When sheet metals are worked on, basically, the gauge thickness is not just a technicality-it is a core consideration affecting design, functionality, and performance across a plethora of industries. From automotive manufacturing and aerospace engineering to construction and HVAC systems, understanding precisely the sheet metal gauge standards significantly influences material selection, production efficiency, and, above all, the quality of the end product. This guide aims to unravel the sheet metal gauge measurement system, exploring its historical roots, industry usage, and the science behind the numbers that correlate to the material’s thickness. Engineers, fabricators, or metalworking enthusiasts will surely gain valuable knowledge from this reference to inform their decisions and make the most of their time. So let’s begin going through the nitty-gritty of sheet metal gauge thickness and all that modern manufacturing entails.

Introduction to Sheet Metal Gauges

Sheet metal gauges are a set of standardized measurements that denote the thickness of sheet metal. These measurements have an inverse relationship to linear measures like millimeters or inches, wherein the higher the gauge number, the thinner the piece of metal. Conversely, a 24-gauge sheet is thinner than an 18-gauge sheet. Those above originated to address the issue of measuring material thickness, considering the various manufacturing processes.

The gauge system is not fully standardized and differs with respect to the type of metal. For example, the gauge measurements for steel will vary slightly from those for aluminum or stainless steel. Nonetheless, a number of gauge charts have been identified and accepted by the industries and manufacturers to ensure the precision and consistency of their respective fabrications. Having an idea about sheet metal gauges should be a key point in the basis for the decision you make in selecting material thickness in a specific application-whether structural for support or aesthetic for design, or even functional for durability.

What Are Sheet Metal Gauges?

Sheet metal gauges are standardized size systems used for defining the thickness of metal sheets. It is an industrial-era system to lessen the hours spent describing metal thickness during production, where smaller gauge numbers imply thicker metals, and bigger gauge numbers imply thinner materials. For steel, a 10-gauge sheet is nearly 0.1345 inches thick, and a 20-gauge sheet is only about 0.0359 inches in thickness. The disclosure has to be made that gauges do not universally apply to all metals; also, there are different gauges-to-thickness charts for different types of materials, including aluminum, copper, and stainless steel, due to differences in densities and material properties. At present, sheet metal gauges are fundamental knowledge in construction, automotive, and manufacturing industries, where exact specifications govern the structural integrity, utility, and overall performance of the completed product.

The Importance of Gauge Thickness in Various Industries

Getting the right gauge means a lot for many industries that require it for materials to be labeled as stronger, durable, and lightweight. For instance, in the automotive industry, the gauge thickness of sheet metal used in forming vehicle panels and structures imparts requirements related to safety, fuel economy, and ease of manufacture. Thin gauges are usually used for lighter designs to enhance fuel economy; on the other hand, thick gauges are used to provide bonding for crash-resistance and to withstand heavy applications.

In construction works, the gauge thickness determines the products’ capacity for load application in roofing, framing, and exterior cladding. The construction industry benefits from optimum gauge thickness, determining compliance with specifications, enhancing the life of the structure and environmental resistance, especially under varied climatic and load conditions.

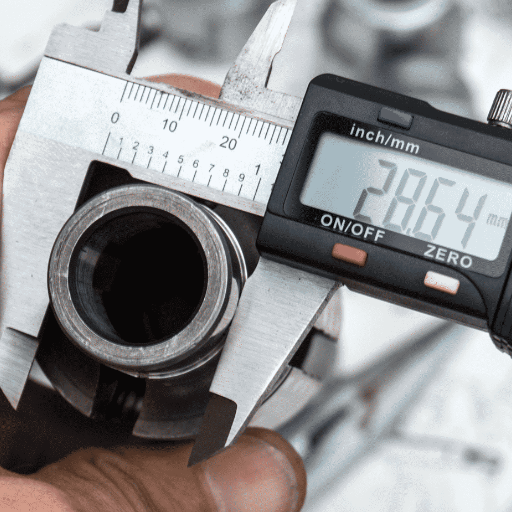

Basics of Sheet Metal Gauge Measurement

Sheet metal gauge measurement is a standard measurement system to specify sheet metal thickness. The gauge number is directly opposite in correlation to the material thickness; hence, the smaller gauge number corresponds with greater thickness and the larger gauge number with lesser thickness. Thus, a 10-gauge steel sheet is thicker than a 20-gauge steel sheet. Gauge is not standard across all materials, although different metals like steel, aluminum, and zinc tend to follow different charts. Most importantly, measurements are converted to their equivalent decimal thickness, be it in inches or millimeters, based on the gauge chart for that material.

Standardization of Gauge Measurements Across Regions

Standardization of gauge measurements actually becomes quite complicated when we consider the systems utilized inconsistently throughout regions and industries. For example, in the United States, the American Wire Gauge (AWG) is popular for electrical conductors, whereas, the U.S. Standard Gauge measures sheet metal. Many European countries, on the contrary, are metric-oriented and use millimeters for the thickness measurement of wires and sheet metals alike. Such a contrast may give rise to trade and manufacturing barriers across borders since conversion from one system to the other may not be perfect. Each system has a different base reference standard.

Efforts to create globally unified standards are ongoing through organizations like the International Organization for Standardization (ISO). The standardization bodies try to reduce, if not entirely abolish, conflicts by creating a single mode of measurement, but the decisions are often overridden by long-standing practices and biases with regional industries. To cite one example, both automotive and aerospace industries may employ regional standards best suited to supply chains and legacy equipments.

The resolution of this problem is further targeted by modern technology and international cooperation. With the help of software tools and very precise instruments, a manufacturer can now easily convert and verify gauge measurements between systems, thus greatly minimizing errors in their application between countries. It is this kind of innovation that will help maintain compatibility and guarantee the highest level of accuracy in the planting grounds of growing globalized manufacturing.

Understanding Gauge Numbers and Their Relation to Thickness

Gauge numbers are standards in their own right that ensure functionality and safety wherever exact material dimensions are needed, thus making construction, automotive manufacturing, and metal fabrication their principal fields of activity. For example, the gauge of structural steel or metal roofing sheets affects their durability, ability to bear loads, and resistance to weather in the construction industry. Automotive manufacturers rely heavily on gauge design specification to allow standardized body panels that affect aerodynamics, weight, and overall efficiency.

In tandem with emerging materials sciences and manufacturing technology, gauge standards have been upgraded, allowing for the introduction of digital conversion aids and comprehensive gauge charts that link gauge numbers to imperial and metric thickness measurements with great accuracy. Such conversions will, therefore, provide critical dimensional tolerances prior to commencing on any conversion project that will help speed up processes. Equally important is the introduction of at least three different material types- aluminum, stainless steel, and copper- that have distinct gauge thickness relationships into designing a complicated assignment with the least amount of human error.

Material-Specific Gauge Measurements

The relation between material type and gauge thickness is vital to accuracy in applications. For instance:

- Aluminum: The typical range of gauge measurement for aluminum is from approximately 0.025 inches (for 22 gauge) to 0.250 inches (for 3 gauge), thus bringing along several opportunities for lightweight yet durable designs.

- Stainless Steel: Stainless steel is denser, with 22 gauge equaling approximately 0.031 inches and 3 gauge equaling 0.250 inches, offering high strength and corrosion resistance.

- Copper: These gauges for copper find more purpose in electrical and plumbing applications, with 22 gauge at 0.025 inches and 3 gauge at 0.229 inches, for balance between conductivity and strength.

The values picture the uniformity of gauge standards, but also the variations in material properties. Accuracy in gauge measurements goes a long way in ensuring that a project complies with specifications in the utmost way and thus meets IPC-conferred adequate performance.

Steel vs. Aluminum: Gauge Variations and Properties

|

Key Point |

Steel |

Aluminum |

|---|---|---|

|

Density |

Typically 7.85 g/cm³ |

Typically 2.70 g/cm³ |

|

Strength-to-Weight Ratio |

Lower compared to aluminum |

Higher, ideal for lightweight applications |

|

Corrosion Resistance |

Requires treatment to resist rust |

Naturally corrosion-resistant in most environments |

|

Workability |

More difficult to shape and weld |

Easier to machine, shape, and weld |

|

Thermal Conductivity |

Lower, about 50 W/m·K |

Higher, about 235 W/m·K |

|

Electrical Conductivity |

Low relative to copper and aluminum |

High, used in electrical systems |

|

Cost |

Generally more affordable |

Typically more expensive |

|

Durability |

High, suitable for heavy-duty applications |

Lower, less suitable for heavy stress use |

|

Weight |

Heavier material |

Lightweight, ideal for transportation needs |

|

Recyclability |

Easily recyclable with strong scrap market |

High recyclability, widely reused |

Other Metals and Their Unique Gauge Characteristics

In determining the metal properties, it is important to take into account their gauge properties in relation to composition and applications . Stainless steel, being highly versatile for corrosion resistance and strength, its gauge thickness determines durability and weight, with thin gauges usually applied in appliances and architectural applications, and thick gauges applied in industrial and marine applications. Further, stainless steel retains its structural integrity over a very wide temperature window, which is very much needed under extreme conditions.

Another case in point is titanium, which showcases an exceptional strength-to-weight ratio coupled with stellar corrosion resistance: here again, gauge variations of titanium are critically important in industries like aerospace and medical implants, where precision and performance matter greatly. Titanium is lighter than steel but mechanically just about the same, especially when thinner gauges of titanium are in question; however, it being costly demands contrapuntal use.

Zinc, contrary to being the softest in its natural state, is used in coating or thin-gauge applications because it gives the best galvanic protection from corrosion. This makes it an important name in roofing, cladding, and automotive work. The thin-gauge zinc is malleable and thus can be shaped quite meaningfully without compromising its utility as a protective coating.

Practical Applications of Sheet Metal in Various Industries

Sheet metal finds its applications into construction, automotive, and aerospace industries due to its editing qualities. The guiding qualities thereof and uses in specifics are provided as below.

- Construction: Sheet metal finds wide applications in roofing and HVAC systems, and distinguishing components. It corrodes very less with environmental agents and therefore is flexible in weathering environmental stress while protecting structural integrity.

- Automotive: The manufacture of body shells and chassis and other components of sheet metal is one of its applications. The properties that make the sheet metal light yet strong make it a good candidate for higher fuel efficiency and safety of vehicles.

- Aerospace: These are high-strength sheet metals, like aluminum alloys, applied for aircraft fuselages and wings. They resist extreme conditions so as to guarantee reliability during flight operations.

- Manufacturing: The manufacturing of household appliances, machinery parts, and electrical enclosure is what sheet-metal spells for this application.

Against the requirements of certain industries, sheet metal remains a fundamental material in contemporary engineering and design.

Construction: Choosing the Right Gauge for Structural Integrity

Proper selection of sheet metal gauge in construction is paramount for structural stability and safety as well as long-term durability. A gauge is a geometric number representing the thickness of the sheet metal. Therefore, it is one among many variables that affect the ability of the materials to bear various loads, flexibility under deformation, and environmental stresses, which include corrosion and temperature changes. Thin gauges such as 24 gauge sheet metal are used for applications such as lightweight cladding and roofing, where flexibility is desired, for example, for installation. On the other side, thick gauges such as 16 or 18 are used in structural applications such as beam and column design, where they must resist higher mechanical loads very well.

Load requirements for a project, wind, and snow loads are some of the factors considered when deciding on the gauge. Also, they must conform to particular building codes or standard requirements. For instance, according to the recommendations made by professional institutions, such as the American Society for Testing and Materials (ASTM), the selection of gauge has been in compliance with the requirements of specified performance. Opposite to this, modern materials, such as aluminum-alloy and galvanized steel, bring forth somewhat thinner gauge sheets having strength equivalent to a thicker gauge sheet based on a traditional material and thus save the consumption of material.

Automotive: Gauge Selection for Safety and Performance

The choice of material gauge in automotive applications is a crucial decision that significantly impacts both safety and vehicle performance. The increasing use of thinner gauges, in this respect, is currently helping to reduce vehicle weight and, thus, further enhancing fuel efficiency and reducing emissions, which aligns with the ever-increasing emphasis on sustainable transport. Thinner materials, however, require very close support in terms of strength to meet the safety criteria.

Advanced materials such as high-strength steels (HSS) and ultrahigh-strength steels (UHSS) helped manufacturers thin down the gauge without sacrificing crashworthiness and structural integrity. For instance, achieving tensile strengths over 1,000 MPa, UHSS grades enable thinner and lighter components with maintained critical safety performance. In the same manner, integration of aluminum alloys that provide a better strength-to-weight ratio is gaining acceptance fast in the body panels and structural components.

Factors to Consider When Selecting Gauge Thickness

- Material Type

Steel, aluminum, or composites are different materials having different mechanical properties to give them a strength-to-weight ratio, elongation, and ductility. For example, high-strength steel may use a thinner gauge than aluminum to give equal structural integrity. Choosing the right material type involves consideration for durability and unnecessary weight.

- Structural Requirements

Gauge thickness has to be compatible with structural performance requirements, such as load-bearing capacity or tensile strength, and so forth, resistance to bending, or deformation. Engineering calculations are to substantiate these requirements against stress distribution and buckling limits. In automotive panel manufacturing, body panels generally range from 0.6 mm to 1.5 mm gauge thickness, depending on function.

- Safety Standards

Incapable of undermining regulations around safety must be met before engineering design is further pursued. Compliance commonly dictates minimum panel thicknesses as defined by an organization such as NHTSA or Euro NCAP to resist impact and protect human lives. The series of crash test simulations and physical tests fully verify that the basic requirements have indeed been achieved.

- Weight Considerations

Fewer materials in weight means better fuel saving and lowered emissions, the key during transport. A lighter gauge is to be preferred, where structure and safety are not sacrificed. For example, the industry tries to cut down the weight by 10-15% without loss of function.

- Manufacturing Process

Depending on whether it is stamped, rolled, or extruded, gauge thickness could be critically limited during fabrication without complete failure of the material. Materials of lower gauge levels would almost always be difficult to work with, for example, thinning during processing and spring-back or cracking occur without finely adjusted tooling.

- Environmental Conditions

Materials can deteriorate over time if there exists exposed to a corrosive agent, changes in temperature due to thermal shock, or exposure to humidity. If the product lowers its expected lifetime because of such adverse conditions, considering corrosion-resistant coatings or alloys of particular gauge thickness could be the answer.

- Cost Efficiency

Durability and Flexibility: What You Need to Know

Experiences like durability and flexibility are among the qualitative performance indicators that define the industrial or structural evaluation of materials. Durability, on the other hand, is the capacity of a material to endure wear, pressure, or damage for some time, and its effect is often subject to the chemicals used, the application of coatings, or environmental exposure. Flexibility, conversely, is termed as the ability of deformation without fracture, and it is a vital property for applications requiring resilience under mechanical stress.

Such are all subordinate to environmental exposure: corrosion can set in if the erosive forces of chemical or physical influences far outweigh the resistive forces of the nature of the chemical and mechanical properties of the protective agent, such as the applied coatings. Corrosion mechanisms can even attack metals and their protective layers, reducing mechanical properties. In all cases, the balance between mechanical performance and durability must be considered in the selection of materials for specific uses. The same set of corrosion hazards may warrant a different choice of materials if it is confronted with a specific set of mechanical requirements.

Making Informed Decisions Based on Project Requirements

Reference Sources

-

- Key Findings: This study reviews advanced mechanical testing methods for sheet metals, focusing on multiaxial stress tests using cruciform and tubular test pieces. It highlights the importance of anisotropic plastic deformation behavior and the validation of material models for accurate forming simulations. The research emphasizes the role of these tests in improving predictive accuracy for forming defects like fractures and springback.

-

Design and Fabrication of Automatic Multipurpose Sieving Machine:

- Key Findings: This research focuses on the design and development of a multipurpose sieving machine for industrial applications. It discusses the use of gauge sheet metal in the machine’s construction and highlights its adaptability for various industries, including agriculture, construction, and food processing.

Frequently Asked Questions (FAQs)

Q: What is a sheet metal gauge chart and how is it used?

A: A sheet metal gauge chart is a reference tool that shows the relationship between sheet metal gauge numbers and their corresponding thicknesses. It is essential for anyone working with metal, as it helps in choosing the right sheet metal for various applications. The higher gauge numbers indicate thinner sheets, while lower numbers represent thicker sheets. For example, a 16-gauge sheet is thicker than a 20-gauge sheet. Understanding these measurements is crucial for ensuring that the right material is selected for outdoor projects or decorative purposes. Additionally, the chart can assist in understanding the actual thickness of different metal gauges, including both ferrous and non-ferrous metals.

Q: How do I choose the right sheet metal gauge for my project?

A: Choosing the right sheet metal gauge involves considering the specific requirements of your project. You should begin by referring to a sheet metal gauge chart to identify the thickness needed for your application. Factors like weight, strength, and durability play significant roles in this decision. For outdoor projects, thicker sheets may be preferred for their resistance to environmental factors. Additionally, consider the tools used for cutting and shaping the metal, as different gauges may require different techniques. Ultimately, assessing your project’s needs and the characteristics of the material used is essential to ensure optimal results.

Q: What is the difference between ferrous and non-ferrous metal gauges?

A: Ferrous and non-ferrous metals differ in their composition and properties, which affects their sheet metal gauge thickness. Ferrous metals, like steel, contain iron and are generally stronger but may corrode if not treated. Non-ferrous metals, such as aluminum and copper, do not contain iron and are often used for applications requiring lightweight or corrosion-resistant materials. The gauge thickness for both types can be measured using the same system, but their actual thickness may vary due to differences in material density. Understanding these distinctions is vital when selecting metal for specific applications, especially in terms of durability and finish.

Q: What tools are used for working with different metal gauges?

A: The tools used for working with metal gauges can vary significantly depending on the thickness and type of metal being handled. For thinner sheets, hand shears or tin snips may be sufficient, while thicker sheets often require power tools like plasma cutters or shearing machines. Additionally, techniques like welding or riveting may be necessary for fastening thicker sheets together. It’s essential to select the right tools based on the gauge of the metal and the complexity of the cuts or joins required. Proper tool selection ensures a smooth finish and enhances the overall quality of the project.

Q: What are the applications of higher gauge numbers in sheet metal?

A: Higher gauge numbers in sheet metal indicate thinner sheets, which can be advantageous in various applications. Thinner sheets are often used in decorative projects where weight and flexibility are crucial. They are also common in manufacturing processes that require intricate designs or lightweight components. For instance, in the automotive industry, higher gauge metals are frequently used to create body panels that must maintain aesthetic appeal while being lightweight. However, considerations must be made regarding their strength and durability, especially in outdoor applications where thicker materials might be preferred.