ASTM A36

Structural Steel

The backbone of construction. We supply certified A36 plates and bars featuring the standard 29,000 ksi (200 GPa) elastic modulus for predictable structural performance.

Decoding the Number

Understanding "Stiffness" vs. "Strength" in Structural Engineering.

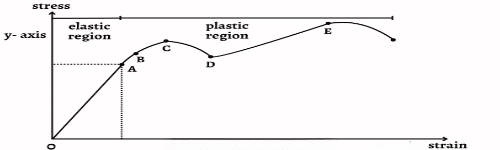

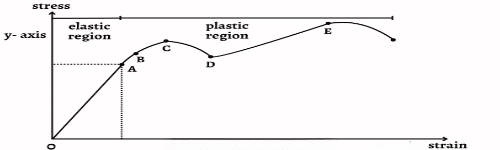

1. What is Elastic Modulus?

Also known as Young's Modulus (E), it measures the "stiffness" of the steel. It defines how much the material will stretch or bend under a given load before it permanently deforms.

Think of A36 steel as a very stiff spring. The Modulus (29,000 ksi) tells you how hard you have to pull that spring to stretch it.

2. Global Unit Conversions

| Unit System | Value | Common Usage |

|---|---|---|

| Imperial (US) | 29,000 ksi | Structural Design |

| Imperial (Alt) | 29 x 10⁶ psi | Lab Testing |

| Metric (SI) | 200 GPa | International |

| Metric (Alt) | 200,000 MPa | Mechanical Eng. |

Myth: High-strength steel (like A572-50) is stiffer than A36.

Fact: They have the same Elastic Modulus (29,000 ksi). Using expensive high-strength steel won't reduce deflection (bending). For stiffness-driven designs, A36 is the most cost-effective choice.

Beyond Stiffness: Strength Data

Elastic Modulus (29,000 ksi) is constant, but Yield Strength defines the grade.

Primary Applications for A36

Utilizing the 29,000 ksi Elastic Modulus for structural stability and deflection control.

Structural Framework

The standard choice for I-beams, H-beams, and channels in warehouse and high-rise construction where loads are static.

Bridge Components

Used for short-span bridge girders, pedestrian walkways, and guardrails where weldability and safety are paramount.

Machine Base Plates

Heavy A36 plates (up to 12" thick) provide a rigid, flat foundation for mounting motors, pumps, and generators.

General Fabrication

The "go-to" steel for storage tanks, agricultural equipment, and truck frames due to its low cost and ease of modification.

Available Forms & Sizes

Standard stock items ready for immediate shipment. All materials include Mill Test Reports (MTRs).

A36 Plate

⬜- Thickness 3/16" - 12.00"

- Widths 48", 60", 96", 120"

- Lengths 96", 120", 240", 480"

- Availability In Stock

Structural Shapes

🏗️- Angles (L) 1/2" to 8" leg

- Channels (C) 3" to 15" depth

- Beams (W/S) 4" to 24" depth

- Availability High Vol.

Bar Stock

📏- Round Bar 1/4" to 12" dia

- Flat Bar 1/8" to 3" thick

- Square Bar 3/8" to 4" side

- Availability In Stock

Need Custom Sizes?

Don't buy full plates if you don't need to. We offer value-added processing to deliver "project-ready" materials.

Technical FAQ

Common engineering queries regarding thermal and physical properties.

Does Elastic Modulus change with temperature?

For example:

- At 20°C (68°F):

E = 29,000 ksi - At 500°C (932°F):

E ≈ 20,000 ksi(Approx 30% reduction)

Is ASTM A36 steel magnetic?

Is A36 steel difficult to weld?

It can be welded using all standard methods (Stick, MIG, TIG) following

AWS D1.1 standards. Pre-heating is generally not required for sections thinner than 3/4".

What is the difference between A36 and 1018?

- ASTM A36 is a "Structural Grade" focusing on mechanical properties (Min Yield 36 ksi). It is typically

Hot Rolledwith a rougher mill scale finish. - AISI 1018 is a "Chemical Grade" focusing on precise composition. It is typically

Cold Rolled(Cold Finished), offering tighter dimensional tolerances, a smoother surface, and slightly higher yield strength (~54 ksi) due to work hardening.