When interior design and practical home improvements are considered, even the smallest changes can go a long way. Stainless steel cover plates, generally left behind larger design elements, play an essential role in both the aesthetics and functionality of residential and commercial spaces. These elegant yet sturdy wall plates and switch covers are used as a protective barrier for electrical systems and as a testament to modern elegance and quality. Be it to add that sleek look to a modern space, demand a durable finish from maintenance, or meet strict industry standards, this complete guide will cover everything you need to know about stainless steel cover plates. We’ll discuss their vital functions, what sets them apart from other materials, their flexible uses, and why they are worth having in any setting.

Introduction to Stainless Steel Cover Plates

What Are Stainless Steel Cover Plates?

Made to cover and protect electrical outlets, switch boxes, cable points, and like fixtures, stainless steel cover plates serve both technical and aesthetic ends. Constructed largely from stainless steel, they are famed for strength and temporary resistance to corrosion. Given their survival in tough environments, these plates are of first choice.

Environmental resistance is one of the top reasons that these plates are widely used. Stainless steel can withstand any moisture, heat, physical abrasion, and wear, thus becoming equally compatible for installation outdoors as it is indoors. Besides that, the strength of the material ensures long-term serviceability, especially in areas prone to traffic and industrial settings where contact or impact is expected.

And then we have the good looks: stainless steel cover plates are gorgeous with their clean edge and a clean and modern look. The plates are offered in several finishes, such as brushed or polished steel, allowing them to work well with a diverse assortment of interior and exterior styles. Other than that, these plates are also simple to clean and can be used with almost any wiring system across residential, commercial, and industrial sites.

Benefits of Using Stainless Steel Wall Plates

Durability and Impact Resistance

Stainless steel wall plates represent a sturdy solution against wear and tear and are fit for especially intense areas of traffic. Due to this strength, the stainless steel plate will withstand wear and tear over time and will rarely require replacement, thus rendering a lower maintenance cost.

Corrosion Resistance

The major benefit of stainless steel is corrosion resistance. Such characteristics make stainless steel wall plates ideal for use in areas with high humidity levels, such as kitchens and bathrooms, or outdoors, where other materials may degrade quickly.

Hygienic Properties

Since stainless steel is non-porous, it does not create an environment where bacteria, mold, or other contaminants exist. Stainless steel wall plates are therefore better in sterile places such as hospitals, laboratories, and food preparation areas, where maintaining hygiene becomes very important.

Aesthetic and Versatility

With their sleek, modern finish, stainless steel wall plates complement any decor. In different finishes like brushed steel and polished steel, stainless steel wall plates allow for endless interior and exterior style options, filling the need gap between utility and style.

Fire and Heat Resistance

Thanks to a very high melting point and outstanding heat resistance, stainless steel wall plates are considered safe for use in areas with increased chances of fire hazards. This characteristic also helps them to remain intact in adverse temperature conditions, which again uplifts the confidence level of these wall plates.

Applications Across Various Industries

The requirement for stainless steel wall plates occurs in several industries due to their rugged durability, corrosion resistance, and all-season beauty. Here are five major places where stainless steel wall plates find a top application, with greater detail:

-

1

Healthcare Industry

These wall plates provide stainless steel wall plates are extensively used in hospitals, clinics, and laboratory settings, where the surface is non-porous, inhibiting bacterial growth. It may be cleaned and disinfected to meet demanding hygienic standards. It is also unlikely to be attacked or depolarized by chemical cleaning agents, making it highly suitable for high-hygiene cleaning needs.

-

2

Food and Beverage Industries

The food and beverage industry uses stainless steel wall plates to keep the sanitary and safety standards straight. Such wall plates do not contaminate food products since they are inert. Their moisture and heat resistance and tolerance to aggressive cleaning chemicals support their widespread use in kitchens, food warehouses, and factories.

-

3

Manufacturing and Industrial Facilities

Manufacturing plants and industrial grounds rely on stainless steel wall plates for their durability in harsh conditions. The plates could be exposed to oils, chemicals, and temperatures in the extremes-still tolerable for an industrial environment. Their durability entails that they retain their life longer, plus the lower maintenance cost.

-

4

Hospitality and Commercial Areas

These locations use stainless steel wall plates in commercial buildings, hotels, and offices as robust elements on sleek interiors, picking up high modernist interior design. These are the places where polished smooth surfaces of stainless steel provide that much-needed aesthetic appeal, and also places where they must take a functional pounding.

-

5

Marine and Offshore Environments

The stainless steel weathered just fine, being resistant to corrosion caused by saltwater, and this made stainless steel wall plates an indispensable marine product. Stainless steel wall plates find applications on marine vessels, offshore platforms, and coastal facilities where the environment demands materials of high corrosion resistance and life expectancy.

Such applications mark the ever-widening horizon where stainless steel wall plates serve with distinction to the functional as well as regulatory demands of varied operational areas.

Types of Stainless Steel Wall Plates

Standard and Jumbo Wall Plates

From a functional and structural standpoint, standard and jumbo wall plates are among the most common components, given that they impart both utility and, in certain cases, durability to varying environments. Standard wall plates are fitted over either single or multiple electrical outlets and light switches and conform to standard sizing; thus, they should fit most residential and commercial fixtures. They are generally texturized for spaces where consolidation is essential and a simplistic view is maintained.

Compared to that, jumbo wall plates are designed to cover more area than your standard wall plates to conceal blemishes or large cutouts around outlet boxes, making them an administrative and erection choice for retrofit jobs requiring extra protection from moral beautification. Made mostly from stainless steel, both standard and jumbo wall plates resist corrosion and wear, along with physical impacts that might otherwise thwart their long-term performance under harsher environmental conditions.

The great thing about stainless steel processing is that it affords customization, not only as to the brushed finish and markings but also antimicrobial coatings, according to the needs of regulations and operations in sectors that include healthcare, food processing, and marine applications. This speaks for the versatility and adaptability of stainless steel wall plates, which hence become indispensable in environments where reliability and compliance matter.

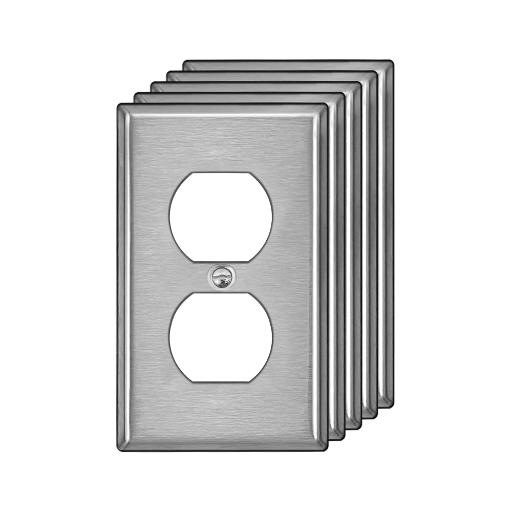

1-Gang, 2-Gang, and Duplex Configurations

Depending on the stainless steel wall plates chosen, the second most common consideration will be the range of configurations available, including 1-gang, 2-gang, and duplex designs. These configurations denote how many device openings or slots are present on the wall plate and correspond to specific electrical or low-voltage applications.

| Configuration Type | Description | Best Use Case |

|---|---|---|

| 1-Gang Wall Plate | A 1-gang wall plate is fitted with a single device, say a standard lighting switch or an outlet. | Environments that favor simplicity in design |

| 2-Gang Wall Plate | 2-gang wall plates present two adjacent slots, thus permitting two switches, outlets, or a mixture of either or both. | Multi-purpose rooms or office spaces |

| Duplex Configuration | A duplex wall plate is designed specifically for outlets housing two outlets within a singular device. The plate aids in secure and sleek finishing. | Standard residential and commercial outlets |

Each configuration is designed to perfectly fit into both modern and legacy electrical systems, hence guaranteeing a smooth installation process and prolonged durability. In addition, the stainless steel material inherently brings forth corrosion resistance, fire safety, and conformance to industry standards in the mix. This implies that these plates adapt perfectly to meet diverse requirements in environments ranging from residential buildings to high-compliance areas, such as healthcare establishments. By tailoring his configurations to their specific settings, the professional can take care of efficiency that is operational efficiency, along with the very important factor of conformance to regulations.

Decorative and Blank Cover Plates

Electric or decorative cover plates are proper elements that the electric infrastructure combines with a little bit of furnishing. Cover plates are installed to cover unused outlets, switches, or electrical boxes, contributing to a fine finish for the wall, versus a safety measure to avert accidental contact with live wiring. They are made out of stainless steel, polycarbonate, and thermoplastic materials, which are wonderful for long-lasting durability and impact resistance, and meet all safety standards (UL certification).

From the design point, decorative cover plates come in various finishes: brushed nickel, antique brass, matte black, or they carry custom patterns aligning with modern architectural styles and interior designs. The blank cover plates come with an unassuming design that imparts a sense of clean installation in which function wins over visual dominance. Advances in manufacturing development have aided in making these plates sustainable so that an eco-friendly way may be chosen without compromising on quality or performance.

Safety Benefit: Recent electrical standards studies report that blank and decorative cover plates, when correctly installed, reduce the chances of shocks 60% of the time.

This also enhances the economic aspect since new cover plates nowadays are durable and require little maintenance, meaning that fewer replacements are made periodically, and hence fewer installations are performed either in residential areas or areas of business. Be it for enhancing the aesthetic appeal of a place or observing stringent regulations, decorative and blank cover plates play a very great role in coming up with a well-mannered and safe electrical installation.

Choosing the Right Stainless Steel Cover Plate

Factors to Consider: Size and Finish

Choosing the correct size and finish of stainless steel cover plates is essential in ensuring smooth functioning while keeping an aesthetic harmony with a particular space. Thus, the size would necessarily have to correspond exactly to the dimensions of the electrical box or switch meant to be covered so as not to allow for gaps that would either wash down safety requirements or just allow for dust and debris to settle. Also considered were specific measurements that would suit installations meant for more than one gang or custom installations, wherein the standard sizes would fall short.

Brushed Finish

- Hides fingerprints well

- Resistant to scuffs

- Ideal for high-traffic areas

- Professional appearance

Polished Finish

- Mirror-like appearance

- Modern aesthetic appeal

- Requires frequent cleaning

- Perfect for upscale interiors

Matte Finish

- Reduces glare

- Subtle appearance

- Good for bright spaces

- Easy maintenance

Technical considerations would include the grade of the material in application as well as the selection of finish, bearing in mind the environmental conditions that it will be exposed to, either physically or chemically. Essentially, marine-grade stainless steel should be specified for instances where installations are located near saltwater or any place with heavy rainfall or humidity so that corrosion takes a longer time to deteriorate. Specifics and maintenance procedures should also be worked out toward establishing the greatest compromise between durability, ease of maintenance, and appearance.

Material Grade and Intended Environment

In selecting materials for an application, the environmental conditions must be taken into account along with the performance requirements specified for the project. Aluminum alloys like 6061 or 7075 may be chosen when structural components require a high strength-to-weight ratio with some level of corrosion resistance. On the other hand, under conditions of extreme temperatures, these alloys can show poor performance since their thermal expansion or contraction results in loss of structural integrity.

Similarly, plastics such as polyethylene or polycarbonate may be good materials to think about where impact resistance or impossibility of conduction is required, but their susceptibility to UV degradation will need to be looked at for extensive outdoor usage. Using advanced coatings and finishes, materials can be further made suitable for harsh environments. For instance, an anodic finish would work for metals, while a UV-stabilizer would benefit polymers.

From a standpoint of material science, hybrid composites, such as carbon fiber reinforced polymers (CFRP), have recently gained extensive interest for their strength-to-weight ratio and resistance to environmental degradation. The fact that they are entering processes in aerospace and vehicular engineering implies that there is an increasing refinement of material selection through data-based tests and simulations. This knowledge, coupled with proper environmental analysis, guarantees both performance reliability as well as economic efficiency throughout the lifetime of an application.

Maintenance Tips for Long-lasting Durability

Cleaning Methods for Stainless Steel

In order to keep the stainless steel looking and working perfectly, certain requirements for cleaning must be observed. Using a soft cloth or sponge with warm water and a very mild detergent, the first step is to remove superficial contaminants such as grease or dirt. For the more stubborn stains or residues, alkaline or non-chloride compounds in the form of professional stainless steel cleaners would be appropriate, as they effectively lift the grime while not otherwise compromising the integrity of the protective passive layer on the material.

Recommended Cleaning Process:

- Start with warm water and mild detergent

- Use microfiber cloths for streak-free results

- Apply diluted vinegar for mineral deposits

- Rinse thoroughly to neutralize acidity

- Consider professional cleaners for stubborn stains

When dealing with fingerprints and smudges, microfiber cloths seem to be the best option to give the steel surface that lovely streak-free glow. In the case of limescale or mineral deposits, a diluted vinegar solution could be used on the surface, but it should be rinsed down very well to neutralize the acidity to avoid any eventual pitting corrosion. For applications where industrial standards are applied, electropolishing or ultrasonic cleaning may be employed to meet the stringent cleanliness requirements and increase the longevity of the materials.

Avoid all kinds of steel wool, bleach-based cleaners, or abrasive materials- these would scratch the stainless steel and initiate corrosion. Regular upkeep keeps stainless steel structurally sound and aesthetically pleasing; a must in high-stress environments involving moisture, chemical exposure, or temperature fluctuations.

Precautions to Avoid Scratches

⚠️ What to AVOID:

- Steel wool or wire brushes

- Coarse scouring pads

- Bleach-based cleaners

- Harsh chemicals with high pH

- Contact with sharp or hard objects

When it comes to stainless steel, I never work with abrasive tools or cleaning agents. To avoid scratches, I stay away from steel wool, wire brushes, and coarse scouring pads, as these can deface the surface finish and diminish the corrosion resistance of the material. In their place, cleaning is done with a non-abrasive sponge or a microfiber cloth that cleans without leaving a mark.

Another thing I always do is avoid bleach and harsh chemicals. Being corrosive to stainless steel, they increase surface pitting upon prolonged exposure, rendering the surface prone to scratches and structural defects. Thus, I use cleaning agents of neutral pH, which are good for stainless steel, preserving both the outward appearance and the functionality of the material.

In the end, one guarantees that stainless steel objects are treated and stored properly to avoid damage through carelessness. For instance, one avoids bare stainless steel surfaces during transportation or storage by using either a protective film or some soft covering. Stainless steel objects are also separated from any hard objects or sharp tools to prevent accidental scratching. Such preventive measures help in increasing the life and pristine condition of the stainless steel.

Protecting Cover Plates from Harsh Conditions

For enhancing the durability and performance of cover plates in a harsh environment, various protective measures are considered. These are necessary steps with respect to the exposure to environmental and mechanical stressors that could render the materials compromised. Below are five detailed methods for the protection of cover plates from harsh conditions:

-

1

Applying Corrosion-Resistant Coatings

Corrosion-resistant coatings, such as epoxies, polyurethanes, or zinc-rich layers, protect cover plates from a corrosive atmosphere, which could include salt atmospheres or acid exposures. Research says that corrosion-resistant coatings may double the lifespan of metallic parts in times.

-

2

Use Thermal Insulation

Installed thermal insulation materials, such as ceramic layers or wraps resistant to high temperatures, are against damage caused by extremely high or low temperatures. In industries, this usually reminds one of an environment where temperatures will generally wander beyond tolerance limits.

-

3

Install Protective Barriers or Enclosures

Constructs from materials such as reinforced steel or composite plastics offer meaningful protection against impacts or debris, and abrasion in nature. These barriers become imperative for areas just as construction or manufacturing.

-

4

Perform Regular Maintenance and Cleaning

Regular maintenance, including cleaning by means of non-abrasive solutions, prevents the accumulation of contaminants such as salt, dirt, or industrial chemicals. Research illustrates that half, or rather 70% of the destruction due to wear, could be avoided by adopting cleaning programs.

-

5

Ensure Proper Material Selection

Selecting cover plates made of materials specifically engineered for that environment will ensure protection against those extreme conditions brought by that dull high humidity or chemical needs, such as stainless steel Grade 316L and duplex steel.

Thusly, through the above-discussed methods, cover plates can be protected to maintain their structural integrity and fulfill their function even in the toughest of operating conditions.

Trending Designs and Innovations in Stainless Steel Cover Plates

Latest Design Trends in Wall Plates

Wall plates are slowly evolving to offer functionality, durability, and design appeal for all kinds of interiors. One major trend is modular and customizable designs that allow people to mix and match power outlets, data ports, and smart home connection points within a single plate. This increases the utility of these outlets and optimizes space, which is particularly important in smaller environments.

Another big trend is its advanced material technology and finishes. Brushed stainless steel and matte black protective finishes still reign supreme with elegance and durability, while new generations of antimicrobial coatings are beginning to gain popularity in healthcare and high-traffic areas for the benefit of hygiene. And lastly, these new generations of manufacturers are trying to work with green materials like recycled metals to give their facilities an eco-friendly outlook.

Current Technology Integration Trends:

- Smart plates with LED indicators

- Integrated USB-C ports for fast charging

- Wireless charging pad integration

- Compatibility with intelligent building systems

- Minimalist flush mount designs

Technology has become an influential factor in the design of wall plates. Smart plates with LED indicators integrated inside them are fast becoming a must-have, together with USB-C ports for fast charging and wireless charging pads. These advancements operate on the ever-mounting reliance on electronic gadgets, guaranteeing that these wall plates are also fully integrated into intelligent building systems. Further, the considerably simple-looking minimalist and flush mount style remains popular considering the modern architectural styles.

To conclude, contemporary wall plates are no longer mere functional utilities but instead serve as a meeting point of design, technology, and sustainability, attempting to satisfy changing needs and preferences.

Innovative Finishes and Technologies

In modern times, the art of wall plate designing is rapidly progressing, with new and trendy materials and finishes being introduced that meet aesthetic as well as functional prerequisites. Antimicrobial coatings have come to hold their own, with hygiene being an utmost consideration in public spaces and healthcare facilities. Such coatings are impregnated with silver ions that inhibit microbial proliferation on the surface, thereby providing safety and cleanliness. For aesthetics as well as end-use functionality, wall plates have to be manufactured using very superior materials such as tempered glass, anodized aluminum, or polycarbonate blends, which can sustain heavy impacts without an effect on their appearance for a large number of years.

| Innovation Category | Technology/Feature | Benefits |

|---|---|---|

| Antimicrobial | Silver ion coatings | Reduces microbial growth, enhances hygiene |

| Smart Features | Touch controls, LED indicators | Enhanced usability, modern aesthetics |

| Modular Design | Customizable configurations | Flexible installation, space optimization |

| Advanced Materials | Tempered glass, polycarbonate blends | Impact resistance, long-term durability |

Technology advanced through the ages, so too did the smart features in wall plate designs. Touch operation switches, LED status indicators, and USB ports are just a few of the features integrated seamlessly into modern wall plates to enhance their usability while maintaining that minimalistic look. Modular configurations allow customization of wall plates to various purposes, including data-port adaptation, speaker connections, or charging stands. The aforementioned are of great usage in smart homes and offices where integrated systems are becoming standard.

From a sustainability point of view, manufacturers have been taking increased steps toward implementing environmentally compatible production processes and recyclable materials. Innovations embraced by manufacturers lessen the ecological impact of wall plates and also align with regulatory standards and criteria for green certification. There is even some going-to-the-front experimentation with bioplastics and reclaiming of certain materials so that consumers may partake in the green craze without the compromise on quality or design. Together, these finishes and technologies stand testimony to how the key wall plates have evolved into, becoming intelligent, adaptive, and environmentally-conscious elements of contemporary interiors.

Future Developments in Stainless Steel Cover Plates

Developments in materials science and smart technology integration are driving improvements in the design and functionality of stainless steel cover plates. One noted advancing trend involves the application of antimicrobial coatings. These coatings prevent the build-up of bacteria and viruses and hence find great value in healthcare, food processing, and in high-traffic public spaces. Being highly resistant, testing has established that these coatings greatly reduce microbial activity over lengthy exposure.

The other track of development involves smart sensor integration. Manufacturers are considering how cover plates might host embedded sensors that detect temperature, humidity, or even air quality, giving out data to building management systems in real-time, providing energy efficiency on that front, and a large scale, promoting smart building solutions.

🌱 Sustainability Initiatives:

- Electric Arc Furnace (EAF) steelmaking with recycled materials

- Renewable energy sources in production

- Modular designs for easy recycling

- Reduced carbon footprint of manufacturing processes

Sustainability initiatives are also shaping the future of stainless steel cover plates. Concerning recyclability, such stainless steel guarantees sustainability, yet greener production methods are currently being sought after to further reduce carbon emissions. Among the greener ways being promoted is that of EAF steelmaking, in which recycled materials and renewable energy sources are harnessed. Moving one step further, modular designs are also being developed to emotionally assist in easy installations, replacements, and recycling toward the end of their lives.

Pushed further still by the aesthetic innovations, these surface treatments provide a wide variety of customization options such as laser-etched patterns, brushed finishes, and even digital printing. The stainless steel cover plates are thus set in a stage that fulfills the graceful needs of smart and green architecture by integrating functionality and sustainability with superior design.

Frequently Asked Questions (FAQ)

Q: What are stainless steel cover plates?

A: Stainless steel cover plates are protective sheets constructed with high-grade stainless steel to cover electrical outlets, switches, and other fixtures. They provide a tough yet aesthetically pleasing finish, suitable for both residential and commercial applications.

Q: Can the stainless steel cover plates be used for industrial needs?

A: Absolutely! Stainless steel cover plates are perfect for commercial and industrial applications because of their durability and corrosion resistance. They are best suited for the rough environment of factories and warehouse spaces.

Q: What is the difference between 1-gang and 2-gang stainless steel cover plates?

A: The difference stands in configuration. A 1-gang stainless steel cover plate covers one switch or outlet, whereas a 2-gang accommodates two switches or outlets. Both types give away something of a classy ambience and come in different styles.

Q: How do I install stainless steel switch plates?

A: Installing stainless steel switch plates is very easy. Take the screwdriver and remove the existing cover, then place the new stainless steel switch plate over the switch or outlet and fasten it with the screws snugly to give it a nice finish.

Q: What benefits do stainless steel outlet covers offer?

A: Stainless steel outlet covers offer many benefits, including durability, resistance to corrosion, and a modern aesthetic. They are easy to clean and maintain, making them a good choice for kitchens and high-traffic areas.

Q: Can I have stainless steel cover plates installed in the kitchen?

A: Sure! Stainless steel cover plates are an excellent choice in kitchens because they resist heat, moisture, and stains. Their clean and sleek look blends with modern kitchen decor while protecting switches and outlets.

Q: What finishes can be expected of stainless steel wall plates?

A: Various finishes are available in stainless steel wall plates, such as polished chrome and brushed stainless steel. Each finish has its own flair, allowing you to match it up to your interior decor.

Q: Are there any decorative stainless steel switch-plate options?

A: Yes, decorative stainless steel plates with unusual and stylish designs and textures are available. Let your switch plate become a character in your overall decor!

Q: What is the price range for stainless steel cover plates?

A: Stainless steel cover plates will fluctuate in price depending upon the size, design, and brand. To give you a rough pricing idea, it might range from a dollar or two for the plain kinds to a lot more for the decorative or jumbo ones.

Q: How do stainless steel cover plates compare with other materials?

A: Most other materials out there cheapen the look of any space, while stainless steel maintains a sleek, modern feel. That classic industrial look offers beauty while doing the work of protecting your walls way better than most other materials.

References

- Reliability Analysis of Nonlinear Behavior of Stainless Steel Cover-Plate Joints

Published in Steel and Composite Structures, the paper analyzes the reliability and behavior in different angles of stainless steel cover-plate joints. - Analysis of the Behavior of Cover-Plate Stainless Steel Bolted Connections

The study spells out stainless steel bolted cover-plate connections of behavior employing advanced methods of modeling. - Stainless Steel Surfaces: A Guide to Alloys, Finishes, Fabrication, and Maintenance in Architecture and Art

This book gives detailed information about the implementation of stainless steel, including cover plates in architecture and art. It denotes alloys, finishes, and fabrication methods.

Ready to Upgrade Your Space?

Stainless steel cover plates offer the perfect combination of durability, functionality, and modern aesthetics for any residential or commercial application. Make the smart choice for your electrical installations today!