Introduction: Materials sciences in engineering, construction, and manufacturing pay immense attention to distinguishing between the two types of metals. This attribute of classification is merely one of elemental composition, but can be useful where its properties are reflected in applications and environmental considerations. Ferrous metals have retained their name and fame for their strength and durability because of the iron contained in them. Non-ferrous metals, on the other hand, because of a lack of iron, offer their own set of advantages: corrosion resistance, lightness, and conductivity.

What are Non-Ferrous Metals?

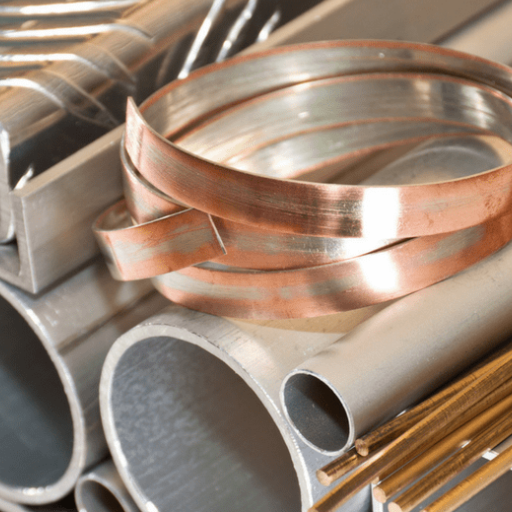

Non-ferrous metals are metals that do not contain significant amounts of iron, making them resistant to rust and corrosion. Common examples include aluminum, copper, lead, zinc, and tin. These metals are known for their lightweight properties, high conductivity, and excellent malleability. Due to these characteristics, non-ferrous metals are widely used in industries such as aerospace, electrical engineering, and construction, where strength, durability, and resistance to environmental degradation are critical.

Definition and Key Characteristics

Non-ferrous metals refer to metals that do not contain any considerable amount of iron, granting them their natural resistance to the rusting process and corrosion. They are valued for their special physical and chemical properties that qualify them for very particular applications.

Corrosion Resistance

Lacking iron, non-ferrous metals such as aluminum, copper, and zinc seldom undergo oxidation and hence get environmentally degraded, making them suitable for marine, chemical, and outdoor usage.

Lightweight Nature

Metals like aluminum and titanium possess very low mass in contrast to ferrous metals and are used extensively in aeronautics and transport industries where weight reduction is highly considered.

High Conductivity

Electrical: Copper offers excellent electrical conductivity at 59.6 × 10^6 S/m at 20°C

Thermal: Aluminum and copper ensure efficient heat transfer for cooling requirements

Malleability and Ductility

It can deform under stress without fracture. They can be stretched into wires or rolled into sheets – tons of copper wires and aluminum foils are made every year.

Non-Magnetic Properties

Unlike ferrous metals, they are not affected by magnetic forces, making them useful in electronics and machinery where magnetic interference needs to be prevented.

Common Non-Ferrous Metals

Aluminum

- Properties: Low density, excellent strength-to-weight ratio, corrosion resistant due to natural oxide layer formation

- Applications: Aerospace, automotive, construction, power lines, heat exchangers

- Benefits: Excellent conductivity of heat and electricity, highly durable under different environmental conditions

Copper

- Properties: Exceptional electrical and thermal conductivity, highly ductile, corrosion resistant

- Applications: Electrical wiring, motors, plumbing, industrial machinery, roofing, coinage

- Alloys: Bronze and brass for specialized applications

Lead

- Properties: Very high density, highly malleable

- Applications: Radiation shielding, lead-acid batteries, soundproofing materials

- Note: Usage highly regulated due to toxicity; often replaced by safer materials

Zinc

- Properties: Excellent corrosion resistance when used as coating

- Applications: Galvanization of steel, brass manufacturing, dietary supplements, pharmaceutical formulations

- Benefits: Essential trace element for human health

Nickel

- Properties: Excellent corrosion resistance, maintains properties at elevated temperatures

- Applications: Stainless steel manufacturing, jet engines, gas turbines, energy production components

- Benefits: Important alloying metal that improves strength and corrosion resistance

Titanium

- Properties: Highest strength-to-weight ratio, exceptional corrosion resistance, biocompatible

- Applications: Aerospace engineering, medical implants, naval applications, prosthetics, surgical tools

- Benefits: Superior performance in demanding environments

Difference Between Ferrous and Non-Ferrous Metals

| Key Point | Ferrous Metals | Non-Ferrous Metals |

|---|---|---|

| Primary Composition | Contain iron | Do not contain iron |

| Corrosion Resistance | Prone to rust without protection | High corrosion resistance |

| Magnetism | Magnetic in general | Non-magnetic typically |

| Weight | Generally heavier and denser | Lighter in comparison |

| Conductivity | Moderate electrical conductivity | High electrical conductivity |

| Strength | High tensile strength | Varies, lower than ferrous metals |

| Common Applications | Construction, tools, automotive components | Aerospace, electronics, medicine |

| Temperature Resistance | Suitable for high-temperature environments | Often limited to lower temperatures |

| Cost | Usually lower cost | Typically more expensive |

| Recyclability | Highly recyclable | Highly recyclable |

Applications of Non-Ferrous Metals

Construction Industry

- Aluminum: Window frames, curtain walls, structural elements with excellent strength-to-weight ratio

- Copper: Electrical wiring, plumbing, roofing applications

- Sustainability: Recycled metal reduces energy consumption by up to 95% compared to production from raw ore

Automotive Applications

Aluminum

- Applications: Engine blocks, cylinder heads, body panels, wheels

- Key Data: 10-15% weight reduction resulting in up to 20% increase in fuel efficiency

- Significance: High strength-to-weight ratio for energy-efficient applications

Copper

- Applications: Electrical wiring, motor systems, electric vehicle charging mechanisms

- Key Data: Internal combustion engines contain 20-25 pounds of copper; electric vehicles require up to 180 pounds

- Significance: Essential for green mobility technologies due to minimal energy resistance

Magnesium

- Applications: Structural components, cross beams, instrument panel frames, gearbox casings

- Key Data: 75% weight savings relative to steel, 33% relative to aluminum

- Significance: Reduces overall vehicle weight, emissions, and enhances performance

Titanium

- Applications: High-stress components like connecting rods, valves, exhaust systems

- Key Data: Major weight reduction without compromising engineering qualifications

- Significance: Premier strength-weight ratio and heat resistance for harsh environments

Zinc

- Applications: Die-casting alloys, corrosion-resistant coatings for steel parts

- Key Data: Over 70% of zinc use in automotive industry is for protective coatings

- Significance: Galvanizes structural parts to resist environmental wear

Other Key Industries

- Aerospace Industry: Aircraft manufacturing using aluminum and titanium for weight and corrosion resistance

- Electrical Applications: Copper and aluminum as first-class conductors for wiring and electrical systems

- Consumer Electronics: Tin and gold in circuit boards and connectors for optimal functionality

Steel vs. Non-Ferrous Alloys Comparison

| Parameter | Steel Alloys | Non-Ferrous Alloys |

|---|---|---|

| Composition | Primarily iron with carbon and other elements | Do not contain iron as main component |

| Density | Higher density, typically heavier | Lower density, lightweight |

| Corrosion Resistance | Low without treatment, prone to rust | High, naturally resistant to corrosion |

| Strength | High tensile strength and durability | Moderate strength but higher flexibility |

| Conductivity | Poor thermal and electrical conductivity | Excellent conductivity properties |

| Magnetic Properties | Magnetic (in most cases) | Non-magnetic |

| Applications | Construction, tools, heavy machinery | Aerospace, electrical, packaging |

| Malleability | Less malleable, harder to machine | Highly malleable, easy to machine |

Advantages of Non-Ferrous Over Ferrous Metals

Superior Corrosion Resistance

Non-ferrous metals like aluminum and copper naturally resist corrosion better than ferrous metals. Aluminum forms a protective oxide layer, while copper develops a patina that guards against further decay. These properties make non-ferrous metals ideal for outdoor use and harsh environmental conditions.

Lightweight Properties

Non-ferrous metals are significantly lighter than ferrous metals. For example:

- Aluminum density: 2.7 g/cm³

- Steel density: 7.8 g/cm³

This weight difference makes non-ferrous metals essential in aerospace, automotive, and packaging industries where weight reduction is critical.

High Electrical Conductivity

Copper and aluminum are excellent electrical conductors:

- Copper conductivity: 59.6 MS/m at 20°C – significantly higher than most ferrous metals

- Essential for electrical wiring, electronics, and power transmission applications

Additional Advantages

- Non-Magnetic Characteristics: Essential for electronic components and motors where magnetic interference must be avoided

- Recyclability: Highly recyclable without losing material quality – aluminum can be recycled infinitely using only 5-10% of primary production energy

- Aesthetic Appeal: Beautiful colors and finishes make them ideal for architecture, interior design, and jewelry

Recycling of Non-Ferrous Metals

Environmental and Economic Benefits

Recycling non-ferrous metals provides significant advantages:

- Reduces need for virgin material extraction

- Conserves natural resources

- Minimizes environmental degradation

- Requires considerably less energy than primary production

- Reduces greenhouse gas emissions

Energy Savings:

- Aluminum recycling: 95% energy savings compared to bauxite extraction

- Steel recycling: 74% energy savings compared to primary production

Commonly Recycled Non-Ferrous Metals

- Aluminum

- Copper

- Lead

- Zinc

- Nickel

Advanced Recycling Technologies

Sensor-Based Sorting Systems

- X-ray fluorescence (XRF) technology

- Near-infrared (NIR) technologies

- Provide precise separation based on compositional characteristics

- Reduce contamination and improve recovered material quality

Enhanced Processing Methods

- Hydrometallurgical processes: Refined recovery from complex waste streams

- Pyrometallurgical processes: Improved smelting with reduced emissions

- Electrochemical methods: Selective recovery and purification

AI and Automation Integration

- AI-powered systems handle waste input variations

- Improved sorting accuracy

- Reduced operational downtime

- Enhanced processing efficiency

Reference Sources

1. Volatile Inhibitors of Atmospheric Corrosion of Ferrous and Nonferrous Metals

- Key Findings: This study explores the efficiency of volatile inhibitors of atmospheric corrosion (VIACs) for ferrous and non-ferrous metals. It highlights the role of molecular parameters, such as ionization potential and hydrophobicity, in predicting the efficiency of inhibitors.

2. Trace Element Content in Honey and Beeswax Near Non-Ferrous Metal Plants

- Key Findings: This study assessed the trace element content in honey and beeswax from areas near non-ferrous metal plants. Despite the proximity to industrial activity, the levels of heavy metals like lead (Pb) and zinc (Zn) in bee products were found to be low, posing no significant health risks.

Frequently Asked Questions (FAQs)

Q: What Are Common Non-Ferrous Metals?

A: Common non-ferrous metals include copper, aluminum, lead, zinc, and nickel. These metals do not contain iron, which differentiates them from ferrous metals. They are valued for their lightweight properties, corrosion resistance, and excellent conductivity. Copper was the first metal to be forged and remains widely used today, while aluminum is preferred in aerospace for its lightweight characteristics.

Q: What’s the Difference Between Ferrous Metals and Non-Ferrous Metals?

A: The primary difference is iron content. Ferrous metals contain iron, making them susceptible to rust when exposed to moisture, while non-ferrous metals do not contain iron and are generally more corrosion-resistant. Ferrous metals are commonly used in construction for their strength, whereas non-ferrous metals are preferred in electrical applications for their superior conductivity.

Q: How Are Non-Ferrous Scrap Metals Recycled?

A: Non-ferrous scrap metals are recycled through shredding, sorting, and melting processes to create new metals and alloys. The process involves collecting materials from industrial waste and discarded products, then purifying them for reuse. This conserves resources and reduces environmental impact while maintaining the high market value of metals like aluminum and copper.

Q: What Are the Properties of Non-Ferrous Metals?

A: Key properties include lightweight nature, rust resistance, excellent conductivity, high malleability, and ductility. Unlike ferrous metals, they don’t rust when exposed to moisture, making them ideal for outdoor applications. Many have superior thermal and electrical conductivity, essential for electrical wiring and heat exchangers.

Q: What Are Ferrous Alloys and How Do They Differ from Non-Ferrous Alloys?

A: Ferrous alloys contain iron as the primary element, providing strength and durability but making them susceptible to corrosion. Non-ferrous alloys, such as brass (copper and zinc) and bronze (copper and tin), don’t contain iron and offer superior corrosion resistance. The choice depends on application requirements – ferrous alloys for construction strength, non-ferrous alloys for marine applications requiring corrosion resistance.

Conclusion

Non-ferrous metals play a crucial role in modern engineering and industrial applications due to their unique properties of corrosion resistance, lightweight nature, excellent conductivity, and recyclability. From aerospace and automotive industries to electronics and construction, these materials offer superior performance in applications where traditional ferrous metals fall short. As technology advances and sustainability becomes increasingly important, the demand for non-ferrous metals continues to grow, supported by innovative recycling technologies and circular economy principles.

Understanding the distinctions between ferrous and non-ferrous metals, along with their specific applications and advantages, is essential for making informed material selection decisions across various industries. The ongoing development of recycling technologies further enhances the environmental and economic benefits of these valuable materials, ensuring their continued importance in building a sustainable future.