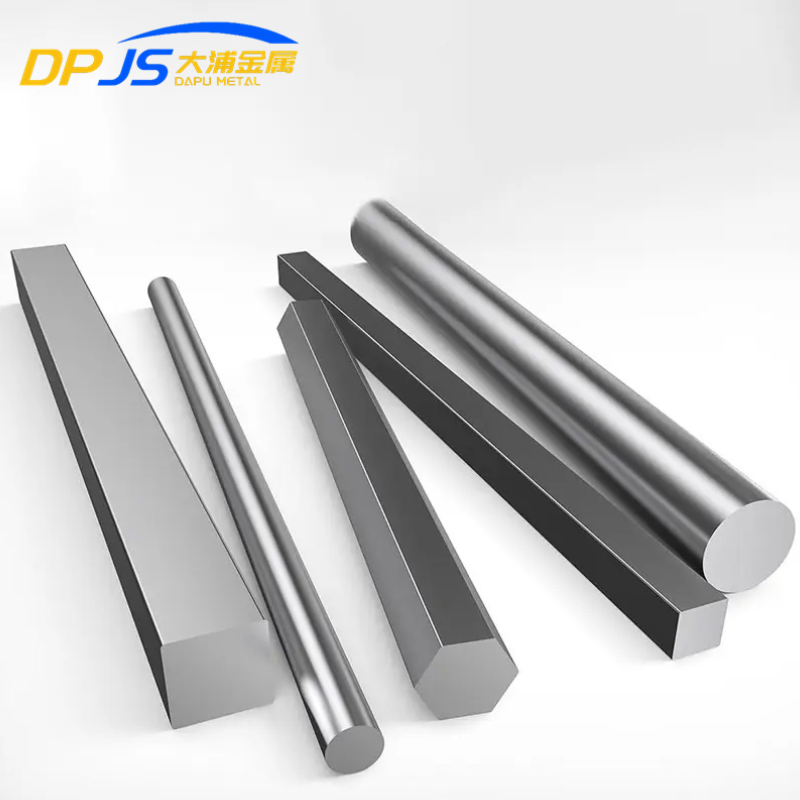

EN 1.4313 / UNS S41500 Stainless Steel Rod

Leading EN 1.4313 / UNS S41500 Stainless Steel Rod Manufacturer in China

EN 1.4313 (UNS S41500) is the premier choice for applications requiring an excellent combination of high strength, good toughness, and corrosion resistance. As a low-carbon martensitic stainless steel, its chemistry is balanced to provide superior weldability compared to other high-strength martensitic grades. This versatile, high-performance steel provides a robust and reliable solution for a wide range of demanding environments, including the oil and gas, hydropower, and chemical processing industries, delivering outstanding performance where mechanical integrity is crucial.

Discover high-quality EN 1.4313 / UNS S41500 Stainless Steel Rod products here.

Home » Stainless Steel Rod » EN 1.4313 / UNS S41500 Stainless Steel Rod

-

Characteristics of EN 1.4313 / UNS S41500 Stainless Steel

- High Strength & Good Toughness: Achieves an excellent combination of high tensile strength and superior toughness after heat treatment.

- Superior Weldability: The low carbon content significantly improves weldability over standard martensitic grades, minimizing cracking.

- Enhanced Corrosion Resistance: Offers good resistance to corrosion in freshwater, steam, and various mild chemical environments.

- Excellent Low-Temperature Properties: Retains good impact strength and ductility at sub-zero temperatures.

- Hardenable for Versatility: Its mechanical properties can be precisely tailored through heat treatment to meet specific application requirements for strength, hardness, and toughness.

- Good Fatigue Resistance: The balanced properties provide excellent resistance to fatigue failure, making it ideal for dynamically loaded parts like turbine blades, shafts, and valves.

- Good Machinability: Can be readily machined in both the annealed and quenched & tempered conditions, allowing for the fabrication of complex components.

- Cost-Effective Performance: Provides a high-performance, long-lasting solution for demanding engineering applications where carbon steels are inadequate.

EN 1.4313 / UNS S41500 Stainless Steel Technical Specifications

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.05 max |

| Chromium (Cr) | 12.0 - 14.0 |

| Nickel (Ni) | 3.5 - 4.5 |

| Molybdenum (Mo) | 0.3 - 0.7 |

| Manganese (Mn) | 1.5 max |

| Silicon (Si) | 1.0 max |

| Phosphorus (P) | 0.040 max |

| Sulfur (S) | 0.015 max |

| Property | Condition QT650 | Condition QT780 | Condition QT900 |

|---|---|---|---|

| Tensile Strength | 650 - 850 MPa | 780 - 980 MPa | 900 - 1100 MPa |

| Yield Strength (0.2% offset, min) | 520 MPa | 620 MPa | 800 MPa |

| Elongation (in 2 in.) | 16% min | 15% min | 12% min |

| Impact Energy (Charpy V-Notch) | ≥ 60 J | ≥ 55 J | ≥ 45 J |

| Property | Value |

|---|---|

| Density | 7.75 g/cm³ (0.280 lb/in³) |

| Modulus of Elasticity | 200 GPa (29.0 x 10⁶ psi) |

| Coefficient of Thermal Expansion (20-100°C) | 11.2 µm/m°C (6.2 µin/in°F) |

| Thermal Conductivity (at 20°C) | 25 W/m·K |

| Specific Heat Capacity | 430 J/kg·K |

- UNS: S41500

- EN (European): 1.4313

- X-Number: X3CrNiMo13-4

- ASTM: A182 Grade F6NM

- API: 6A (as material F6NM)

Common Applications of EN 1.4313 / UNS S41500 Stainless Steel

Hydropower & Power Generation

Oil & Gas Industry

Pump & Valve Manufacturing

Mechanical & Plant Engineering

-

EN 1.4313 / UNS S41500 Stainless Steel Rod Customization

In addition to standard stock, we offer comprehensive processing services to ensure products that meet your exact project requirements.

- Custom Dimensions: We offer precision cutting-to-length and centerless grinding services to match your specific diameter and length needs with tight tolerances.

- Heat Treatment Conditions: Rods are available in various quenched and tempered (QT) conditions, including QT650, QT780, and QT900, to achieve specific mechanical properties.

- Surface Finishing: Choose from multiple finishes, including cold drawn, smooth turned, polished, or a precision ground finish for the most demanding applications.

- Machining Services: We offer value-added fabrication, including CNC machining, threading, chamfering, and drilling, to deliver components ready for assembly.

Contact our technical team to discuss your custom fabrication needs.

Contact Us

Your project’s success hinges on the use of superior materials. We supply certified EN 1.4313 stainless steel rods that meet rigorous industry standards, ensuring absolute confidence in the performance and longevity of your application. As your dedicated partner, we utilize our vast inventory and advanced processing services to meet your exact specifications, from standard stock to fully customized and heat-treated components. We deliver not just a product, but a promise of unwavering quality and reliability for your most demanding projects.

Ready to begin? Contact our expert team for a detailed, no-obligation quote and professional material consultation. We are here to discuss your technical requirements and provide a tailored solution with competitive pricing and on-time delivery. Let us simplify your procurement process and help bring your project to life with the support it deserves. Send your inquiry now to secure the premium materials you need.

Latest Articles ※