Copper was always respected for the versatility offered by it and for its necessity in modern industries. Electrical wire, plumbing, artistic drippings, and even advanced alloys—there is hardly any sphere of life that does not see copper put to some use. Still, arrived yours ever into the question of how copper—the reddish-brown metal—can somehow carry so much versatility and importance? One is the melting point—an essential property that determines the usability of copper in various fields. This article will attempt an insight into copper’s melting point, its significance, and how this critical property of copper facilitates respecting demands of both old technology and the new. And so, for the enthusiast, student, or industry professional, this blog will explore copper’s melting point from the scientific perspective to an explanation of its importance an engaging way.

Introduction to Copper

Historical Significance of Copper

Copper is one of the earliest metals used by man, with important technological and cultural implications. The discovery of copper has been assumed to have taken place around 9000 BCE, with some archeological evidence pointing to its use in the Middle East. Early peoples made use of native copper—this means copper found in pure metallic form—for their tools, weapons, and ornaments. Copper used so extensively brought forth the onset of the Chalcolithic age, or Copper Age, when copper came to be increasingly utilized in preference to stone for various uses.

In combination with tin, copper would forge a landmark alloy that characterized the Bronze Age (roughly 3300-1200 BCE). First appearing around 3500 BCE, this innovation saw the dramatic improvement of durability and utility of tools and weapons, so civilizations could develop in agriculture, warfare, and trade. The so-called ‘major ancient societies’—the Mesopotamians, Egyptians, and Chinese—had relied heavily on copper and its alloys for the development and advancement of their cultures. The malleability of the metal also allowed it to be used in artistic applications, as demonstrated by the intricately worked jewelry and statues of these cultures.

Since antiquity, copper has remained a necessary tool in the development of metallurgy and engineering. The Industrial Revolution saw new methods of copper extraction and refining, so that copper was being used for electrical wiring and machinery. Considering all the various ways copper survives into modern technology, it is a testament to the spirit of humanity—an expression of the fusion of human thought and creativity over millennia. Its great importance is wrapped not only in artwork but also in the history of human societies and their development.

Common Forms of Copper

Copper occurs in various forms suitable for different purposes, depending on its unique properties. Pure copper is among the very common forms prevalent in electrical wiring due to its superior conductivity and malleability. This type of copper is generally refined to the highest levels of purity to ensure the highest performance in electrical and electronic systems.

This other usual type comprises copper alloys, where copper is mixed with other metals to achieve desired properties for specific applications. Brass (copper and zinc) and bronze (copper and tin) are two well-known varieties. Brass is used in appliances, decorative items, and plumbing fixtures because of its bright look and corrosion resistance. Bronze is favored for its strength in Sculpting and in bearing and marine jobs.

Copper can also be bought in industrial forms such as sheets, pipes, and rods, which are essential in construction, industrial manufacturing, and transportation. Copper pipes, in particular, are generally used by plumbing systems because copper does not easily rust in the presence of water and can withstand very high temperatures. Copper is available in so many types and forms that it continues to play an important role in traditional applications as well as industries of the new era.

Fundamental Properties of Copper

Copper is characterized as a highly versatile and concrete metal with all of its essential properties unique to it. One of the most noteworthy properties is its superior thermal and electrical conductivity, which has made it an indispensable element in electrical wiring and electronic components. Copper has the best electrical and thermal conductivity in metals, only surpassed by silver, which makes it an economically viable alternative for heavy industrial and domestic uses.

An equally important property of copper is corrosion resistance. Copper slowly reacts with oxygen to form a protective patina after some years and this layer, in turn, prevents further corrosion, thus ensuring the longevity of the metal. This is the characteristic that makes it good for pipes, roofing, and marine applications where durability is important.

Copper, malleable with ductility, can be shaped or stretched without breaking. Because of these properties, applications requiring flexibility are the design and synthesis of wires, sheets, and intricate parts. Meanwhile, being antimicrobial, it also finds use in health care to keep harmful microorganisms from spreading over frequently touched surfaces. These properties of copper thus make it an asset across a range of industries.

Understanding the Melting Point of Copper

What is the Melting Point of Pure Copper?

Key Fact: The melting point of pure copper is 1,084.62 degrees Celsius (1,984.32 degrees Fahrenheit).

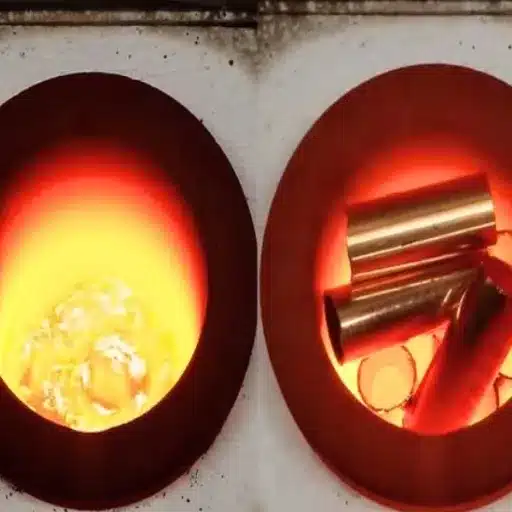

This particular temperature is the transition point between the solid and the liquid states of copper, under normal atmospheric pressure. The higher melting point is another motivation of copper utilization where it is needed to remain stable at high temperatures, like in electrical components, industrial machinery, and heat exchanger-related apparatus.

It is due to its melting point that copper is considered very consistent and reliable in processing within manufacturing plants. As a good thermal conductor, it means copper can retain heat very well so that one can control heat with better precision during processing operations like casting, welding, and alloying. This is plus especially in the copper alloy industries, where copper is allied with small amounts of other metals such as zinc and tin to bestow certain characteristics upon the alloy, such as strength or corrosion resistance.

Additionally, the melting point often varies in the real-world cases of copper alloys or impurities. In very minute small percentages, impurities or alloying elements may alter the melting point of the original material, sometimes slightly lowering it or sometimes slightly raising it; this depends on the very nature of their composition. It is necessary that we use this law when going through advanced manufacturing/metallurgical processes to provide precise temperature control because the quality and functionality of the product depend on it. Consequently, the melting point of copper is a basic property and an important factor involving its wide industrial application.

Factors Affecting the Melting Point of Copper

🔍 Factors to Consider

1. Alloying Elements: When copper is alloyed with metals such as zinc, tin, or nickel, variations in the melting point may appear dependent on composition. For example, brass (copper with zinc) has a lower melting temperature compared to pure copper.

2. Impurities: Impurities introduced during extraction or processing can alter the melting behavior, thereby influencing application performance where dimensional accuracy is critical.

3. External Pressure: Under high-pressure environments, the melting point can increase because copper exhibits delayed vibrations of atoms, appearing thermally more stable.

4. Vacuum or Low Pressure: In low-pressure environments, the potential for vaporization becomes an issue in accurately discerning the melt transition.

5. Nanoscale Structure: Smaller particles of copper possess the characteristic melting point depression effect because of high surface-area-to-volume ratio and increased atomic activity at its surface.

Copper melts around 1,984°F (1,085°C), and such behavior may be affected by a number of factors, chiefly by interactions with alloying elements or environmental conditions. This occurs because the atomic structure has been disrupted by alloying, and so has the physical pathway for transitioning into a liquid.

Modern technologies and untamed experimentation have permitted some scientists to explore how nanoscale structure influences the melting point of copper. This phenomenon renders nano-copper potentially useful for many applications in low-temperature processing techniques—on microelectronics and sensors. The insights into this reveal the very complication of the factors impinging on copper melting point, hence showing its great adaptability and utility to various fields of industry and science.

Comparison of Melting Points: Copper vs. Other Metals

The melting point of copper is 1084°C (1983°F), which is lower than that of cast iron (1204°C) but higher than that of gold (1063°C), lead (328°C), or most copper alloys (913-1082°C).

| Metal | Melting Point (°C) | Melting Point (°F) | Key Use |

|---|---|---|---|

| Copper | 1084 | 1983 | Electrical wiring, heat exchangers |

| Cast Iron | 1204 | 2199 | Engine blocks, cookware |

| Gold | 1063 | 1945 | Jewelry, electronics |

| Brass | 913-927 | 1675-1700 | Plumbing fixtures, musical instruments |

| Bronze | 950-1082 | 1742-1980 | Bearings, sculptures, marine hardware |

| Lead | 328 | 622 | Batteries, radiation shielding |

| Aluminum | 660 | 1220 | Aircraft, packaging, construction |

| Steel | 1370-1540 | 2500-2800 | Construction, automotive, tools |

Applications of Copper Based on Its Melting Point

Use in Electrical Wiring

Electrical wiring is the most crucial application of copper, and its melting point plays an important role in ensuring safety and efficiency. Copper conducts electricity much better than most other metals—second only to silver—making it the preferred material for power transmission, household wiring, and electronics. The relatively high melting point of copper ensures that wires can handle electrical currents without softening or losing integrity, even when heat is generated during operation.

The stability of copper at elevated temperatures prevents risks associated with overheating, such as melted insulation or electrical fires. This reliability makes copper indispensable in residential, commercial, and industrial electrical installations, where safety and long-term performance are paramount. In addition to its thermal stability, copper’s malleability allows for easy bending and shaping during installation without compromising its strength or conductivity.

Copper also excels in managing high-voltage applications, such as in transformers and power grids, where consistent performance under thermal stress is essential. Furthermore, its resistance to oxidation ensures that connections remain efficient over time, reducing maintenance requirements. The combination of conductivity, durability, and thermal resilience makes copper the backbone of modern electrical infrastructure.

⚡ Key Advantages of Copper in Electrical Wiring

✓ Superior Conductivity: Copper boasts exceptional electrical conductivity, enabling efficient energy transfer with minimal power loss, making it ideal for power transmission.

✓ Thermal Stability: With its high melting point, copper maintains structural integrity at elevated temperatures, ensuring safe operation under high electrical loads.

✓ Corrosion Resistant: Copper resists oxidation and corrosion, providing long-lasting performance and reducing the need for frequent maintenance or replacement.

✓ Flexible and Malleable: Copper wires can be easily shaped and routed through complex pathways without breaking, simplifying installation processes.

✓ High Tensile Strength: The tensile strength provides durability and withstanding mechanical stress applied on it, suitable for installation in tension or heavy handling.

These properties, along with its abundance and low price, have made copper the first choice in many industries for electrical wiring.

Role in Heat Exchangers and Plumbing

🔧 Why Copper Excels in Heat Exchangers & Plumbing

Excellent Thermal Conductivity: Copper, with its high thermal conductivity, transfers heat very well and so is used as a primary material for heat exchangers in HVAC systems, refrigerators, and other scaling industrial processes.

Corrosion Resistance: Copper is highly corrosion-resistant, giving plumbing systems and heat exchanger applications a long life and low maintenance, even in environments where moisture levels can be high and chemicals aggressive.

Antimicrobial Properties: Copper, by nature, inhibits the growth of harmful bacteria and microbes and thus provides for safer water distribution systems while enhancing the sanitation of plumbing applications.

Malleable and Ductile: It is malleable and ductile, allowing it to be easily shaped and installed in complex plumbing networks and heat exchanger designs, thus saving labor and installation costs.

Pressure & Temperature Tolerant: Being malleable under pressure and temperature fluctuations, copper allows heat transfer or high-pressure plumbing systems to work efficiently under heavy loads without being structurally compromised by the pressure.

Industrial Components Requiring Excellent Thermal Conductivity

Industrial processes require materials with extreme thermal conductivity for the assurance of efficient operations and maintenance of reliability in service. Among the metals used, copper stands out, as it swiftly and constantly transfers heat. Among some of the heavy industrial applications are the heat exchangers that require fast heat management. Copper with its superior thermal conductivity properties is preferred in such devices to convey heat from one medium to another—two liquids or gases—so that the hardware performs well and energy-efficiently. Essentially, copper is indispensable in those systems where heat transfer should occur with low energy loss in cooling or heating processes. It is also less prone to deterioration caused by thermal stresses, which keeps maintenance significantly low and extends the system’s life and performance.

Another vital application is in electrical and mechanical systems where transformers, motor coils, or electrical wires act as good thermal conductors. Industrial electrical motors tend to generate a lot of heat while working, thus posing performance and safety hazards. Copper’s property of being both an electrical and thermal conductor enables it to dissipate heat generated when conducting the electric current, thus eliminating overheating and the possibility of failure. This feature is exceptionally important in cases of high-powered systems where steady operations equate directly to being productive.

With the modern developments, copper was also introduced into cooling systems that included high-performance type radiators and heat sinks for advanced machinery and electronics. These technologies require heat to be taken away as fast as possible to stay stable and avoid component damage. The versatility of copper in these high-performance cooling systems not only ensures maximum operational efficiency but also supports environmentally sustainable practices through energy conservation. Copper remains, therefore, a much sought material for thermal management industries, aiming for better heat dissipation and reliable system performance from high-level heavy machinery down to cutting-edge digital devices.

References

- 📚

Princeton University – Copper : This page provides detailed information about copper, including its melting point of 1083°C. - 📚

MIT – Copper (Cu): A resource from MIT detailing copper’s properties, including its melting point of 1083°C. - 📚

PubChem – Copper (Cu): A comprehensive entry on copper, listing its melting point as 1083°C.

Frequently Asked Questions (FAQ)

❓ What is the melting temperature of copper?

It is approximately 1,984°F (1,085°C). So, from now on, this temperature will be useful in many applications like welding and working with molten copper.

❓ How are the melting temperatures of copper and other metals compared?

It is thus, this melting point is higher than many common metals, such as aluminum, which melts at about 1,221°F (660°C). At the same time, it is lower than tungsten, which melts above 6,192°F (3,422°C).

❓ What factors influence the melting point of copper?

The melting point of copper changes with the changes in purity and presence of alloying elements. For example, copper alloys with zinc might have a different melting temperature.

❓ What occurs during the melting process of copper?

Upon melting heat is absorbed by the solid atoms of copper, which make them vibrate faster until they melt in the liquid state. With respect to various manipulations, copper may be cast into forms such as copper wires or decorative pieces.

❓ What does the melting point of copper mean to the welding operation?

The melting point of copper is critical in the operation of welding, because it tells the welders how much heat should melt copper without impairing the other materials in its vicinity.

❓ What are some uses of molten copper?

Molten copper is used in many processes to manufacture copper wires and other copper alloys, because of its excellent conductivity.

❓ Do impurities affect the melting temperature of copper?

Impurities in copper may either increase or reduce the melting temperature, depending on the nature of the contaminating elements. Certain impurities will create a copper that melts at a lower temperature than the pure copper.

❓ The melting point of a copper wire is?

As far as copper wire is concerned, its melting point is more or less the same as that of solid copper: 1,984°F or 1,085°C. Wire dimension and structure would definitely affect behavior of copper wire when subjected to heat during melting operations.

🔑 Key Takeaway

Understanding copper’s melting point of 1,084.62°C (1,984.32°F) is essential for optimizing its use across electrical, plumbing, and industrial applications. This fundamental property, combined with copper’s exceptional conductivity, corrosion resistance, and malleability, makes it an irreplaceable material in modern technology and manufacturing processes.