Titanium and iron are known to be two of the most remarkable super metals in the world of industrial and engineering materials. These metals have been built into the worldwide construction industry, starting with the mere remote control of a button till the present, where even oversized steel buildings or airplanes can be built. Thus, if both of them are not just ideas, but physically exist, what can be their comparative strength, longevity, and practicality in use? The examination of the properties of titanium and iron has, therefore, focused particular attention on how they perform, their expected benefits and disadvantages, and key parameters that should be taken into consideration when selecting whether either of the metals is appropriate for utilization within the domains of various sectors. The article addresses all the main technological, constructional, and mechanical aspects that are characteristic of the extended use of metals, pushing their limits.

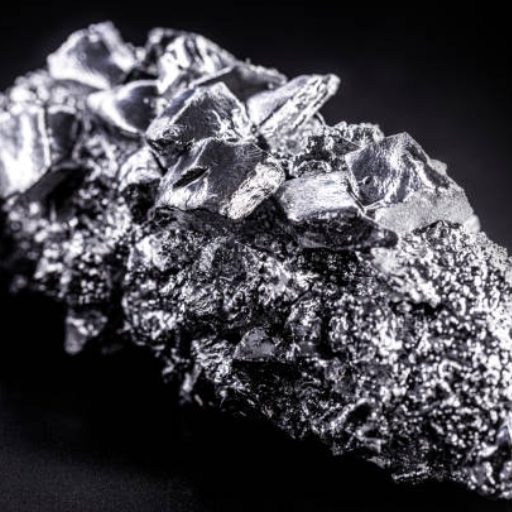

Understanding the Properties of Titanium

Titanium’s amazing physical strength, in relation to its weight, is the most notable feature. It is a durable material that does not break under stress and does not have an additive cost for corrosion. The metal is mostly acidic and is commonly used in the production of various forms of aircraft, medical equipment known for its biocompatibility, and in certain applications where it is subjected to salt, moisture, and oxygen co-exposure. Despite the price of titanium being higher than that of other metals like iron, there is no limit to its usage in certain technical industries owing to its performance.

What Makes Titanium Unique?

Among the spectrum of materials that exists today, titanium has one property that can be claimed to be the most striking and unique to it. It possesses strength that even exceeds that of most metals, when corrections for their densities are made. For a given volume of titanium, GS4 steel is nearly twice as low in terms of its density and might have a lower tensile strength of about 430 MPa, even for alloyed forms extending to, at most, about 1400 MPa. Thus, in situations where both strength and weight are major issues, such as in aeroplane components, under-bonnet automotive components as well as high-performance sporting goods, titanium has become so much coveted.

Moreover, titanium is an outstanding metal in the conditions of extremely high and low temperatures. It can withstand temperatures as high as 600°C (1112°F) before losing its mechanical properties, and certain industrial titanium alloys can even tolerate even higher temperatures. Because this property of the material reduces engine downtime and also mitigates thermal bridging, it is utilized in engines, including jet engines and gas turbines, as well as in other high-temperature applications.

Titanium Strength vs Steel: A Detailed Comparison

| Parameter | Titanium | Steel |

|---|---|---|

| Density | Approximately 4.5 g/cm³ | Approximately 7.8 g/cm³ |

| Strength-to-Weight Ratio | Higher than steel | Lower than titanium |

| Ultimate Tensile Strength | Around 1000 MPa (varies by alloy) | 400-1400 MPa (varies by grade) |

| Corrosion Resistance | Exceptional, resists most environments | Susceptible to rust and corrosion |

| Thermal Conductivity | Lower than steel | Higher than titanium |

| Temperature Resistance | Stable up to 600°C (alloys even higher) | Varies widely, some grades perform well |

| Cost | Generally more expensive than steel | Typically less expensive |

| Machinability | More challenging to machine | Easier to machine |

| Applications | Aerospace, medical, marine, and sports | Construction, tools, automotive, etc. |

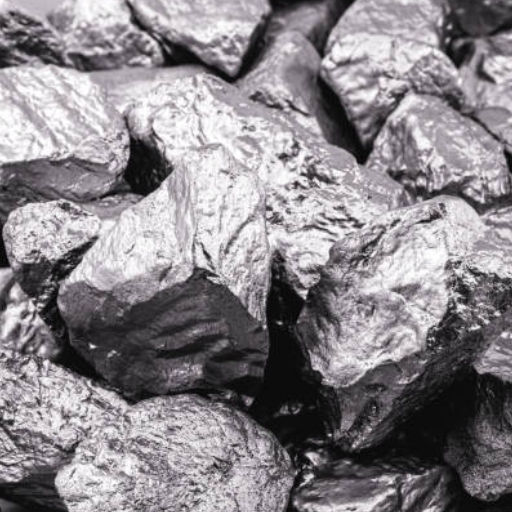

Exploring Iron: A Traditional Metal

Iron, as a metal, is one element that has seen the most extensive, consistent and practical use in the history of humanity. This multifaceted utility is primarily justified by its strength, availability in large quantities and ease of shaping. Despite these, it is mostly used in the fabrication of steel – an alloy that has truly transformed the architecture, transport and production industries. It is an age-old material known for its non-negligible tensile and compressive bending strengths, allowing it to be used in both construction and in heavy machinery structures. Nonetheless, with all its excellent properties, Iron ought to be shielded or serviced using various types of treatments such as galvanizing or applying protective paint. Just the fact that Iron is everywhere and its cost is very pragmatic, has allowed it to be widely employed in a great number of situations, such as frameworks for buildings, tools, pipes, and objects intended for the house. Compared with some modern high-tech materials, it’s best in terms of heating or electrical conductivity, thermal stability, but its malleability and the ease in its retrieval contribute to the continuous utilization of the material in contemporary engineering and geographical development.

Characteristics of Iron

High Strength and Durability

Iron is a metal with a relatively high strength-to-weight ratio, which makes it convenient to be utilized in any structure that is constantly subjected to substantial loads. That said, it is important to point out that it can be persistently used in construction as well as other industrial-related fields due to its ability to last long.

Abundance and Availability

Iron accounts for more than 5% of the Earth’s crust, making it the 4th most prevalent element in the crust. This affluence guarantees minimal variation in the price of iron metal, thus enabling the industrial sector to meet its demands for the metal without a significant break-even rise in the metal prices that occurs in case of metal scarcity.

Magnetism

It can also be noted that Iron shows ferromagnetic properties – a characteristic that can make it magnetized. Such an aspect will make it useful in building electrical instruments and components such as electric motors, transformers, inductors, among others.

Corrosion Susceptibility and Solutions

However, despite these beneficial properties, iron has a shortcoming in that is susceptible to corrosion in response to oxygen or humidity. Nevertheless, many methods can be employed to enhance the performance and increase the longevity of iron metal, such as galvanizing it (with zinc), painting, or utilizing stainless steel or other combinations of metals.

Malleability and Workability

Iron is also readily castable and cohesive. It can be bent, shaped, die, or assembled, which facilitates creating many various goods and details made out of this material.

Recyclability

A further interesting aspect of iron is that it’s 100% recyclable with zero loss of quality. It’s rather important that recycled iron can be re-used over and over again, and there are different attributes of used iron. Recycled iron equals freshness, such as energy-saving and endurance transmission of metals through time.

Made from Iron: Understanding Its Composition

Iron is one of the metallic raw materials used for the synthesis of a wide range of alloys and machinery important for the industries. For the most part, iron comprises additional components such as carbon, silicon, manganese, sulphur, and phosphorus in negligible quantities. These elements affect the ductility, strength, and tribological wear properties of the materials. An important role of iron is the manufacture of steel, where iron is mixed with a small amount of carbon to improve its mechanical properties, such as tensile adhesion, which is its impact resistance.

Other metallic additives are used in the construction of certain steel grades, plate steel as well, pickling grade, wear and abrasion, thus special procedure heat treatment may be required for these grades. Thus picture of how these grades’ chemical composition has been selected today is not very different from that of how it used to be chosen even some decades ago. In this paper, reasons for the preferred use of iron in construction and the mechanical engineering aspects are further explored.

The Cost of Iron Compared to Titanium

There is a substantial price difference between Titanium and Iron, other than the fact that Iron is highly abundant in nature, which leads to all the operational and managing costs being cheap. Being a very common element, iron is cheaply mined and processed. It is largely mined and for a long time its availability has continually improved, making it one of the industry’s cheapest sources of input. On the contrary, titanium is an expensive metal mainly due to its scarcity and costly refining and recovery procedures, such as the Kroll process, which is both energy wasteful and costly.

Cost Comparison:

- Raw Iron: $0.1 to $0.2 per pound

- Titanium: $3 to $9 per pound (depending on grade and market conditions)

Also, varying market values can attribute to build how much something costs; in general, titanium is more useful in terms of its strength against its weight, resistance to any destructing forces and ability not to provoke any allergies which makes it more preferable than iron in very many cases, particularly in the aerospace, medical and high performance industries. This proves why titanium is more expensive as opposed to iron which sees more use in structural works needing low initial investment.

Titanium vs Iron: Strength and Durability

It is important to note that the structural properties of titanium and iron are immensely different. Titanium exhibits a high strength-to-density ratio, which provides the benefits of the material being tough while not being heavy, which is necessary in modern strength-to-weight ratios. It also excels in terms of its strength in stressed and liaison conditions and service life as well as its ability to withstand corrosion even in the most hostile environments.

Compared to the element titanium, iron is not an especially lightweight material. However, it can be employed extensively in carrying out structural functions due to its capacity to carry heavy loads with ease and under great conditions at the same time. Nevertheless, with no treatment, it is subject to degeneration because of it is easily rusted. Whether to opt for titanium or steel all comes down to the respective purposes; do you seek a material that is light weight with all the attendant poor behavior? We must then prohibit corrosion by using light structural materials such as clay.

Comparative Strength: Which Material Holds Up Better?

Deciphering the structural integrity of titanium and iron, it is impossible to overlook the physics and chemistry of their composition, which in turn gives rise to the mechanical properties of these solids. What distinguishes titanium is its good weight-to-strength ratio, which contributes to its use with materials that need to withstand many tons of force with minimal mass. Its tensile strength usually falls between 434 MPa and 1,400 MPa, depending on the alloy and manufacturing processes. Iron, on the one hand, is known to be hard, but it is interesting to note that its tensile strength defies this rule and exhibits vast variances, geographically, when it is in either cast iron or wrought iron form. Take, for example, cast iron is found to exhibit tensile strengths ranging from 200 MPa to 1,100 MPa; yet, most cast irons exhibit high brittleness, which precludes any ductility extension.

Moreover, the relatively high density of titanium enables its resistance to penetration and other detrimental effects very effectively. Its strength does not quite compare to that of iron, and flexure problems, such as cracking the shaft, also arise at much lower applications. For pure or untreated iron, however, embrittlement may occur at low temperatures, and high thermal stresses may bring on some structural collapse. Metals such as iron and steel are also known for their magnetic properties. Then again, the carbon and other composition elements in steel combine to form steel reinforcing structure making it mechanical and structurally stronger than iron. Nonetheless, iron is quite cheap and readily available compared to many other metals. This alone makes iron the most common structural material used globally for buildings and other structures beyond wear steel.

Weight Considerations: Titanium vs Iron

Among the many attributes of titanium, one of the major differences from iron is its density. It is known that titanium has a density of about 4.5 g/cm³ while on the other hand, iron comes second in density with about 7.87 g/cm³. Therefore, it has an average section of about 40% less than the one for iron but is substantially defined only by the use for reducing weight, such as for automotive, and high-grade sports materials. Furthermore, even when dealing with its reduced densities, the most basic characteristics and in terms of its strength, titanium performs better than most conventional metals and can be especially beneficial to joint members that need to be strong but also light.

Nevertheless, designing an antenna for installation on an aircraft or a spaceship may present weight issues, but refraining, either way, from such an exciting development would be a deeply sad affair. Aluminium, which is the lightest of these materials, should be used to the extent possible in the design and manufacture of the structure. Specific weight denotes the weight of a material dimensionless scale. Common examples include plastics, rubbers, pore formers, and plasters etc. Structures must have a very feedback relationship between design and material to be effectively used.

Commercial Viability of Titanium

However, as long as the overall costs of titanium are balanced relative to the desired end-user properties, the metal remains profitable. One of the key attributes of titanium that undermines this competitive advantage equation is benefits that are provided by titanium to the construction industry. So, although a high cost of extraction and processing for titanium outweighs the manufacturers’ association with metals that are easier to process, titanium’s excellent chemical inertness normally makes it a material of choice in aerospace, medical, and marine applications. Wholly over the use of titanium is probably the wear-and-tear and replacement concerns which might come along with the raw material so as to be able to reduce the maintenance and replacement costs and particularly in aggressive environments. For demanding applications where the structural capital is also treated as O&M operation, Titanium Potential and its cost are important elements to be taken into consideration, even with its high cost on the initial investment.

Applications in Aerospace and Manufacturing

Aerospace

- Aircraft Structures: Titanium aircrafts has been used in critical sections such as airframes, wings and landing gears due to its superior qualities combine lightness and strength. For instance, titanium makes up about 14-15% of an empty weight of commercial aircraft, such as the Boeing 787 and the Airbus A350.

- Jet Engines: These are mostly used in the fan blades, compressor sections and other similar workings of the jet engine that can reach temperatures of up to 800°F (426°C) because titanium alloys perform in such conditions without fail.

Automotive Manufacturing

- High-Performance Vehicles: Titanium parts, notably the exhaust system and connecting rod are also found in sports and luxury cars for improved performance and reduction in mass at the same time, consequently enhancing acceleration and fuel efficiency.

- Additive Manufacturing: Titanium in powder form is recently deployed in 3D printing for automotive component fabrication, particularly for producing intricate and weight-saving materials.

Medical Device Production

- Prosthetics and Implants: Due to its high biocompatibility, titanium is a perfect metal for designing dental, prosthetic and orthopedic technologies which include implants for example hip or knee replacements. A recent study revealed that more than 95% of these implants made from titanium last over ten years

Marine Engineering

- Shipbuilding: Titanium is used for making ship hulls, propeller shafts and heat exchangers due to its corrosion resistance in sea water (also in brackish water), which reduces the surface maintenance of structure thereby increase durability.

- Submarine Components: It goes without saying that the strength should be high given that submarines operate deep under water. This makes the use of titanium necessary as the material, is strong and non magnetic.

Titanium vs Steel: Industry Preferences

Moreover, steel has no match in the building, construction, and auto industries, where steel constructions are marginally not as weight-effective in price application as the alternative titanium building practices are mostly in the air industrial process. Integer value weight is not as cost-effective in the building, construction, and auto industries as alternative building practices that employ titanium as the primary material, as they are in the aerospace industry.

In instances where titanium is demanded for its resistance against corrosive environments, titanium is most likely to supersede stainless steel in use, especially in marine works and chemical facilities. Taking advantage of the anti-corrosive effect of titanium against chlorides and seawater, some designers and contractors strap titanium components in structures that should be shielded from a near-aggressive environment, while steel may be coated with additional liners or combined with other materials to attain a service life of equal or greater tuberculation. The wide application of titanium is also hindered by high method and fabrication costs that are further heightened by the use of harder materials with dimensions.

Beyond these considerations, many engineering designs allow a choice between types of materials according to both the performance and the financial aspect of the project.

Common Applications and Real-World Examples

The use of Aerospace Titanium Alloys may be one of the most symbolically promising materials in technological engineering. Its special strength-to-density value and immunity to the acids result in the most preferable characteristics concerning the aircraft details, the airplane engine parts and the spacecraft technologies. Also, the use of these alloys is determined by biological compatibility, as in medicine, where the alloys are used in artificial limbs, endoprostheses, and tools for surgical interventions.

In contrast, steel is the most basic building material that served as a substance for constructing foundations of buildings, spans, and other infrastructures because of its strength, the capability to withstand long impacts, and price. That is why the areas of application of steel is very wide in automobile construction, shipbuilding, and tool production, in which its physical characteristics suit both functional and economic aspects. Such cases clearly indicate how the choice of materials is customized in accordance to the exact needs of various industries.

Titanium in Medical Devices and Implants

Due to its great biocompatibility, corrosion, and mechanical resistance characteristics, titanium is one of the indispensable contributors in the technology of modern medical devices and implants. The process is enhanced by its ability to bond to the bone called osseointegration and is thus used in professions like prosthodontics and orthoses. In addition to the above, the ability of titanium to withstand the high loads of wear and tear, without excessive metallic consumption or patient weight gain, is owing to its characteristic relation of high strength to light weight. Further coated body parts and components prevent corrosion for an even longer service life of the implant and medical advice on the replacement is minimized. The advent of new technologies improving the application of titanium, such as the procedure of showing 3D images on a screen, is even more pronounced in the making of medical aids that can be assembled for a given individual. With that these points highlight titanium as one of the base materials in the emerging health technology.

Iron in Construction: The Backbone of Infrastructure

Iron has always been indispensable in construction due to its stiff power, potential and wide availability. The majority of its structure is in the form of steel, which is a composite material made of iron and carbon, suitable for long service, such as constructing thousands of structures, including bridges, buildings, and railways. Faradically, metals have undergone further development, leading to high-strength low-alloy (HSLA) steels. Which afford improved service characteristics, weight reduction, and enhanced resistance to corrosion. In the same vein, extensive application of ductile iron in pipes offers extraordinary tensile and flexibility properties, which the pressure systems require and protects against damage during seismic shaking.

It is indicated in the most up-to-date market research that the implementation of sustainable construction techniques has led to a higher usage of waste steel. In modern steel production, where as much as 90% of the raw materials used are recycled materials, such practices function to mitigate CO2 emissions and other negative effects on the environment. Engineering is not their only concern here; professionals from other fields also consider the safety and longevity of whatever they build while keeping the environment in mind. The mentioned technology has been applied in the framework of global sustainable development and addresses the challenge of making stronger, more efficient, and most importantly, sustainable urban environments.

Choosing the Right Metal for Your Needs

When it comes to selecting the most suitable metal for a specific application, it is crucial to consider multiple factors, both technical and functional, to achieve optimal results and minimize costs. As such, the first step in selecting a metal is assessing its mechanical properties, which include tensile, hardness, and plastic properties. These properties determine or limit the material’s suitability for structural or strength-bearing functions. For example, one corrosion-resistant material is very high-strength alloys such as stainless steel, which are equally suitable for tough situations as they would not distort easily.

Second, consideration has to be made on the corrosion resistance of the material, especially in places undergoing high amounts of precipitation or in the surface that is exposed to different chemicals or in extreme temperatures. Aluminum is one of the examples of metals that have natural protection to corrosion, making it a preferred material in marine and aerospace.

Conductivity in the field, such as electronics or energy, is produced as one more argument of consideration. Copper is exclusively known for its high electrical conductivity; for this very reason, it is used more as a better conductor than any other metal, like aluminum.

Lastly, one needs to consider costs and the damage metals can have to the earth around them. The eco-friendly metals can be recycled, and the use of materials that can be therefore obtained in an environmentally conscientious manner accompanies all the attendant advantages. Metal parts to be manufactured should follow this treatment, i.e., to be based on the technical requirements and the imperative of the ecological issues.

Reference Sources

-

“Complex titanium-containing reagents in the processes of wastewater treatment in the metallurgical industry”

- Key Findings: This study explores the use of titanium and iron sulfates in wastewater treatment, highlighting the hydrolysis phenomena of titanium and its interaction with iron hydroxocomplexes.

- Read more

-

“Titanium dioxide recovery from ilmenite contained in ferrotitaniferous sands from Mompiche, Ecuador”

- Key Findings: The study identifies the presence of titanium and iron minerals in sands, with a focus on recovering titanium dioxide.

- Read more

Frequently Asked Questions (FAQs)

Q: What Are the Properties of Titanium Compared to Iron?

A: Titanium’s unique property in the rank of one of the strongest metals is attributed to its remarkable strength-to-weight ratio, which is very high. Galvanized steel which is plagued by rust if there is even the slightest moisture, it locally corrodes, unlike titanium. To put it simply, the resistance of titanium against corrosion is better than that of iron because of the metals structure. Permeability of the oxygen into the structure of the metal causes destruction of its properties by forming different oxides which are specific for the particular metal. That is the main reason why after the advances in graphite and other composites, titanium still remains the choice for these elevated temperature applications. In order to ensure the tensile strength by all means, titanium can be rolled or cast while some types even surpass steel in that respect. As far as steel and titanium are concerned, yield elongation is where they differ, this means that at a minimum weight problem, titanium is preferable.

Q: Is Titanium Stronger Than Steel or Iron?

A: In choosing between titanium and steel the question of titanium vs steel being stronger is crucial. The reason for this is that titanium is generally much stronger even than some steel grades considering the fact that it’s less dense. Most often, if not very often, it is common practice for steel to be associated with being endowed with strength and strength only. Strength of material is quantified and if we were to do so, then titanium would attract a higher strength to weight ratio. The strength to weight ratio makes titanium perform better even in some duties where strength and toughness are necessary at the same time it is considerably less heavy. In any event, there are some environmental conditions where titanium can do things what steel simply cannot do, particularly where its excellent corrosion resistance is an advantage. On the other hand, porn titanium is usually lower in strength than some of the toughest grades of steel respectfully, instigating a complex competition over whether titanium or steel possesses superior strength. This considerably slim and concise article gives such extensive support that the users will find the decision between titanium or steel feasible and effective.

Q: How Does the Commercial Viability of Titanium Compare to Iron?

A: Usage of Titanium in industrial application is popular and growing in the economy because of its special properties such as high melting point and no rust. It is a material known as an alloy that is evident in most everyday products that can be found everywhere hence it is cheap. The same cannot be said of Titanium. Titanium is much difficult to extract and process, so its costs associated with handling are relative high. However, some advantages make titanium worth the high expenses, lightweight and hard strengths. There are industrial sectors particularly concerned with aviation and medical devices which are not fond of Iron, Iron based instead make use of this type of metal for they are convinced of its efficiency. The expansion of the use of titanium is expected especially due to the fact that the technology in human societies is advancing creating a larger market for people looking forward to improve materials that are currently used such as iron and still.

Q: Can Titanium Be Used in Steel Alloys?

A: Yes, titanium is compatible with steel alloys to improve a number of properties. For example, adding titanium to steel can boost its tensile strength, toughness, wear and corrosion resistances thus widening its scope. In this way, stainless titanium steels are formed, which can serve better in some working conditions than ordinary steels. It is also known that the addition of titanium enhances the control of the grain size of the steel alloy, so the mechanical properties are also enhanced. It is the trend of many sectors to look for tougher and durable products, yet at a significant level of enhancement, the possibility of incorporating titanium into steel seems appealing.