Stainless steel flat bars have become an essential component in numerous industries due to their strength, versatility, and resistance to corrosion. The specific dimensions of 3/8 x 1/2 stainless steel flat bars make them particularly suitable for applications requiring a balance between durability and precision. This blog post will provide a comprehensive overview of the key properties, manufacturing processes, and common applications of these flat bars. Additionally, we will explore the different grades of stainless steel used in their production, the advantages they offer over alternative materials, and considerations for their selection and maintenance in industrial and commercial settings. By the end of this article, you will have a thorough understanding of why 3/8 x 1/2 stainless steel flat bars remain a popular choice among engineers and manufacturers.

What Is the Product Description of a 3/8 x 1/2 Stainless Steel Flat Bar?

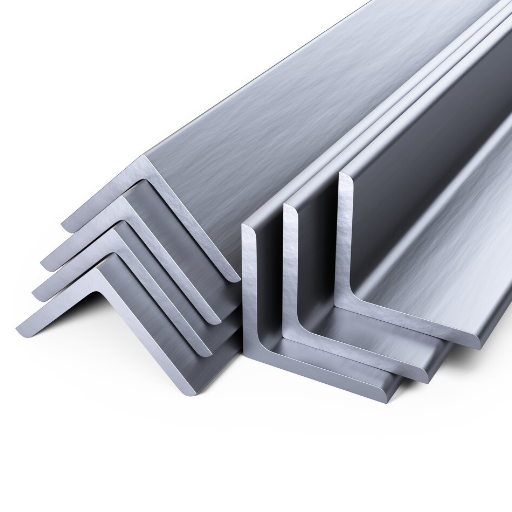

A 3/8 x 1/2 stainless steel flat bar is a rectangular prism whose height is 3/8 inches, width is 1/2, and it is made up of stainless steel. Because of these dimensions, it is perfect for many structural and fabrication works where strength, resistance to corrosion, and accuracy are very important. This bar is often utilized within the construction, production, and marine industries because of its dependable mechanical properties and capacity to endure extreme conditions.

Understanding the Material Composition

Stainless steel consists of iron, chromium, and carbon, with chromium content usually preset to a minimum of 10.5 percent to provide corrosion resistance. Other alloying elements like nickel, molybdenum, and manganese, can be added to improve specific properties which include increased strength, heat resistance, or better machinability. Stainless steel is available in different grades, and each one is tailored to the performance requirements of different industries. This material achieves its corrosion-resistant properties due to the formation of a passive chromium oxide layer, which protects from oxidation and degradation in harsh environments.

Specification for 304 Stainless Steel Flat Bar

304 stainless steel flat bars are widely recognized for their excellent corrosion resistance, durability, and versatility. They are composed primarily of iron, with approximately 18-20% chromium and 8-10.5% nickel, along with trace elements such as manganese, silicon, and carbon. This composition enables the material to form a protective chromium oxide layer, enhancing its resistance to oxidation and most corrosive environments.

Key Properties:

- Corrosion Resistance: Offers superior resistance to rust and corrosion, making it suitable for both indoor and outdoor applications.

- Tensile Strength: Approximately 515 MPa (75,000 psi), ensuring structural integrity under mechanical stress.

- Yield Strength: Around 205 MPa (30,000 psi), indicating its ability to resist deformation.

- Hardness: Typically measured at 70-90 HRB, providing sufficient durability for various applications.

- Machinability and Weldability: Exhibits good machinability and excellent weldability, particularly when post-weld annealing is performed to enhance corrosion resistance.

Applications:

304 stainless steel flat bars are commonly used in construction, manufacturing, food processing equipment, chemical containers, and architectural projects requiring both strength and aesthetic appeal. They are preferred for components exposed to moisture or chemicals due to their exceptional corrosion properties.

Specifications:

The dimensions of 304 stainless steel flat bars are highly customizable, typically ranging in thickness from 0.125 inches to 2 inches and widths between 0.5 inches to 6 inches, depending on specific requirements. Compliance with ASTM A276 and ASTM A484 standards ensures consistency in quality and performance. For enhanced surface finishing, they are often available in mill, brushed, or polished finishes.

Common Applications and Uses

304 stainless steel flat bars are widely utilized across diverse industries due to their excellent strength, corrosion resistance, and versatility. Key applications include:

- Construction and Structural Frameworks: Frequently used in building supports, braces, and reinforcements due to their durability and ability to withstand environmental exposure.

- Food and Beverage Industry: Ideal for equipment such as countertops, sinks, and food processing machinery thanks to their ease of cleaning and resistance to food acids.

- Chemical and Pharmaceutical Equipment: Suitable for manufacturing tanks, piping, and other components exposed to chemicals, as they resist corrosion caused by a wide range of substances.

- Automotive and Transportation: Used in automotive parts, trailers, and rail components for their combination of strength and aesthetic finish.

- Architectural Applications: Popular for decorative elements, handrails, and cladding where appearance and performance are equally critical.

These applications highlight the versatility of 304 stainless steel, making it a staple material for projects requiring reliable and long-lasting performance.

How Is 3/8 x 1/2 Stainless Steel Flat Bar Stock Processed?

Like manufacturing any other flat bar stock stainless steel 3/8 x 1/2 is a meticulous process that requires attention to detail at every step. It starts with stainless steel raw material which is heat-treated to improve machinability and mechanical properties. Next, the material is hot-rolled or cold-rolled to acquire the required thickness and width. Afterward, a flat bar is cut into specific dimensions through shearing or laser cutting. Then, surface finishing is done to remove any imperfections and improve the corrosion resistance of the material. This is done through grinding, polishing, or brushing. Finally, the flat bar undergoes quality compliance inspection to make sure it is ready for shipment.

The Hot Rolled Steel Flat Bar Process

Hot rolling describes the procedure in which steel is heated above 1,700ºF to achieve a plasticity state. This enables the material to be turned and formed into flat bars with ease. The steel is then put through several rollers to achieve the desired height and width. The steel’s high temperature improves the ability to be scorched and eliminates internal stresses, allowing for a properly grained structure. After formation, the heated steel is slowly cooled down to room temperature. They will assist in the formation of a scale. However, regulative treatments that gravitationally push surface oxide scale through descriptive processes such as pickling or grinding serve to obliterate this oxide layer and enhance the finish. Final products undergo detailed checks to confirm adherence to dimensional and strength requirements for use in construction, machinery, and industrial manufacturing.

Benefits of Cold Finished vs. Hot Rolled

Cold-finished steel and hot-rolled steel each have distinct characteristics, making them suitable for different applications depending on the required specifications. The primary difference lies in their production processes and subsequent properties.

- Surface Finish and Precision: Cold finished steel delivers a smoother surface finish and tighter dimensional tolerances compared to hot rolled steel. This is because cold finishing involves additional processing steps such as cold drawing, peeling, or grinding, which refine the material’s surface and dimensions. Conversely, hot rolled steel has a rougher surface due to the high-temperature rolling process and subsequent cooling.

- Strength and Hardness: Cold-finished steel exhibits higher strength and hardness due to work hardening during the cold processing phase. This makes it particularly well-suited for precise applications requiring dimensional accuracy and better surface characteristics. Hot rolled steel, while less strong, remains more malleable, which is useful for structural applications where precision is less critical.

- Cost and Application: Hot rolled steel tends to be more cost-effective because of its simpler production process, making it ideal for large structural components such as beams, rails, and construction-grade sheets. Cold finished steel, while more expensive, is preferred for applications demanding high precision, such as the fabrication of machinery parts, automotive components, and tools.

- Internal Stress: Cold finished steel can have residual internal stresses resulting from the working processes, which may require stress relief treatments for certain applications. Hot rolled steel is generally free from such stresses since it is cooled more gradually.

Choosing between cold finished and hot rolled steel depends on the specific requirements of the intended use, factoring in budget, desired mechanical properties, and aesthetic considerations.

What Are the Key Specifications of 3/8 x 1/2 Stainless Steel Flat Bar?

- Material: Typically composed of stainless steel grades such as 304 or 316, known for their corrosion resistance and durability.

- Dimensions: The flat bar measures 3/8 inch in thickness and 1/2 inch in width, with customizable lengths depending on application needs.

- Corrosion Resistance: Offers high resistance to rust, oxidation, and chemical exposure, making it suitable for both indoor and outdoor applications.

- Strength: Exhibits excellent tensile strength and durability, capable of withstanding heavy loads and stress.

- Surface Finish: Available in various finishes, including mill, polished, or brushed, depending on aesthetic and functional requirements.

- Applications: Commonly used in structural frameworks, brackets, automotive parts, and marine hardware due to its versatility and robust properties.

These specifications ensure the flat bar meets diverse industrial and commercial needs, providing reliability and performance across applications.

Grade and Quality of the Metal

The composition, the procedure used to make it, and the level of industry regulation adherence will determine the grade and quality of the stainless steel metal. Stainless steel grades 304 and 316 are categorized according to their chromium and nickel ratios, with 316 containing molybdenum for improved corrosion resistance. The grade of the material is claimed to meet the requirements of ASTM and ISO standards which assure certain mechanical parameters, chemical composition, and surface quality. Apart from integrating such materials, the quality assurance step implements thorough testing for tensile strength, impact resistance, and corrosion resistance analysis and certifies the metal’s operating conditions. Choosing the appropriate grade and accurate manufacturing technique of the material aids the ability of the metal to withstand harsh industrial and commercial conditions.

Dimensions: Thickness and Width

Metal width and thickness are key elements for utilizing the metal and its performance. Thickness can be divided into two categories: thick plates (over 1/4 inch) and thin sheets (under 1/4 inch), which have accepted tolerances such as ASTM A480. Depending on the purpose and capacity of the manufacturer, widths can vary from a few inches to over 100 inches making them strips or sheets respectively. The measurements of these dimensions define their suitability for machining, forming, and joining processes, turning waste into structure guarantee and fitting accuracy. These dimensions should satisfy a set of criteria about the project, and such restrictions are very often embedded in engineering designs for industrial uses for load bearing, flexibility, and durability.

Understanding Corrosion Resistance

The term corrosion resistance is defined as the ability of a material to resist degradation from environmental factors like moisture, chemicals, or atmospheric conditions. Metals generally depend on their components, protective layers, and passive oxide layers of some type, such as in stainless steel which includes chromium to inhibit oxidation. Corrosion resistance is also affected by pH level, temperature, concentration of chloride ions, and the presence of electrolytes in the environment.

Some materials such as stainless alloys, aluminum, and titanium have high corrosion resistance because of their stable self-repairing oxide layer. In order to increase the corrosion resistance of metals, the right materials must be chosen, applied with corrosion resistant coatings, such as zinc galvanizing, epoxy, or cathodic protection systems. Knowing these factors about the operating conditions allows long-term use and decreases maintenance and safety hazards in the industrial and engineering fields.

Where Can I Shop for a 3/8 x 1/2 Stainless Steel Flat Bar?

Finding an appropriate industrial supplier, metal distributor, or online marketplace that sells 3/8 x 1/2 stainless steel flat bars should not be a problem. Well-known companies such as Online Metals, Metal Supermarkets, and McMaster-Carr sell stainless steel products on their websites with specifications and delivery options. Just remember to double-check the material grade and the dimensions before making the purchase. Furthermore, local hardware shops or metal fabrication stores may already have these sizes in stock or at least be able to get them for you once they are requested.

Finding a Reliable Metal Supply Store

Inventory variety, quality of the metal, and customer support are central elements to focus on when searching for a reliable metal supply shop, and Online Metals, Metal Supermarkets, and McMaster-Carr seem to check them off. Alongside offering a variety of products like stainless steel flat bars in different grades and sizes, it is worthwhile noticing that Online Metals offers detailed product specifications as well as custom cut options for ease of shopping. Metal Supermarkets guarantees fast service such as in-store pickup and delivery. Meanwhile, McMaster-Carr is notorious for its all-inclusive industrial and individual catalog offerings alongside rapid delivery and dependable customer support. Materials need to come with clear certifications while orders should come with flexible sizes and generous return policies if customers are going to trust the purchasing experience.

How to Buy Online Safely

Purchasing metal supplies online can be efficient and secure when following several essential steps. Begin by verifying the reliability of the supplier; look for well-established retailers such as Online Metals, Metal Supermarkets, and McMaster-Carr that feature robust customer reviews, certifications, and transparent policies. Review product specifications thoroughly to ensure the materials meet your technical requirements, and confirm the availability of certifications like mill test reports for quality assurance. Use secure payment methods and ensure the website employs encryption protocols, typically indicated by “https://” in the URL. Take advantage of customer support options, like live chat or phone assistance, to address any questions before completing the transaction. Lastly, confirm delivery terms, return policies, and any associated costs to prevent unexpected issues. By consolidating these steps, you can confidently make your online purchases from trusted sources.

Why Choose a 3/8 x 1/2 Stainless Steel Flat Bar for Your Project?

Due to its resiliency and how easy it is to machine and work with, our 3/8 x 1/2 flat bars are very popular in a variety of industries Stainless steel’s weight-to-strength ratio makes it ideal for structural applications. Additionally, it makes it corrosion resistant, which increases the life span of the material in extreme conditions. This specific dimension offers excellent rigidity and strength while maintaining a manageable size for fabrication. The specific grade of stainless steel used in the fabrication of a 3/8 x 1/2 flat bar renders it very popular in construction, automotive, and manufacturing industries where accuracy and dependability are very important. Stainless steel is also one of the easiest materials to keep clean and can be finished in a multitude of ways which increases its usefulness for various purposes and makes it aesthetically pleasing.

Advantages of Using 304 Stainless Steel

304 stainless steel partly consists of nickel and chromium, making it one of the most widely used materials in various industries and households. One of its beneficial characteristics is high corrosion resistance due to chromium which passively oxidizes in numerous environments like moisture, acid, and oxidizing agents. Moreover, 304 stainless steel is also resistant to high levels of mechanical force and shock, as well as extreme temperature changes, giving it commendable durability and strength.

The material is versatile due to its high tensile strength which makes it appropriate for tough applications, along with non-magnetic properties in an annealed state. Most importantly, 304 stainless steel can be easily machined and welded, making it efficient for construction, automotive, food processing, and medical industries. Being bacterial and easy to clean also makes it useful in food and beverage or highly sterile industries. Such characteristics make 304 stainless steel a highly affordable and dependable option for most industries where functionality and aesthetic appeal are required.

Compared with Other Materials

In attempting to compare any two materials, matters like the strength, the cost, the durability, and even the environmental sensitivity are very critical. For example, in structural uses, steel is famous for its high tensile strength as well as its ability to resist deformation. While steel is well known for its strength, aluminium is also corrosion resistant and lightweight which makes it suitable for the transportation and aerospace industry. However, composite materials such as carbon fiber while being far more expensive and less recyclable, outperform traditional metals in energy efficiency and weight reduction. Furthermore, plastics are average in the environmental measures due to their biodegradability and recycling processes but are traded a lot due to their versatility and affordability. Each material comes with a set of unique features that have its specific use that must be taken into account with regards to performance as well as the working environment during selection.

References

Frequently Asked Questions (FAQ)

Q: What is a 3/8 x 1/2 stainless steel flat bar?

A: A 3/8 x 1/2 stainless steel flat bar is a solid piece of flat stock made from stainless steel, specifically designed for various general purpose and structural applications. It is known for its excellent corrosion resistance and mechanical properties.

Q: What are the common uses of a 3/8 x 1/2 stainless steel flat bar?

A: This type of flat bar is widely used in architectural projects, kitchen and food and beverage applications, and outdoor and indoor structural work due to its high-temperature resistance and protection against environmental factors.

Q: How is a stainless steel flat bar made?

A: A stainless steel flat bar is drawn through a pre-formed die to achieve more exacting detail and dimensions. This process provides a high-quality finish and ensures that the bar meets specific ASTM standards.

Q: Why is stainless steel a preferred material for flat bars?

A: Stainless steel is preferred due to its excellent corrosion resistance, high-temperature resistance, and good mechanical properties. It typically includes chromium and nickel, which provide added durability and protection.

Q: What sizes are available for stainless steel flat bars?

A: Flat bars, such as the 3/8 x 1/2 size, are available in various lengths to suit different project requirements. Manufacturers often provide custom lengths upon request to meet specific customer needs.

Q: Can stainless steel flat bars be welded?

A: Yes, stainless steel flat bars can be welded. They are suitable for welding, making them ideal for creating strong, durable connections in a variety of structural and architectural applications.

Q: What is the significance of having chromium and nickel in stainless steel?

A: Chromium and nickel are crucial elements in stainless steel, providing excellent corrosion resistance and enhancing the material’s overall mechanical properties. Chromium helps form a protective layer on the steel surface, while nickel adds toughness and strength.

Q: How quickly can stainless steel flat bars be shipped to customers?

A: Depending on the manufacturer and availability, stainless steel flat bars can often be shipped quickly to meet customer demands. Many suppliers offer fast and reliable shipping options.

Q: Are there any special considerations for storing stainless steel flat bars?

A: To maintain their quality, stainless steel flat bars should be stored in a clean, dry environment. If stored outdoors, they should be covered to protect against moisture and other environmental factors.