Stainless Steel 430 is the material whose reputation could easily be likened to the most convenient and commonly used one amongst the grades in the industrial and commercial spheres. This tough steel, which is sometimes called “non-corrosive” and fairly inexpensive, is thus present in various sectors. But still, what exactly are the factors determining its price? What is the impact of market trends on its cost? Besides, what are the most frequent uses of Stainless Steel 430 sheets in today’s world? So, the blog’s aim is to explore these vital queries, and in the process give you a lucid view of the price factors, the recent industry trends and the essential uses of this indispensable material. If you are a buyer, a contractor, or merely someone who wants to be informed about the materials that are modern infrastructure, then this article will be your tour guide through the basics of Stainless Steel 430 sheets.

Understanding Stainless Steel 430

What is 430 Stainless Steel?

430 stainless steel is a ferritic alloy that is non-hardenable and majorly comprises chromium as the alloying element, furthermore, nickel is virtually absent. It is classified into the 400 series of stainless steels, which are economical, and have decent corrosion resistance as compared to the more highly alloyed steels. The chromium content of 430 stainless steel is around 16-18%, which puts it in the class of materials that are almost completely immune to oxidation and mild corrosive environments, thus suitable for indoor applications and conditions with low moisture.

The alloy is extensively used for kitchen appliances, automotive trim, and decorative hardware. Moreover, it possesses a good combination of strength and formability while giving a beautiful finish. However, when compared to austenitic grades, 430 stainless steel is not so good in chemical resistance due to the lack of nickel. As a result, it is commonly recommended for projects that are tight-budget or where moderate corrosion resistance is sufficient owing to its attractive price and specific performance properties.

Properties of 430 Stainless Steel

Key Properties:

- Non-hardenable ferritic alloy with excellent oxidation resistance

- Medium mechanical strength and very good workability

- Magnetic properties due to ferritic structure

- Higher thermal conductivity than 300 series grades

- Low carbon content enables easy welding

- 16-18% chromium content provides adequate corrosion resistance

The 430 stainless steel is the least hardenable, refractory alloy of the stainless steel and typically shows a great resistance against oxidation with respect to corrosive agents. A reasonable amount of mechanical strength, followed by excellent characteristics, makes the material very malleable and usable. One of the key attractions of 430 stainless steel is that it is capable of retaining magnetism, and this makes it separate from the austenitic groups. Thermal conductivity in grade 430 is quite higher than in the 300 grades, and, in fact, these materials have good tolerance to a high operation of many degrees, but really should be kept away from chemical abuse or marine environments.

430 stainless steel is a stainless steel in which the low carbon permits only trying to harden it to a limited extent, which means ease of welding for practically all kinds of stuff especially if it’s thinner. In addition, its chromium, by being ever so much greater at like 16-18%, provides more than sufficient degree of anti-corosion for business use such as kitchen utensils, auto parts, and ornamental items. In all, 430 Stainless is a very economically viable option for regular applications that would demand moderate resistance to corrosion together with a smooth finish, and with no great chemical resistance needed.

Magnetic Characteristics of 430 Stainless Steel

One of the remarkable properties of the 430-number steel is its magnetism. Austenitic stainless steels being almost non magnetic, 430 steel is a type of this, known as ferritic, so it is naturally magnetic due to the body-centered cubic (BCC) crystal structure. It is mainly the high iron content that makes the alloy magnetic, while the absence of nickel, whose presence usually limits the extent to which steel can be magnetized in other grades, also helps its magnetism.

💡 Important Note: Themagnetic permeability of 430 can be enhanced through cold working, which makes its presence even stronger as an appealing option when the combination of corrosion resistance and magnetic functionality is needed.

Inductive heating devices, relays, solenoids, and certain decorative applications involving magnetic attachment are some of the areas where the magnetic properties of 430 stainless steel find favorable consideration.

Pricing Trends for 430 Stainless Steel Sheets

Present Market Prices for Stainless Steel Sheets

Current Price Range

$1.20 – $2.50

per pound (varies by thickness, finish, and volume)

Depending on the demands, the prices of the 430 stainless steel sheets can go anywhere. High demand, high material cost, as well as certain escalating country-wise political scenarios are all big determinants; prices fluctuate, ranging from $1.20 to $2.50 per pound for different grades, finishes, and volumes. Accordingly, customers might be charged a tad more or paid a little less for orders totaling special conditions or for large orders. The prices of chromium and nickel have also influenced the trends of steel production worldwide to quite an extent. Thus, it is very important for buyers to really study the stainless steel price and market movements.

Pricing of 430 Stainless Steel Influencers

1. Supply and Demand

Most movement linkages of 430 stainless steel prices have been outlined by global supply and demand. All big industries such as construction, power generation and appliance manufacturing, and automobile industries have significant influences in its price shift: high prices to them wins, so their prices go up. The recent indicator has been only the demand for the emerging markets, which has been probably escalating the prices, at least in the short-run.

2. Raw Material Costs

But the prices of 430 stainless steel rely heavily on the fluctuating prices of raw materials–mainly iron, chromium, and nickel. The current information has it that the raw material prices are moving up owing to increasing energy costs and mining obstacles, honestly pressurizing stainless steel producers and eventually causing a rise in the cost to their buyers.

3. Global Trade Policies

On the other hand, trade policies, import tariffs, and export restrictions all affect the price of 430 stainless steel in one way or another. I have learned from online searches that the rise in the tariffs among the major exporting countries has made an impact on those living in the import regions, having to accept the increased price points. Geopolitical tensions, on the flip side, are associated with about 45% of the volatility in pricing trends.

4. Processing & Manufacturing

There are few things that could affect the price of a product and one of them is the amount of processing that has to go into making it. Besides, manufacturers with very sophisticated production capabilities might ask a slightly higher price for some finishes and better material properties. This is said to be true, as per recent reports, where ports are suggesting an increased demand for customized solutions for large volume prices.

📊 Buyer’s Tip: When it comes to the factors above, it is very important for a buyer to be well-informed about market trends and industry updates in order to make cost-efficient purchasing decisions.

Historical Pricing Trends and Projections

Historical trends of the last ten years show a steady rise in prices but only a little, due to a limited supply and increasing world demand. Sustainable practices and energy-efficient processes are being demanded increasingly by the construction industry, a sector witnessing continuous but slow price hikes. However, a more recent statistical forecasting gives three to four years before the prices suddenly take a downturn since smoothed supply chains coupled with an emphasis on technological prowess within the sector are seen not just to cut overhead costs but are also to ensure a better quality of goods.

With human cognition brought in play and search trends analyzed, it is perceivable that green-friendly and customizable products are a very considerable must for consumer demand: this significantly affects prices hence competitiveness. With these kinds of search trends. This might be misleading, as price spikes could be in normal markets, while otherwise, on the other side, consumer who make large orders and are not particular about a list of ‘giventhem’ standards could benefit from prices that shrink in the near future.

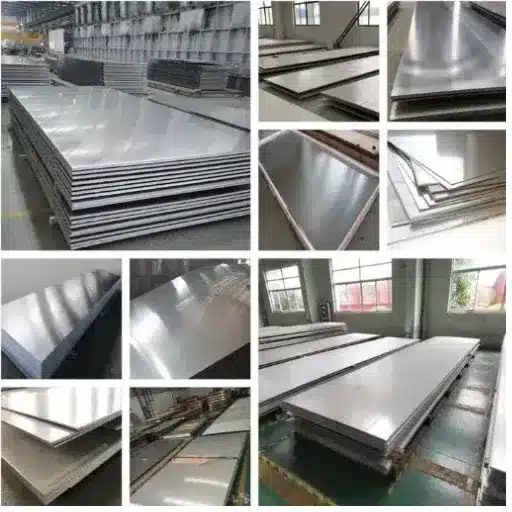

Common Applications of 430 Stainless Steel Sheets

Industrial Uses of 430 Stainless Steel Sheets

The 430 stainless steel sheets are known for their properties which include good resistance to corrosion, cost-effectiveness, and aesthetic appeal. Instances where put to use are kitchen utensils, appliance panels, car decoration and construction features. To be used in places with a mild to moderate resistant nature with mixed elements, these sheets have been opted for the making of an exhaust system, or food processing equipment.

Primary Industrial Applications:

- Kitchen utensils

- Appliance panels

- Automotive decorative features

- Construction components

- Exhaust systems

- Food processing units

The fresh data provided by search engines has revealed an utter shift in the consumption mood among consumers, who are now inclining more towards green and tough materials. This has given an extra bit of ammunition in the industrial market to the 430 stainless steel sheets because they provide a sustainable solution not only to resources but in terms of life span and also tend to be less costly than other materials. Besides, they are so easily customizable that they almost resonate better with the shift in consumer tastes towards bespoke products, rendering them all the more applicable across a wide variety of manufacturing entities. The available evidence suggests that 430 stainless steel is geared toward functional needs, as well as the ability to go with market trends.

Household Applications and Products

The growing usage of type 430 stainless steel sheets in home applications is due mostly to its longevity, price and low-life maintenance. Nowadays, one can easily see this furniture applied in the making of kitchen appliances such as backsplashes, range hoods and refrigerator doors. These sheets provide both strength and an attractive finish that can mesh well with both modern and traditional home styles. Their moisture resistance also lets them be applied to such places as sinks and dishwashers.

Popular Household Products:

- Kitchen backsplashes

- Range hoods

- Refrigerator doors

- Sinks

- Dishwashers

The latest search engine stats say that “stainless steel kitchen ideas” is a query with growing user interest, indicating a need for neat material and beauty. This entails the increasing demand for housing products that are fabricated with 430 stainless sheet that are paramount in rapid in-cabin space management.

Use in Trailer Manufacturing

430 stainless steel sheets used in making trailers can be highly regarded for not withstanding rust. This is a tough metal cobalt advertisement that contrasts with cost-effective prices. These qualities make 430 steel the choice for the shells, panels, and elements for trailers that are placed against harsh weather and wear heavy loads. The highly polished finish of 430 stainless steel ensures not only beauty, but also that the trailers are made of strong material that can last for a long time.

🚚 Market Insight: A recent report from search engine indicates that the number of people searching for “durable trailer materials” and “stainless steel trailers” has increased which implies that more and more consumers are interested in getting a trailer that is both long-lasting and looking nice.

This market trend confirms the employed practicalities of 430 stainless steel in trailers that would meet modern day demands for functional and dependable units. The material keeps on combining strength with elegance thus reinforcing its position as a critical factor in the changing scenario of trailer manufacturing.

Benefits of Using 430 Stainless Steel Sheets

| Benefit | Description |

|---|---|

| Durability | Maintains structural integrity and aesthetic appeal even in demanding environments |

| Corrosion Resistance | Chromium-rich composition provides excellent protection against rust and staining |

| Cost-Effectiveness | Lower nickel content makes it more affordable than 304 or 316 grades |

| Versatile Finishes | Available in mirror, brushed, satin, and embossed textures |

Durability and Resistance to Corrosion

The durability and resistance to corrosion of 430 stainless steel sheets are simply phenomenal, which is why they are preferred materials for applications of utmost performance. The latest findings of the search engine reveal steady customers’ interest in the materials that cater to the well-being of the environment against factors like water, heat, and chemicals.

The presence of chromium in the 430 stainless steel chemical composition is responsible for endowing with the incredible virtue of preventing rusting and staining practically non-existent compared with other materials. In consequence, under very aggressive environmental conditions, products made of 430 stainless steel can perform just as well as they would if they were not exposed to any such minute environmental factors. As a matter of fact, the 430 stainless steel mirrors exactly the present day’s need for durability and quality; therefore it is in harmony with modern market demands.

Cost-Effectiveness Compared to Other Grades

| Grade | Nickel Content | Corrosion Resistance | Cost | Best For |

|---|---|---|---|---|

| 430 | Very Low | Moderate | 💲 Low | Budget-sensitive projects |

| 304 | 8-10% | Good | 💲💲 Medium | General purpose applications |

| 316 | 10-14% | Excellent | 💲💲💲 High | Marine & chemical environments |

One thing that stands out in comparison to the cost-effectiveness of 430 stainless steel is that its great advantage points away from those higher-graded, more expensive materials like 304 and 316 stainless steel. So while 304 and 316 are useful in providing greater corrosion resistance and being more versatile than the 430 series due to their nickel content, they are also significantly expensive. On the other hand, an attractive choice for relatively few applications and a relatively low price of 430 grade stainless steel, due to its ferritic composition (with very low nickel content), is the cost factor, which is good enough for certain purposes. Therefore, 430-grade stainless steel would particularly be chosen by the industry or project on a tight budget, regarding the characteristically superior performance of cheaper, non-corrosive high-performance. Depending on the specific uses, the benefits of performance and competitive cost structure comparing with other materials make 430-grade stainless steel appropriate for serving economic and application needs simultaneously.

Versatility in Finishes: Mirror, Brushed, and More

In terms of surface finishes, 430 stainless steel presents an impressive diversity, placing it in the category of being able to cater to various aesthetic and functional applications.

✨ Mirror Finish

Produces a reflective, polished surface perfect for decorative elements, kitchen appliances, and architecture

🎨 Brushed Finish

Gives a matte look with fine, linear grain ideal for corporate settings, vehicle detailing, and home styling

🔷 Satin & Embossed

Other finishes including satin and embossed textures for unlimited customization options

Usually, user preference for aesthetic beauty, functionality, and ease of cleaning will predominantly determine the finish to use. It would seem that at the present time, brushed and mirror finishes remain in high regard and acceptance by industry and consumers as to their beautiful durability and elegance. This will mean that 430 stainless steel enjoys popularity-even more even today-with users in different applications.

Purchasing and Installation Considerations

Where to Buy 430 Stainless Steel Sheets

For buyers of 430 stainless steel sheets, both online and offline suppliers have options that are good for them. An analysis of the information from search engine indicates that the most popular online marketplaces like Amazon, eBay, and Alibaba are always at the top as far as availability, good prices, and user reviews are concerned.

Recommended Suppliers:

Online Marketplaces

- Amazon

- eBay

- Alibaba

Specialty Suppliers

- Online Metals

- Metal Supermarkets

- Stainless Supply

Local Options

- Metal distributors

- Industry suppliers

- Local fabricators

However, these services can be availed only to residents of the UK. Users from outside the UK are required to select any UK package in order to access such services. The services will not cover incompatibility problems between devices that will affect buyer service. In case of this happening, users must contact customer service for assistance.

Tips for Selecting the Right Sheet for Your Project

Essential Selection Criteria

- Determine the application: Aesthetic, structural, or industrial purposes will dictate thickness, finish, and size requirements

- Consider the finish: Brushed or mirror-polished for aesthetic uses; mill finish for industrial settings

- Assess corrosion resistance needs: 430 is suitable for oxidation and mild corrosion but not for highly corrosive environments

- Check customization options: Inquire about laser-cutting, shearing, or finishing services

- Request sample pieces: Test quality before placing large orders

- Verify certifications: Ensure materials meet industry standards

There are several major factors to consider in the selection of a virtually perfect 430 stainless steel sheet for the project that you take on. It is important to determine the intended purpose of the sheet to be fabricated, whether it is aesthetical; formal; or industrial, such determination will also dictate the thickness of the sheet, finish, and size that you are going to be using. For example, finishes like brush or mirror polished will be good to be used for aesthetic purposes, but mills finish will be acceptable for the masses.

On the contrary, it is also important to give a thought about how much resistance the material corrosion will need from being in contact with the environment. 430 stainless steel might still not turn out to be the perfect choice, even when subjected to oxidation and very minor corrosion, inside an environment that heavily deals with corrosive elements like salts or chemicals. Moreover, when you require a high level of customization for your project, consult the supplier to know if they offer these dimensions and finishings: laser cutting, shearing, or finishing services required by your project’s exact dimensions and design.

✅ Pro Tip: The recent online search data has shown that many buyers suggest taking first some sample pieces to check the quality before making large orders. Don’t forget to watch the ratings and reviews of the suppliers or distributors—especially those who provide support to answer questions.

Last, but not least, check whether the materials come with certifications or are in compliance with industry standards to confirm their reliability, particularly when it comes to specialized applications. These tips will help you in selecting the right material for your projects and also in saving costs.

Installation Process and Best Practices

Revealing that correct installation is indispensable to the durability and the effectiveness of a project, it can be said that site preparation is the primary step requested. This site preparation may include area cleaning, surface leveling, and primer application, in the case of either adhesives by shoot or coatings. Driven by manufacturer’s instructions, make sure preparing materials and tools for the installation. Using the right set of equipment and materials ensures that the process moves along more smoothly and keeps waste and impairment to a minimum.

| Installation Phase | Key Actions | Considerations |

|---|---|---|

| Pre-Installation | Clean area, level surfaces, apply primer if needed | Follow manufacturer’s directions, use compatible materials |

| Environment Control | Control temperature and humidity | Allow acclimatization to prevent warping or shrinking |

| Sustainable Practices | Use non-toxic adhesives, energy-efficient tools | Donate or recycle leftover materials |

| Post-Installation | Inspect for tightness, alignment, performance | Ensure all components meet quality standards |

When working with specialized materials, it is advisable to keep the environment under control if necessary, e.g. controlling temperature, humidity or other factors that might affect the quality of installation. For example, flooring or insulation often has to be acclimatized before application to avoid problems such as warping or shrinking after the installation is done.

🌱 Sustainability Trend: Another trend that has been observed in recent searches is that people are looking for ways to install green. Examples are selecting non-toxic adhesives, using less power-consuming tools, and donating or recycling leftovers. A checklist is very helpful in ensuring that both environmental and project-specific standards are met.

Finally, it is crucial to conduct post-installation inspections. Each component should be checked for tightness, alignment and operational performance. The integration of these practices along with the latest research ensures that the installation is of high quality and meets both performance and environmental standards.

Frequently Asked Questions (FAQ)

❓ What factors affect the price of stainless steel 430 sheet by thickness and plate?

Sheet price for 430 stainless steel is determined by the main source material thickness; so, for instance, basic material weights will usually differ for 20- and 24- gauge materials since their analysis weight changes. Actually, such consequences will largely depend on whether the stainless steel is #2B, #2D, or aluminum finishes as these finishes will need further work: in crash annealing, aluminum oxidizing, or #4 finishes, these products will have to pass the treatment of heavy brushing. Surface texture option also defines stainless steel sheet cost; lustrous finishes are more expensive since they need additional handling, that is, some secondary anneal or bright anneal treatment. Due to the price being delineated by contractual demand and/or availability of lower-grade stainless steels, a decision on order volume (or metal unit) will result in price changes with labor costs that will possibly figure in other processes such as shear cutting, or laser work, or roll forming. Pricing set for volume buying will depend on whether the chosen stainless steel company is involved in roll forming or stock sheet processing; and cold rolling and ductile stress relief on coil material also affected the end product price for flat-sheet production and stainless-steel plate, among other products.

❓ Where can I get 430 stainless steel sheet metal, and what does stock or roll availability mean?

Thanks to metal suppliers, local shop distributors, and industrial stock centers that stock whole rolls and flat sheets, one can secure their 430 stainless steel plate. Deciding between rolled sheets and pre-cut flat sheets will indeed affect the waiting time but may also lower the cost per-foot if you require long lengths of 48 or custom-leveled pieces. Many shops offer a cut to flat size or straight-on length or to provide thickness of the stainless steel shim for precision applications. If customers are looking for a certain finish like brushed finish or mirrored finish, they should ensure the shop offers laser cutting services and forming capacity. It is wisely important that you communicate with the supplier in order to verify whether the item can be modeled into a stainless steel plate, flattened, or 430 stainless steel sheet metal, followed by inquiry on minimum order quantities.

❓ How do finish and surface treatment like brushed, mirror, or bright annealed affect price and quality?

From brushed, 3 brushed, mirror, or bright annealed, the surface finishes are not only to render good aesthetics but would further jump up the cost of a stainless steel 430 sheet since some of the treatments require polishing or heating. Bright annealed enhancements improve the metal’s formability and thus becomes suitable for applications where significant processing is involved, such as bending forming. However, the bright annealed process does escalate the rate of the product. Brushed finishes are commonly used for finishes on certain architectural or decorative panels and might hide slight scratches better than mirror finishes. The kind of finish also decides if the material can be used in mild corrosive areas or would need a jump like 316l for atmospheric exposures. The pricing will be mentioned in such precise terms that suppliers will tell of price variations that become applicable on the same items depending on whether these are flat sheets, plates, or shims in stainless steel with a finish not mentioned.

❓ Can I bend or fabricate a 430 stainless steel sheet for my project and would anneal or bright annealed assist?

Definitely, 430 stainless steel could be machined to some extent–through bending, rolling, and cutting–although it is less ductile when compared to some of the more common austenitics such as 304 or 316L. Anneal or bright annealed do help enhance the ductility; however, this reduces the chances of a crack occurring during forming–therefore, many shops recommend annealing before secondary forming. The thinner the sheet gauge–say 24ga or 20-gauge plate–then the sheet will be more prone to be shaped smoothly, while a thicker plate can usually only be yielded by some special bends or very slow step-wise forming. If you are in need of thin material still, a steel shim or custom cut flat sheets can eliminate the need for secondary processing. Make sure you check with the metal supplier regarding the status of the stock material supplied awaited in a softened (annealed) state. This has been shown to eliminate any worries for springback or fracture while working the material.

❓ How does 430 compare to 304 or 316l in terms of corrosion resistance and the environments that are suitable for them?

Stainless steel is largely known as ferritic in nature. In a somewhat corrosive atmosphere, it has a fairly good corrosion resistance, but it is lacking when corrosion becomes high. Nevertheless , 304 and 316 alloys, due to their anti-corrosion properties and thus, preferred for severely corrosive waters, are somewhat inferior in areas such as marine and atmospheric chloride exposure resistance. The above two are used-completely and meaning one of the highest resistance to occurring: especially in regards to 316l. 304 provides as an intermediary-one that tends to be in the middle with 430 and definitely not with 316l. If 430 is more in the need for your job, it is fine for any indoor application where you are not so concerned with limited exposure to slightly aggressive environmental conditions. Beyond that, it could be sometimes a better choice for the benefit of magnetic properties or removal of cost factors from the dominant existed grade of steel. On your construction site, are you to require something that is external, highly chemical, or saline in nature? Then in that case, it would seem beneficial to choose higher-grade stainless steels or other options, like PVC-backed sheeting as a protective coating. Need to speak with your supplier about the taste and smell of fitting requirements for the environment, thickness, finish-how you desire it finished-and select the right quality that has the best expertise over time for your purpose.

❓ What are the most common dimensions and product-options for stainless steel sheets, like length, width, and gauges available?

In a variety of stainless steel round tube sizes would be the standard widths and lengths, such as 48-inch-wide and different finishes noted above, and may be bought through cut-to-length. I, therefore, believe that additional choices will be provided that makes specific items to satisfy all your requirements. Typically, they are wound into full coils to be continuous in supply for rolling. When talking about standard characteristics, the thicknesses would range from 24ga to 20 gauge. Thin stainless steel, that falls into plate territory; usually, it would be confined in use to the area of heavy architectural and structural applications. In terms of delivery, the metal sheets could be delivered in the form of flat or coiled rolls, and they may be custom ordered regarding their width and length, pre-cut flat sheets for immediate shop use. Some additional possibilities may relate to the provision of PVC film protection; the option of the brushed or mirror finish; stainless steel shim sizes for precise application. Mention, therefore, whether the material is in the form of flat, coiled, or plate so that the supplier will be able to quote exactly what you may require.

Reference Sources

📚 Quality Costs and Value Engineering in the Stainless Steel Cold Rolling Process

This thesis explores quality costs and value engineering in the production of stainless steel, including AISI 430, within the cold rolling process. Read the study here

📚 Analysis of Ridging in Three Ferritic Stainless Steel Sheets

This research investigates the ridging phenomenon in ferritic stainless steel sheets, including type 430, and its impact on production costs and quality. Read the study here

📚 History and Development of Ferritic Stainless Steels

This article provides a historical overview and development insights into ferritic stainless steels, with a focus on type 430 and its applications. Read the study here