Indeed, stainless steel diamond plate, commonly referred to as diamond tread plate, is more than just a utilitarian material—it is the flooring solution for various industries. With its unique raised diamond pattern, it presents itself as a very durable and visually appealing material, combining functionality with aesthetic beauty, thus giving good grip and resistance against slips and a professional polished look. What makes it so popular is that these applications can be equally beautiful in an industrial way. Whether you are an architect, a contractor, or just being enthralled by some heavy-duty flooring ideas, this guide will take you through everything you need to know about stainless steel diamond plates. We shall discuss everything about the properties to practical use and why it is one of the very superior choices for floors that need to perform under pressure yet look good. Read further and learn how this material could make your next project shine!

Understanding Stainless Steel Diamond Plate

What is Stainless Steel Diamond Plate?

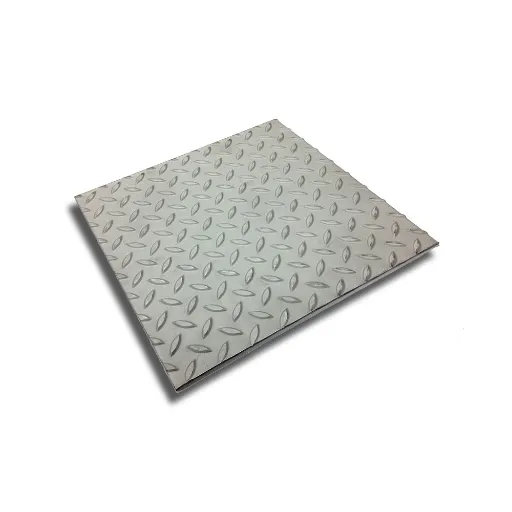

Stainless steel diamond plate box is also called tread plate or checker plate. Here, the metal sheet is characterized by the raised diamond pattern on one side. This not only beautifies the sheet but also enhances traction and slip resistance capacity, thereby keeping the flooring and such safety applications in demand.

Manufactured of stainless steel, it holds qualities of long life, corrosion resistance, and simple maintenance. Heavy loads and harsh environments are not foreign to stainless steel diamond plate, hence its application in industrial facilities, transportation, and outdoor settings. The resilient construction of this metal guarantees the performance of the material for a longer duration even in adverse conditions.

By means of a rolling process, the diamond pattern is set on a plate by imprinting raised shapes into the sheet material. This pattern is designed for better gripping and also doubles up for aesthetic beauty in architectural or decorative applications. With its blend of practical use, safety, and beauty, stainless steel diamond plates are used in all kinds of projects.

Characteristics of 304 Stainless Steel

Key Properties

The applications of this grade are considered very diverse since this steel provides corrosion resistance and durability. The 18% chrome and 8% nickel content gives the steel its primary resistance to rust and oxidation. Since 304-AISI stainless steel can resist extreme temperature conditions without losing structural integrity, it can be used in highly versatile applications.

It is also known for placing emphasis on strength and toughness. Even though it is so light, it is highly valued for its higher structural strength, which is much needed in big projects. In the annealed condition, grade 304 stainless steel is non-magnetic, and it is the same property that it exhibits across several temperatures, thus ensuring that it maintains its structural properties under widely varied operating conditions.

Another noteworthy feature is the easy maintenance and fabrication of 304-grade stainless steel. It can be cleaned, polished, or fabricated quite easily by using rather simple techniques that bring a really nice finish to the metal. Having such features makes it popular for applications in architecture, food processing, medical equipments, and transportation, where hygiene and appearance are paramount.

Comparison with Other Metal Plates

Stainless-steel diamond plates are considered better or worse than aluminum, carbon steel, and galvanized steel plates based on durability, corrosion resistance, weight, and cost.

| Feature | Stainless Steel | Aluminum | Carbon Steel | Galvanized Steel |

|---|---|---|---|---|

| Strength | High | Moderate | High | Moderate |

| Rust Resistance | Excellent | Good | Poor | Good |

| Mass | Heavy | Light | Heavy | Heavy |

| Expense | High | Moderate | Low | Moderate |

Applications of Diamond Plate Sheets

Industrial Uses of Stainless Steel Diamond Plate

1. Platform Flooring

The stainless steel diamond plates are a preferred floor choice in industrial facilities due to their slip-resistant surface, the strength of which promotes safety in areas characterized by heavy foot traffic or movement of machinery.

2. Manufacturing Equipment Protection

The strength and corrosion resistance that a stainless steel diamond plate possesses are the eventual factors that make it invaluable in protecting machinery or equipment from harsh environments, especially in chemical plants or factories.

3. Truck Bed Liners

The stainless steel diamond plates provide an anti-slip surface for bed liners on trucks, able to withstand heavier loads of damage: they will not succumb to damages from weather in the way of common aluminum plates, or weather and chemicals as common mild steel plates are subjected to.

4. Walkways and Stair Treads

Generally in industrial use, these plates are suited for walkways, stairs, and ramps, granting utmost safety with their textured surface while being subject to heavy stresses.

5. Wall Cladding and Other Surfaces

These are cladded onto walls or any surface to protect from wear and tear, safeguard from occasional damage, and to retain that slick industrial appearance.

Residential Applications for Tread Plate

- Garage Floorings: For garage floors, Tread Plate provides a very durable and slip-resistant surface withstanding vehicular traffic and heavy-tool traffic. The textured pattern otherwise goes in favor of safety, thereby giving a very modern-industrial look.

- Kitchen Backsplash: Homeowners set tread plates as backsplashes in kitchens for a unique metallic finish. The material is easy to clean, resists heat and stain, and lends a durable yet stylish touch to the place.

- Covering Staircases: Tread plates provide staircases of the house with extra safety by providing a non-slip surface. These become more useful to homes having outdoor or basement stairs which sometimes get slippery due to moisture.

- Flooring for Mudroom and Entryway: Tread plates are perfect for areas of very high human traffic such as mudrooms or entryways. It stops flooring from getting worn out and creates a rugged surface that can take on dirt, water, and frequent feet.

- Decorative Wall Accents: For walls, tread plates can, of course, serve fine as decorative panels to enhance a modern, industrial design in home interiors. They are quite durable and require little maintenance, so they will prove to be a practical and visually pleasing choice.

Creative Uses for Diamond Tread Plate

Truck Bed Liners

Diamond tread plates are usually used as truck bed liners. The surface is tough and has scratches, dents, and moisture that can affect the truck bed; thus, they actually extend the life of the vehicle. Also, they provide sufficient grip so that the cargo does not shift during transit.

Toolbox Construction

Diamond tread plate toolboxes provide strength and protection for the tools. The rugged surface may also resist an impact. It will further resist abrasion and look good even after an extended use, which is pertinent for an industrial or home toolbox.

Stair Treads

Diamond plate stair treads are very much an option in terms of safety and grit. The raised pattern adds friction, thereby lowering the chance of slips in high-traffic areas such as factories, garages, and outdoor stairs when raining or icing.

Protective Flooring

In industrial and commercial environments, diamond-plated floors serve as protective flooring. Their rugged nature safeguards the floors beneath from heavy machineries, heavy foot steps, and chemical splashes, making them a long-lasting and cost-efficient solution.

Furniture Design

Diamond tread plate is increasingly in use for the making of furniture—like tables, shelves, and cabinets—for those who prefer a contemporaneous and industrial décor. Their unique texture with reflective finish adds the contemporary flair while still being durable and easy to maintain.

Benefits of Using Stainless Steel Diamond Plate

Durability and Strength

- High Tensile Strength: Stainless steel diamond plates bear a significant amount of weight and pressure, tensile strength ranging generally between 515 and 827 MPa (megapascals), depending on the grade of the steel considered.

- Corrosion Resistance: Being stainless steel in nature, these plates exhibit resistance against rusting, oxidization, and chemical attacks, thereby making them usable in harsh environmental conditions such as marine or industrial ones.

- Impact Resistance: The strength of stainless steel diamond plates helps them resist and absorb forceful impacts without bending, cracking, or getting majorly damaged; hence, they offer very good durability in heavy uplift.

- Wear and Tear Protection: The raised diamond pattern protects the surface well against abrasion and wear, ensuring that the appearances and functionality remain constant over time, even in tough and demanding environments.

- Temperature Tolerance: Depending on what the user needs, diamond plates of stainless steel can be able to maintain their structural integrity under extremes of temperature. From flooring in freezers to platforms for heavy machinery, these applications are very reliable.

Safety Features of Tread Plate

Critical Safety Advantages

Slip Resistance: Raised diamonds or treading are basically provided to grip better and thereby reduce accidents from slipping, especially under wet or oily conditions. This makes it a perfect option for walkways, ramps, and industrial floors.

Enhanced Visibility: In certain applications, the plates reflect light off their patterned surface hence invigorating visibility in low-light conditions—actually promoting safer navigation in areas like warehouses and construction sites.

Impact Absorption: Protecting surfaces from being damaged and decreasing the potential of accident caused by equipment or machinery is the highlight of such plates. Defend from huge impact.

Durable Surface: The surface is very tough to guard the tread plate much against abrasive action, thus maintaining the safety until the end of time, even in areas with great foot traffic.

Corrosion Resistance: Usually, aluminum or stainless steel materials are stained with the added coating for anti-rust or corrosion so that they retain their structural integrity and safety features when placed in harsh or outdoor conditions.

Easy Cleaning and Maintenance

Smooth Surface Cleaning

Tread patterns on plates are designed to minimize dirt and debris build-up so that they remain easy and quick to clean with simple tools like mops or cloths.

Compatible with Cleaning Solutions

Tread plates withstand nearly every kind of cleaning chemical, thus allowing for absolutely thorough sanitation without ever risking damage to the surface.

Water and Pressure Tolerance

The plates can be washed or rinsed under heavy pressure, which makes them appropriate for areas that demand tough hygiene standards, such as kitchens or clinics.

Less Maintenance Required

Also, the durability of the materials means that tread plates do not need to be repaired or refinished too often, thus saving on wear-and-tear maintenance.

Corrosion-Resistant Materials

Aluminum and stainless-steel tread plates being corrosion resistant allow for easy maintenance even in moist environments such as outdoor or marine.

Types and Specifications of Diamond Plate

Different Grades of Stainless Steel Diamond Plate

Depending upon the grade of stainless steel, the diamond plates will serve a particular application with respect to strength, anticorrosive treatment, and durability. The commonly used stainless steel grades are 304, 316, and 430.

304 Stainless Steel

Due to its excellent balance of strength, durability, and economic price, this is the most commonly used grade. It has reasonable corrosion resistance and is hence used in general applications like commercial and industrial flooring.

316 Stainless Steel

Offering higher resistance against corrosions, 316 stainless steel contains more molybdenum, allowing it to endure harsh environments such as those exposed to saline water and chemicals. Hence, it is suitable for marine, chemical processing, and outdoor applications.

430 Stainless Steel

This is an affordable grade with decent corrosion resistance in dry conditions and is typically used in decorative or low moisture environments, especially when the economic aspect is stressed.

These various grades allow the user to choose the most suitable type of stainless steel diamond plate according to environmental conditions, maintenance, and budget. The choice of grade guarantees the best performance and the longest life for any specific application.

Understanding Diamond Plate Specifications

Key Factors to Consider

Before commencing to understand the specifications, a number of factors must be considered to ascertain whether the material fits one’s specific requirements. Diamond plate is usually made of aluminum or stainless steel, and sometimes even just plain steel, with the raised diamond-shaped patterns providing for better traction and wear. Thickness is one of the major factors; most times, it ranges between 1/8 inch and 3/8 inch, depending on the strength it needs to impose and certainly on the application at hand. Besides environmental hazards such as high humidity or chemicals, which stand in opposition to corrosion resistance of a certain alloy composition of the plates, corrosion resistance weighs out also in selection depending upon the weight thereof and its suitability for environmental conditions.

Another more important aspect concerns the finish quality. Some of the common finishes are reflective polished finish and mill finish, and the finish does have an impact in terms of looks and function. Then much like any structural steel, diamond plate is also graded for tensile strength—A higher tensile strength means the plate can handle greater loads and resist wear for a longer time. Other coatings or treatments may be applied depending on whether the diamond plate has to perform exceptionally well in a marine or industrial environment, such as anodizing or powder coating.

Matching these specifications with its intended use is the surest way to buy the correct diamond plate, balancing price, service life, and appearance a particular job calls for.

Installation and Maintenance Tips

Preparing the Surface for Installation

Surface preparation is critical to ensure that the diamond plate is effectively and durably installed. Start with the thorough cleaning of the surface to which the diamond plate would be applied. Remove any dirt, grease, oil, or other debris using a degreasing agent or household cleaner. A clean surface gives way to better adhesion, warpage is avoided, and a uniform finish is guaranteed. Otherwise, sanding or scraping might be required in order to bring out a smooth and even base in case the area has old coat or paint on it.

The cleaned surface should be inspected for irregularities or damages such as cracks, holes, or bumps, where relevant. All such issues should be settled using suitable fillers or leveling materials as per the need to bring about a smooth base. Rust or corrosion must be looked for on metal surfaces as these can weaken the bonding and will compromise installation with time. Sanding off the rust and treating it with a rust inhibitor can provide protection for the surface and give the diamond plate a longer life. Other considerations for surface preparations include being completely dry, as any moisture present may jeopardize the adhesives or fasteners.

Before starting installation, ensure you give your measurements for the area properly and cut the diamond plate to size. Make sure to leave enough clearance around edges or corners for easy alignment and fastening. Depending upon your application, mechanical fasteners, adhesives, or a combination of both can be used to secure the plate. A proper surface preparation will not just make an easy installation but will also make the finished project look better and last longer.

Best Practices for Installing Diamond Plate Sheets

When laying down diamond plate sheets, precision and preparation are the key factors for best results. The first consideration is that the surface where the sheet is to be applied must be clean, dry, and away from dust or grease. This step is very crucial for proper adhesion if adhesives are to be used or for secure fitting in mechanistic fasteners. Thereafter, I take measurements and cut the diamond plate to exact size while allowing clearances around edges and corners. Therefore, ensuring a well-prepared surface will repay one with allotment of time in the long run, in addition to a professional-looking installation.

Then, I decide on the fastening method according to the project. For heavy-duty applications, I use mechanical fasteners. They provide a better stability: screws and bolts, mainly. Otherwise, if we are talking about light projects or where looks going to matter, glue or an adhesive tape gives a smooth finish. Sometimes I resort to combining the two for added strength and durability, especially where constant use or some environmental action is expected.

Most importantly, I give attention and patience when aligning and installing to make sure everything fits well. If the sheet is not checked and adjusted before securing, even a slight misalignment can greatly lower the quality of the work. Once done, I go through another rigorous assessment of the entire installation to check for uneven surfaces or loose edges. These steps followed carefully guarantee a finish with strength, functionality, and beauty that meets practical needs and elevates the aesthetic value of the space.

Long-Term Maintenance Considerations

Essential Maintenance Guidelines

Maintenance is crucial to extend an installation’s life and good performance. Regular inspection of the surface for signs of wear, damage, and loosened parts can prevent larger problems from developing over time. Attending to minor issues as they arise—such as cracks or lifting edges—can save the cost and effort of large-scale repair later. Removing dirt, debris, and stains from the surface while keeping it clean maintains its appearance, and supports in keeping its structural integrity intact.

Environmental factors can greatly impact the longevity of an installation. This means that moisture, direct sunlight, or severe temperature alterations eventually wear down the materials. The application of protective treatments like sealants or UV coatings may shield against these effects and consequently enhance the lifetime of a surface. Furthermore, one should consider whatever particular care requirements its materials possess so that maintenance techniques applied will be both conducive to and safe for the surface.

New developments in material technology and maintenance instruments offer opportunities to improve care regimens. For instance, by employing some new cleaning agents or materials, along with the use of tools and processes for polishing that minimize the risk of scratching, one may maximize results and minimize damage to the surfaces. By keeping up to speed with advances in their field, one can implement proactive measures to improve functionality and aesthetics over a longer period. When these measures are coupled with early diagnosis of problems and vigorous maintenance programs, a space can stay visually attractive and functionally usable for many years.

References

- University of Texas – Materials Database provides detailed information about stainless steel diamond plates, including their properties and applications.

- Northwestern University – Design Guidelines for HVAC Systems outlines the specific requirements for stainless steel diamond plates used in air handling units.

- University of Wisconsin – Division 05 Metals Guidelines provides guidelines for the use of diamond plates, including stainless steel, in construction and design.

- Click here to read more.

Frequently Asked Questions (FAQ)

A: Stainless steel diamond plate is a metal sheet with a raised diamond pattern to provide extra grip and durability. It finds uses in flooring, ramps, and industrial equipment, thanks to its strength and resistivity to corrosion.

A: Stainless steel diamond plates are generally used in environments where durability and traction are essential. Popular applications include floorings in commercial kitchens, truck beds, and places of industry. Its unique design also makes it a popular choice for decoration and custom fabrication.

A: Stainless steel diamond plate comes in a variety of lengths and sizes to meet different project requirements, and manufacturers usually provide customer-specific dimensions so that the product can be perfectly installed in the application.

A: While aluminum and stainless steel diamond plates generally serve a similar purpose, stainless steel is generally made of stronger materials that confer better corrosion resistance and life. Aluminum can be preferred when weight is an issue, while stainless steel is actually more durable.

A: Yes, custom sizes of stainless steel diamond plate can be supplied; this depends mainly on unique project requirements. Customers can specify certain dimensions required for their application to achieve a perfect fit.

A: The diamond plate shipping process involves packaging to avoid any damage en route. Most suppliers systems are stocked, and orders can be shipped on an expedited basis so that customers get their orders in a timely manner.

A: Yes, various finishes can be offered on stainless steel diamond plate, including mirror and brushed finishes. The chosen finish can alter the aesthetic appeal and functional properties of the plate, thus making the plate suitable for one or several particular applications.

A: Maintenance of stainless steel diamond plate is relatively simple. Cleaning it from time to time with mild detergents and without using abrasive materials will help keep it looking good and functioning well. This means that the plate will hold its anti-slip property and pleasing look.

Ready to Transform Your Space?

Stainless steel diamond plates offer the perfect combination of durability, safety, and aesthetic appeal for your next project. Whether you’re working on an industrial facility, residential renovation, or creative design, this versatile material delivers exceptional performance and long-lasting results.