The stainless steel perforated sheet is a flexible and unavoidable raw material that has many more or less industrial, architectural, and design applications. These sheets are manufactured with an accuracy that, first, involves the punching of the patterns into the metal, thus providing both practicality and beauty at the same time. The article will at the end of the day give a thorough knowledge of the perforated metal, revealing its main characteristics, advantages, and the extensive list of industries it serves. Among the various fields where perforated stainless steel metal sheets are used, construction is the first one to benefit from its impact on structural integrity. In addition, the sheets are used in modern design, filtration systems, and other areas where efficiency and adaptability are demanded. The article will thus cater to both the professionals who look for durable materials as their primary requirement and the designers who seek creative inspiration as their primary need by providing the unique advantages and different applications of perforated metal through valuable insights.

What is a Stainless Steel Perforated Sheet?

Definition and Overview of Perforated Metal

Perforated metal or perforated sheet has different names referring to one and the same material. It has been mechanically treated to form a pattern of holes, slots, or other shapes on its surface. The material is usually made from stainless steel, aluminum or other hard metals, while the precise model is obtained through punching, stamping or laser cutting methods, all of them creating less than 0.1% deviation from the original design. The very property of these sheets implies their application in areas like medical, automotive, and filtration technology, such as.

Key Applications Overview

- Air Circulation: Enhanced ventilation in industrial and commercial settings

- Sound Absorption: Acoustic management in architectural interiors

- Aesthetic Element: Modern design features in contemporary spaces

- Filtration: Precise particle separation in industrial processes

More and more people are looking for perforated metal because it has many applications in industrial, architectural, and environmental areas according to the most recent data and www.perforatedmetalmart.com. It is used, among other ways, to provide better air circulation, sound absorption, and as an aesthetic element in modern interiors. Some of the rather unique features – like resistance to corrosion, openness to custom design, and straightforward incorporation into existing systems – which produce such situations, make perforated stainless steel sheets especially beneficial for industries like construction, automotive, and filtration technology.

Composition and Types of Stainless Steel

Steel and chromium (minimum 10.5%), nickel, molybdenum, silicon, and manganese in different variable proportions according to grade and use are the main components of stainless steel, which is an alloy. The stainless steel’s resistance to corrosion is largely due to the presence of chromium which oxidizes the surface and makes it less susceptible to further oxidation. Nevertheless, there are many other elements which are often added in order to enhance with chemicals and high temperatures or to give the steel more ductility, weldability, or strength.

Five Major Categories of Stainless Steel

1. Austenitic Stainless Steel

This type is the most used one and it has a high amount of chromium and nickel. Its resistance to corrosion is excellent, its ductility is great and its fabrication is quite easy. Therefore, it is the most applied in the making of dining appliance, surgical instruments and components in shipbuilding. The most commonly used grades are 304 and 316 stainless steels.

2. Ferritic Stainless Steel

Ferritic stainless steel is low in nickel and mainly consists of chromium, which makes it magnetic. It is one of the good and inexpensive materials to resist corrosion. The main applications are in automotive parts, industrial machinery, and architecture.

3. Martensitic Stainless Steel

Martensitic stainless steel is the type of steel which can be hardened and contains a lot of carbon. The steels of this category have less corrosion resistance than the austenitic grades, but they also possess very high strength. The making of knives, blades for turbines, and tools for surgery are some of the examples of applications. 410 and 420 are representative of martensitic steels.

4. Duplex Stainless Steel

Duplex stainless steels combine austenitic and ferritic characteristics to give high strength, excellent corrosion resistance, and good stress corrosion cracking resistance. These new materials will be suitable for chemical processing, the oil and gas sectors, and new construction projects.

5. Precipitation-Hardening Stainless Steel

Wear resistance is one of the main features of this kind of stainless steel, which is mostly due to heat treatment processes that involve the precipitation of strengthening elements. It is employed in the manufacture of aerospace components, top-quality tools, and defense applications.

Important Note: The selection of a specific type and grade of stainless steel is based on the combination of mechanical properties, environmental compatibility, and the intended application, which ensures that performance is optimally distributed across various industrial sectors.

Manufacturing Process of Perforated Sheets

The production of perforated sheets is a procedure that involves the use of exact machinery and up-to-date techniques to serve both industrial and architectural markets. Choosing the raw material, stainless steel, aluminum, or carbon steel, according to the required mechanical properties and application-specific needs, is the first step in the process.

Primary Perforation Methods

| Method | Description | Best For |

|---|---|---|

| Punching | Mechanical or CNC-controlled press using die and punch for specific hole patterns | Large quantities with standardized repetitive patterns |

| Laser Cutting | High-powered lasers create exact and elaborate perforations | Complicated and custom-made designs |

Various finishing operations are performed on the sheets, which may include deburring to get rid of the sharp edges, applying surface treatments like galvanization or powder coating to improve the resistivity against corrosion, and flattening or leveling to make sure the sheets are absolutely flat. During the entire production process, quality inspections are done on the sheets to make sure that they comply with the predetermined dimensions, tolerances, and durability criteria. Moreover, modern manufacturing plants that use cutting-edge technology, also rely on automation and real-time monitoring systems to speed up the production process and reduce waste.

The production of perforated sheets is very meticulously done to keep the precision side and also the adaptability to different sector needs balanced. Perforated sheets find usage in many sectors

Applications of Stainless Steel Perforated Sheets

Industrial Uses of Perforated Metal

Perforated metal has become a staple for various industries owing to its exceptional strength and durability, as well as its ability to be tailored to specific requirements. Filtration systems are one of the main applications of perforated metal, where, thanks to the uniform distribution of the holes, utmost control can be exercised over the segmentation of the particles, while the flow of liquids or gases is still at the very best level. Some industries like oil and gas, water treatment, and chemical processing use stainless steel perforated sheets to improve efficiency and at the same time ensure safety by contamination preventions.

🔧 Filtration Systems

Uniform hole distribution enables precise particle segmentation while maintaining optimal flow rates in oil and gas, water treatment, and chemical processing industries.

🏗️ Structural Applications

Used in ducting and building skeletons, providing both support and weight reduction for efficient and aesthetically flexible solutions.

🚗 Automotive Industry

Essential in exhausts and grilles where heat resistance and optimal airflow are critical performance factors.

Besides that, perforated metal is often seen in structural applications like ducting and the building’s skeletons. By having the role of both support and the factor that reduces the weight of the structure, it is the protagonist of the creation of the efficient and aesthetically flexible solutions. The car industry, for example, uses it in exhausts and grilles, where resistance to heat and airflow are the main factors. Some evidence reports an increasing demand for these materials in eco-friendly designs and power-saving systems, thus their importance in the current industrial scene is getting bigger and bigger.

Architectural Applications of Perforated Steel

Due to the combination of the practical aspect, the strength, and the aesthetic appeal, perforated steel has already been recognized as one of the key materials for contemporary architecture. Architect’s tendency to adopt perforated steel for façades, sun-shading devices, and ventilation solutions is a strong indicator of the material’s diverse applicability, according to the newest data available. Envelopes that allow energy-saving through improvement of natural airflow and less dependence on cooling systems are one of the most important uses of this type of material. In addition, the ability to filter light while creating the illusion of openness makes it a ‘must-have’ for decorative screens and external walls. Good to know, the nature-friendly construction and sustainable construction are getting more and more attention from the building sector, especially in urban areas that offer green building certifications. This trend is indeed panning out along with the global architectural shifts that are currently happening and which are defined by combining design innovation with environmental sustainability.

Architectural Benefits Checklist

- ✓ Energy Efficiency: Improved natural airflow reduces cooling system dependence

- ✓ Light Filtration: Creates balanced illumination while maintaining visual openness

- ✓ Sustainability: Supports green building certifications in urban developments

- ✓ Design Versatility: Suitable for façades, sun-shading, and decorative applications

Consumer Products Utilizing Perforated Sheets

The use of perforated sheets in consumer products has been on the rise and this is largely due to their features that cut across versatility, aesthetic appeal, and functionality. Evidence from the latest search engine data indicates a remarkable increase in the interest towards perforated sheets in applications such as ventilation panels, speaker grilles, and electronic device protective casing. These applications take advantage of the material’s characteristics in that it allows airflow and sound transmission while still providing structural integrity. Moreover, the prevailing trend is to use them in home furniture designs, decorative lighting fixtures, and shelving which gives the areas a nice modern industrial look. The retail trend clearly indicates that the consumer has grown fond of materials that are able to marry function and design in a very tasteful way.

Benefits of Using Stainless Steel Perforated Sheets

Durability and Resilience of Stainless Steel

Stainless steel is known for its exceptional durability and strength and hence, it is the most widely used material across industries. Its inherent property of not rusting and being eroded by environmental conditions is that its chromium oxide coating, which acts as a shield, is the reason why it can last even in the most extreme environments for a very long time. Different grades of stainless steel have alloy grades ranging from 72,000 to 220,000 psi tensile strengths, and therefore, such great amounts of mechanical stress and deformation can be applied without losing its structural integrity. Also, this material can be very, very resistant to impacts and keep its performance if subjected to extreme temperature changes or under heavy weights.

Key Performance Statistics

| Property | Performance Range |

|---|---|

| Tensile Strength | 72,000 – 220,000 psi |

| Manufacturing Precision | < 0.1% deviation from design |

| Chromium Content | Minimum 10.5% |

The most recent information from this search engine indicates that, stainless steel is still among the most popular materials in industrial and architectural applications, mainly due to the factor of trust by consumers and its environment-friendly status. Lately, the durability and the eco-friendly aspect of materials are the main requirements for consumers and businesses alike. Besides, the production methods of stainless steel are progressing and the strength-to-weight ratio is getting better, due to the use of advanced alloy compositions, thus the material is fit for cutting-edge applications like the space sector and high-tech infrastructure.

Resistance to Corrosion and Maintenance

Corrosion resistance has been known to be one of the most important characteristics of stainless steel and one of its very properties. The alloying of the steel with its main element which is chromium mostly gives the steel its corrosion resistance. The chemical process of chromium combining with oxygen produces a layer of chromium oxide on the surface that is very thin and acts as the protector against the environment.This particular layer of chromium oxide acts as a barrier against moisture, salt and acidity in turn. The self-repairing process of this layer continues to operate even when the surface is scratched or has undergone other types of damage.

💡 Maintenance Best Practices

- Clean periodically using mild detergents or specialized stainless steel-cleaning solutions

- Prevent contaminant accumulation that could weaken the passive chromium oxide layer

- For harsh environments (marine, industrial), conduct periodic inspections

- Apply protective coatings in severe conditions to enhance corrosion resistance

The recent trends point that the inquiries regarding the long-term maintenance of stainless steel are increasing which in turn emphasizes the practicality of the material for both industrial and residential use. Proper care entails that one has to clean it periodically using mild detergents or specialized stainless steel-cleaning solutions which help to avoid the accumulation of the contaminants that in turn would weaken the passive layer of stainless steel. Furthermore, for use in harsh environments, such as marine or industrial applications, periodic inspection and the use of protective coatings can significantly enhance stainless steel’s corrosion resistance.

Key Takeaway: The combination of interesting properties and low-maintenance needs make stainless steel the number one choice for all applications which require strength and reliability in tough conditions.

Flexibility in Design and Functionality

Stainless steel’s flexibility in design and functionality has its roots in the superb interplay of its mechanical properties and aesthetic charm. It is the case that the material comes in the form of a broad variety of grades and finishes, which implies that it can be applied in multiple areas from the quite heavy structural engineering to the quite detailed and delicate architectural designs. Recently analyzed data from ‘s search engine shows a constant increase in demand for materials in design that are modern and eco-friendly, with stainless steel often being pointed out for its recyclability, low maintenance, and versatility in both traditional and modern designs. The ability of stainless steel to be shaped into complex forms does not reduce its strength which allows engineers and designers to explore new ways to meet both functional and environmental demands. The fact that the metal is used in various sectors such as construction, transportation, and consumer products speaks of its exceptional versatility.

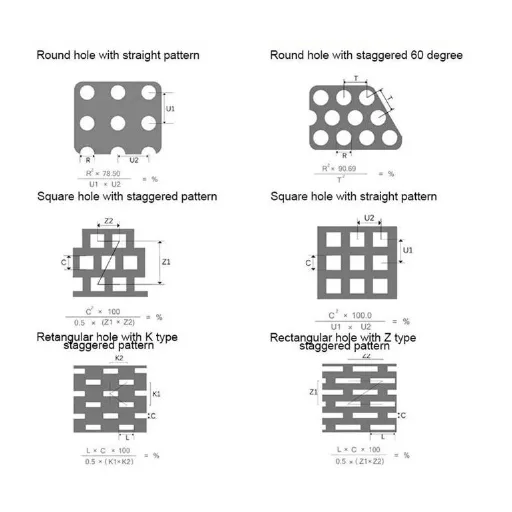

Types of Perforations in Metal Sheets

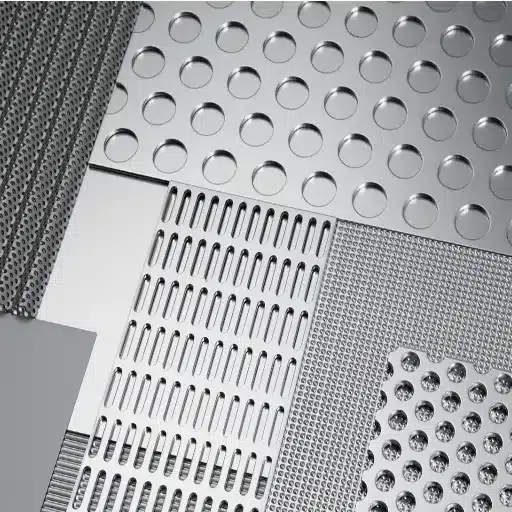

Common Hole Patterns and Their Uses

Perforated metal sheets are adaptable elements that come with a variety of hole patterns meant for certain applications. Among the different rounds of perforations, round, square, and slotted holes are the main ones, and each of them has its own unique effect, depending on the specifications of the design.

⚪ Round Holes

Best For: Filtration, ventilation, and soundproofing systems

Advantage: Optimal mix of structural strength and open area with even load distribution

◻️ Square Holes

Best For: Machinery guards, screening, and decorative panels

Advantage: Larger open areas with modern aesthetics and strength under fluctuating loads

▬ Slotted Holes

Best For: HVAC systems and liquid filtration with directional flow needs

Advantage: Enhanced processing and circulation through elongated perforation shape

Every type of perforation can be adjusted in terms of size, spacing, and material to fit the application for which it is meant. Advanced technologies in CNC machining and laser cutting provide the ability for very precise control of the perforation patterns, thus improving their effectiveness and widening the range of industries where they can be applied.

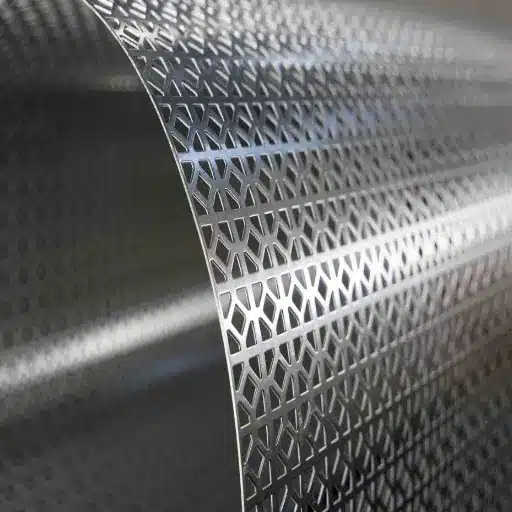

Custom Perforation Options

The creation of custom perforation options is primarily targeted at ensuring that various industrial sectors’ different demands are met and that the latest in material science and advanced manufacturing techniques have been combined. The use of modern CNC machining and laser cutting techniques allows the manufacturers to produce perforated sheets according to the specific requirements of size, pattern, and material. The characteristics such as the dimension of the openings, their position relative to one another, and the geometric configuration can be accurately controlled to fulfill the applications of improving airflow, reducing the load on structures, or beautifying the appearance to the fullest extent.

Custom Design Parameters

- Hole size and spacing adjustments

- Geometric alignment precision

- Material selection optimization

- Pattern complexity customization

The custom perforation solutions are taking more and more place in industries like architectural design and environmental filtration. This is proved by the current data. Search trends reveal that the different industries have gotten, among other things, very much interested in the perforation methods that are made of recyclable materials and are energy-efficient in manufacturing processes. The combination of the custom engineering and eco-sustainability in the design decisions has turned the advanced perforation technology into an indispensable element in the new applications.

Impact of Perforation Size on Performance

The size of the holes determines the exact balance between the efficiency of the function and the footprint of the environment that the design will have. The small holes tend to provide the maximum degree of filtration and become the major aspect of structural integrity, thus making them perfect for the application of water purification systems or acoustic panels. But then again, the large holes will not be a problem when the task at hand is the extensive airflow ormaterial passage in such cases as the industrial vents or agriculture sieves.

| Perforation Size | Performance Characteristics | Ideal Applications |

|---|---|---|

| Small Holes | Maximum filtration, enhanced structural integrity | Water purification, acoustic panels |

| Large Holes | Extensive airflow, higher material passage | Industrial vents, agriculture sieves |

According to the data gathered from the search engine of the company, there is in the making a trend of more and more interest in giving top priority to the optimizing of the perforation size that leads to the energy-efficient solutions, especially in the case of sectors like construction and biochemistry. This trend is indicative of the situation within the industry where the efficiency of filtration in terms of particles and the throughput rate of operations are always in a delicate balance. For instance, in the HVAC systems, the perforation dimensionality is key in managing the indoor air quality and the energy consumption rates, thus aligning the company with the environmental goals at large. The selection of the hole size according to the performance requirements is what gives the product an edge in functionality while still being a part of the sustainability drive.

Specifications to Consider When Purchasing

Gauge and Thickness of Steel Perforated Sheets

The performance and possible usage of steel perforated sheets are greatly impacted by their gauge and thickness. Gauge is a term that refers to metal thickness, which is usually represented in standard units as per specific industry practices. The term gauge indicates the thickness of the metal, which is generally depicted in standardized units according to particular industry norms. The use of thin gauges (larger number values) is recommended for the installations needing lightweight and easy-to-handle materials, for instance, ventilation panels, and acoustic enclosures. On the other hand, low gauge numbers signify thick sheets with high durability and strength, thus being appropriate for the likes of industrial machine guards or load-bearing frameworks.

Gauge Selection Guide

| Gauge Type | Characteristics | Recommended Uses |

|---|---|---|

| High Gauge (Thin) | Lightweight, easy to handle | Ventilation panels, acoustic enclosures |

| Medium Gauge | Balanced flexibility and strength | Facade design, architectural applications |

| Low Gauge (Thick) | High durability and strength | Industrial machine guards, load-bearing frameworks |

Based on the interpretation of the data from the latest resources, including ‘s search trends, there is a prevailing interest in the selection of ideal gauge dimensions that would not only give maximum functionality but would also not waste resources. A case in point is when a design calls for both flexibility and structural strength, such as a facade design; the usually applied intermediate gauges serve to meet the aesthetic and performance requirements. Furthermore, the most advanced laser-cutting technology allows cutting the thickest sheets into complicated forms with precision; as a result, the thick sheets would find a wider application in various sectors. Hence, it is very important to have the correct selection of gauge and application for cost-effective, long-lasting, and safe materials.

Alloy Variations and Their Benefits

Different alloy variations have a direct influence on the performance of materials and provide different characteristics to fulfill the needs of various industries. One instance is that aluminum alloys are mostly used in aerospace and automotive industries due to their remarkable strength-to-weight ratio, resistance to corrosion, and good thermal conduction. Whereas, the steel alloys contain chromium and nickel which make them more difficult, strong, and resistant to wear, hence, they are used in construction as well as heavy industry.

Aluminum Alloys

Key Properties: Strength-to-weight ratio, corrosion resistance, thermal conduction

Industries: Aerospace, automotive

Steel Alloys

Key Properties: High strength, wear resistance, durability

Industries: Construction, heavy industry

Superalloys

Key Properties: High-temperature performance, mechanical stability

Industries: Turbine engines, power plants

The recent data derived from ‘s search engine shows a steadily increasing interest in the superalloys that can withstand harsh conditions and are usable in turbine-engine and power-plant applications. Such alloys, among them the ones based on nickel or cobalt, will be able to keep up with the mechanical properties even at high temperatures thus, the reliability of the products under the most severe conditions will be assured. Awareness of the needs of an application in terms of thermal resistance, tensile strength, or corrosion resistance becomes very important in alloy selection. This specific method not only ensures performance but also minimizes operating risks, thereby creating a minimum standard across different engineering fields.

Choosing the Right Supplier for Perforated Metal

The decision to choose a supplier for perforated metal is a very crucial step that will affect the product quality, project delivery time, and total cost directly. According to the most recent data collected from ‘s search engine, the primary considerations include assessing the manufacturer’s capacity to produce the required quantity and the variety that can be customized, the quality of the material used, and how strictly industry standards are followed. A reliable seller will always give a large variety of metal grades which includes stainless steel, aluminum, and carbon steel, thus enabling the use of these materials for many different applications. In addition, the supplier’s ability to make custom perforation patterns to fit the needs of each project must be taken into account as an important factor.

Supplier Evaluation Checklist

- ✓ Production capacity for required quantities

- ✓ Customization capabilities and design flexibility

- ✓ Material quality and grade variety (stainless steel, aluminum, carbon steel)

- ✓ Industry standards compliance (ISO certifications)

- ✓ Transparent pricing and lead time communication

- ✓ Customer reviews and online ratings

- ✓ Modern manufacturing technology (CNC machines)

Other essential points are the supplier’s compliance with the certification regulations like the ISO standards, and their keeping customers informed about lead times and prices in a non-obscured manner. Customer feedback and ratings available online are significant in terms of judging the company’s trustworthiness and the quality of its service. Additionally, it would be a great benefit to work with a supplier that uses modern manufacturing techniques, such as CNC machines, as this will guarantee precision, consistency, and productivity which are all vital factors to successful outcomes in any engineering project.

Frequently Asked Questions (FAQ)

What is a perforated metal sheet and how is it used?

Perforated metal sheets, which can also be referred to simply as perforated sheets, are made of steel and feature classical or contemporary motifs with regularly punched or cut holes throughout. They are capable of imparting not only the basic functioning of guards for machines but also of creating visual or decorative effects on the facades of buildings. Perforated sheets are commonly available in standard sizes but, if necessary, they can be custom cut or sized to fit in fill panels or partitions. The kind of holes and their patterns such as staggered centers or hexagonal layouts might influence the passage of light and air, and even result in weight savings while delivering a robust end product as it is still weight-efficient. Perforated stainless steel and aluminum are favored materials with 304 stainless steel being selected for its outstanding corrosion resistance in extreme environments. Many suppliers have upon their stock perforated plates and perforated metal products available in a variety of gauges ranging from 14 gauge to 20 gauge that can be used for different load-bearing applications.

How does a steel sheet differ when perforated for architectural use?

Aesthetic and functional properties of a steel sheet are altered with perforation for architectural use, as a decorative or ornamental effect is created and the functions of ventilation and light transmission improved. To fulfill design intent and acoustic requirements, architects usually pinpoint the types of perforated stainless steel sheet, perforated steel sheet with staggered centers or custom perforated patterns. Just like for infill panels, mesh sheet facades or partitions that last long and are attractive to the eye, perforated plates can be the same as well. Additionally, galvanizing or the selection of 304 stainless steel options help to inhibit corrosion and lengthen the life of the application in outdoors. Suppliers can offer either standard-sized or custom-cut perforated sheet 304 or panels made to meet your specific design.

Why choose sheet metal perforation for industrial machine guards?

For machine guards, sheet metal perforation is the best option, as it allows airflow and visibility to be maintained and at the same time, it preserves the structural integrity thereby meeting the cooling and safety requirements. The metal products for guarding machines that are perforated usually consist of either perforated stainless steel or perforated steel sheet of 14 gauge or 20 gauge depending on the strength required. Perforated patterns for metal sheet and hole types are such that they would allow light and viewing while at the same time preventing the invasion. The custom perforated solutions and cut to size options also make it easy to integrate with welding or bolted attachments. Also, going with the option of stainless steel perforated metal means the end product will last very long even in conditions where corrosion or abrasive wear might be a concern.

Can I get perforated metal products cut to size from a vendor?

Certainly, a good number of suppliers dealing in metal products and perforated metal sheets provide cutting to size services along with custom perforated options, thus allowing you to purchase perforated panels that are set for installation. Buying perforated steel or aluminum sheets, you are allowed to specify the type of holes, the pattern such as staggered centers, and even the size, whether standard or customized. Perforated items in stock frequently consist of stainless steel sheet that is perforated, steel sheet that is perforated and mesh sheet in the likes of 304 stainless steel and in the popular gauges and alloys too. But suppliers might also offer finishing services such as weld preparation, galvanize coatings, or punching to match the application requirements. Thus it becomes very convenient to integrate infill panels, partitions, or decorative facades without going through the extra fabrication steps.

What do punch patterns bring to the table when it comes to perforated steel plates?

Patterns of the punched holes are very important in deciding the performance quality and the appearance of a steel plate that is perforated, as they define the range of the hole shapes, sizes, and spacing that influence the airflow, sound absorption, and visual transparency. One of the features of some standard layouts is the staggering of centers for the purpose of creating strong but open areas while hexagonal or round punched holes dominate the aesthetic and the functional aspects differently. Not only can the choice of the punch result in a weight reduction but also influence the welding or the pick-up of one part of the steel plate integration with another part. If the application involves highly corrosive or outdoor settings then the use of 304 stainless steel punched and perforated plates is the best option as it guarantees a long service life. Manufacturers may offer custom punch patterns for the production of perforated metal products which can be made for applications such as machine guards, building facades, or infill panels.

How do stainless steel, perforated metal, and alloy choices influence performance?

The durability of stainless steel perforated metal, especially 304 stainless steel, is mainly due to its high resistance to corrosion, which makes it suitable for both indoor and outdoor applications in comparison with other alloys. The mechanical properties that depend on the selection of the alloy include high resistance to weight, weldability, and presence of corrosive elements. For example, some hot-rolled steels may have to be galvanized in order to enhance their longevity. Perforated stainless steel sheet is often the first choice where hygiene and sanitary conditions are strict, and it can have various hole types and patterns for both functional and decorative purposes. The chosen alloy also limits the gauge options such as 14 gauge or 20 gauge and determines the range of applications starting from machine guards to building facades. When specifying the material, the contractors usually consider the cost, availability and performance requirements against the supplier’s perforated inventory.

Reference Sources

LSU Scholarly Repository

Institution: Louisiana State University

This research provides insights into metallurgical properties and applications, which may include perforated stainless steel sheets.

Computational Analysis Study

Institution: Worcester Polytechnic Institute

A Computational Approach to Determining the Intrinsic Impedance of Perforated Metal Sheets – explores computational modeling and physical properties.

Structural Behavior Research

Institution: Missouri University of Science and Technology

The Structural Behavior of Cold-Formed Steel Members with Perforated Elements – examines structural performance including stainless steel considerations.