The increasing demand for stainless steel worldwide has been construed based on the steel’s ability to stand unparalleled strength, resisting corrosion with incredible pest control applications. From finding uses in building skyscrapers to working on medical instruments needing minute engineering, stainless steel has established itself as the cornerstone of modern industry and innovation. The article sheds light on the leading manufacturers and their advancements in fabrication methods, making drastic improvements in sustainable practices, and coming to terms with product innovation to meet both present and future demand. Whether you practice engineering, have sustainability as your passion, or are just a lapsed industry enthusiast, this comprehensive overview will have its glamorized spotlight on the part that manufacturers play in stainless steel’s future. Stay arrayed to learn how innovation and expertise foster an industry powering the world.

Overview of Stainless Steel Manufacturing

What is Stainless Steel?

Stainless steel is an exceedingly strong and corrosion-resistant alloy mainly consisting of iron, chromium, and smaller proportions of various elements, such as nickel, molybdenum, and carbon. Its distinguishing feature is resistance to rust and oxidation; thus, the chromium content must be at least 10.5%. This chromium develops a thin and transparent oxide coating, known as the passive layer, on the surface of stainless steel, preventing further corrosion. Due to its durability and resistance, stainless steel finds myriad applications across many industries.

Types of Stainless Steel:

- Austenitic: Excellent corrosion resistance, high ductility, and non-magnetic

- Ferritic: Moderate corrosion resistance, mainly for automotive and industrial systems

- Martensitic: Can be hardened and tempered for high strength and wear resistance

- Duplex: Outstanding strength and resistance to stress corrosion cracking

- Precipitation-hardened: Specialized applications requiring enhanced mechanical properties

Stainless steel has been valued as an adaptable material that can resist very harsh environments. Being heat-resistant and hygienic, the material is employed in construction, food processing, medical instruments, aerospace, and chemical processing. It is also considered sustainable since it is recyclable without losing any properties essential to its use; thus, it fits an environmentally friendly category. These performing qualities, durability, and sustainability together account for the significant presence of stainless steel in contemporary manufacturing and infrastructure development.

History and Evolution of Stainless Steel

Resisting corrosion and maintaining strength were the first attributes of stainless steel discovered in the early 20th century. Usually recognized as being invented by Harry Brearley of Sheffield, England, who, in 1913, developed an alloy with approximately 12.8% chromium. This chromium-containing alloy would resist rusting, a property not exhibited by ordinary steels. This moment marked the initial commercial and industrial attention given to stainless steel.

Throughout the 20th century, the composition and production of stainless steel underwent continual changes to fulfill various requirements set by the industry. Through studying the variations of chromium, nickel, and carbon, numerous steels were developed, namely austenitic, ferritic, and martensitic stainless steels. For example, the addition of nickel in the formation of austenitic stainless steel largely enhanced ductility and corrosion resistance and made it an ideal option for chemical processing and cookware applications. Ferritic stainless steel, on the other hand, gained popularity due to its low carbon content and relatively low price and was more commonly used in automotive and architectural work.

Mass production of high-purity stainless steel is made possible through the introduction of other technologies of production, such as the Argon Oxygen Decarburization process during the 20th century. The field of application, consequently, was enlarged to encompass medicine, aerospace, and construction. With innovations in alloy compositions and surface finishes, stainless steel will continue to evolve to stay relevant to solve present-day engineering problems and sustainability goals.

Key Properties of Stainless Steel

🛡️ Corrosion Resistance

The most noteworthy property, features a minimum of 10.5% chromium that forms a passive oxide layer, rendering it immune to rust in hostile environments.

💪 Mechanical Strength

Excellent tensile strength, impact strength, and high-temperature capability, enabling it to sustain heavy stresses and strains for extended periods.

♻️ Recyclability

Highly versatile and recyclable, making it relevant to modern environmental and sustainability issues while maintaining quality through recycling.

Industry Applications of Stainless Steel

Stainless Steel in Construction

The stainless steel industry saw milestones in real estate in the past few decades, and continues to tailor this sector to all needs, being mainly popular for its durability, corrosion resistance, and private aesthetic options. Structurally, stainless steels find applications in designing elements that need strength and longevity for load-bearing beam-like applications and supports, and reinforcement. Due to corrosion resistance, the best applications are marine environments, locations exposed to harsh climates, or even pollutants, thus cutting down on maintenance expenses.

The corollary of this for the design arts lies in the use of cladding systems, roofing, and façades. Some of these projects are high-profile as stainless maintains both the structural integrity and appearance for decades. For instance, in landmark architectural edifices such as the Chrysler Building, New York, the finishing has become an architectural feature in itself because of stainless steel’s reflective qualities and resistance to tarnishing.

According to industry reports, stainless steel in construction is viewed to be a steadily growing market owing to its suitability for sustainable building practices. This stainless steel is recycled in keeping with green construction practices, and with lifecycle cost maintenance, its further adoption is guaranteed. Stainless steel enhances the resilience of the built environment, keeping modern and future edifices secure yet aesthetically viable.

Use of Stainless Steel in the Automotive Sector

Stainless steel carries great importance in the modern automotive industry, with its unique amalgamation of mechanical properties, corrosion resistance, and sustainability. Stainless steel is used by automotive manufacturers in critical areas such as underbody, exhausts, fuel tanks, chassis structures, and decorative trim, where endurance and performance matter the most. Due to its high tensile strength, it is used in those automotive components that have to withstand great amounts of stress or impact and to resistance against rust, thereby ensuring a long life even in the harshest of environmental conditions.

🚗 Key Automotive Applications:

- Underbody components – Protection against road salt and corrosion

- Exhaust systems – High-temperature resistance and durability

- Fuel tanks – Chemical resistance and safety

- Chassis structures – Structural integrity and weight reduction

- Decorative trim – Aesthetic appeal and longevity

The material actively supports the weight reduction process, considering the application of the latest grades of stainless steel that allow the engineers to develop thinner yet dimensionally strong automotive parts. Lesser weight on the vehicle, in return, helps in better fuel efficiency and is also aligned with stringent regulations on emissions to curb downhill impact upon the environmental impact. In addition, stainless steel being recyclable is one of the vital features of closing rounds in the economy of this sector. Studies reveal that stainless steel can be recycled infinitely without losing quality, hence it should be categorized by every manufacturer trying to fulfill sustainability goals.

With the recent advances in alloy technology, also comes in the making of high-performance stainless steel with improved heat resistance and formability. The above stands true for EVs in particular, wherein the material supports the design of battery housings and thermal management systems. As the global EV market grows at an unprecedented pace, so shall the demand for stainless steel in automotive production, which, in turn, tries to stresses its crucial role in satisfying the demands the automotive sector has right now and will have in the immediate future.

Medical Equipment and Stainless Steel

When we think of metals used in the medical field, one considers stainless steel: corrosion-resistant, biocompatibility traits, and quite easy to sanitize. Stainless steels such as 304 and 316 are general-purpose varieties well suited for producing surgical instruments, implants, and hospital furniture. These steel grades have non-porous surfaces that do not encourage bacterial growth and hence, guarantee levels higher in hygiene and patient safety. While stainless steel offers structural advantages, it also offers an economical option for items needing repeated cleaning cycles and wear over time.

Recently, in advanced medical technologies, stainless steel has enjoyed increased demand. For instance, stainless steels find their usage in robotic-assisted surgical systems and 3D-printed implants, speaking about the versatility given to this metal in high-end applications. Further, the fallout of minimally invasive procedures is seen in the designing of precision instruments made up of high-strength stainless steel alloys.

The medical world, by putting the health of billions onto the unmatched qualities and innovation potential of stainless steel, thereby preserves the stringent standards of performance, safety, and reliability that form the backbone of health care.

Innovations in Stainless Steel Manufacturing

Emerging Technologies in Fabrication

The integration of advanced technologies has forged a new path for stainless steel fabrication in recent times, with applications for efficiency, precision, and sustainability. Additive manufacturing, or 3D printing as it is commonly called, has fundamentally changed the design and manufacture of very complex stainless steel components. This technology enables the production of parts with highly intricate geometries while minimizing the wastage of material, beneficial in the aerospace and healthcare industries.

Laser cutting and welding systems remain pivotal in the landscape of recent innovations: they use high-energy laser beams to cut, shape, or join various stainless steel parts very accurately and very quickly, with manufacturers able to meet strict specifications and generate revenue by reducing production cycles.

In addition, treatment methods, such as cryogenic or nano-coatings, enhance the stainless steel’s properties in further treatment processes, such as the ability to wear and fatigue resistance. The application of automated robotic systems, integrated with machine learning algorithms, is an increasingly popular approach for streamlining manufacturing processes, enabling real-time anomaly detection, and ensuring that certain quality control standards are maintained.

The application of these emerging technologies enables the stainless steel manufacturing industry to continue pushing the boundaries of possibility, thereby providing high-performance and sustainable applications that are demanded by increasingly large sectors.

Advancements in Precision Manufacturing

With cutting-edge technologies integrated into automated manufacturing, material science, and computational modeling, precision manufacturing has come into much greater development. Automated systems use CNC machines of such a nature that tolerances within half a millimeter ensure unparalleled consistency and accuracy of components. Advanced metrology is among those fields that use laser scanning and CMMs to verify the dimensional accuracy against specification standards.

Instead, additive manufacturing techniques have taken prototyping and complex part manufacturing into a different era. Using selective laser melting and electron beam melting, one can now manufacture complex geometries previously deemed impossible using traditional subtractive methods.

Along with digital twins and IoT-enabled sensors, the system is real-time monitored and given predictive maintenance in precision manufacturing systems. Resultantly, these technologies help reduce downtime and support data-driven efficiency improvements in operations. Altogether, these developments thus mark an era of manufacturing where precision, reliability, and scalability are embarked upon concurrently.

Laser Cutting and Its Impact on the Industry

Laser cutting is among the most transformative manufacturing technologies of the present era, offering extreme precision and speed with the necessary versatility. With this process, a concentrated beam of high-energy light assists in cutting and shaping nearly all sorts of materials, such as metals, plastics, and composites, with utmost accuracy. By facilitating precision cutting with a thin kerf, considerable material waste has come down using the technology.

⚡ Laser Cutting Benefits

Laser cutting had much better acceptance in industries with improved laser power density and computerized control, such as aerospace, automotive, and medical device manufacturing. For example, owing to its energy efficiency, higher cutting speeds, and ability to accommodate thicker materials, fiber laser cutting has become more widely adopted.

In terms of automation and AI-driven optimization, Industry 4.0 is extending its influence on additional factors affecting injection laser cutting. The use of IoT-enabled laser systems allows for real-time monitoring and predictive analytics, thereby improving overall system reliability while minimizing downtime. Not only does this make maximum use of operational throughput, but it also ensures that lean manufacturing goals are met by conserving resources.

Laser cutting has, thus, become a yardstick against which other precision manufacturing solutions are measured. This process, apt for scaling productions as well as for high-mix low-volume environments to continue driving innovation, has witnessed efficiency gains in an array of industrial applications.

Sustainability Trends in Stainless Steel Production

Environmental Impact of Stainless Steel Manufacturing

Though stainless steel has been indispensable for modern industries, with such applications come environmental effects. Hence, to practice sustainability in the sector, the effects must be studied and mitigated. Below are five crucial environmental effects caused by stainless steel production:

| Environmental Impact | Key Statistics | Description |

|---|---|---|

| ⚡ Energy Consumption | 14-16 GJ per ton | High-temperature processes like smelting and refining consume enormous energy, resulting in significant carbon emissions |

| 🌫️ CO2 Emissions | 2.5 metric tons CO2 per ton | A major contributor to global CO2 emissions, though EAF technology has reduced emissions compared to basic oxygen furnaces |

| ⛏️ Raw Material Extraction | 2M metric tons of nickel/year | Mining for iron ore, nickel, and chromium causes habitat destruction, soil degradation, and water depletion |

| 💧 Water Pollution | 10,000 m³ polluted water/day | Used for cooling and processing, untreated wastewater can contaminate local water bodies with heavy metals |

| 🗑️ Waste Generation | 150-200 kg slag per ton | Processing generates slag, dust, and chemical residues; partial recycling in construction, but significant landfill disposal |

A sustained reduction in all these effects will require a multi-pronged approach, including the introduction of clean energy technologies, improved recycling practices, and the application of improved processes in manufacturing to minimize wastage and inefficiencies.

Recycling and Sustainability Practices

This is how the main waste and resource consumption problems come into being in industrial environments and must be properly solved through recycling and sustainability practices that are truly beneficial. Upgraded technologies for recycling may be used to keep materials–metal, plastic, glass–from losing their quality in being reprocessed and reused. One such chemical recycling technique will, for example, convert complicated polymers into their building blocks so that they can create new high-quality products and reduce the dependence on virgin resources.

The other ensures that, by the circular economy concept, products and systems are designed from scratch to prevent waste. Industrial symbiosis, for example, gives great potential for waste reduction by turning by-products from one manufacturing process into raw materials for another. An excellent application is steel slag reuse in construction, thus reducing solid waste and helping to lessen the environmental burden of construction.

Sustainability will be further supported when renewable energy becomes an integral part of industrial processes, as transitioning away from fossil fuels to solar, wind, or hydro will heavily cut back greenhouse gas emissions. Using energy-efficient manufacturing technologies further reduces the industry’s carbon footprint, while promoting optimized energy use.

In the final sense, a data-driven approach is also very central. By implementing advanced monitoring systems and using predictive analytics, they can better identify inefficiencies, allocate resources smartly, and improve waste reduction strategies. The government and private sectors should work hand in hand to enact strict legislation and facilitate sustainable practices to preserve the ecology over the long term.

Future Directions for Sustainable Steel Solutions

The future trend of sustainable steel production will depend greatly on integrating advanced technologies and novel processes that severely reduce environmental impacts. The key will probably be the development and implementation of hydrogen-DRI-type production processes. By applying green hydrogen instead of carbon-heavy coke as the main reducing agent, steel producers can realize practically zero emissions with high production efficiency. Also, further development of EAF technologies, especially shareable with renewable electricity, is even more crucial to speeding up the transition to circular and low-emission steelmaking.

🌱 Key Future Technologies:

- Hydrogen-DRI Production: Green hydrogen replacing carbon-heavy coke for zero-emission steel production

- Enhanced EAF Technologies: Integration with renewable electricity for circular steelmaking

- CCUS Implementation: Carbon Capture, Utilization, and Storage throughout steelmaking plants

- Advanced Recycling: Better sorting and melting processes for maximum scrap steel utilization

- Molten Oxide Electrolysis: Revolutionary emission-free steel production methods

Another important avenue is the deployment at a vast scale of CCUS technologies throughout steel-making plants. Such a system could capture large proportions of CO2 emissions, after which they could be either stored safely or used in other processes useful in industry, such as creating synthetic fuels or construction materials. Simultaneously, the industry should strive to make steel more recyclable. Any step that leads to better sorting methods and melting processes for scrap steel will allow producers to use as much recycled material as possible, therefore reducing the areas where virgin resources are required.

Collaboration between stakeholders will become a mandatory element, including governments, manufacturers, and research institutions. Such public-private partnerships can steer investments into R&D for disruptive approaches like molten oxide electrolysis that would eliminate steel emissions. Policymakers need to implement appropriate carbon-priced regimes and account for incentives that would catalyze the adoption of sustainable approaches to make these disruptive solutions viable and scalable.

Eventually, operational efficiency will be optimized alongside energy consumption reduction and data-driven acceleration toward sustainability through real-time data analytics and machine learning. Combined, these future-oriented strategies surely form a solid scaffolding toward greener and more sustainable steel.

The Global Market Dynamics of Stainless Steel

Market Trends and Forecasts

The stainless steel market is rapidly growing due to the demand arising from various industries, including construction, automotive, and consumer goods. In particular, there is a rising adoption trend of duplex stainless steels, which provide better mechanical strength, corrosion resistance, and cost performance as compared to traditional stainless steels. New types of materials that promote sustainable solutions and lessen environmental impacts are being established across the world.

📈 Market Growth Projections

Rapid industrialization within emerging economies, especially those of the Asia-Pacific region, has gone on to shape the market, with this region taking a significant share in production and consumption across the globe. Countries such as China and India are heavily investing in infrastructure projects, thus creating demand. On the other hand, improved manufacturing processes ensure that production is also energy efficient, thereby emerging as another growth driver.

From a forecast point of view, the global stainless steel market will achieve a CAGR of nearly 5% within the next five years. This growth will be facilitated by increased urbanization, greater attention towards renewable energy projects where stainless steel has a prominent role, and the availability of recycled stainless steel, which accounts for over 50% of the volume of stainless steel used for production today. All these factors prove the resilience of the industry and keep it adaptable in the face of emerging industrial and environmental challenges.

Challenges Facing the Stainless Steel Industry

The stainless steel industry inextricably faces several opposing challenges that require strategic solutions for sustainability and growth. Among them, high fluctuations in raw material prices, nickel, and chromium, which are sine qua non for stainless steel manufacture. The rise and fall in these commodity prices directly affect their production costs and could put a dent in long-term planning from manufacturers.

⚠️ Industry Challenges Overview:

Fluctuations in nickel and chromium prices are affecting production costs

Compliance with stringent carbon emission and energy consumption policies

Pressure from countries with lower production costs is affecting profit margins

Vulnerabilities in raw material availability and product delivery

Another challenge lies in environmental regulations that aim at curbing carbon emissions and energy consumption in industrial operations. Often, compliance with such stringent policies means installing energy-efficient technologies and systems for waste disposal, which involve enormous capital investments. Besides, the global competition, especially from countries with lower production costs, exerts pressure on the profit margins and sustains all forms of innovation and optimization.

The current disruptions in supply chains further reveal systemic vulnerabilities. Because of this, the availability of raw materials and the timely delivery of finished products have equally suffered. Recycling technological advancements and the circular economy present opportunities that the industry must consider to decrease its raw material dependency while meeting environmental objectives.

Last, the industry has to tackle the ever-increasing demand for alternative materials, including composites and advanced polymers, in some applications can serve as competing substitutes. Adjusting to these changes demands substantial research and development investments that guarantee improvements in stainless steel performance and sustainability so that it can compete in a fast-evolving market.

Opportunities for Growth in Emerging Markets

Owing to rapid industrialization, urbanization, and rapidly growing middle-class populations, emerging markets pose more than adequate opportunities for the stainless steel industry. Key players in infrastructure development, such as India, Indonesia, and Brazil, mandate the supply of durable, corrosion-resistant materials such as stainless steel into sectors like construction, transportation, and energy development.

The energy transition in these jurisdictions also potentializes growth, as renewable energy infrastructure in solar and wind energy systems requires a systemic stainless steel application with an emphasis on strength, durability, and resistance to adverse environmental conditions. Growing production of electric vehicles (EVs) in emerging markets will only bolster demand for specialty grades of stainless steel required for battery casings, fuel cell stacks, and structural components.

Emerging markets have, in the recent past, contributed a huge share to the consumption of global stainless steel, and this will remain so for the foreseeable future. Strategic investment into local production capacity, forging partnerships with domestic industries, and focusing R&D on understanding local-market requirements will be the levers that will enable one to seize the growth opportunities in these regions. Also, sorting out logistical concerns and valuing competitively will go a long way in cementing their position in these regions with immense potential.

References

-

Forever Stainless Steel, Inc.

Provides insights into stainless steel manufacturing and its applications across various industries. -

World Stainless Association

A global organization offering comprehensive data, research, and insights on the stainless steel industry. -

Custom Stainless

A multidisciplinary design-build company specializing in custom stainless steel equipment, showcasing industry standards and innovations. - Click here to read more.

Frequently Asked Questions (FAQ)

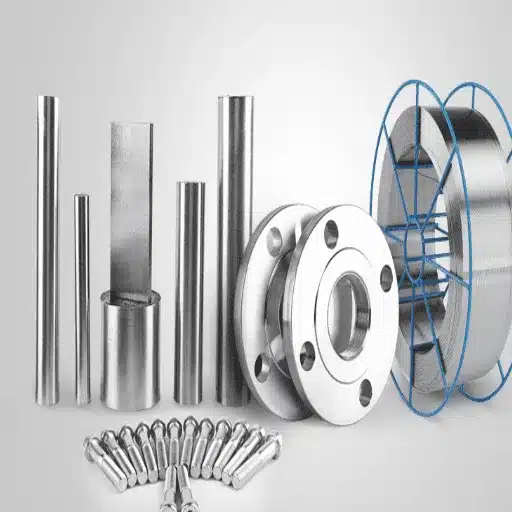

❓ What are the major products that stainless steel manufacturers offer?

Stainless steel manufacturers produce a wide range of products such as sheets, plates, tubing, rods, and coils. These products come in different grades of stainless steel, such as 316 stainless steel or 430 stainless steel, intended for different applications that include kitchen appliance manufacturing, pharmaceutical equipment manufacturing, and the oil and gas industries.

🔧 How do stainless steel fabricators assure the quality?

Stainless steel fabricators assure the quality by ensuring they adhere to ISO compliance, and a certain degree of quality control is imposed. The resistance to corrosion and oxidation can be heightened by using heat treatment and annealing techniques with a view to fulfilling the requirements of industries at large.

⚡ How does weldability affect stainless steel manufacturing?

Weldability is of great importance in stainless steel manufacturing as it describes the ease with which stainless steel can be joined together. Manufacturers prefer weldable stainless steel grades such as 17-4 PH and 310 because their weldability can be best exploited in such applications as aerospace, shipbuilding, and structural fabrication.

🚚 How do stainless steel suppliers contribute to manufacturing?

Stainless steel suppliers are, in effect, the raw materials suppliers for the manufacturers and fabricators. They guarantee a continuous supply of high-quality stainless steel products necessary for fulfilling the manufacturing requirements of the automotive, electronic, and beverage filtration industries.

🔨 What kinds of custom fabrication works are accomplished by stainless steel manufacturers?

Stainless steel manufacturers usually undertake custom fabrication, which includes cutting, bending, punching, and stamping to fabricate components for use in various applications in the petrochemical and food and beverage industries.

🛡️ What benefits does stainless steel give in a corrosive environment?

The benefits of stainless steel in corrosive environments are its excellent corrosion and oxidation resistance. Several grades of stainless steel under manufacture today are designed by the manufacturers for those given harsh operating conditions, fitting the application for marine, chemical processing, and cryogenic.