Steel is malleable, or easily shaped, and is an essential raw material for construction, automotive, and manufacturing industries. It exhibits extreme plasticity, allowing it to be manipulated into any shape with greater ease. However, the raw steel, in the form of solids, such as carbon steel, is not suitable as is because it does not possess the specific mechanical properties characteristic of other types of steel. This temporary limitation is overcome through the adoption of a technique known as heat treatment, with the controlling of tempering being an important step in adjusting the microstructure of the steel to acquire the other specified properties.

Understanding the Tempering Process

Cooling is done for steel materials without working on them to attain a process also known as tempering. However, at high temperatures, steel becomes brittle. However, these deficiencies are largely reduced after quenching, as the progressive cooling causes cracking of the material.

What is Tempering?

Tempering, as a heat treatment technique, is primarily applied to steel and other ferrous components. The process aims to impart specific mechanical strength to steel and also minimize or eliminate brittleness. It is a process that involves heating the structural material to its critical temperature and then deliberately lowering it, most frequently to a level of about 150°C (302°F) and 650°C (1202°F).

- Low tempering temperatures: It is used when maximum hard material is needed.

- Higher tempering temperatures: These are used when the emphasis direction is to toughness.

- Applications: It is crucial in aerospace, automotive and tool areas of industry.

Metallurgical Changes During Tempering

One of the most important applications of post-quench tempering consists of improving the mechanical strength by changing the inner structure of materials to form different phases or structures that are more efficient in resisting any deformation or fracture.

Martensite Transformation

Quenching causes martensitic steel to undergo structural changes which include superficial low-temperature carbon penetration. In the case of tempering, the cooling results in a more stable structure than quenching and also a greater improvement in resistance to mechanical permanent deformation.

Carbide Formation

Stress Relief

Thermal treatment is at the core of tempering, thanks to which it alleviates thermal stresses, an improvement, while incorporating dimensional stability as compared to the resting parts, it is easy to be fabricated without affecting tolerances or worsening the deformability.

Benefits of Tempering Steel

Enhanced Toughness

Tempering is also effective due to its ability to roughen steel by increasing the strength possessed in figures and reducing the ductile nature of the steel. These changes to the steels’ structure have the simple effect that the impact forces can be withstood much better, with tempered steel showing up to 200% better impact properties than that of the untreated steels.

Improved Hardness and Wear Resistance

It is well known that controlled tempering can increase hardness sufficiently without sacrificing wear resistance. When steels are tempered between 400°F to 600°F, hardness increases are significant as the toughness properties are maintained.

Dimensional Stability

Reduced Risk of Fracture

This also aids in reducing the ductile fracturing process; this is essential for materials of structural importance, for instance, the shafts of vehicles and the beams used in construction.

Tailored Mechanical Properties

- Low-temperature tempering (150–300°F): Maintains high strength

- High-temperature tempering (900–1,100°F): Enhances impact toughness

Improved Fatigue Strength

Heating Metal: Techniques and Considerations

| Type of Heat | Key Points | Parameters to Know |

|---|---|---|

| Torch Heating | Manual, high concentration heat | Limited precision, small-scale use |

| Infrared Heating | Effective for surface applications | Non-contact, limited depth |

| Convection Heating | Uniform heat distribution | Requires airflow, slower process |

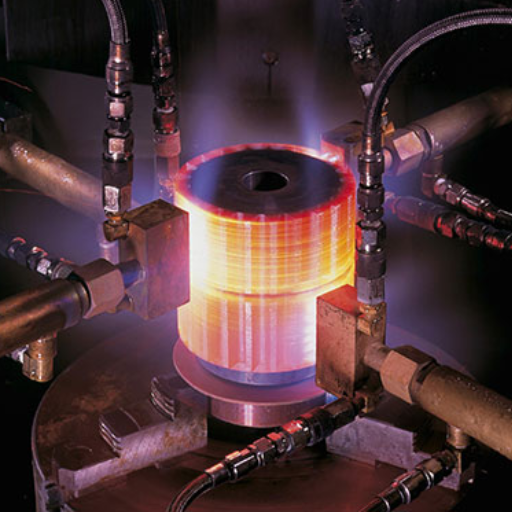

| Induction Heating | Rapid heating via electromagnetic fields | High precision, energy-efficient |

| Radiant Heating | Direct heat transfer to surfaces | No contact, uneven on complex shapes |

| Furnace Heating | Controlled and uniform heating environment | High cost, batch processing |

| Resistive Heating | Heat through electrical resistance | Consistent, power-intensive |

| Laser Heating | Highly focused, localized heating | Specialized, precise, high cost |

Step-by-Step Guide to Heating Steel

1Preparation of Steel Material

Determine which type and class of steel would be most appropriate for the purpose. It is also important to pay attention that the steel is clean and within shape for the appropriate heat treatment to occur. There can be issues during the heat treatment resulting from impurities such as oil or remnants.

2Choice of Heating Method

Depending on the purpose and material qualities, different methods of heating are advised. In terms of the ability to heat precisely, using a laser is the most appropriate method and applicable only for particular sectors. Altering the temperature distribution for thermal treatments is achieved by heating in the furnace and that’s why most industries use that method.

3Heating Environment Setup

Prepare the heating equipment properly. For furnace heating, pre-warm equipment to desired temperatures. For induction heating, ensure proper coil alignment for even energy transmission.

4Temperature Regulation

Raise temperature of the steel up to the desired temperature in the heating steps. Austenitizing temperature is generally higher i.e. around 1,500°F (815°C) for low carbon steels. Temperature sensing devices and infrared thermometer are very useful in temperature control whenever it is necessary.

5Holding Time

6Cooling Process

Execute appropriate cooling method to achieve desired mechanical properties:

- Quenching: Water, oil, or polymer solutions for higher hardness

- Air cooling: For more malleable surfaces

- Furnace cooling: For annealing processes

7Post-Heating Analysis

Once steel reaches room temperature, conduct hardness testing and microstructural analysis to verify desired properties and tolerances are achieved.

Cooling Methods: Quenching and Beyond

Quenching Techniques Explained

- Oil Bath Quenching: Common technique with low damage risk, suitable for complex shapes with medium cooling rates

- Water Quenching: Rapid heat transfer for carbon steels requiring increased hardness and tensile strength

- Polymer Solution Quenching: Accurate rates of cooling dependent on polymer concentrations

- Gas Quenching: On that note, this procedure uses nitrogen or argon so as to impede oxidation and to prevent distortion in intricate/thin walls

Slow Cooling: Importance and Methods

- Furnace Cooling: Controlled temperature reduction in furnaces

- Air Cooling: Used for low hardness steels and specific alloys

Common Cooling Issues

- Temperature Gradients: Cause distortion and warping

- Residual Stresses: Lead to structural deformation and crack initiation

- Surface Oxidation: Occurs during high-temperature cooling in uncontrolled environments

Applications of Tempered Steel

Automotive Industry

| Application | Benefits | Performance Data |

|---|---|---|

| Chassis and Frame Construction | High strength, structural stability | 25% weight reduction while maintaining strength |

| Suspension Components | Strength and flexibility | Enhanced durability under operational conditions |

| Safety Features | Energy absorption in collisions | Resist over 100 kilonewtons compressive force |

| Engine Components | Heat and stress resistance | Reliable performance under high temperatures |

| Transmission Systems | Wear resistance, surface hardness | Efficient power transfer, reduced maintenance |

| Brake Systems | Heat dissipation, structural integrity | Maintains performance during extreme braking |

Construction Industry

Tempered steel is utilized in construction for beams, reinforcement bars, and various structural mechanisms. It prevents brittleness under high external forces and enables:

- Reduced steel consumption while increasing building height

- Enhanced earthquake resistance through improved elasticity

- Better energy absorption and dissipation during seismic activities

Manufacturing and Tools

Heat treatment is crucial in manufacturing for affecting mechanical features of components. Applications include:

- Cutting tools that retain shape through multiple processes

- Dies and molds requiring dimensional stability

- Components requiring specific hardness-to-toughness ratios

Challenges in Tempering Steel

Common Problems and Solutions

| Problem | Cause | Solution |

|---|---|---|

| Cracking | Too rapid cooling or uneven heating | Controlled heating rate and uniform warming |

| Residual Stresses | Improper cooling process | Stress-relieving mode after quenching and tempering |

| Surface Oxidation | Exposure to reactive environment | Non-reactive environment or vacuum furnaces |

| Property Imbalance | Incorrect hardening-toughness mix | Multiple tempering operations with real-time monitoring |

Tips for Achieving Accurate Tempering

Control Heating Rates Precisely

Use programmable furnaces with controllable heating rates. Research shows 20% reduction in internal stresses when uniform heating rates are used, resulting in better structural reliability.

Monitor Temperature Uniformity

Equilibrium temperatures are recommended to be maintained within the heat treatment furnace. The strategic use of thermal yaoring is necessary to detect temperature differentials through the use of infrared, and thermocouples with a deviation of at least -3 degrees much as well as a bearem.

Select Appropriate Tempering Time

Base tempering time on thickness and chemical composition. Thicker sections require longer tempering times to achieve uniform core and surface properties.

Use Protective Atmospheres

Leverage Real-Time Monitoring

Implement advanced tracking systems for temperature, atmosphere quality, and component heat soaks. This enables immediate corrective actions and improves tempered material quality.

Test Material Properties Post-Tempering

Conduct comprehensive evaluation using:

- Rockwell or Brinell hardness testing

- Microstructural analysis

- Non-destructive testing (ultrasonic, magnetic particle)

- Tensile strength and ductility measurements

Reference Sources

1. Analysis of the Mechanical Characteristics of Mild Steel Using Different Heat Treatments

Source: World Journal of Advanced Research and Reviews, 2024

Key Findings:

- Tempering at 450°C improved ductility and reduced hardness compared to hardened samples.

- Hardened samples exhibited the highest tensile strength and hardness but the lowest ductility.

2. Effect of Quenching and Tempering on Mechanical Properties and Microstructure of 304-SS Welded Plates

Source: Research Paper, 2022

Key Findings:

- Tempering improved toughness by 150% compared to quenched specimens.

- Quenched specimens had higher hardness but lower ductility and toughness.

- Microstructural analysis revealed refined grains and

Frequently Asked Questions (FAQs)

Q: What is the tempering process for steel?

A: Steel tempering is a very specific process oriented towards changing steel characteristics, and commonly tool steels in particular. With steel chilled after quenching, the metal affects hardness with the drawback brittle. Temped steels are usually tempered at a temperature below the upper critical temperature of the metal after this process, the metal is allowed to be cooled. The hardening produces a relief of residual stresses in the metals and the resultant improvement in resistance to yielding and fracture toughness.

Q: How does heating and cooling affect carbon steel?

A: Rising of carbon steel to high temperature and then exposing them to artificial cooling to make them hard is a heat treatment process that causes corrections on the properties of the carbon steel. When steel is heated to a temperature above its upper critical temperature and then quenched it become hard and brittle; heat treatment of tempered steel involves reheating at a lower temperature to release the stressed regions and enhancing both strength and toughness with controlled cooling.

Q: What are the benefits of tempering steel?

A: Many of the advantages in the quenching treatment of steel are strength and brittleness; both can be overcome by evolution of tempered martensite in steels at higher temperatures. One often appreciates large rearangements in difficult systems – such as plastic behavior of different materials, formation and recovery of vacancies in crystals and especially grain boundary rearrangements. Size efficiency enhancement can now be done in most intuitive way and has many implications to various industrial branches.

Q: What is the difference between annealed steel and tempered steel?

A: Deironed or descaled steel was primarily made to prevent iron from blackening or staining the workpiece while also extending the life of the blade. More knowledge on product quality and mechanical properties are needed, and the emphasis should be reduced. Professional designer must think of stunning design and trendy outlook which is the part of his day to day activity therefore one should claim proportions and make it wait.

Q: How does quenching relate to tempering steel?

A: The rapid cooling of hot steel is achieved by quenching it in water, oil or gas. This operation transforms the steel into a harder but more brittle state. Subsequent tempering refers to re-heating the steel to an intermediate temperature to to control its level of brittleness. Such a process makes it possible to combine strength and toughness of steel which is called high-strength low-alloy steel. This kind of steel is used in different industries.

Key Takeaways

- Tempering is essential for balancing hardness and toughness in steel

- Temperature control and timing are critical for achieving desired properties

- Different industries require specific tempering approaches for optimal performance

- Proper cooling methods prevent defects and ensure quality results

- Real-time monitoring and testing ensure consistent, reliable outcomes