steel can last maintenance and material costs. In some environments, steel can often exceed 50 years.

In addition, hot-dip galvanization’s upfront costs are lower than those of other advanced corrosion-resistant treatments over the entire life cycle. This process guarantees the application of uniform coating, contributing to material strength and eliminating localized corrosion structural failure surprises. Born from the need for efficient material processing, galvanization becomes effortlessly integrated into mass production processes and thus, scalable and efficient for industrial use. Collectively, these factors improve economic feasibility while exacerbating the imbalance in spending versus investment in construction, manufacturing, and infrastructure.

Research has added to the cost benefits of galvanized steel by further elucidating its recyclability. This practice reduces the cost of raw materials of production and increases efficiency by recovering and reusing the zinc coating, which is in line with contemporary sustainability practices, as well as meeting standards for corporate environmental responsibility. These features explain the continued popularity of hot-dipped galvanization in projects that require enduring dependability and economic cost savings.

How Do Galvanized Steel Coils Compare to Other Steel Products?

Galvanized steel coils are more advantageous than other steel goods, especially where area of application corrosion resistance is extremely important. Galvanized steel coils are treated Untreated steel does not compare with galvanized steel coils which are treated with zinc which serves as a protective layer against rust and oxidation. Thus these are perfect for external usage or regions with high moisture levels. Moreover, outsourced steel coils also saves maintenance expense after a period of time. Although stainless steel have comparable protective capabilities against corrosion, galvanized steel coils proves more economical and less expensive for broad industrial and construction applications. In addition, the numerous sectors these coils are used in is also contributed by the ease of fabrication and flexible application of the coils.

Comparison Between Cold-Rolled and Hot-Rolled Steel Coils

The cold-rolled and hot-rolled steel coils difference primarily exists in the processes of manufacture which determines the traits and uses of the steel. Heat is applied to hot-rolled steel above the region of steel recrystallization to allow easy shaping and forming of the metal into different steel products. This method save costs and is suitable for mass production of steel items such as beams, plates, and sheets. However, the process of surface finishing and almost all high-temperature processes tends to be lacking when it comes to the smooth and precise finish needed and accurate tolerance.

In contrast, the processes performed on cold-rolled steel follow hot-rolling and include further machining at room temperature. This yields a product with better accuracy and surface finish, hot strength, and improved tensile strength. In addition, cold rolling increases the material’s hardness along with its resistance to deformation due to strain hardening. The combination of these properties contributes to the effectiveness of cold-rolled steel in Precision Engineering, including automotive components, appliances, and furniture.

Differences in functionality also translate to other aspects like price. Because of the more complex manufacturing procedure, hot-rolled steel is usually cheaper. This makes it ideal for structural parts where appearance and exact measurements aren’t as important. On the other hand, cold-rolled steel is more costly but is better in parts where ideal the surface finish or exact dimensions are critical. Both types of steel coils are indispensable across industries and their manufacturing and the choice depends on the needs of the working for the particular project.

Galvanized Steel vs. Non-Galvanized Steel

Galvanized steel has a layer of zinc in order to protect it from corrosions, which is applied through hot dip galvanization and electro-galvanization. The zinc coating serves as further protection, increasing the steel’s strength making it appropriate for the outdoors, as well as for places with high humidity and chemical exposure. The protection surpasses all expectations even for places where the coating has been scratched due to the zinc’s constant protection through cathodic protection.

Conversely, non-galvanized steel does not utilize protective coatings and is more prone externally induced corrosion. While less expensive than galvanized steel, non-galvanized steel’s performance is significantly reduced if placed in high humidity environments. Non-galvanized steel is optimal for indoor use or places devoid of harsh conditions, lets budgets slide without compromising too much functionality in a controlled scenario.

In both processes, the coating thickness is diffusion and electrolytic galvanizing; each has its own merits. Choosing one or the other depends heavily on application. At a higher cost, galvanized steel provides better lifespan and strength under workload. Non-galvanized steel is a cost-effective solution for projects where resistance against corrosion is unimportant, which shows how important material selection in regard to the weather and purpose is.

Reference Sources

- Curtis Steel: A leading supplier of galvanized steel sheets and coils, offering ASTM-A653 compliant products.

- ThomasNet: A distributor of corrosion-resistant hot-dipped galvanized steel coils for various applications.

- American Metals Supply Co.: Offers galvanized coils and slit coils for different uses.

- Chesterfield Steel: Supplies galvanized coils commonly used in construction, automotive, and solar industries.

Frequently Asked Questions (FAQs)

Q: What are the main benefits of using galvanized steel sheets?

A: Galvanized steel sheets offer excellent corrosion resistance due to their zinc coating, making them ideal for various applications in the steel industry. They also provide durability, strength, and a longer lifespan compared to untreated steel, which helps reduce maintenance costs.

Q: What is the difference between hot dipped galvanized and cold rolled steel?

A: Hot dipped galvanized steel is coated with zinc through a process of immersing the steel in molten zinc, providing a thicker coating for enhanced corrosion resistance. In contrast, cold rolled steel is processed at room temperature, resulting in a smoother finish but without the added corrosion protection of zinc.

Q: Can I get pre-painted galvanized steel coils from Curtis Steel?

A: Yes, Curtis Steel offers high-quality prepainted galvanized steel coils that are suitable for various applications, including roofing and siding. The prepainting process adds an additional layer of protection and aesthetic appeal to the galvanized steel sheets.

Q: What types of processing services do Chesterfield Steel provide for galvanized steel coils?

A: Chesterfield Steel provides a range of processing services for galvanized steel coils, including slitting, shearing, and custom cutting. These services allow for the creation of tailored steel sheets and coils to meet specific project requirements.

Q: What is MST Steel Corp known for in the galvanized steel market?

A: MST Steel Corp is recognized for its high-quality galvanized steel products, including hot dipped galvanized steel coils and sheets. They are known for their reliable supply and commitment to customer satisfaction in the steel industry.

Q: What is the significance of the base metal in galvanized steel sheets?

A: The base metal in galvanized steel sheets refers to the underlying steel that is coated with zinc. The quality of the base metal, often low carbon steel, is crucial as it affects the overall strength, ductility, and performance of the finished galvanized product.

Q: Are galvanized steel coils used in construction projects?

A: Yes, galvanized steel coils are widely used in construction due to their durability and resistance to corrosion. They are often utilized in roofing, siding, and structural applications, making them a preferred choice for builders and contractors.

Q: What is the difference between galvanized and galvalume steel?

A: Galvanized steel is coated with zinc, while galvalume steel is coated with a mixture of aluminum and zinc. Galvalume offers better corrosion resistance in certain environments and is often used for roofing and siding applications where exposure to the elements is a concern.