Renowned for the attributes of durability, conductivity, and refinement, copper plate has found its place in almost every field of manufacture and creative activity. From complicated architectural works to heavy industrial applications and DIY projects for arts and crafts, copper sheets have the versatility that continues to fascinate engineers, architects, and hobbyists. This write-up aims to explore the applications of copper plates, highlighting their unique properties and advantages in various settings. This copper guide, whether you are drawn to its beauty or its practical uses, will explain how to utilize this wonderful material to enhance your next creation. Stay tuned as we explore the various potential applications of copper sheets and share some practical considerations for combining these possibilities effectively.

Understanding Copper Plates

Thin, flat copper sheets mainly find applications in manufacturing due to such properties as strength, conductivity, and processing versatility. With excellent thermal and electrical properties, copper plates have numerous applications, including electrical components, construction, and art. These properties also provide a measure of resistance against corrosion, making the copper plate last longer. Additionally, its capacity to be bent or twisted makes it convenient for shaping or personalization. In projects that demand strength together with flexibility and appearance, these very features of copper plates make them the material of choice.

What is a Copper Plate?

Copper plates are flat sheets of copper metal prepared in usual commercial thicknesses and dimensions. Having very good thermal and electrical conductivities, copper plates find extensive uses in many technical and industrial applications such as the building of electrical systems, heat exchangers, and the fabrication of precision components. Natural resistance from corrosion enables the material to be used in applications where it may be exposed to moisture or weathering and remains durable after some time. Copper plates have also become very interesting to renewable energy industries, where they are often utilized in photovoltaic systems due to their good energy-conducting efficiency. Its ductility and malleability are the properties that have made copper adaptable for easy fabrication processes, including cutting, bending, and welding. This greatly increases the range of its applications.

Characteristics of Copper Sheet Metal

- Corrosion Resistance

Copper offers a remarkable type of corrosion resistance, especially for humid or marine environments. Typically, a patina-rusting layer of copper carbonate forms over the surface layer over time, acting as an additional layer of protection against environmental factors and thereby reducing material degradation.

- Thermal and Electrical Conductivity

It is widely considered that copper is the best metal for thermal and electrical conductivity, with thermal conductivity estimated to be in the region of 400 W/m·K and electrical conductivity rated at nearly 5.96 x 10⁷ S/m (at 20°C). This certainly puts copper sheet metal in an interesting position for usage in heat exchangers, wiring, and electrical circuits.

- High Ductility and Malleability

Its great ductility and malleability make it feasible to bend, stretch, or shape copper sheets without breaking. This characteristic supports complicated manufacturing processes and applications that require precision forming.

- Antimicrobial Properties

Inherent antimicrobial properties make copper immediately interesting in the fields of medicine and food processing or public infrastructure: they are able to kill bacteria, viruses, and fungi present on their surface. Moreover, the tests showed that it is likely that the pathogens would be destroyed within a few hours after they made contact with it.

- Aesthetic Appeal

Types of Copper: 110 Copper Sheet vs. Other Alloys

|

Parameter |

110 Copper Sheet |

Other Copper Alloys |

|---|---|---|

|

Composition |

99.9% pure copper |

Varies with alloying elements (e.g., zinc, tin) |

|

Thermal Conductivity |

High (approx. 401 W/m•K) |

Depends on alloy type, generally lower |

|

Electrical Conductivity |

Exceptional (IACS 100%) |

Lower than 110 copper alloy |

|

Corrosion Resistance |

Excellent |

Good to excellent |

|

Workability |

Highly malleable and ductile |

Varies, some alloys harder to work with |

|

Tensile Strength |

~31,000 psi (annealed state) |

Higher in alloys like bronze or brass |

|

Applications |

Electrical, roofing, industrial applications |

Plumbing, automotive, marine applications |

|

Cost |

Relatively high due to purity |

More economical options available |

|

Appearance |

Reddish-brown color, patinates over time |

Varies depending on alloy composition |

|

Health Benefits |

Antimicrobial properties |

Limited antimicrobial effects |

Applications of Copper Plates

Copper plates are utilized across different industries for their high electrical conductivity, thermal conductivity, and corrosion resistance. Some major applications include:

- Electrical Engineering: Busbars, terminals, connectors, and many other things that can be required to conduct current in very high quantities make use of copper plates because of their best conducting properties.

- Architecture: They are used for roofing and cladding on account of being weather-resistant and aesthetically pleasing.

- Industrial Machinery: Heat exchangers, the process of electroplating, and moulds; these are areas that call for copper plates for their heat transfer properties.

- Marine Industry: Copper plates are utilized in shipbuilding for hull sheathing while concurrently providing resistance from bio-fouling in seawater.

These applications underscore copper’s versatility and its critical role in modern technology and construction.

Industrial Uses of Copper Plates

- Electrical Engineering: Copper plates, due to their high rate of conductivity, with a particular rating of about 59.6 x 10⁶ S/m at 20°C, find their place as an integral part of electrical systems. They find use in being parts of switchgear and transformers, and in conductive busbars, thus guaranteeing fair performance and power transmission efficiency.

- HVAC Systems: Copper plates contribute to the manufacture of high-efficiency heat exchangers in HVAC systems. Their excellent thermal conductivity property (approximately 401 W/mK) aids actual heat transfer, thereby reducing the consumption of energy in a modern-day climate control system.

- Automotive Industry: Copper plates are being used in sources for engines, radiators, and electric battery vehicles to enhance heat dissipation and electrical conductivity. This improvement is very important in the quest for better and more energy-efficient vehicles.

- Aerospace Engineering: Copper plates operate well under harsh environmental conditions, including high temperatures and mechanical stresses, hence often implemented in aerospace applications, such as fuel systems and thermal protection systems.

- Chemical Industry: The exceptional corrosion resistance of copper plates renders them suitable for chemical processing equipment, such as reaction vessels, tanks, and piping systems. They withstand exposure to corrosive substances and volatile compounds while maintaining structural integrity.

Copper Plates in Jewelry Design

Copper plates have become an integral material in jewelry design, valued for their versatility, durability, and aesthetic appeal. Due to their malleability, copper plates are easily shaped into intricate designs and patterns, allowing artisans to create detailed and unique jewelry pieces. Additionally, copper’s natural reddish-orange hue and ability to develop a patina over time make it a sought-after choice for creating timeless and character-rich designs.

From a hypoallergenic standpoint, copper is another key point to boost its qualities in jewelry. It turns out to be the metal of choice for anyone suffering from a metal allergy, such as that to nickel. Another recent trend facilitated by improvements in workmanship allows the use of copper plates with other materials such as semiprecious stones and precious metals to create contemporary and sophisticated designs. Additionally, it is eco-friendly and recyclable, another step into the realm of green jewelry, thus making copper plates a resource of value in today’s jewelry industry.

Electrical Applications of Copper Sheets

- Printed Circuit Boards (PCBs):

Copper sheets are a fairly important working material used in the fabrication of printed circuit boards. Because of their ability to conduct electricity better than most metals (with an approximate conductivity of 59.6 x 10⁶ S/m), copper sheets provide efficient electrical transmission between different components, thus guaranteeing the reliable operation of electronic devices.

- Busbars and Conductors:

Copper sheets are used for the fabrication of busbars, which distribute power within electrical substations, industrial plants, and data centers. The excellent thermal and electrical conductivity of the copper sheets ensures minimal energy losses and proper distribution of the current.

- Electromagnetic Shielding:

Thin copper sheets are used to shield sensitive electronics from electromagnetic interference (EMI) and radio frequency interference (RFI). Copper sheets, through their conductive property, form a shield to protect the equipment used in industries like telecommunications and medical equipment.

- Transformer Manufacturing:

The copper sheets are put to use in both transformer cores and windings. They are capable of carrying very high electrical loads with minimum resistance and hence, reducing energy losses, which increases operational efficiency and maintenance intervals.

- Battery Components:

Choosing the Right Copper Plate

- Application Requirements:

Determine the specific purpose of the copper plate. Applications requiring high conductivity, such as electrical components, will benefit from plates with a high-purity copper grade, like C110 (electrolytic tough pitch copper).

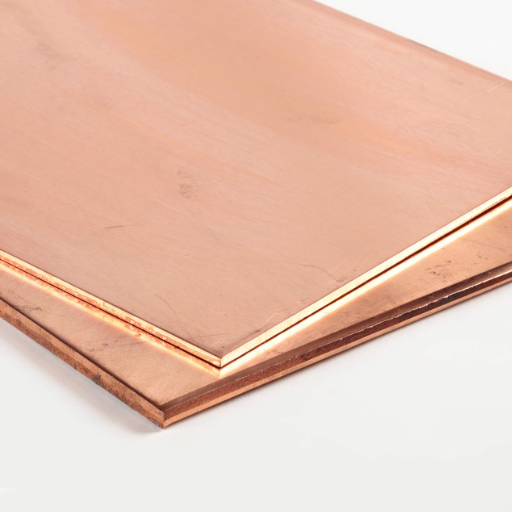

- Thickness and Dimensions:

Thickness and size must suit the mechanical and structural requirements of your project. The thicker, the more durable, but also heavier.

- Corrosion Resistance:

In the case of a high-moisture environment or chemical exposure, the copper plate should provide its corrosion resistance, or consider a treatment or an alloy suited for such conditions.

- Thermal and Electrical Conductivity:

Examine whether thermal conductivity or electrical efficiency is a matter of consideration. If so, pure copper grades are the best.

- Environmental Standards:

Check if it can meet relevant environmental and safety regulations, if applicable, especially for green energy or industrial applications.

With all these factors analyzed, you will be able to conclude in choosing a copper plate that meets both technical and operational requirements in a very successful way.

Evaluating the Finish and Color

The finish and color quality of copper plates are excellent signs of quality, durability, and operational utility in different industries. A highly polished finish finds application wherever precision in conductivity is required or where visual appeal is important; the copper would then be deemed unacceptable if surface irregularities disrupted trustworthy performance. Folding or dull finishes are considered desirable for applications demanding surface adhesion, such as adhesive bonding or coating.

The colors commonly range from bright reddish-orange pure copper shades through darker colors induced by oxidation effects or alloying processes, thus providing some background on the purity of the copper and its treatment record. Contrasts in coloration, on the other hand, might indicate that there is some contamination on the surface or that it has been handled incorrectly after fabrication. Recent industrial progressions bias uniformity of finishes and consistency in color to meet rigid operational standards. More contemporary practices include spectrophotometric means to examine finish and color nuances, thereby certifying good quality of the material by relevant specifications.

Understanding the Properties of Copper for Your Project Needs

Renowned for thermal and electrical conductivity, copper is used in numerous industrial applications. With a conductivity factor that stands at approximately 59.6 x 10⁶ S/m at room temperature, second only to silver in conducting power, this guarantees that efficient conduction of energy takes place in all electrical gadgets. Its malleability and ductility enable it to be formed into wires, sheets, and intricately designed components without compromising its integrity.

It has an advantage from corrosion resistance by forming a protective oxide coating, which makes the metal durable in an adverse atmosphere. The antimicrobial effect of the material increases the above usefulness in healthcare areas and sanitation, which guarantees the elimination of harmful pathogens on its surface. Another function of copper is copper alloys such as brass and bronze, which improve mechanical strength and offer some color variations for different purposes.

For architectural and construction purposes, copper’s pointed aesthetics and high recyclability make it an ideal choice for environmentally sustainable design practices. The properties support such design, coupled with heat-related applications to render it essential for HVAC and heat exchangers. Understanding these properties often leads to better material choices, which offer compatibility and efficiency aligned toward tailoring any actual need in any project.

Working with Copper Sheets

Precision cutting and shaping of copper sheets are of utmost importance for attaining the desired work. The copper can be cut by hand tools such as tin snips for thin sheets while shears or laser cutters are utilized for thicker sheets or more intricate patterns. While bending, a sheet metal brake or similar tool should be used for precise and clean bending operations. Additionally, one must go for safety measures such as gloves and eye protection because the edges might be very sharp. One should accurately measure and mark the cuts or bends to save materials and generally work towards efficient projects.

Cutting and Shaping Copper Plates

Engraving Techniques for Copperplate Art

Copperplate engraving is an elaborate complex with an abundance of artistic inspiration. The procedure is executed with precision tools and techniques that allow the engraving of elaborate designs and accurate details. One of the common approaches of engraving is with the use of a burin, a steel tool that is pushed by hand over the surface of the copper to incise fine lines used for both elaborate illustrations and text. However, to increase productivity and accuracy, the use of laser engraving has become universally accepted over the past few years. Laser engraving permits artists and manufacturers to reproduce highly detailed designs, waste very little material and reproduce the design with consistent quality and accuracy.

Acid etching applies a resist material to the copper surface, exposes the areas to be engraved, then places the plate in an acid bath. The acid eats into the exposed areas, producing lines that are fine, clear, and consistent. Photochemical etching is employed for more specialized applications with photographic masks and UV light to attain very detailed patterns. This method has opened new avenues for creativity while preserving the structural integrity and visual attractiveness of copperplate artwork.

Etching and Other Surface Treatments

The combination of etching with other surface treatment processes has, to a large extent, widened the scope of their artistic and industrial use. During this method, electroplating is combined with etching to create extremely complex designs while improving surface resistance and texture. For example, electroplating a thin layer of another metal, like gold or nickel, on top of an etched surface will protect the underlying materials and introduce contrasting visual features.

Laser etching has now evolved into a flexible and precise method more widely applied for designing structures with extremely fine details with controlled depth. This technology is relevant in applications that need microstructures in the field of electronics and medical device manufacturing. By combining laser etching with chemical treatment, manufacturers can engineer multifunctional surfaces bearing specific functions such as superhydrophobicity or conductivity. Both methods result in surfaces engineered for their performance requirements as well as imparting great aesthetic appeal>

The Future of Copper Plates in Industry

Future industrial applications for copper plates will be able to reconcile technical advancement with emerging industrial demands. Due to the unique characteristics related to thermal and electrical conductivity, copper plates will remain essential in processes of energy transmission, electronics, and renewable energy systems. Gaining in importance are the novel surface treatments and alloys that promote long-term usage and surface enhancements in durability, corrosion resistance, and mechanical properties for copper plates in high-performance settings. Coupled with emphasis on sustainability by industry, copper-based recycling and its energy-saving preference make it the material of choice from a sustainability point of view.

Trends in Copper Plate Manufacturing

The manufacture of copper plates is seeing momentous advancements brought about by technological innovation, market demand, and sustainability issues. More automation and precision engineering are finding their way into manufacturing processes, giving the ability to achieve tighter tolerances with better surface finishes. In the backdrop of these new processes, we treat ourselves with methods considered as special machining plus laser cutting for yielding copper plates that go through greater accuracy and less wastage of materials.

Sustainability is a particular trend to watch. Work using recycled copper is being increasingly considered by industries trying to reduce the environmental footprint of hauling virgin materials. Hence, advanced smelting and refining could provide high-purity copper from recycled input, so that quality will never be compromised to satisfy the highest standards of any industry.

Different from the other above application-based ones in renewables and EVs shaping production are new emerging applications. For EV batteries and solar panels, the search for lightweight metals with high conductivity is, in fact, behind the increasingly thinner, high-performance copper plates. On an ongoing basis, at the same time, copper alloys are also under exploration with an aim to offer a sound performance balance between conductivity and thermal stability/corrosion resistance to withstand harsh environmental conditions.

Innovations in Copper Applications

Other thriving realms of innovation in copper applications are through the introduction of newer technologies of manufacturing processes such as additive manufacturing and precision rolling. Additive manufacturing- better known worldwide as 3D printing-provides an opportunity for highly intricate designs that enhance copper’s thermal and electrical properties while minimizing copper waste. This technology is more appropriate to the manufacturing of heat exchangers and custom electrical components. Contrastingly, precision rolling gives ultrathin copper sheets demanded in the fabrication of microelectronic devices, which require performance and scalability on equal terms.

Reference Sources

-

Plating of Copper into Through‐Holes and Vias

- Key Findings: This study reviews the current technology for copper plating in through-holes and vias, focusing on the fundamental aspects of electroless copper plating. It highlights advancements in plating techniques and their applications in electronics.

- Read more

-

Understanding the Antimicrobial Activity Behind Thin-and Thick-Rolled Copper Plates

- Key Findings: The study investigates the antimicrobial properties of copper plates with varying thicknesses (25 μm and 100 μm). It identifies differences in surface topology and their impact on antimicrobial activity.

- Read more

-

Preserving History in Copper: Richard Rawlinson’s Collection of Printing Plates

- Key Findings: This research explores the historical significance of engraved copper plates, focusing on their provenance, manufacturing techniques, and intended uses.

- Read more

Frequently Asked Questions (FAQs)

Q: What is a copper plate and what are its properties?

A: A copper plate is a flat piece of copper metal that is commonly used in various applications due to its excellent conductivity and good corrosion resistance. These plates can be found in different thicknesses and sizes, making them versatile for projects ranging from electrical components to artistic jewelry designs. The properties of copper plates include high thermal and electrical conductivity, along with a malleable nature that allows for easier shaping and cutting. When choosing a copper plate for your project needs, consider the specific thickness and finish required for optimal performance.

Q: How do I select the right size of copper sheet for my project?

A: Selecting the right size of copper sheet for your project involves measuring the dimensions required and considering the thickness that will best suit your application. Copper sheets can be ordered in various lengths and widths, and many suppliers offer custom cut options to meet specific requirements. When shopping online, ensure you check the available sizes and the possibility of cutting to size for a perfect fit. Additionally, consider the weight and handling of the sheet, especially for larger pieces, to ensure you can manage it effectively during your project.

Q: Can I buy copper plate online and what should I consider?

A: Yes, you can buy copper plate online from various suppliers that specialize in metal supply. When ordering online, it’s important to consider the quality of the product, including its thickness and finish, as well as the supplier’s reputation. Look for options that allow for custom cuts or sizes to suit your specific needs. Additionally, check if the supplier offers good corrosion resistance in their copper plates, as this can impact the longevity of your project. Always read reviews and verify that the supplier is reliable before placing your order.

Q: What is the difference between a copper sheet and a copper plate?

A: The difference between a copper sheet and a copper plate primarily lies in their thickness and application. Typically, copper sheets are thinner and used for applications requiring flexibility, such as in jewelry making or decorative projects. In contrast, copper plates are thicker and often utilized in industrial applications, electrical components, and as substrates for etching processes. Both materials can be found in a variety of sizes and can be ordered online or cut to size depending on the project requirements. Understanding the specific characteristics of each can help you select the right product for your needs.

Q: What are common applications for copper round bars?

A: Copper round bars are commonly used in various industries for their excellent conductivity and machinability. They are often utilized in electrical applications, plumbing, and manufacturing components that require good corrosion resistance. Additionally, copper round bars can be shaped and cut for use in creating custom fittings, connectors, and decorative elements in jewelry and art. When selecting a copper round bar for your project, consider the dimensions, thickness, and finish to ensure it meets your specific application requirements. Whether for industrial use or artistic endeavors, copper round bars provide versatility and reliability.