Master one of welding’s most challenging techniques! Considered one of the most difficult welds in the world of welding, aluminum stick welding offers a very valuable and rewarding skill when approached with the right knowledge and preparation. Aluminum, with its peculiar properties such as low melting point and quick oxidation, calls for a precise approach and techniques in order to produce strong and clean welds.

This comprehensive guide will unravel the complexities of stick welding aluminum and shed light on the tools, materials, and methods you need to conquer the process. Whether you’re an experienced welder looking to expand your skills or a newcomer ready to tackle this challenging material, this guide will provide the critical knowledge to build your expertise beyond expectations.

Understanding Stick Welding

What is Stick Welding?

Stick welding, also referred to as SMAW (Shielded Metal Arc Welding), is a manual arc welding process where a consumable flux-coated electrode is used to fuse metals. The heat needed for welding is generated by means of an electric arc established between the electrode and the workpiece.

Key Characteristics of Stick Welding:

- Versatility: Accommodates various metals, including steel, cast iron, and aluminum

- Adaptability: Can be used in different positions and environments

- Self-Shielding: Flux coating produces shielding gas and slag protection

- Portability: No external shielding gases required

Advantages of Stick Welding Aluminum

| Advantage | Description | Best Applications |

|---|---|---|

| Portability and Versatility | Minimal equipment requirements, no shielding gases needed | Remote job sites, outdoor applications |

| Cost-Effectiveness | Inexpensive electrodes, economically viable for small jobs | Budget-conscious projects, quick repairs |

| Weather Resistant | Performs well in windy or damp conditions | Outdoor welding, marine environments |

| Maintenance Friendly | Easy setup, flexible for various alloys and thicknesses | On-site repairs, maintenance work |

| Thickness Versatility | Handles varying aluminum thicknesses effectively | Projects with mixed material specifications |

Common Applications for Stick-Welded Aluminum

- Maritime Industry Repairs: Aluminum hulls, decks, and structural components in corrosive marine environments

- Automotive Frame Construction: Repair and fabrication of aluminum frames, engine mounts, and critical components

- Construction Equipment Fabrication: Ladders, scaffolds, and support structures requiring speed and reliability

- HVAC and Roofing Systems: Ducting and structural supports with varying installation conditions

- Aerospace Component Adjustments: Quick fixes and prototype adjustments for non-critical assemblies

Essential Tools and Materials

Types of Stick Welders for Aluminum

AC Stick Welders

- Cost: Most economical option

- Function: Alternating current breaks through oxide layers effectively

- Best For: General-purpose welding, applications where aesthetics are less critical

DC Stick Welders

- Control: Superior precision and arc stability

- Quality: Produces cleaner, stronger welds

- Best For: Aerospace, construction applications requiring durability

Multi-Process Welders

- Versatility: Capable of stick and TIG welding

- Features: Adjustable polarity, hot start capabilities

- Best For: Professional applications requiring flexibility

Selecting the Right Electrode

Choosing the correct electrode is crucial for successful aluminum stick welding. Due to aluminum’s unique properties—high thermal conductivity and oxide layer formation—electrode selection directly impacts weld quality.

| Electrode Type | Characteristics | Applications |

|---|---|---|

| E4047 | Excellent arc stability, good strength | General aluminum welding, structural applications |

| E4345 | Superior corrosion resistance, minimal porosity | Marine applications, high-corrosion environments |

🔧 Electrode Selection Guidelines:

- Diameter: Match electrode diameter to material thickness

- Coating: Choose coatings that enhance arc stability and reduce spatter

- Amperage: Follow manufacturer recommendations to avoid overheating

- Storage: Maintain low humidity conditions to preserve electrode properties

Other Necessary Equipment

- Personal Protective Equipment (PPE):

- Auto-darkening welding helmet

- Fire-resistant gloves and a welding jacket

- Safety glasses and respiratory protection

- Ventilation Systems:

- Portable fume extractors

- Fixed ventilation systems for enclosed spaces

- Measuring and Preparation Tools:

- Calipers, welding gauges, and levels

- Wire brushes, grinders, and chipping hammers

- Stainless steel brushes for aluminum cleaning

Step-by-Step Guide to Stick Welding Aluminum

1. Preparing Your Work Area

- Select Clean Environment: Choose an area with adequate ventilation for fume dissipation

- Set Up Workbench: Ensure sturdy, non-combustible surface with sufficient space

- Install Proper Lighting: Provide clear visibility of the weld puddle for precision

- Clean Aluminum Surface: Remove dirt, oil, oxides using a stainless steel wire brush or approved solvent

- Inspect Equipment: Check cables, clamps, and connectors for defects and clean connections

- Organize Tools: Arrange welding machine, rods, and tools for easy access

- Ensure Safety: Position fire extinguishers, remove flammable materials

2. Setting Up Your Stick Welder

Power Supply Setup:

- Verify Voltage: Ensure power source matches welder requirements (120V or 240V)

- Connect Safely: Secure the power cord to a properly grounded outlet

- Set Polarity:

- Electrode holder → Positive terminal (+)

- Ground clamp → Negative terminal (-)

- Select Electrodes: Choose an appropriate type (E4047, E4345) for your application

- Adjust Amperage: Set according to electrode size and material thickness

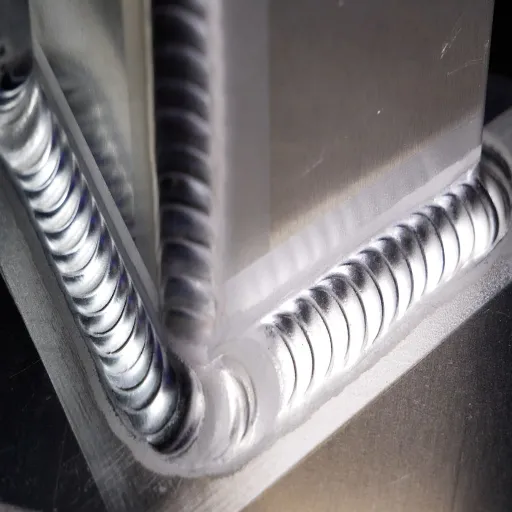

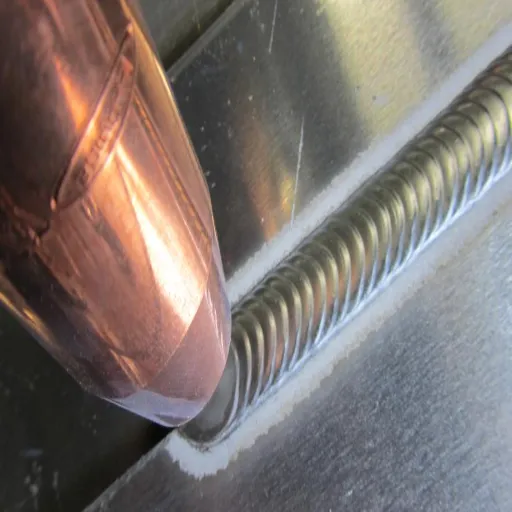

3. Executing the Welding Process

| Step | Action | Key Points |

|---|---|---|

| Arc Strike | Tap or scratch the electrode on the workpiece | Maintain a 10-15° angle to the travel direction |

| Travel Speed | Maintain consistent movement | Too slow = warping; too fast = poor fusion |

| Arc Length | Keep a short, consistent distance | Long arc = instability and spatter |

| Slag Removal | Clean between passes | Use a chipping hammer and a wire brush |

| Heat Monitoring | Watch heat-affected zones | Control cooling rates to prevent cracking |

Safety Precautions for Welders

⚠️ Common Hazards in Aluminum Welding

- Toxic Fumes: Ozone, nitrogen oxides, and metal oxides from heated aluminum

- Severe Burns: Molten aluminum and high heat conductivity

- Eye Damage: Intense welding glare and UV radiation

- Electric Shock: Particularly dangerous in moist environments

- Fire/Explosion Risk: Aluminum dust particles are highly flammable

Best Practices for Safe Welding

- Personal Protective Equipment (PPE):

- Flame-resistant clothing and insulated gloves

- Welding helmet with an appropriate filter shade

- Respiratory protection (N95 or PAPR systems)

- Ventilation Systems:

- Local exhaust ventilation to capture fumes at the source

- Maintain OSHA permissible exposure limits (PEL)

- Equipment Maintenance:

- Regular inspection for cable damage or defects

- Proper grounding of all welding circuits

- Keep the work area dry for electrical safety

- Fire Prevention:

- Remove flammable materials from the work area

- Use fire-resistant barriers as needed

- Keep appropriate fire extinguishers accessible

Advanced Techniques for Experienced Welders

Working with Different Aluminum Alloys

| Alloy Series | Characteristics | Weldability | Special Considerations |

|---|---|---|---|

| 1xxx Series | Essentially pure aluminum, good corrosion resistance | Challenging due to softness | Requires careful heat control |

| 5xxx Series | Excellent strength-to-weight ratio | Very weldable | Ideal for marine applications |

| 2xxx Series | High strength, contains copper | Lower weldability, crack susceptible | May require preheating/stress relief |

| 7xxx Series | Very high strength, contains zinc | Limited weldability | Avoid unless necessary |

Innovative Approaches to Stick Welding Aluminum

- Heat Input Management: Use precision amperage control to prevent warping and burn-through

- Electrode Selection: Choose flux compositions specifically designed to overcome aluminum’s oxide layer

- Surface Preparation: Meticulous cleaning with stainless steel brushes or chemical cleaners

- Arc Length Control: Maintain short, consistent arc length to minimize spatter and instability

- Thermal Monitoring: Use advanced thermal imaging to optimize heat distribution

Enhancing Efficiency in Aluminum Welding

Modern Optimization Techniques:

- Advanced Modeling: Use thermal imaging systems to assess heat distribution

- High-Performance Fillers: 5xxx and 6xxx systems minimize porosity and enhance corrosion resistance

- Automated Processes: Pulsed GMAW (GMAW-P) for increased deposition rates

- Data-Driven Approaches: Machine learning models for real-time parameter optimization

Frequently Asked Questions (FAQ)

Conclusion

Mastering aluminum stick welding is a challenging but highly rewarding skill that opens doors to diverse applications across industries. By understanding the unique properties of aluminum, selecting the right equipment and electrodes, following proper safety protocols, and practicing advanced techniques, you can achieve professional-quality results even in demanding conditions.

Remember that success in aluminum stick welding comes from attention to detail, proper preparation, and continuous learning. Whether you’re working on marine repairs, automotive fabrication, or construction projects, the principles and techniques outlined in this guide will help you tackle aluminum welding with confidence and precision.

References

Aluminum Alloys’ Friction Stir Spot Welding

Missouri University of Science and Technology

This source discusses advanced welding methods for aluminum alloys.

Spot Impact Welding of Aluminum Sheet

OhioLINK Electronic Theses and Dissertations Center

An extensive study of the optimization of spot impact welding processes for aluminum.

Joining Dissimilar Structural Alloys by Vaporizing Foil Actuator Welding

OhioLINK Electronic Theses and Dissertations Center

Research in welding aluminum alloys with other materials towards automotive applications.

The Development of a Curriculum for Shielded Metal Arc Welding

California State University, San Bernardino ScholarWorks

This paper contains interfaces on welding techniques, which include aluminum welding.

Advanced Friction Stir Spot Welding of Aluminum Alloy to Transformation-Induced Plasticity Steel

University of Michigan Deep Blue Repository

A study for advanced welding methods for aluminum alloys and high-strength steel.