Precision is everything when working with stainless steel. Easy materials can be for Components Industrial Use, or tougher materials can be for Architectural Components, but generally whatever damage the cutter puts on is irreparable. Fortunately, the highly sophisticated cutting machine is capable of performing this job flawlessly. In this article, however, we will cover the capacities, benefits, and critical features of the stainless steel plate cutters while pointing out their contribution toward clean cut and perfect, waste-restrained frontwork. If you want to improve your existing metalworking processes and are interested in top-notch craftsmanship, stay in touch and learn about how this latest tool is changing the game for the professionals and the hobbyists alike.

Introduction to Stainless Steel Plate Cutters

Importance of Stainless Steel Plate Cutters

Cutters for stainless steel plates are essential objects for metalworking as they provide precision and efficiency. These are tools utilized for clean and uniform cuts, which is detrimental when working with stainless steel because of its inherent higher strength and corrosion resistance. The use of proper cutting tools gives opportunities for less deformation of materials, thus preserving the integrity and structural properties of the steel. This precision not only guarantees the finished product’s visual appeal but also confirms its compatibility with other components in assembly processes.

Another enormous advantage that stainless steel plate cutters have is that they help in reducing waste. A disadvantage of cutting with improper methods is the loss of material, which unreasonably increases costs and inefficiencies. Good cutters are designed in such a manner that maximum yield is obtained, which enables the utilitarian application of resources while keeping frivolous expenses at bay. When the manufacturers of high-volume steel are accustomed to these right cutting tools, cost-saving occurs, which promotes the act of going green.

The cutters further enhance productivity and safety in the workplace. The advanced cutters are equipped with adjustable settings, ergonomic design, and higher durability to facilitate metalworking tasks. Due to its user-friendly operation, it is easy for the operators to complete their tasks in a shorter time while assuring a consistent level of quality. The tools also reduce workplace injuries by lessening the physical exertion required and providing safety features. From construction to the automotive industries, stainless steel plate cutters will truly get the job done safely and professionally in no time.

Applications in Various Industries

Stainless steel plate cutters have become essential in many industries due to precision-based working, durability, and efficient functioning. Major industry sectors where these tools find greater application are described below, along with the detailed purpose of utilization:

- Construction Industry: The construction phase uses stainless steel plate cutters to shape or fabricate metal components for building frameworks, roofing structures, and finishes. The ability to shear heavy plates with very little distortion provides for the creation of structurally sound and dependable components. The cutters also allow work to be finished faster, which is necessary for large-scale projects.

- Automotive Manufacturing: In vehicle manufacturing, stainless steel plate cutters cut chassis parts, exhaust systems, and decorative trims. Stainless steel, with its high strength, is an appropriate material used for vehicle manufacture, while precise cutting ensures perfect fit and finish of parts. This enhances vehicle performance while remaining aesthetically pleasing.

- Shipbuilding and Marine: For the marine industry, stainless steel plate cutters help in the creation of ship hulls, decks, and binding internal frameworks. Because stainless steel is corrosion-resistant and these cutters proficiently cut big steel plates, these components are able to withstand adverse marine environmental conditions for a long time.

- Aerospace Sector: Stainless steel plate cutters become handy, making those intricate and highly durable components, such as engine parts, fuselage sections, and support structures, destined to match the exacting standards of aerospace. These tools represent precision and reliability, and hence they form a worthy partner to aerospace manufacturing with its stringent engineering and safety requirements.

- Energy and Power Generation: In the energy industries, stainless steel cutters find their heaviest use in the fabrication of components for wind turbines, hydroelectric plants, and thermal power stations. The strength of stainless steel under extremely trying conditions and the ability of the cutters to produce efficiently custom-shaped parts such as turbine blades and heat exchangers make it indispensable to these industries.

In servicing the areas mentioned above, stainless steel plate cutters prove their varied functionality and continued worth in modern manufacturing and infrastructure development.

Why Choosing the Right Cutter Matters

The right cutter must be suitable for stainless steel plates to capitalize on precision, efficiency, and economy during fabrication processes. Proper cutters ensure minimal wastage of material, lower downtime, and meet specifications on demand. Thus, being a tough and resistant material, stainless steel warrants only supreme cutters to meet the requirements of complex and quality parts.

Using inappropriate cutters leads to operational issues ranging from poor cuts, rapid wear and tear, to damage to the stainless steel material itself. In the long run, this raises the production cost, infringes safety measures, and downgrades the capabilities of the components produced. Hence, a cutter designed for stainless steel will run smoother while providing better service life to its respective tooling.

When selecting a cutter, the material thickness, cutting speed, and stainless steel type should be thoroughly considered. Applications of laser cutters, plasma systems, or otherwise have to be considered for high-precision applications, split between aerospace and medical. Upon considering correct cutter application, producers can streamline their processes, come out with finer results, and realize an increase in market demand.

Types of Stainless Steel Plate Cutters

Manual vs. Electric Plate Cutters

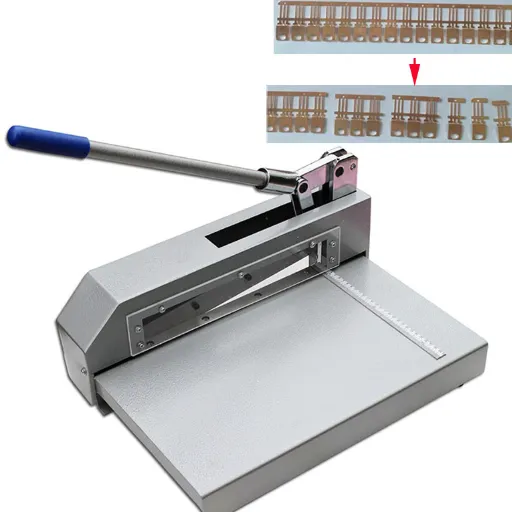

The manual stainless steel plate cutter is cheap and portable for those using physical effort, while the electric cutter can perform its work more rapidly and in a more precise manner, drawing energy.

| Key Point | Manual | Electric |

|---|---|---|

| Cost | Low | High |

| Portability | High | Low |

| Effort | High | Low |

| Speed | Slow | Fast |

| Precision | Moderate | High |

| Power Need | None | Electricity |

| Maintenance | Low | Moderate |

| Durability | High | Moderate |

Plasma Cutters for Stainless Steel

Plasma cutters are indeed essential tools for industrial and manufacturing applications, ensuring an accurate and clean cut in stainless steel. A plasma cutter creates a high-temperature jet of plasma where the electrically conductive gases used, like oxygen, argon, or nitrogen, are generally above 25,000°F (13,870°C), thereby melting and blowing away the material of the cut. This produces perfectly clean edges with a minimal distortion of the material due to heat.

Today, plasma cutting systems are more advanced, offering CNC integration and variable amperage settings for different thicknesses of stainless steel, from thin sheets of 1/16-in. (1.6 mm) to thicker plates, even up to 2-in. (50 mm). These tools are faster than traditional cutting methods and offer more precision to work with intricate designs.

However, a few considerations pop up in the operation of plasma cutters, such as the thermal conductivity of stainless steel and its oxidation resistance, that call for high-purity gases to be employed rigorously while calibrating the system to yield the best results. Plasma cutting setups also require a steady and sufficient electrical power supply and periodic maintenance of consumable parts such as the nozzle and electrode to uphold cutting quality and extend the life of the system.

For their operational strength and versatility, plasma cutters are considered among the top investments in any industry where stainless steel is a main material, such as the automobile, aerospace, and construction sectors. By utilizing cutting-edge technology of plasma cutting, operators are assured of consistent results, minimum rejection, and initial lower running costs.

Band Saws and Their Uses

Band saws are precision cutting tools used mostly for metalworking, woodworking, and logging industries. They have a continuous band of toothed metal that moves uniformly over two or more wheels to make accurate and consistent cuts. Whereas these saws are known to cut intricate curves, the band saw refines straight cuts and is a machine to carry out tasks that require versatility and speed.

Industrial band saws are used for the processing of metal alloys, plastics, and composite materials of varying thicknesses with negligible waste of material. Modern types are equipped with variable blade speeds, adjustable table angles, and automatic feed systems so operators can tailor the tool for very specific cutting jobs. Recent industry studies note how advances in blade technology based on carbide-tipped and bimetal blades have not only increased the durability of the bandsaw but also improved precision in cutting, thus reducing the frequency of blade replacement.

On the safety front, mechanization from an earlier generation has vastly improved workplace safety. From blade tension monitors to blade brakes, these have seen the operational risks decrease drastically and productivity rise. The necessity for innovation places band saws at an important strategic point within present-day industry, in construction, and artisan work, where things have to be done with material efficiency and accuracy.

Key Features of a Quality Plate Cutter

Blade Material and Design

The blade determines the efficiency and durability of a plate cutter, raising the bar on the tough demands that its design has to undergo. Very high-performance blades are commonly made from superior quality alloys like HSS (high-speed steel), carbide-tipped materials, or bi-metal. All these materials have their own benefits in different situations, wherein, for example, if the blade is made of HSS, it will possess very good resistance to wear and heat, and hence will be usable for a longer period under conditions of severe stress. On the other hand, carbide-tipped blades may be more brittle but have better precision and are suited to cut harder metals with the least deformation possible.

The layout geometry of the blades is of utmost importance. The tooth gullet, pitch of the teeth, and variable tooth design are all tailored to perform smooth cuts with reduced vibration. These features enable the blade to cut accurately and have a longer life. Coatings now exist that take advantage of these factors, such as titanium nitride, which reduces friction, or a ceramic-based surface treatment that resists corrosion and produces constant performance even under harsh industrial conditions.

The correct blade to use in any application must be chosen with due consideration to material hardness, thickness, and operational speeds that must be applied. Correspondence to these blades assures the achievement of desired results combined with improved operational efficiency.

Cutting Speed and Capacity

Speed and efficiency lie at the heart of deciding upon industrial blades for high-precision operations. Overtly, the cutting speed is generally dictated by the rotational velocity, i.e., the number of revolutions per minute (RPM), and the diameter of the blade, with calibration of both necessary against the material being cut so that one may realize utmost efficiency and minimum wear. An interesting rule of thumb is that a harder material, such as stainless steel or titanium alloys, would require slower cutting speeds to stop the heat build-up that impairs the blade. On the other hand, aluminum or plastics, which are softer materials, permit a fast cutting rate.

Capacity largely depends on the design characteristics of the blade, such as diameter, tooth geometry, and grade of material. A bigger diameter of a blade means a greater depth for the cut, whereas the more advanced tooth designs with differing sizes of gullet and rake angles take care of the smoother removal of material and better precision. For instance, carbide-tipped blades are generally used for higher load applications where strong retention of the edge and resistance to deformation under load are of prime importance.

Advanced computer-aided simulations and empirical test methods have shown that coupling the cutting speed and capacity to the material properties can greatly enhance the adjustment of the service life of a blade. A favorable feed rate during the operation, for example, will always make sure that chips are evacuated steadily and that less heat is built up to deteriorate clamping fixtures and materials. Sound maintenance systems are recommended by the industry reaching including the checks coupled with the automated lubrication systems to achieve a competent bordering effect in ever-varying working conditions.

Motor Power and Performance

The dance of motors matters in various benefits of system efficiency, so much so that the motor may adapt its power to the variation in loads and demands set upon it. The highest class of motors is designed with heavy-duty torque to maintain performance at differing speeds, a much-needed ability in applications requiring control and confidence under conditions demanding utmost stresses.

On the other hand, the latest technological advances in motor design, such as variable frequency drives (VFDs) with energy-efficient features, have optimized energy consumption levels while limiting mechanical stresses. In combination with this, effective thermal management systems prevent performance from degrading along with mechanisms for cooling and heat extraction, even during hours of use.

Power ratings must always be correctly calculated to suit operational needs to avoid energy wastage and the appropriate rate of wear-out. Through real-time monitoring and IoT-based analytics systems, equipment performance can be tracked continuously, allowing predictive maintenance and reducing downtime. All of these improvements aim to ensure that, given the strict standards industries impose on motor-driven equipment, motors provide the utmost operational efficiency.

Benefits of Using Stainless Steel Plate Cutters

Precision and Accuracy in Metal Cutting

Cutting and shaping metal is a matter of precision and accuracy, and these industries require that the inventor fabricate high-quality work with very minimal margin of error. Plate cutting in stainless steel can obtain the highest degree of precision with techniques such as laser cutting, abrasive water jet cutting, and perhaps CNC integration. These cutting technologies are made to provide an adjacent result in which every cut follows the exact pre-programmed measurement, thus reducing scrap material and maintaining the integrity of the structure from one production run to the other. The computer-aided design added an extra element of precision through the use of digital templates that act as references for the exact specifications that need to be met during the cutting process.

🎯 Key Precision Benefits:

- Tolerances as close as ±0.005 inches with laser cutting

- No heat-affected zones (HAZ) with water jet cutting

- Reduced material waste by up to 30%

- Increased productivity by 25%

Stainless steel plate cutters with state-of-the-art features ensure high levels of accuracy across a number of applications. In particular, laser cutting technology allows narrow beams of light to cut highly intricate patterns with tolerances as close as ±0.005 inches. Water jets are cold-cutters, so no heat-affected zones (HAZ) could develop that would mar the quality of the metal. These precision-constrained technologies have been put to the test in aerospace, automotive, construction, and many other industries. Ongoing research confirms their effectiveness, with performance metrics remaining consistently at or well above the accepted industrial standards.

Moving to more advanced steel plate cutters improves time and overall output. This makes the first step of cutting somewhat safer from human mistakes. It does increase production so that manufacturers may meet time expectations without compromising any quality. Per recent case studies, companies that use CNC-cutting systems in their production stand to reduce waste material by 30 percent, with productivity increasing by 25 percent. Capitalizing on these advancements in the industry positions businesses well in markets that largely promote precision-engineered components, thereby ensuring that every component is manufactured to stringent standards and customer specifications.

Durability and Longevity of Tools

Example considerations should be made while determining tool wear and tool life. These include consideration of tool materials, maintenance of tools, and the nature of the application. Good tools made from the best materials, such as tungsten carbide or high-speed steel, have good wear resistance and may undergo long operating cycles without experiencing wear. Moreover, by buying durable tools, manufacturers will cut production costs and increase production efficiency by reducing downtime.

In my view, design-for-durability tools entail many benefits beyond just cost considerations. Such tools guarantee continued functionality, enabling the attainment of very precise and repeatable results, which is very critical in industries where tolerances are very tight. Fewer replacement operations also mean eco-friendly processes, which minimize the effects on the environment due to tool manufacturing and disposal.

For instance, if a tool is designed to perform within the constraints assumed under normal working conditions for a given period, it will have its performance below par if maintenance is not undertaken within that period. Appropriate maintenance shall follow the inspection of tools, service proper lubrication, and use of tools worthy of their purposes according to the manufacturer’s instructions. If the designer thinks of durability and the engineer implements a good maintenance schedule, they can be sure that the tool will perform and will give them a competitive edge going into the market, where precision and efficiency are paramount.

Maintenance Tips for Your Plate Cutter

Regular Cleaning and Inspection

With an eye toward optimal performance and longevity, periodic cleaning and inspection of your plate cutter are obligatory. Clean any such debris, dust, or material build-up from the blade after its use and the cutting surfaces by wiping them a wipe from a soft brush or nail-free cloth. Look for a wearable sign, dull edges, or nicks on the blade that may affect accuracy and cutting power. The guidebars, alignment, and any adjustment system should also be cleaned of any obstruction or build-up that may hinder accuracy.

Lubricate the moving parts after cleaning and inspection, using the lubricant that the machine manufacturer recommends. This will protect against corrosion and reduce friction during movement, especially around the hinges and sliding parts. Electrical parts should be checked for any frayed wiring or loose connections since such faults could pose hazards in operation or lessen machine performance.

By adhering to the above methodical cleaning and inspection, the chances of failure in operation are greatly reduced. Systematic servicing in itself ensures tool reliability with its persistent accuracy, reducing cost along the way in maintenance during the whole service life.

Replacing Blades and Parts

⚠️ Safety First: Blade Replacement Procedure

- Disconnect all power sources (electrical, pneumatic, or batteries)

- Remove locking mechanisms and fasteners safely

- Inspect the mounting area for wear or damage

- Ensure proper alignment during reassembly

- Test the new installation before full operation

Blade and part replacement is a critical maintenance procedure that helps the tool maintain maximum efficiency and operation. Begin by following the manufacturer’s instructions to identify the required specifications and replacement intervals for components. Improper or uncertified parts could hamper performance, void warranties, and create other hazards.

Disconnection of the tool from any source of power—including electrical, pneumatic, or batteries—is an imperative step for blade replacement. Avoid operating locked tools where a blade-in-hand could slip; remove any locking mechanisms or fasteners-screws, bolts, clamps-and hold the blade or part securely. Before mounting the new component, carefully inspect the mounting area for excessive wear, corrosion, or damage. Tight and proper alignment ensures no wobbling or uneven cutting occurs during reassembly, which is key, as such conditions could prove to be more damaging to the equipment.

With other consumables and wear items like bearings, belts, and clipping wires, continue with the disassembly according to the set step-by-step instructions and measure all the critical tolerances with appropriate tools-chalk gauge, calipers, or micrometers-before proceeding with the replacements. All connections, fasteners, and lubrication points must be secured and fixed correctly to allow for proper functionality.

Early observation and monitoring of the newly installed parts during operation are strongly encouraged to ensure that wear patterns are consistent, and installation problems can be rectified early. Following these procedures reduces downtime, improves tool longevity, and ensures safety compliance. The maintenance records must be kept for every replacement done, which shall lead to the establishment of a proper maintenance schedule.

Storing Your Cutting Tool Properly

The cutting tool must be stored properly to maintain and safeguard its life and operational efficiency. Tools may be cleaned if necessary to often with dirt deposits, oily substances, or any forms of residues causing corrosion or degradation in performance. Store them under weather-proof conditions of temperature or humidity because, either murky or otherwise, these factors can impair the establishment of the tools with the flow of time.

Organize your tools by type and size, using separate labeled compartments or racks that preserve the physical integrity of their content from undue knocks or misalignments. Precise cutting tools such as end mills or drill bits could be stored in double plastic sleeves or layers of foam, which protect the sharp cutting edges from damage during storage; whereas, tools treated with oil coatings or rust inhibitors should be kept in sealed containers to maintain their protective layers.

In facilities where a large number of items are handled, an optimally organized management system for storing and retrieving tools becomes a necessity. Equipped with automated systems such as vertical lift modules or CNC tool cabinets, this system can track and store tools on its own, thereby reducing human error from manual handling. Adhering to the above laws of storing not only extends tool life but also allows one to cope with unexpected downtime and polish operational accuracy. A periodic audit of storage conditions and tool organization must also find a tucked place in the maintenance protocol, ensuring performance sustainment.

Frequently Asked Questions (FAQ)

❓ What is meant by a stainless steel plate cutter?

A stainless steel plate cutter is a cutting tool made specifically for stainless steel plates and sheets. It can cut extremely tough materials and is another tool to consider in a workshop or home garage where metal fabrication or repairs are taking place.

❓ Can I use these cutters to cut metals other than stainless steel?

Yes, stainless steel plate cutters are also cuttin’ tin, copper, even thick carbon steel. One should always confirm the suitability of the cutter on a particular metal whenever there is a concern; else, one could burn or damage the blade.

❓ Why would I use a stainless steel plate cutter?

Accurate cuts, for thick stuff, that last best-these are a few advantages that stainless steel plate cutters offer. Another factor in favor of replaceable blades is the extended life span of the cutter and a profitable investment for any user who has to use it frequently.

❓ Is it dangerous to use stainless steel plate cutters?

A stainless steel plate cutter is safe so long as you follow all safety guidelines. These guidelines include using protective gear like gloves and safety glasses, and having the working area well-ventilated, especially when the material being cut might result in air contaminants.

❓ What do I do if my stainless steel plate cutter becomes dull?

Once your stainless steel plate cutter gets dull, you can either sharpen the blade if it is meant to be sharpened or replace the blade with a new one. Taking care of your cutting tools with cleaning and lubrication will also extend the time before you ever experience dullness.

❓ Can stainless steel plate cutters be used for home DIY?

Yes, absolutely! The stainless steel plate cutter works great for home DIY, especially if you want to get into metal fabrication or repairs. With some safety measures, you’ll be able to complete your projects and get a professional finish, cutting stainless steel or any other metal.

References

-

- 📄 Improvement of cutting performance for thick stainless steel – A study on improving cutting performance using fiber lasers.

- 📄 Laser Cutting Services | Tech Foundry – UC Davis – Information on industrial-class laser cutters for stainless steel.

- 📄 Laser cutting studies on 10-60 mm thick stainless steels – Research on laser cutting techniques for thick stainless steel plates.

- 📄 Machine Tools | School of Engineering – George Washington University – Guidelines for machining and cutting stainless steel.

- 📄CNC Plasma Cutter SOP – University of Nebraska – Standard operating procedures for plasma cutters, including stainless steel.

🎯 Ready to Upgrade Your Metalworking?

Choosing the right stainless steel plate cutter is essential for precision, efficiency, and long-term cost savings. Whether you’re a professional fabricator or a DIY enthusiast, investing in quality cutting tools will transform your metalworking experience.