Stainless steel plates have chosen to be the main material for construction, manufacturing, or DIY projects because of their versatility, durability, and good appearance. The 8×4 sheet has gained the reputation of being the most popular size since it offers the ideal combination of characteristics and usability in a wide range of applications. Nevertheless, the pricing of an 8×4 stainless steel sheet is still not very clear due to the fact that different material grades, finishes, and market trends greatly affect the prices.

The guide covers the basic things that you need to know and not only gives you a clearer understanding of what affects the price but also guides you through making decisions that suit you best. The write-up will equip you with the information to choose the most suitable option for your wallet no matter if you are a contractor, a businessman, or just someone who enjoys doing things as a hobby. Continue to read as we reveal the different pricing models, important factors and tips for getting the best deal for your projects.

Factors Influencing Stainless Steel Sheet Pricing

Material Grade and Type

The grade and type of stainless steel have a huge influence on the price range. The stainless steel sheets are offered in a variety of grades like 304, 316, and 430, which again, have special characteristics that make them suited for various applications.

📊 Common Stainless Steel Grades Comparison

- Grade 304 – General Purpose

Extremely versatile and resistant to corrosion; therefore, it is usually the material for general purposes. Perfect for kitchen appliances and food processing equipment. - Grade 316 – Premium Marine Grade

Gives the advantage of being extra durable in marine environments on account of its higher molybdenum content. Ideal for harsh chemical and saltwater exposure. - Grade 430 – Economical Option

The economical choice but does not give the same resistance against corrosion as 304 and 316. Suitable for applications with mild corrosive conditions.

Choosing the right grade relies on the specific needs of your project, such as, for example, resistance to tough environments, good-looking finishes, or a small budget. If you are aware of the properties of various materials, you can easily make a decision that not only provides a good performance but also suits the financial resources perfectly.

Thickness and Gauge Variations

The necessary factors for successful project development in selecting and anticipating stainless steel with desired properties of strength, durability, and flexibility are the thickness and gauge variations. The thickness of stainless steel is determined by its gauge number; lower gauge number means thicker sheet. Therefore, for example, 16 gauge stainless steel is stronger and thicker than 20 gauge making it a suitable choice for heavy-duty applications such as industrial countertops or equipment production.

| Gauge | Thickness | Best Applications |

|---|---|---|

| 16 Gauge | ~1.5mm | Heavy-duty countertops, industrial equipment, professional kitchens |

| 18 Gauge | ~1.2mm | Kitchen sinks, countertops, general fabrication |

| 20 Gauge | ~0.9mm | Backsplashes, lighter applications, residential projects |

| 22 Gauge | ~0.7mm | Decorative panels, trim work, lightweight applications |

💡 Expert Recommendation: Current search trends reveal that users’ most common questions are about the best gauge for specific applications, with the kitchen and architectural areas being the most questioned. Experts recommend 16 or 18 gauge for countertops and sinks as the best combination in terms of cost and life. The thinner gauges like 22 are mainly used for decorative applications, where the cost and weight of the material are the main considerations, and they are also the most commonly used.

Determination of the right thickness needs to take into account the load, degree of wear, and overall requirements of the project to ensure the material’s longevity and functionality.

Market Demand and Supply Dynamics

Sustainability trends along with the growing range of industrial applications are the main factors that keep driving the demand for stainless steel products. The demand is also reflected in the numbers of the latest data issued by search engine which show that the interest of consumers is steadily increasing in the area of stainless steel countertops, sinks, and architectural features among others.

The supply-side manufacturers have begun to raise their production rates in line with this and are also putting their innovation resources into the creation of better and more corrosion-resistant products. However, the global supply chain difficulties like fluctuating raw material prices and transport problems have all contributed to the cost and availability of the product. The customers are increasingly assessing and looking for alternatives that are lower in price but have long quality and good life, hence it signifies the essentiality of interrelating the quality and cost to meet the market demand.

Types of Stainless Steel Sheets

430 Stainless Steel Sheets

430 stainless steel sheets have gained a reputation for providing very good protection against corrosion and that is a very important property for their manufacturing and use. Consequently, these stainless steels are accepted by many different sectors. To be more precise, they are the ferritic type of stainless steels; that is, the basic alloying element is chromium, which is generally in the range of 16-18%.

304 Stainless Steel Sheets

304 stainless steel sheets are among the most flexible and universally accepted materials in various sectors; probably their outstanding properties of being durable, corrosion resistant, and good looking have made them so. Ideal for kitchen gadgets and food handling.

316 Stainless Steel Sheets

The sheets of 316 stainless steel are considered to be high-performance materials that possess superb capabilities to resist corrosion and heat, thus allowing them to be applicable in different difficult environments. They are perfectly suited for the marine and chemical sectors.

430 Stainless Steel Sheets Overview

This not only facilitates oxidation and mild pits but also makes the steel magnetic, tough, and friendly to the fabricating processes. This type is cheaper than stainless steel and is therefore suited to applications where the latter’s superior durability is not required.

Common Applications of 430 Stainless Steel

- Home appliances and kitchen equipment

- Automotive trim and decorative parts

- Architectural applications and building facades

- Indoor decorative purposes requiring aesthetic finishes

The newest trends indicate that 430 stainless steel sheets are widely used in the industries such as appliances, kitchen equipment, automotive trim, and architecture. Their appealing option for functional and decorative purposes lies in the aesthetic finish and the ability to resist general wear and tear. Furthermore, search insights point out that there is a rising interest in 430 stainless steel’s fitness for outdoor use. They are capable of surviving in slightly corrosive environments, but are not with additional protective coatings the best choice for harsh and marine conditions. Hence, their application must be done carefully according to the needs of particular projects to achieve performance and longevity.

304 Stainless Steel Sheets

304 stainless steel sheets are regarded as one of the most flexible and extensively used materials across various industries, mainly because they provide an outstanding combination of durability, resistance to corrosion, and visual attraction. Recent search trend data shows that both the professionals and the consumers are asking about the usability and the benefits of 304 stainless steel sheets in diverse applications very often.

✓ Key Benefits of 304 Stainless Steel

- Superior Corrosion Resistance: Can resist corrosion even in environments exposed to acids or alkaline chemicals

- Excellent Workability: High malleability and weldability support the making of complex and precise designs easily

- Versatile Applications: Suitable for kitchen appliances, food processing equipment, and chemical containers

- Aesthetic Appeal: Remarkable strength together with a sleek, polished finish for both structural and decorative use

To sum up, 304 stainless steel sheets remain the most favored material in modern applications that require enhanced performance and dependability through a range of demanding conditions because of their perfect blend of practicality, longevity and great look.

316 Stainless Steel Sheets Comparing

| Feature | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Molybdenum Content | None | 2-3% |

| Corrosion Resistance | Good | Excellent |

| Marine Environment | Moderate | Ideal |

| Price Range | Lower Cost | Higher Cost |

| Best Applications | General purpose, kitchens | Marine, chemical processing |

Current statistics say that 316 stainless steel sheets are becoming increasingly popular in those industrial applications where prolonged service and no breakdown at all are necessary. Despite the fact that 316 is still more costly than 304 in general, the price is often counterbalanced by the long life and low maintenance in severe environments. No matter if a company is constructing equipment for offshore use, making medical instruments, or creating machinery with the highest performance, 316 stainless steel provides the unbeatable strength and reliability that keep the performance optimal even in extreme conditions.

Applications Across Industries

Construction and Architectural Uses

Owing to its remarkable resistance to corrosion, attractive look, and along with durable nature, 316 stainless steel has been a very preferred material in the construction and architectural industry. It is commonly used in the above-mentioned structural components like handrails, cladding, and roofing in places where the environment is either saltwater or heavily polluted.

📈 Market Trend: Recent data from search engine trend indicates that the interest in “316 stainless steel in architecture” searches is noticeably increasing which is an indication of the growing acceptance of its application in modern and eco-friendly building designs. The rise in searches denotes that there is an increasingly high demand for materials combining functionality and aesthetic appeal.

Low maintenance and the aesthetic quality over the years are reasons why architects also consider 316 for the prolonged coastal and urban projects. Its strength and versatility ensure it being a key factor in the high-performance construction applications all over.

Manufacturing and Industrial Applications

316 stainless steel is of utmost importance in manufacturing and the industrial sector because it can resist extreme conditions like corrosion, heat, and chemical exposure. Commonly found in food processing, chemical production, and pharmaceutical manufacturing, 316 stainless steel is a material that allows the areas to be very demanding in terms of durability and hygiene.

Industrial Applications Include:

- Machinery parts and components

- Storage tanks for chemicals and liquids

- Heat exchangers in processing plants

- Food processing and packaging equipment

- Pharmaceutical manufacturing systems

The latest data shows that there is a considerable increase in the number of searches for “uses of 316 stainless steel in manufacturing” which indicates that the material is still relevant and that interest among engineers and industrial designers is growing. The fact that it combines strength, and the cleanliness standards makes it a must-have when it comes to machinery parts, storage tanks, and heat exchangers production. The extraordinary characteristic of the material that enables it to survive tough conditions is one of the driving forces of the global innovation and efficiency that are taking place in the manufacturing processes.

Home Improvement and Decorative Purposes

Another point is that the adaptability of 316 stainless steel has helped a lot in the home improvement and decoration applications. The data obtained from the search trends has shown that the questions about using 316 stainless steel in kitchen fixtures, railings, and outdoor furniture have increased remarkably. This sudden increase in interest is an indication of its appeal to homeowners, who desire both durability and beauty. Modern 316 stainless steel is very much адапtable to bathrooms and kitchens where it is exposed to moisture and also in exterior design. Its low maintenance and stylish look features make it a preferred material for elegant yet practical home solutions.

Where to Buy Stainless Steel Sheets

Identifying Reliable Suppliers

The choice of supplier for stainless steel sheets has to rely on factors like reputation, quality certifications, and customer reviews, which are very important to consider. The list of potential suppliers might include those that have created, through their knowledge and experience, a positive image in the metal sector thus, getting great references.

🔍 Checklist for Selecting Suppliers

- Reputation and Experience: Look for suppliers with established expertise and positive feedback in the metal industry

- Quality Certifications: Prioritize those suppliers who have ISO 9001, a certification that guarantees compliance with international quality standards

- Online Resources: Use platforms like ThomasNet and Alibaba as excellent resources for finding trusted manufacturers

- Local Options: Consider local hardware stores and specialized metal retailers as reliable sources

- Comprehensive Comparison: Always compare prices, delivery options, and support services to ensure smooth purchasing experience

Understanding Pricing Variations

The variation in the costs of basic materials, such as metals and hardware, can be attributed to several key factors. One of the primary causes is the market demand; prices may go up when the demand for certain materials is at its peak during large-scale projects or seasonal trends, which is the case of construction and remodeling activities.

Key Factors Affecting Pricing:

- Market Demand: Prices can rise when demand peaks during large-scale projects or seasonal trends

- Raw Material Costs: Vary due to global events, trade tariffs, or supply chain disruptions

- Manufacturing Processes: Higher-quality materials or custom specifications often come at a premium

- Quality Standards: Certifications and compliance requirements influence final pricing

- Regional Availability: Locally sourced materials sometimes cost less due to lower transportation costs

In addition, fluctuations in the prices of raw materials may occur as a result of global events, trade tariffs, and supply chain disruptions, and this may also impact the final price directly. Furthermore, processes, standards, and certifications involved in manufacturing affect pricing — use of better materials or peculiar specifications often incurs a higher cost. Research shows that the proximity of the material source has an impact on pricing as well, and sometimes materials that are sourced locally are cheaper due to the savings on transport costs. If you are knowledgeable about the factors affecting quality and price, you can, at the same time, develop your sourcing strategy, compete for better prices, and keep up the quality.

Ensuring Quality Assurance in Purchases

Quality assurance in purchases is the key to making sure that performance and value are up to the mark. By using the latest data from search engine, buyers can get back to the basic question: How can quality be ensured while optimizing costs? A combination of a thorough research approach, supplier vetting, and the use of analytics is what the answer boils down to.

Best Practices for Quality Assurance:

- Research Supplier Reviews: Look at the online supplier posts and ratings, as these give you a hint on the reliability and product consistency

- Verify Certifications: Look into the certifications and quality audits suppliers provide to confirm compliance with industry standards

- Use Analytics: Combining information with the latest trends helps spot suppliers with the most impeccable record

- Balance Price and Quality: Identify materials that offer the right mix of price and quality

- Risk Management: This well-thought-out approach is helpful in keeping risks at bay whilst obtaining top-notch purchases

Frequently Asked Questions (FAQ)

What is the price of a 4×8 stainless steel sheet and where can I find a trustworthy distributor?

The cost tag of a 4×8 stainless steel sheet is variable depending on its thickness, surface finish, and also the material type i.e., either 304 or 316. A supplier often quotes the price either by per sheet or by per weight. The delivery and packing will significantly influence the total estimation especially when the order is for a large quantity and the product is of damaged mirror finish or brushed options. If you are into a fabrication project or a trailer project, it is advisable to get in touch with suppliers who have facilities for custom processing. To get not only the best rates but also the finest options you can also look for related searches like stainless 304, 316 stainless steel, and 2b finish. Just remember to check if the sheet metal is cold rolled, has a 4 brushed finish, or is 24ga or another gauge before placing your order.

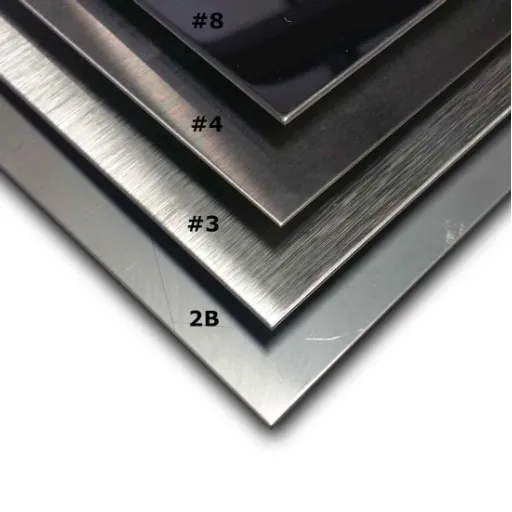

What are the finishes available for stainless steel sheet metal?

2b, brushed (all 4 brushed and 4 brushed finish) and mirror are the most applied finishes, the finisher of which being applicable in different areas such as back splashes and decorative trim. The main reason for brushed finishes to be the most popular choice in residential and kitchen projects is that their aesthetic qualities and hygienic properties have been the factors driving their popularity. They are not as easily stained and are not so difficult to clean as the conventional polishing methods.

However, the top choosing will depend on the project; customers may eventually opt for a mirror finish just for its reflective nature and elegance. Welding becomes more challenging with a highly polished surface and it might depend on the seller’s skill level whether processing with the use of a laser would leave any visible marks. Additionally, some finishes are more resistant to corrosion than others; hence, they are the ones that will be found in marine or food processing applications.

Is type 304 stainless steel sheet still the most popular choice for applications like kitchen or food processing?

Type 304 stainless steel is the most preference given for numerous and varied applications because of its composed character and excellent corrosion resistance even in such harsh environments, thus it can be used in kitchens, back splashes, and food processing machinery. T304 grade stainless steel is often used in 24 ga, 1mm thick, 2mm thick, etc., and the standard sheet sizes are 4ft x 8ft or 4 x 8 format. It can also be provided in heavier dimensions of stainless steel plate for applications that require more weight and thickness stacking.

Even though 304 stainless steel has excellent performance and is the most commonly selected material, it may sometimes be necessary to use the type 316 stainless steel or stainless 304 with higher resistance in very harsh environments or applications related to the sea. One of the factors that the customers usually consider when making a comparison of stainless steel plate sheet with aluminum sheet or aluminum diamond plate is the difference in weight, price and corrosion resistance. For welding and fabrication, check the compatibility of the metal with your welding technology and the suitability of the heat treatment.

What gauge and thickness options like 24ga, 0.2mm or 1mm thick are available for stainless 304 sheets?

The stainless steel sheets have a great variety of thicknesses and gauges which make them 24ga, 0.2mm, 1mm thick, 2mm and even thicker plates depending on the structure and how one wants the finish to be. The thinner sheets e.g. 0.2mm are, for example, used for trimming or decorative panels, whilst the thicker stainless steel plates are used for industrial, welding, or trailer applications. The weight and the price of the steel depend on its gauge.

Furthermore, there is a possibility that the sheet will be subjected to cold rolling or even special processing. Along with the laser cutting and other machining processes that are often provided for these thicknesses, it is still necessary to see if the material is designated as 310, 301, 303, or 202 in order to obtain the correct mechanical and corrosion properties. The suppliers will let you know that the material is of good quality, undamaged, and appropriate for the atmosphere in which it is going to be installed.

How do stainless steel plate and aluminum plate compare when considering price and applications like trailer or residential use?

Stainless steel plate is generally regarded as the most expensive of all but it comes with the main benefits of higher tensile strength and corrosion resistance that would still be applicable in such extreme applications like trailers, marine hardware, or even industrial fabrication. In contrast, aluminum diamond plate and aluminum diamond are lighter and thus they are often less expensive so they are used in making trailer floors or decorative trims where weight and if not cost are the main consequences.

In residential kitchens and back splashes, stainless steel sheet metal is the most commonly used material due to its cleanliness and easy maintenance, while aluminum could be utilized if its lightness and cost benefits were considered. One has to take into account possible corrosion of the environment and the effect of magnetism (magnetic versus non-magnetic grades), especially 430 stainless steel compared to austenitic grades like 304. Further, check if the vendor provides packaging, shipping, and cut-to-size or custom processing services.

How does packaging, shipping, and quantity affect the final stainless steel sheet 8×4 price?

The final price of a stainless steel sheet 8×4 is greatly influenced by packaging and shipping because the costs of freight increase with larger and heavier gauges while the prevention of surface damage requires also more protective packaging. Nevertheless, buying in bulk will reduce the unit price of the sheet, and the usage of pallets or special packaging for protecting mirror finish or brushed surfaces from grit and scratches may be justified by bulk orders.

The shipping of large plates, for instance, can be costly to remote or residential locations, especially when shipping aluminum diamond plate that could be an alternative for trailers or industrial settings. Sellers might give prices that are lower for returning customers or for the orders that combine metal sheets, plate sheet, or aluminum plate. Always ask for the detailed quotes that will separate material, processing like laser cutting, and delivery in order to compare the total landed costs accurately.

Reference Sources

- Stainless Steel in Construction: A Review of Research, Applications, Challenges, and Opportunities

This review discusses the use of stainless steel in construction, highlighting research advancements and cost considerations. Read the review here - Stainless Steel

This study explores the properties and safety of stainless steel, including its applications in various industries. Access the study here - The Use of Stainless Steel in Structures

This research examines the viability of stainless steel as an alternative to carbon steel in structural applications. View the study here