Durable, versatile, and affordable materials tend to be selected in the 4×8 galvanized sheets by both technically proficient individuals and common laypersons for their projects. So what exactly is galvanized steel, and why is it so widely treasured in commercial circles? Whether you’re working on an application or want to know the price factors involved or best alternatives in a project, this article will cover it all for you. Beyond its protection with zinc coating and excellent resistive qualities, galvanized steel offers much more. Read on to find out about more advantages, market insights, and useful tips pertaining to 4×8 galvanized sheet metal that you can utilize for your project.

Understanding 4×8 Galvanized Sheet Metal

What is Galvanized Sheet Metal?

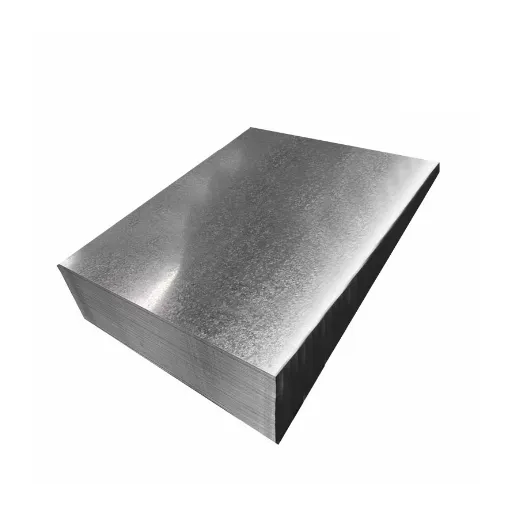

The zinc coating on galvanized sheet metal is intended to keep rust and corrosion at bay. This process is called galvanization. Galvanization offers better durability and life to the metal; hence it goes into construction, roofing, manufacturing, etc. The zinc coating affords some protection to the metal from harsh environment conditions such as moisture and temperature extremes.

Hot-dip galvanization is the most common method for galvanizing steel. In this process, the steel is dipped into molten zinc to ensure complete and uniform coating over all surfaces. Hence, the coating acts not only against rust formation but also self-heals. When the zinc coating is scratched and damaged, it protects the exposed steel by reacting to form a barrier over the small exposed areas.

Typically, galvanized sheets in the standard size of 4×8 are in demand for applications that call for big uniform panels, easy to handle and cut to specifications. It finds wide application because it is cheap, strong, and requires low maintenance. Galvanized sheet metal, therefore, offers a good alternative for unnumbered weather-resistant structures or industrial parts.

Properties of 4×8 Galvanized Steel Sheets

Renowned for their durability and toughness, 4×8 galvanized steel sheets have this title. During the galvanization process, a steel is immersed in molten zinc to form a very thin and protective coating on it. Such a zinc coating provides the ultimate protection against rust and corrosion, thus making it an excellent choice for outdoor use or in humid conditions. The zinc coating resists abrasion and even if minor damaging incidents take place, it greatly extends the working life of the sheet.

High strength-to-weight ratio is another widely respected property of these steel sheets. Although these sheets are lightweight and hence easy to handle, they allow for excellent structural integrity and load-bearing capacity. This arguably makes them best fit for construction purposes such as roofing, wall cladding, and support structures. The 4 x 8 sheets are a standard size, and the thickness is uniform. This allows for accurate combined cutting and shaping to a wide range of applicability.

Lastly, 4×8 galvanized steel sheets are cost-effective and low maintenance. Untreated steel may rust and require frequent repairs or replacement, whereas galvanized sheets require almost no maintenance. Combined with their longevity, their affordability makes steel sheets highly competitive in industrial as well as residential applications for high returns. These features make 4×8 galvanized steel sheets to be a favorite among commercial applications as well as the do-ityourselfers in order to maintain reliability and versatility in several projects.

Types of Galvanization Processes

In essence, galvanization entails coating steel or iron with zinc, acting as a resistant layer against corrosion. There are some important types of galvanizing processes; each has its own set of applications and advantages.

- Hot-Dip Galvanization: This is the most popular type and involves dipping the steel or iron in molten zinc. The zinc layer forms a very strong and corrosion-resistant coating fit for outdoor use like gates, roofing, platform works, etc. These are known for their durability and full coverage, even in the remotest places.

- Electro-Galvanization: This form of galvanization uses an electric current to shoot a layer of zinc onto the steel or iron. Electro-galvanized steel has a very smooth finish generally used in products that require a polished appearance, such as automotive parts or household appliances. Hence, they do not resist corrosion very well as compared to their hot-dip counterparts.

- Mechanical Plating: The steel parts are tumbled with zinc powder and chemicals to plater them. In general, mechanical plating is done for small parts like bolts, screws, and fasteners. Because it works by cold processes, thermal deterioration of the delicate parts is prevented. Also, it is more environment-friendly but less used in the large-scale industries.

Depending upon the end use, the environment, and the kind of project, each type of galvanizing will present certain advantages. Choosing suitable one will provide good protection and long life.

Applications of 4×8 Galvanized Sheet Metal

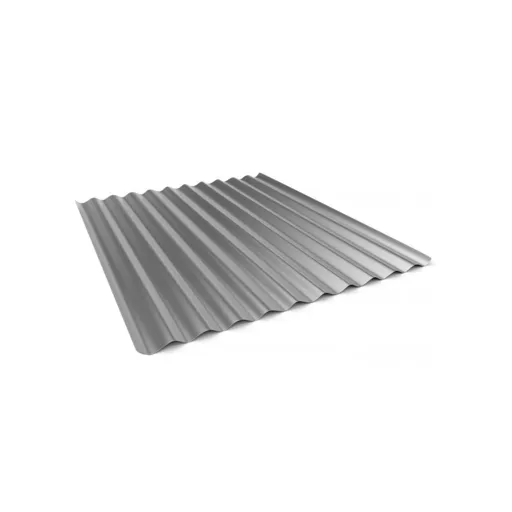

Roofing Solutions with Galvanized Sheets

This galvanized metal sheet offers a sturdy yet inexpensive roofing for a multitude of purposes, making it resistant to corrosion and hence the preferred choice for the builder and homeowner alike. Following is a list of five areas where galvanized sheet metal finds application in a roofing solution:

- Residential Roofing: Being strong, galvanized sheet is often laid on residential buildings in areas where harsh weather conditions prevail. Weight-wise, they are light and therefore ensure that there is less structural strain.

- Commercial and Industrial Roofs: Due to their long life and less maintenance, galvanized sheets find application in roofing warehouses, factories, and offices. The zinc coating protects against wear under demanding conditions.

- Agricultural Building: Farm buildings, storage sheds, and barns stand to gain largely from being roofed with galvanized sheet. These sheets protect against the ingress of moisture and pests and are crucial for the needs of agriculture.

- Canopies and Overhangs: Galvanized sheet metal can be used in canopies and overhangs for protection against inclement weather in an otherwise open-air space and attractive beauty.

- Temporary Roofing and Shelters: Being affordable and easy to install, galvanized sheet metal proves suitable for temporary roofs and emergency shelters during disasters or construction.

Whatever type of roof is being put in, guaranteed performance and protection are given by the user-galvanized sheet metal.

Artistic Applications and Custom Projects

Its broad possibility in manipulation and its inherent beauty open the door to myriad artistic uses and custom creations. An artist, designer, or builder values its potential for a variety of uses and its unique qualities. Below are five prominent uses in artistic or custom project environments:

- Sculpture and Installation: The material being flexible and formable makes it excellent for sculpture and large-scale installation work. Often, it is used by artists to realize aesthetically bold creations that must have a degree of permanency and weatherproofing.

- Decorative Wall Panels: These are custom-designed wall panels having intricate patterns or textures, popular for interior and exterior smoothing with a dash of modern arty touch.

- Furniture Design:Be it chairs, tables, or the sort, the material is employed by artisans to have furniture that is creative and yet able to function. It is favored in furniture design for its strength and ability to be molded into innumerable shapes.

- Architectural Accents:Architectural compositions are seldom complete without delicate metalwork in unique architectural elements, custom railings, banisters, or decorative trim. These ornaments allow for an artistic personalized touch for any commercial or residential edifice.

- Jewelry and Fashion Accessories: Into wearable art, the design application travels. Bracelets, necklaces, and other fashion accessories are constructed to show the versatility of this material in fine, intricate designs.

Such a broad spectrum of application bridges function and creativity for the material.

Benefits of Using Galvanized Steel Sheets

Corrosion Resistance and Longevity

Because of their corrosion resistance, galvanized steel sheets are commonly used in semi-tropical climates that sometimes experience extreme climatic factors. Steel undergoes galvanization by applying zinc coating on it, which forms a protective barrier against rust and other forms of deterioration. There are many benefits:

- Durable against Extreme Weather Conditions: Galvanized steel remains intact in heavy-duty rains, snows, or strong UV exposure, ensuring long-term performances.

- Low Maintenance: With its high resistance to rust, galvanized steel requires lesser maintenance and thus contributes to a low maintenance cost.

- Tested Life-Span: Recent studies concluded that galvanized steel may last for more than 50 years in countryside locations and 20 to 25 years postponed for major repairs in extreme industrial or coastal settings.

- Self-Healing Properties: Small scratches or some damages to the zinc coating are able to heal themselves via a natural galvanic action, thus ensuring continued corrosion protection.

- Sustainability: The galvanized steel is recyclable and retains its properties after recycling, rendering it constructive toward a green life cycle in terms of construction and manufacturing.

It is these benefits that make galvanized steel sheets a preferred choice in applications where durability and economy are to be considered.

Durability in Various Environments

Galvanized steel sheets are highly versatile, adapting to many environmental conditions, some of which are extremely severe or demanding. Here are five crucial environments where galvanized steel material prove to be resilient:

- Urban Locations: The zinc coating protects galvanized steel from the common pollutants and chemicals present in the urban atmosphere, like sulfur dioxide and nitrogen oxides, thus guaranteeing long performance in cities and areas of industry.

- Coastal Areas: The salty air and the high humidity in coastal region present unique challenges to all materials. Galvanized steel offers corrosion resistance in the marine environment that reduces maintenance cost and extends lifespan.

- Industrial Environments:Heavy industries generate corrosives like acids and alkalis. Whenever aggression these agents, galvanized steel stands. Thus, for applications like pipes, storage tanks, and structural supports, industrial applications stand best.

- Rural Environments: Lower pollutant and moisture contents in rural environments may correlate positively with the corrosive atmosphere. A reliable performance is achieved by galvanized steel, which keeps its integrity for decades under such conditions.

- Cold Climate: Frost and ice impart physical damage onto the materials susceptible to it, but galvanized steel can stand up pretty well to the causes of any damage associated with freezing temperatures; its main job is to resist structural degradation and help further the resilience of structures to withstand harsh winter climates.

Through these qualities, galvanized steel becomes quite worthy of being applied by industries into various areas in different environments. Its performance, plus its cheap yet environmentally friendly qualities, place it at the top of the list for durable projects.

Cost-Effectiveness Over Time

Galvanized steel is found very cost-efficient when considered over time and thus is usually chosen for both short- and long-term jobs. It is extraordinarily durable and requires very low maintenance expenses, thereby saving considerable sums of money that would otherwise be spent on alternative materials. A few details describing its cost efficiency are given below:

- Reduced Maintenance Costs: Galvanized steel requires very little maintenance as a layer of zinc protects it from corrosion and other environmental conditions for many years. This further means very few costs for repairs and replacement.

- Extended Lifespan: Galvanized steel structures last, on average, more than 50 years in rural areas and 20-25 years in coastal or industrial areas, thereby reducing reinvestment frequency.

- Lower Initial Investment: This may somewhat increase the first cost of galvanized steel; however, the overall costs will be reduced as periodic painting or other corrosion prevention treatments are eliminated.

- Resistance to Harsh Conditions: Weathering en route, solar glare, hurricane, gale, rain, and sandstorms blowing across deserts-thought to offer extreme exposure to metal surface-have become trivial matters for this protected metal that almost resists corrosion.

- Recyclable and scrap value: Being 100 percent recyclable, at the end of its working life, galvanized steel finds some value and helps to offset disposal costs, even providing some return for that matter.

The very properties that stand the galvanized steel apart as an economically sustainable option for modern infrastructure and industrial application.

Cutting and Installation Tips

How to Cut Galvanized Sheet Metal

Galvanized sheet metal must be cut using the right tools and techniques to reach that precise location and keep the zinc coating intact.

- Choose Your Tools Wisely: A tool must be selected on the basis of sheet metal thickness: tin snips for thin sheets, electric shears for medium thickness, and angle grinders with cut-off wheels for thicker materials. Also, remember to keep tools sharp and well maintained.

- Wear Safety Gear: Wear gloves, safety goggles, and a dust mask whenever cutting the galvanized metal to protect from sharp edges, flying debris, and unpleasant fumes.

- Mark the Cutting Line: Using a ruler or a set square, mark the area to be cut with a permanent marker. Double the measurement checks for correct dimensions.

- Secure the Metal Sheet on the Working Surface: Clamp the sheet down on a stable working surface to prevent movement during cutting, serving to ensure cleaner cuts and also in the interest of your safety.

- Make the Cut: Cut along the line marked with a steady hand. For long cuts, take intermittent breaks to check on your progress and make adjustments if necessary. Rough or jagged edge finishes may impair the structural integrity of the metal.

- Clean the Edges: Once the cutting is done, smooth out the bombs with a metal file or some sandpaper just to get rid of any burrs that might be sharp. It’s necessary to prevent injury and also to make it easier to handle.

- Repair the Zinc Coating: Upon the zinc coating getting damaged during the cutting process, apply a cold galvanizing compound to the exposed edges for the reestablishment of corrosion protection.

Using these work procedures will enable you to cut galvanized sheet metal properly while retaining its strength and protection. Careful but firm handling coupled with an eye for detail gives a professional finish.

Installation Best Practices for Longevity

When assuring the long-term performance of galvanized sheet metal, extra considerations should be made during installation. Here are some best practices to consider:

- Select the Proper Fasteners: Since some can cause galvanic corrosion when used with galvanized sheet metals, the fasteners should be selected accordingly. Stainless steel screws and bolts or zinc-coated options are best for retaining corrosion resistance.

- Seal Joints and Overlaps: Seal joints, overlaps, and seams with good quality sealant to keep the interface dry. This is especially important in areas where high humidity or precipitation is common.

- Ventilate Properly: Good ventilation must be ensured in the vicinity of the installed sheet metal to avoid moisture entrapment that can later cause corrosion.

- Thermal Expansion Gaps: Allow for thermal expansion and contraction of the sheet metal by leaving gaps wherever required. These gaps help in preventing warping or buckling upon temperature changes.

- Damage Inspection: Inspect the material for any damages-scratches, or exposed edges, to the zinc coating-before and during installation. These areas should be repaired immediately, employing cold galvanizing spray, in order to retain the corrosion protection.

- Avoid Direct Contact with Dissimilar Metals: Avoid the contact between galvanized sheet metal and dissimilar metals (like copper or uncoated steel). Where such contact cannot be avoided, use separators or protective tape to prevent galvanic corrosion.

By adhering to these practices, you can enhance the lifespan of your galvanized sheet metal and ensure it remains effective in providing structural stability and corrosion resistance for years to come.

Tools Required for Working with Galvanized Steel

The nature of working with galvanized steel necessitates certain tools for accuracy, safety, and the maintenance of the innate protective coating. Here follows a list of the essential tools with which most users would be familiar:

- Metal Snips or Shears: Used for cutting galvanized steel sheets, ensuring that the zinc coating is not damaged.

- Angle Grinder: Trimming or shaping galvanized steel may be what’s needed, although one has to be careful about the heat generated that may affect the coating.

- Drills with Specialty Bits: Normal or cobalt metal drill bits should be used for making clean holes in galvanized steel.

- Welding Accessories: Use proper ventilation and welding rods appropriate for galvanized materials to avoid noxious fumes.

- Measuring Tools: Tape measures, straight edges, levels, etc., are vital for checking out dimensions and alignment.

- Safety Equipment: Protective gloves, safety goggles, and respirators are crucial in preventing injury and protecting against harmful zinc oxide fumes during cutting or welding.

- Deburring Tools: These tools smooth the edges after cutting to minimize chance of injury and maintain the integrity of the material.

Proper tooling thus makes the job easier and helps in maintaining the structural and corrosion-resistant properties of galvanized steel. Always abide by safety procedures when working with these tools to ensure personal safety and the longevity of the material.

Maintenance of Galvanized Sheet Metal

Long-Term Care for Durability

Proper maintenance of galvanized sheet metal is indispensable to keep it durable and corrosion resistant through a long period of time. One of these long-term care measures is the regular examination of the surface to ascertain signs of damage like scratches, dents, or corrosion spots. Such issues, if ever coming to view, should be given prompt attention of cleaning and repainting of the exposed areas, for such would greatly increase the lifespan of the metal.

Furthermore, it is advisable to clean periodically the galvanized surface to prevent a possible build-up of dirt, debris, or chemicals that may undermine the protective zinc coating. Use a solution of mild detergent, along with a soft brush or sponge to clean the surface, and remember not to impose any abrasive material that might scratch it.

In humid conditions or in the presence of rigorous chemicals, protective sealants or paints may be recommended over the galvanizing layer to provide an extra measure of protection. Another way of preventing premature corrosion would be to ensure that drainage is efficient around any galvanized items, and water does not pool there.

If these maintenance features are included in the periodic care schedule, the metal will retain its original strength and corrosion resistance, and this works in almost any application.

When to Replace Galvanized Sheets

Determining the right time for replacement of galvanized sheets involves a few key factors that point towards wear and inefficiency. The first thing I look out for is a manifestation of corrosion, such as white rust appearing on the surface or perhaps flaking or pitting. While galvanized sheets are designed to resist corrosion, severe environmental conditions could eventually take their toll on the zinc layer. The second situation arises when corrosion snowballs into a situation where it affects the integrity of the material. Usually, in this case, it is often best to opt for replacement.

Another aspect I consider is structural damage that could include warping, cracking, or significant dents. Even if a sheet is not yet fully corroded, damage-related reduction of performance could render the sheet insufficient for its purpose. Such damage may result from impacts, heavy loads, or environmental loads over time, and as soon as the sheet’s functionality is hampered, replacement becomes imperative.

Lastly, I take into consideration the age of the sheets and their performance over time. While galvanized sheets are made to last, no material can last indefinitely. If the sheets begin to show signs of failure, be it from changes in the environment, higher load demands, or simply aging, then I know they have to be replaced. A regular inspection schedule and a proactive attitude help me immensely in arriving at a best-case scenario time for replacement to be done, so that what they support remains reliable and long-lasting.

References

-

University of Arizona – Tom’s Metalworking Pages

This page discusses the availability of plate steel, including 4×8 foot pieces, and provides insights into cutting and machining processes. -

Princeton University – Shed-tacular: Discover The Versatility Of Lean-to Metal Sheds

This resource highlights the use of galvanized steel in lean-to sheds, showcasing its versatility and applications. -

Illinois Department of Transportation – Deck Plate with Curbs Typical Section

This plan includes specifications for galvanized steel used in construction projects, such as steel railings and deck plates. - Click here to read more.

Frequently Asked Questions (FAQ)

Q: What are 4×8 galvanized sheets?

A: 4×8 galvanized sheet metal is a term used to describe sheets of metal measuring 4 feet by 8 feet coated with zinc for corrosion prevention. This type of sheet metal is used in a variety of different fields, such as construction, ductwork, and siding.

Q: Possibilities for gauging 4×8 galvanized sheet metal?

A: Going about the most common gauge options for 4×8 galvanized steel sheet are 22 gauge, 24 gauge, and 26 gauge. Thus, 22 gauge sheets would be the thickest and those of 26 gauge would be the thinnest technically.

Q: What are the various applications and uses of 4×8 galvanized sheet metal?

A: Stored 4×8 galvanized sheet metal finds myriad applications ranging from roofing, siding, ducting, to automotive parts. With that corrosion resistance, it is best suited for outdoor and industrial applications.

Q: What’s the difference between cold rolled and galvanized sheet metal?

A: A cold rolled sheet metal, basically, is given a finishing treatment at room temperature to provide a smooth finish and tighter tolerances; whereas galvanized sheet metal is the one that absorbs zinc for the prevention of rust. Galvanized options are advised for applications where there is an additional requirement of protection.

Q: Can one purchase 4×8 galvanized sheet metal in bulk?

A: It sure is; many suppliers carry 4×8 galvanized sheet metal in bulk quantities, which translates to a pact on the price and beautifies the choice in gauge sizes. Bulk purchase renders the option most friendly-to-the-pocket in relation to fulfilling demand for large projects.

Q: How to select the thickness for my project?

A: Choosing the right thickness for your sheet metal-galvanized 4×8 project depends on what it is to be used for. Generally speaking, thicker sheets tend to be heavier duty and thus used for structural purposes, while thinner are for decoration or those whose application are not so demanding.

Q: What are the advantages of galvanized sheet metal?

A: The main advantages of galvanized sheet metal are corrosion resistance, electric equipments maintenance, and durability. It is consequently used in construction and another fabrication, making it a very prestigious material for almost any application.