Yellow Zinc vs

Stainless Steel

Chemical Protection Methods

The difference in longevity lies in how each material interacts with oxygen and moisture at the molecular level.

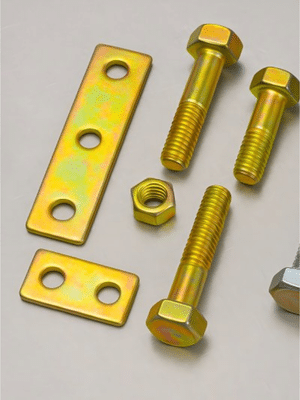

Yellow Zinc Plating

Yellow zinc is a two-stage coating applied to carbon steel. First, a layer of zinc is electroplated to the surface. Second, a yellow chromate film (Hexavalent or Trivalent) is applied to seal the zinc.

- Mechanism: The zinc acts as a "sacrificial" layer, corroding before the base steel is attacked.

- The Barrier: The yellow chromate dye provides an additional 24-48 hours of protection over clear zinc.

- Vulnerability: Once the thin zinc layer is scratched or depleted, the raw steel beneath rusts rapidly.

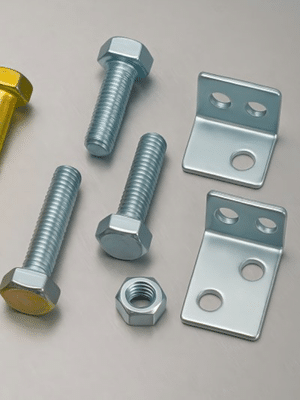

Stainless Steel (304/316)

Unlike plated steel, stainless steel is a homogeneous alloy. It contains a minimum of 10.5% Chromium, which reacts with oxygen to form an invisible, microscopic Passive Layer of Chromium Oxide.

- Mechanism: The material does not rely on a coating; the protection is integrated throughout the entire metal.

- Self-Healing: If the surface is scratched, the chromium oxide layer "re-heals" itself instantly in the presence of oxygen.

- Durability: Highly resistant to pitting and crevice corrosion in chlorides and high-moisture environments.

Salt Spray Benchmark

Comparing standardized ASTM B117 salt spray test results for industrial fasteners and components.

| Material / Coating | White Rust (Hrs) | Red Rust (Hrs) | Best Environment |

|---|---|---|---|

| Yellow Zinc (Cr6+) | 48 - 72 | 96 - 120 | Indoor / Dry Warehousing |

| Yellow Zinc (Cr3+) | 24 - 48 | 72 - 96 | Indoor / Automotive Interior |

| Stainless Steel 304 | N/A | 800 - 1,500+ | Outdoor / Humid / Food Grade |

| Stainless Steel 316 | N/A | 2,000 - 5,000+ | Marine / Chemical Processing |

🏔️ Rural / Indoor Highly Recommended

Both materials perform excellently. Yellow Zinc is the smarter choice here for cost-efficiency unless aesthetics require a silver finish.

🏗️ Urban / Industrial Zinc: Conditional

Yellow zinc will begin to dull and spot within 1-2 years. Stainless Steel 304 is recommended for exposed architectural elements.

🌊 Marine / Coastal Zinc: Avoid

High chloride levels will strip yellow zinc in months. Stainless Steel 316 is mandatory to prevent structural failure and tea-staining.

Yellow Chromate Finish

Metallic Luster

Color Evolution Over Time

Initial Install

Zinc is bright and "rainbow-like." Stainless is crisp and reflective.

5 Years Exposure

Zinc fades to a dull brown/grey as chromate erodes. Stainless remains unchanged with simple cleaning.

Surface Finish &

Application Branding

Material choice often doubles as a branding signal. The finish tells the end-user whether the product is built for "Heavy Duty Industrial" use or "Precision Premium" performance.

- Yellow Zinc: Often associated with automotive engine bays, hydraulic systems, and internal structural hardware where a "pro-industrial" look is desired.

- Stainless Steel: The universal symbol of hygiene, luxury, and high-tech. Essential for consumer-facing products or "white-room" environments like labs and kitchens.

- The "Fake Gold" Factor: Yellow zinc is frequently used as a budget-friendly aesthetic alternative to brass or gold plating in non-critical decorative fasteners.

Initial Savings vs. Long-Term Value

Understanding the financial impact of material failure and replacement cycles.

Yellow Zinc Plated Steel

- Production Cost: Economical

- Installation: Standard

- Maintenance: High (Rust Risk)

- Replacement: 3-5 Years

Best for high-volume, cost-critical parts with limited environmental exposure.

Stainless Steel (316 Grade)

- Production Cost: Higher (Alloy Cost)

- Installation: Precision Required

- Maintenance: Zero to Minimal

- Replacement: 25+ Years / Lifetime

The strategic choice for critical infrastructure and marine projects.

The "Hidden Cost" of Failure

While yellow zinc saves 60-70% on initial procurement, the True Cost includes labor for replacement, system downtime, and potential structural damage. If a part requires replacement twice within a 10-year span, Stainless Steel becomes the cheaper option.

Procurement Pro-Tip

"Inland industrial projects can often utilize Yellow Zinc safely, saving significant capital for other components. However, if the project is within 5 miles of a coastline, the premium for Stainless Steel is effectively insurance against catastrophic rust failure."

Common Technical Queries

Optimize Your Bill of Materials

Unsure which grade is right for your project? Speak with an SS Alloy Steel technical advisor for a custom material analysis.