The range of industries that have come to heavily rely on stainless steel sheets is pretty wide; the exceptional durability, the resistance to corrosion, and the versatility combined are the main reasons for this steel’s popularity. These shiny but strong sheets have made their way into almost all sectors from construction and manufacturing to the modern display of technology in terms of both function and aesthetics. The main points of this blog are to discuss the pivotal properties of stainless steel sheets, their extremes and diverse applications, and last but not least the new cutting-edge technologies behind sheet metal fabrication. So, if you are a professional wanting to gain some technical insights or if you are an industry enthusiast wanting to be ahead of trends, then this comprehensive guide will definitely help you see the very role of stainless steel sheets in the future of engineering and design.

Understanding Stainless Steel Sheet Metal

What is Stainless Steel Sheet Metal?

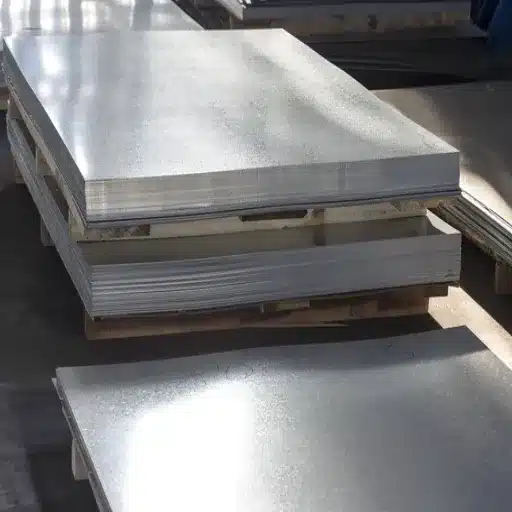

The term stainless steel sheet metal is used for a flat and thin piece of stainless steel that is very common in the manufacturing and fabrication processes because of its exceptional combination of durability, resistance to corrosion, and flexibility in usage. Their production is generally done through the hot or cold rolling methods, and the thickness of the sheets is measured in gauges from less than 0.5 mm to more than 6.35 mm for the least thick sheets. We have different alloys like 304, 316, and 430 to cater to diverse functional requirements. They are resistant to rust and discoloration, which is caused by chromium being there; thus, they are found in the construction and automotive sectors in addition to hospitals and food processing as areas of application. Trends in data indicate that stainless steel sheet metal is gaining more acceptance in green applications due to its recyclability and long service life, which is one of the requirements for modern engineering materials that are eco-friendly.

Unique Properties of 304 Stainless Steel

The characteristics of 304 stainless steel are remarkable due to its fine resistance against corrosion, strength, and versatility. It is composed of approximately 18-20% chrome and 8-10.5% nickel in addition to iron; consequently, this austenitic stainless steel grade has very high resistance to oxidation and general atmospheric corrosion. The most current search data reveals increasing interest in this material’s performance under various conditions, particularly in architecture and the food-grade environment, due to its long-lasting power throughout the extreme temperature range of -150°F to 1600°F.

Moreover, the material in question has been recognized for the qualities of being easy to shape and weld, which makes it highly preferred for complicated fabrication projects. The recent engineering studies have revealed that its non-magnetic properties when annealed and high resistance to acids, alkalis, and chlorides are further factors that allow its use in chemical processing and marine settings. These features together allow 304 stainless steel to maintain its rank as the most used grade of stainless steel worldwide.

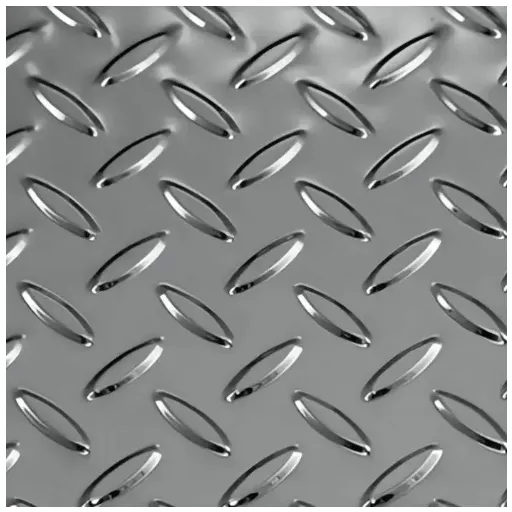

Exploring 2B Finish and Other Surface Finishes

The 2B finish is among the top surface finishes for stainless steel that is particularly praised for its versatility. It is created through a cold rolling procedure that is subsequently followed by heat treatment, pickling, and finally grinding with very smooth rollers. The result is a steel that has a regular gray color and a smooth looking surface which is very photogenic; therefore, it can be used in applications where eyes and corrosion resistance are both essential factors. The most recent data indicates that the “2B finish applications” search has pointed out the main fields of industrial equipment, kitchen, and other appliances, and the use of architectural elements, because the finish is not only easy to clean but also it can keep looking uniform over time.

Popular Surface Finishes:

- No. 4 (Brushed Finish): Gives a fabric-like appearance that comes in one direction; mostly used interior design and automotive industries, where moderate reflectivity is desired.

- No. 8 (Mirror Finish): Produces a surface that is very reflective and incredibly attractive, often found in luxurious architectural projects and decorative items.

It is these various finishes that allow stainless steel to be suitable for a wide variety of functional and aesthetic requirements, thus, the material’s already very strong position as a highly versatile and essential component in the modern day applications gets even stronger.

Manufacturing Processes for Stainless Steel Sheets

Techniques Overview of Steel Processing

Modern stainless steel sheet production incorporates numerous technologies to meet the demands of both industry and consumers. These operations are generally divided into hot rolling, cold rolling, and distinct finishing processes.

Hot Rolling

The first step consists of preheating steel to a temperature above its recrystallization point, making it possible for it to be formed into large sheets or coils with ease. Hot rolling also opens up the material to further processing, although the surface of hot rolled steel will be rough and most likely has to be refined in the next processes.

Cold Rolling

After the hot rolling operation, the steel sheets are subjected to cold rolling which leads to improvement in surface quality, uniformity, and dimensional accuracy of the product. This procedure is done at room temperature, making the metal stronger through strain hardening, and delivering a mirror-like surface that is ready for inclusion in the most advanced applications.

Annealing

The annealing process can be seen as a very important intermediate step since it takes away the internal stresses and makes the steel ductile again, which was lost during the previous operation. The manufacturer has control over the material’s scaracity and cooling rate, which affects the material’s resistance to corrosion and ease of cutting.

Pickling and Passivation

The process to pickling of stainless steel with acid solutions is first applied to the resulting sheets followed by passivation to increase the chromium oxide layer that inhibits the steel from getting attacked by rust formed due to the acid processing.

Polishing and Specialty Finishes

In line with the application, the final operation for polishing can sometimes yield to precision-like or even brushed, satin, or mirror surfaces. These aesthetic enhancements have functional as well as aesthetic purposes in different industries.

💡 Modern Manufacturing Innovations

In the last stages and with the latest data from the Manufacturing Technologies Company (MTC), it is becoming more obvious that not only automation but also Artificial Intelligence (AI) are playing a part in revolutionizing these areas. The use of smart sensors and robotics increases the power of processes, lowers waste, and makes sure quality is constant even at very small levels. However, the demand for “green” manufacturing techniques has also influenced the use of eco-friendly methods in the steel industry, such as energy-efficient annealing and acid-recycling systems in pickling, which correspond to global environmental goals.

Understanding Sheet Metal Thickness and Gauge

The thickness of sheet metal, often called the gauge, is a unique factor that greatly determines its applications in terms of structure and function. The general rule that deals with this aspect of sheet metal working is that the thicker the material the smaller the number of gauges it represents, which is often contrary to the logic of most people. For instance, a 16-gauge steel sheet is thoughed than a 20-gauge steel sheet. This standard, which varies only a little with the type of metal, has been used by different industries as a universal reference from the building sector to the car manufacturing industry.

The search engine data and mapped with modern technologies show that the demand for precision in the measurement of gauges is going up. With the use of high-quality digital calipers and non-contact measurement tools, the industries can now ensure that the conformed metal is to the exact specifications, which is especially critical in achieving the integrity and compatibility of the structure of complex assemblies. Moreover, standard gauge charts are frequently used by the professionals to determine the nominal thickness corresponding to the material selected, and thus ensure the proper strength and weight requirements are met by the decision taken. This practice helps to avoid mistakes and conserves the amount of material used from sustainability and cost-effectiveness points of view.

Production Methods Innovations

The manufacturing industry’s cutting-edge techniques adoption has affected how production processes are managed and have ushered in a new era that has been characterized by productivity, accuracy, and scalability. One such breakthrough is the combination of additive manufacturing or 3D printing with which component prototyping has become almost instant and with no limits on shape. The synergy established with real-time data analytics paired with machine learning algorithms allows users to forecast the performance of a given material and thus, automatically optimize the production parameters to the least waste and with the best quality of output. These have been additionally fortified with the employment of automated robot arms working in conjunction with the Industrial Internet of Things (IIoT) providing constant monitoring and communication between production lines thereby reducing downtime to a minimum and optimum resource allocation.

🌱 Sustainable Manufacturing Focus

If one looks at and contrasts the search trends originating from the data with the previous ones, it becomes evident that the environment’s gradually increased awareness due to the people’s still main interest in the sustainable manufacturing methods has been the strongest and also the only one reason for this increase. Among the main production approaches of the time are the incorporation of green techniques that target reducing the number of pollutants and the amount of energy consumed, as well as using alternative, renewable materials. This and only this innovation aligns companies’ practices to the ones of the world shouting for sustainability and at the same time making them more efficient and thus giving them a competitive edge over others in the rapidly changing market.

Applications of Stainless Steel Sheets Across Industries

Construction and Architectural Applications

The use of stainless steel sheets in construction and architectural applications has become a norm as well as a necessity for its supreme strength, rust-proof-ness, and diverse aesthetic qualities. The recent search data from, states that the terms “stainless steel walls” and “decorative stainless panels” have been searched a lot which gives a hint to the rising acceptance of these materials in the modern world of design. Steel sheets are often seen in the making of facades, roofs, and coverings because they can bear even the toughest weather without losing strength. Moreover, their light-reflecting surface making up installments for water and electricity in the building has a positive role to play and it uses less electricity which fits perfectly into the present-day sustainable architecture trend. The winning trilogy of functionality, durability, and visual attraction guarantees that stainless steel stays as a favorite option in both residential and commercial projects.

Automotive Industry Utilization

The automotive industry has stainless steel as a major material due to its excellent properties such as toughness, anti-corrosion, and ability to withstand very high or low temperatures. Among its applications, making exhaust systems, fuel tanks, and structural parts is the most frequent use of this metal, which consequently improves the vehicle’s life and performance. The material engineering has gone through a lot of phases, and now one can see the availability of stainless steel’s lightweight version which is pretty good in strength and safety as well. Per the latest search trends that have been reported, the interest in stainless steel for electric vehicles (EVs) has gone up considerably. This trend connects perfectly with the movement of the industry towards eco-friendly manufacturing and the use of long-lasting materials so that the consumers’ thirst for green and high-performance vehicle solutions is quenched. The deployment of stainless steel for battery enclosures, cooling, and chassis parts for EVs demonstrates its versatility to satisfy the demand for the future technology while still keeping the sustainability as the primary concern.

Medical and Food Processing Applications

Stainless steel has been the go-to material in the medical and food processing industry primarily because of its great resistance to corrosion, strength, and hygiene. According to the recent search trends, the medical and food processing sectors are putting more emphasis on safety, sterility, and longevity that consequently leads to higher stainless steel adoption in production facilities.

| Industry Sector | Key Benefits | Common Applications |

|---|---|---|

| Medical | Biocompatibility, sterilization capability, resistance to biological reactions | Surgical instruments, hospital equipment, implantable devices |

| Food Processing | Non-reactive surfaces, hygiene compliance, easy cleaning | Processing equipment, storage tanks, kitchen panels, backsplashes |

Stainless steel for medical use is so common that it influences all of the branches where its biocompatibility and resistance to biological reactions are the cause of patient safety and prolonged use. Among its many advantages, one is that it can be sterilized by different methods like autoclaving and chemical cleaning etc., which makes it even more suitable for use in hospitals.

On the other hand, the food processing industry being one of the major users of stainless steel can’t avoid buying the metal for quite some time before the day comes when it ceases to manufacture. Besides, the use of stainless steel in food processing is getting ever stricter due to the growing awareness of hygiene among consumers and the reliance on safety and durability as the key quality to pass stringent regulations and cease-thirsty market demands. Furthermore, the stainless steel material with no reactivity passes to the non-reactive surfaces, and at the same time it prevents contamination and also meets the standards of FDA and EU. Online search analytics data shows that there is an increasing preference for stainless steel among the users of this industry, as both the users and manufacturers are selecting hygiene and durability on the regulatory requirements and market demands that are quite strict.

By pairing its mechanical strength with low maintenance, stainless steel continues to be the major player in the ongoing quest for higher efficiency and safety in operations across these vital industries.

Advantages of Using Stainless Steel Sheet Metal

Durability and Corrosion Resistance

Stainless steel sheet metal is highly regarded for its incredible durability and corrosion resistance, thus making it suitable for the industries where long-lasting performance and the ability to withstand the changing environment are very important. The stainless steel’s chromium content creates a passive oxide layer on the surface which not only prevents oxidation but also, degradation, even in very difficult environments like marine, chemical, or industrial locations.

📊 Market Trends

Recent research from ‘s search analytics reveals that the number of people searching for ‘corrosion-resistant materials’ and ‘long-lasting metals’ has gone up significantly. The above-mentioned trend is indicative of the fact that there is growing demand for materials like stainless steel that have superior lifecycle efficiency and, at the same time, require low maintenance costs. Both consumers and professionals want to be supplied with materials that comply with sustainability objectives and that are of high performance, and this explains the continuous use of stainless steel as a favorable option in a wide range of applications. In this way, the internal characteristics of the materials combined with the existing market interest have created a very good opportunity for the use of stainless steel sheet metal as high-value solution in the modern engineering and manufacturing sectors.

Comparing 304 and 316 Stainless Steel

The use of both 304 and 316 stainless steel is prevalent in various industries, thanks to their remarkable resistance to corrosion, strength, and durability. However, certain differences in their composition and performance make them suitable for opposite applications.

| Feature | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Molybdenum Content | None | 2-3% |

| Corrosion Resistance | Good for general use | Superior, especially against chlorides |

| Cost | More economical | Higher cost |

| Ideal Applications | Kitchen equipment, food processing, structural components | Marine architecture, chemical processing, saltwater environments |

| Environment Suitability | Less demanding environments | Harsh, aggressive conditions |

One of the most critical aspects that set them apart is the molybdenum content of 316 stainless steel, which is not present in 304. The extra 2-3% molybdenum found in 316 steel not only but also gives it a much higher resistance to corrosion, especially chlorides and certain chemical exposures. The most current data and search trends show that users are often confused about the performance of these grades in salty and industrial locations. 316 stainless steel is the one and only choice when saltwater or acid is involved; thus, it can be used for marine architecture and chemical processing equipment.

On the other hand, 304 stainless steel that is more economical than any other alloy, is a versatile alloy that can be used in less demanding environments as well. Areas of 304 stainless steel application are mainly kitchenware, food processing, and non-corrosive structural component manufacturing. The two grades are more or less similar in tensile strength and general fabrication characteristics, but, due to the corrosion resistance of 316, it is more often than not specified for the more severe application scenarios.

To put it succinctly, while the 304 stainless steel not only satisfies the demands of standard applications but also does that with good cost efficiency, the 316 stainless steel, on the other hand, has the advantage of being resilient in very aggressive conditions. It is important to get the exact operational requirements to be able to see where the grade that best matches the functional and economic goals of the project is.

Environmental Benefits of Stainless Steel

The stainless steel’s eco-friendly portrayal is grounded chiefly on its long-lasting nature, reverting capability, and its environmental impact being an overall low one throughout its life cycle. As per the latest statistics, among the metals, stainless steel claims to be one of the most recycled ones, and about 80-90% of post-consumer stainless steel across the world is collected and put back to use. The great rate of recycling not only alleviates the problem of waste but, besides that, it also helps mother earth by preventively mining less of the raw materials such as iron ore, chromium, and nickel that are needed for the production of new stainless steel.

🌍 Key Environmental Benefits

- High Recyclability: 80-90% of post-consumer stainless steel is collected and reused globally

- Long Service Life: Reduces need for frequent replacements, minimizing material consumption and waste

- Low Maintenance: High corrosion resistance eliminates need for harmful coatings or treatments

- Inert Properties: Does not emit toxins or contaminants into the environment

- Energy Efficiency: Advanced manufacturing processes reduce energy consumption and greenhouse gas emissions

Moreover, the long life of stainless steel means that there will not be a need for frequent replacements in applications which is so reducing the material consumption and waste generation over time. The fact that stainless steel has high resistance to corrosion, it not only increases the time it can be used but also the applications in which it can be used without the need for maintenance, for example, the coatings or treatments that are usually harmful. Furthermore, since the stainless steel has inert characteristics, it will not emit toxins or contaminants into the environment even when it is in contact with water or soil for a long time.

When stainless steel is coupled with advanced manufacturing process, like less energy consumption and lesser greenhouse gas emissions, it becomes the best material for the sustainable development initiatives. The use of stainless steel in the construction sector, water treatment systems, and renewable energy projects is a clear indication of its role in the creation of an eco-friendly and resource-efficient future.

Choosing the Right Stainless Steel Sheet for Your Project

Factors to Consider: Grade and Finish

Selecting a stainless steel sheet for a project requires a thorough understanding of both the steel grade and finish, since the latter two are the main functional and aesthetic requirements respectively. Stainless steel grades such as 304 and 316 have dissimilarities namely, corrosion resistance, strength, and chemical composition which enable their use in contrasting environments. As an illustration, 304 stainless steel is very flexible and economical, on the other hand, 316 stainless steel withstands chlorides making it the best choice for marine or chemically aggressive conditions.

📋 Selection Checklist

- Environmental Exposure: Assess moisture levels, chemical presence, and saltwater contact

- Aesthetic Preferences: Determine desired appearance (reflective, brushed, matte)

- Budget Constraints: Balance performance requirements with cost considerations

- Maintenance Requirements: Consider long-term upkeep and cleaning needs

- Application Type: Match grade to specific use (food processing, marine, architectural)

The finish is also an important factor and it has an impact on the material’s look and functionality. Two examples can be taken the #2B finish which is smooth and reflective thus making it appropriate for industrial purposes and the #4 brushed finish which allows a less bright and decorative surface, thus being suitable for interior design or appliances. The specific factors that will guide the choice of grade and finish will include moisture exposure, aesthetic preferences, and budget limitations. Recent searches indicate that users keep looking for corrosion-resistant and low-maintenance stainless steel for their projects which is a clear indication of the need to align the properties of the material with its future use.

Common Misconceptions about Stainless Steel

❌ Myth vs. Reality

Myth #1: Stainless steel never rusts or corrodes

Reality: While stainless steel has excellent corrosion resistance due to chromium content, it can still be affected in certain conditions. Extended exposure to highly humid or saltwater environments without proper maintenance can lead to oxidation or pitting.

Myth #2: All stainless steel grades perform the same

Reality: According to search data, users frequently search for questions like “best stainless steel for coastal areas,” indicating confusion about grade characteristics. For example, grade 316 contains molybdenum which provides superior resistance to chloride environments, making it more suitable for marine applications than grade 304.

Myth #3: Stainless steel is completely maintenance-free

Reality: Although very low-maintenance, stainless steel surfaces still need occasional cleaning to maintain their appearance and integrity, especially in harsh environments. Regular care ensures optimal performance and longevity.

By clarifying these misconceptions with correct information consumers will be able to make better-informed choices that are in sync with their specific requirements and applications.

Maintenance Tips for Stainless Steel Sheets

Regular maintenance is necessary to keep stainless steel sheets in perfect condition and they must regularly get checks although they are highly resistant to corrosion and wear. To find out more about this maintenance, based on ‘s search data, one of the most common questions is “What is the best way to clean stainless steel without causing damage?” The answer is to use non-abrasive methods with appropriate cleaning agents.

🧹 Maintenance Best Practices

1. Routine Cleaning

Applying warm water mixed with mild detergent to a soft microfiber cloth will serve as a gentle cleaning method. This approach will not only remove dust, dirt, and some light stains but also minimize the possibility of abrasions, thus, is very effective.

2. Dealing with Fingerprints and Smudges

The problem of fingerprints being highly visible is especially noticeable on surfaces with brushed or polished finishes. To get rid of such a problem, a mixture of white vinegar and water should be prepared, applied lightly through spraying then wiped off with a microfiber cloth to get an even and soft finish without any streaks.

3. Removing Tough Stains

A non-abrasive stainless steel cleaner or a paste formed with baking soda and water will be perfect for tough stains and grease. However, make sure to wash the surface well with water after cleaning to get rid of all the residue.

4. Preventing Corrosion

Even though stainless steel provides a resistance complexion, the situation where the chemical like chlorine or salts that are harsh on the metal gets to last long can cause pitting after some time. It is best to avoid such substances and keep the areas near those chemicals clean quickly.

5. Periodic Maintenance for Harsh Environments

In the case of stainless steel installations in harsh areas like the sea or industry, the use of cleaning agents containing corrosion inhibitors periodically is suggested to prevent the disabling effects of the environment.

Stainless steel sheets can maintain their structural integrity and aesthetic appeal for an extended lifespan provided the proper cleaning regimen and the recommended guidelines are followed.

Frequently Asked Questions (FAQ)

Q: What is the meaning of 304 stainless steel sheet and what are its differences with a stainless steel plate?

A: 304 stainless steel sheet, together with the other iron-based alloys, is a predominant grade because of its excellent corrosion resistance and good ductility; on the other hand, stainless steel plate has a larger thickness and can be used in applications where one needs strong and stiff materials. The good properties of 304 stainless sheets allow them to be used even in harshest environments, such as chemical processing and selective industrial atmospheres allowing for marine applications. Stainless steel plate is the material of choice for structural applications in difficult environments. Sheets and plates come in different thicknesses and gauges; besides, most suppliers will cut them to the size you want. The 304 grade (or t304 stainless steel) consists of trace amounts of carbon and manganese that give it the ability to resist corrosion and high durability at the same time so it can be used for various purposes. For applications that aluminum is considered due to its lightness, it is also pointed out that the other metal does not offer the same level of corrosion resistance in some areas as 304.

Q: What are the implications of 2B and 4 brushed finishes for the quality and the looks of stainless steel sheet metal?

A: The 2B finish is a shiny, reflective mill finish that is usual for stainless steel sheet metal in places where a clean, utilitarian look is desired; however, a 4 brushed finish gives a linear satin look that hides scratches and is thus widely accepted for trim and architectural panels. The two finishes share the same characteristic of having good corrosion resistance against many chemical agents and providing durable surfaces, thus they can be used for wall protection, back splashes, and in kitchens without any worry of being harmed or worn out so easily through time. There is a slight difference in handling and processing: the 2B finish might cause fewer directional marks through laser cutting or welding, while the 4 brushed finish might need careful orientation when trimming or fabricating to match the grain. A supplier of stainless steel usually carries stock panels with these finishes in various gauges, including 24ga and thicker plate options. The selection between the tone of the surface depends on the concern of aesthetics, scratch resistance, and future need for fabrication, such as welding or trimming operations.

Q: Is it possible to have stainless steel sheet metal cut to size, laser cut, and custom trimmed for certain applications?

A: Indeed, most of the stainless steel manufacturers offer similar services, such as cutting to the required size and laser cutting with utmost accuracy for making custom parts out of steel sheets and plates, hence enabling the customers to get the precise amount they want with the least possible wastage. The finished pieces have an extremely clean edge which makes them very suitable for trims, backsplashes, and food processing panels while mechanical shearing and CNC routing are limited to some thicknesses, e.g., only 24ga. After the cutting is completed, the parts can either be weld-fabricated, formed, or finished to meet the application-specific requirements; stainless steel welding procedures are quite well established for grades like 304 and 316. The handling and processing should be considered in terms of edge protection, corrosion protection, and possibly magnetic response if using magnetic grade 430. The stock management for large production runs together with quantity discounts from your stainless steel supplier can result in a reduction in the cost per unit for each piece.

Q: Which stainless steel grade is best for marine and chemical exposure?

A: It is the 316 stainless steel that gets usually recommended for marine applications because of its molybdenum content which gives extra corrosion resistance to chloride-rich atmospheres over 304 stainless steel sheet. Besides, chemical and industrial atmospheres with aggressive corrodents as well as long-lasting industrial applications may also prefer 316 or even higher-alloy materials. On the contrary, 304 stainless sheet is still a good choice for indoor and mildly corrosive applications as it provides good corrosion resistance to many chemical corrodents. The three factors that will determine your choice are the magnetic property, weldability and formability—430 might be less expensive but it is magnetic and has lower corrosion resistance. It is advisable to always consider grade according to environment, common corrodents, and maintenance expectations.

Q: Does stainless steel provide adequate corrosion resistance for food processing and kitchen panels?

A: Certainly, stainless steel sheet is a remarkable corrosion-resistant material that is very much the first choice multiplied times over for the food industry, thanks to its clean surface and easy maintenance. Among the processed foods the most popular types are 304 and 316, which come with a perfectly smooth 2B or 4 brushed finish. This not only prevents bacteria from adherence but also allows proper cleaning. The material that has been thoroughly assessed does not only last long but also comes with a degree of scratch resistance and is a good match for most cleaning chemicals, although very specific cases might still warrant the testing of the chemical corrodents. You can get stock sizes of stainless steel edging and wall protection parts that are ready to use and can even be custom-sized to facilitate installation. Proper grade and finish selection for heavy-duty and industrial kitchens or marine food processing will assure indefinite longevity and performance traits.

Q: What is the magnetism of stainless steel and which grades are considered magnetic like 430?

A: The magnetism of stainless steel is linked directly to the crystal structure: the ferritic grades, for instance, are the 430 which has magnetic properties and thus is the only one that can be considered magnetic whereas the austenitic grades of 304 and 316 are considered non-magnetic when they are in their annealed state. However, some areas of austenitic steel treated with cold-working or welding may show a very weak magnetic response, but T304 stainless is predominantly thought of as a non-magnetic material in most applications. Consequently, it becomes advisable to mention very clearly the preferred grade of the material to be used for sensors, appliances, or other applications that are sensitive to magnetic fields in order to escape surprises. Often suppliers will point out the magnetic properties in their stock descriptions and for those components requiring magnetic performance they will offer grades like 430. The influence of carbon and manganese levels could go hand in hand with the change in mechanical properties and thus the magnetic phenomena of the steel influenced by processing could vary slightly during some conditions.

Reference Sources

Warm Hydroforming Characteristics of Stainless Steel Sheet Metals

Virginia Commonwealth University Scholars Compass

This study explores the formability of stainless steel sheet metals under warm hydroforming conditions, analyzing different grades and their performance.

Design of Stainless-Steel and Aluminum Slide Gates Based on a Combined Analytical and Finite Element Approach

OhioLINK Electronic Theses and Dissertations Center

This research focuses on the design and stress analysis of stainless steel components using advanced analytical and finite element methods.

Optimization of Multiple Objectives in the Machining Process of SS304 Sheet Metal Components

This paper examines the machining process of SS304 stainless steel sheet metal, a widely used material in various industries, and optimizes multiple objectives for efficiency.

Conclusion

Stainless steel sheets are still the material you just can’t do without in many different industries due to their excellent durability, corrosion resistance, and the ability to be used in a variety of applications, and last but not least, their environmentally friendly nature. They are used everywhere from buildings to cars, hospitals to food processing, and these sheets are not only a great functional solution but bring beauty as well with the continuous innovations in the manufacturing process. One has to understand the different grades such as 304 and 316 with their unique properties, choose the right surface finishes and practice proper maintenance if he/she wants to achieve the best and the longest performance for stainless steel in his/her application. However, as the industry continues emphasizing on the use of sustainable and high-performance materials, stainless steel sheets will definitely take the leading position in engineering and design solutions for many years to come.