The industries of construction, manufacturing, electronics, and transportation are just a few examples of industries based on metals. Additionally, given that there is a variety of metals, each having diverse properties and characteristics, the use of the right metal in the optimal way is essential. This comprehensive guide explores the key aspects of metals, their uses, and characterizations to help you make informed decisions for your projects.

Overview of Different Types of Metal

Metallic substances are generally categorized into two main groups: ferrous and non-ferrous metals.

Ferrous Metals

Contain iron as their primary component. Highly valued in construction, shipbuilding, and automobile industries for their high density and resilience.

Non-Ferrous Metals

Do not contain significant amounts of iron. Resistant to rust and corrosion, often lightweight. Include aluminum, copper, and titanium.

Common Metals and Their Characteristics

| Metal | Key Properties | Common Applications | Corrosion Resistance | Density (g/cm³) | Conductivity |

|---|---|---|---|---|---|

| Aluminum | Lightweight, high corrosion resistance | Aerospace, transportation | High | 2.7 | Excellent |

| Copper | Excellent electrical conductivity | Electronics, wiring | Moderate | 8.9 | Superior |

| Titanium | High strength-to-weight ratio | Medical implants, aerospace | Outstanding | 4.5 | Moderate |

| Iron | Strong, durable | Construction, machinery | Low | 7.9 | Poor |

| Steel | Versatile, cost-effective | Infrastructure, tools | Depends on alloy | ~7.8 | Moderate |

| Gold | Non-reactive, excellent malleability | Electronics, jewelry | Very High | 19.3 | Good |

| Silver | Best electrical conductivity | Electronics, jewelry | Low | 10.5 | Superior |

| Nickel | Hard, corrosion-resistant | Batteries, plating | High | 8.9 | Moderate |

| Magnesium | Lightweight, highly reactive | Automotive, aerospace | Low | 1.7 | Moderate |

| Zinc | Corrosion-resistant, low cost | Galvanizing, die-casting | High | 7.1 | Poor |

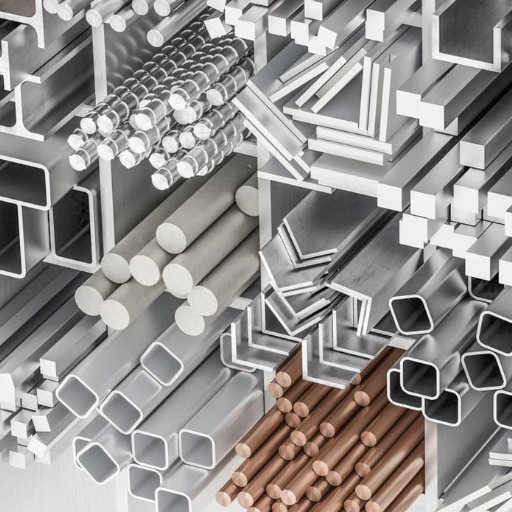

Overview of Alloys and Their Uses

Steel (Iron + Carbon and other elements)

- Key Properties: High tensile strength, ductility, and durability

- Applications: Construction (beams, bridges), automotive (frames, parts), and tools

- Density: 7.8 g/cm³

- Advantages: Versatility and cost-effectiveness make it one of the most widely used materials globally

Brass (Copper + Zinc)

- Key Properties: High corrosion resistance, excellent machinability, and good acoustic properties

- Applications: Musical instruments, plumbing fittings, and decorative elements

- Density: 8.4 g/cm³

- Advantages: Aesthetic appeal and ability to resist tarnish

Stainless Steel (Iron + Chromium, Nickel)

- Key Properties: Exceptional corrosion resistance, heat resistance, and aesthetic finish

- Applications: Kitchenware, medical equipment, and chemical processing

- Density: 7.9 g/cm³

- Advantages: Long lifespan and low maintenance in harsh environments

Bronze (Copper + Tin)

- Key Properties: High wear resistance, low friction against other metals, and superior thermal conductivity

- Applications: Bearings, bushings, and historical statues

- Density: 8.8 g/cm³

- Advantages: Durability and resistance to saltwater corrosion

Aluminum Alloys (Aluminum + Magnesium, Silicon, Copper, or Zinc)

- Key Properties: Lightweight, corrosion resistance, and excellent machinability

- Applications: Aerospace, automotive body panels, and beverage containers

- Density: 2.7 g/cm³

- Advantages: Favorable strength-to-weight ratio and recyclability

Titanium Alloys (Titanium + Aluminum, Vanadium)

- Key Properties: High strength, lightweight, and resistance to extreme temperatures and corrosion

- Applications: Aircraft components, medical implants, and marine equipment

- Density: 4.5 g/cm³

- Advantages: Biocompatibility and exceptional performance under demanding conditions

Properties of Metals

Metals possess unique physical and chemical properties that make them valuable across various applications:

Conductivity

Excellent conductors of heat and electricity due to mobile valence electrons. Copper and silver are prime examples.

Malleability & Ductility

It can be shaped into desired forms (malleability) and drawn into wires (ductility). Aluminum exemplifies these properties.

Strength & Hardness

Resist shape changes and surface indentation. Steel and copper demonstrate exceptional strength and hardness.

Corrosion Resistance

Some metals, like stainless steel and aluminum, resist degradation in harsh environments.

Luster

They have a characteristic metallic shine when polished, making them ideal for decorative and reflective applications.

Metal Identification Methods

Traditional Identification Techniques

- Magnet Test: Determine if the metal is ferrous or non-ferrous using a strong magnet

- Color and Visual Inspection: Examine surface characteristics, color, and texture

- Weight and Density: Compare relative weights and calculate density

- Spark Test: Observe spark patterns when grinding ferrous metals

- Scratch or Hardness Test: Test resistance to scratching

- Chemical Testing: Use acids to observe reactions

- Thermal Conductivity Test: Examine heat transfer properties

Modern Identification Methods

- X-Ray Fluorescence Spectroscopy (XRF): Non-destructive elemental analysis

- Optical Emission Spectroscopy (OES): Uses spark excitation for composition analysis

- Laser-Induced Breakdown Spectroscopy (LIBS): Portable on-site analysis capability

Applications of Different Metal Types

Key Application Areas

- Aluminum: Aerospace, construction, automotive, food packaging

- Stainless Steel: Medical equipment, kitchen appliances, building components

- Copper: Electrical systems, water supply, heating networks, renewable energy

- Carbon Steel: Building construction, equipment manufacturing, tool production

- Titanium: Aerospace engineering, medical applications, sports equipment

Metals in Construction and Architecture

Metals play crucial roles in modern construction due to their robustness, flexibility, and aesthetic appeal:

- Structural Steel: Essential for skyscrapers, bridges, and industrial facilities due to incredible tensile strength

- Stainless Steel: Preferred for marine structures and arid climate construction due to corrosion resistance

- Aluminum: Ideal for curtain walls, cladding systems, and window structures due to lightweight properties

- Copper: Used in plumbing, electrical systems, and roofing with added antimicrobial benefits

Selecting the Right Metal for Your Project

Key Considerations

- Application Requirements: Identify specific mechanical, electrical, chemical, thermal, or corrosion resistance needs

- Environmental Conditions: Consider operating environment stress levels and temperature requirements

- Cost vs. Performance: Balance performance requirements with budget constraints

- Budget and Durability: Consider long-term costs including maintenance and replacement

- Environmental Impact: Evaluate carbon footprint, recyclability, and sustainable sourcing

Environmental Impact of Metal Selection

Modern engineering increasingly considers environmental factors in metal selection. For example:

- Primary aluminum production requires 14,000 kWh per ton, while recycling uses only 5% of that energy

- Stainless steel and copper offer excellent recyclability potential

- Life cycle analyses help minimize total environmental costs through sustainable sourcing and low-carbon processes

Emerging Trends in Lightweight and Sustainable Alloys

Current developments focus on creating lightweight alloys that maintain strength and environmental resistance:

- Advanced Magnesium Alloys: Enhanced processing techniques for improved performance

- Aluminum-Scandium Alloys: High strength with cost benefits over premium materials

- Rare-Earth Enhanced Magnesium: Improved creep and heat resistance for high-temperature applications

- Solid State Joining Technologies: Innovative processing methods reducing environmental impact

Reference Sources

-

AAS Detection of Heavy Metal in Sheep Cheese (Banat Area, Romania)

- Key Findings: The study analyzed the presence of heavy metals in sheep cheese and found extremely low levels, making detection challenging.

- Read more

-

Simple Attenuation Models of Metallic Cables for G.fast Frequencies

- Key Findings: Developed models for metallic cables, focusing on attenuation characteristics relevant to G.fast frequencies.

- Read more

-

Metal Complexes from Aryl and Hetarylazocompounds

- Key Findings: Synthesized 3d-metal coordination compounds with specific coordination sites using pyrazole and quinoline fragments.

- Read more

Frequently Asked Questions

Q: What are the different types of metal based on their properties?

A: Metals can be classified into ferrous (containing iron, magnetic, strong) and non-ferrous (lighter, rust-resistant like aluminum and copper) categories. Precious metals (gold, silver) are valued for rarity and corrosion resistance. Understanding these classifications helps in metal identification and selection for specific applications.

Q: How can you identify metals using different identification methods?

A: Metal identification involves visual inspection, chemical tests, periodic table reference, hardness testing, and conductivity measurement. Magnet tests quickly indicate ferrous metals. Modern methods include XRF spectroscopy and LIBS for precise elemental analysis.

Q: What are alloys and how do they differ from pure metals?

A: Alloys are mixtures of two or more metals or a metal with another element, enhancing specific properties. For example, brass (copper + zinc) offers strength and corrosion resistance. Pure metals have distinct properties but may lack the versatility of tailored alloys designed for specific applications.

Q: What is the significance of melting point in metals?

A: Melting point affects usability in various applications. Low melting point metals like aluminum are easier to work with, while high melting point metals like tungsten suit high-temperature applications. This property is vital for manufacturing processes and metal recycling.

Q: What are base metals and how do they compare to precious metals?

A: Base metals (copper, zinc, nickel) are abundant and less expensive, used primarily for structural purposes. Precious metals (gold, platinum) are rare, valuable, and corrosion-resistant, typically used in luxury goods and high-tech applications. The distinction lies in economic value, rarity, and specialized applications.