Non-conductive metals are a fascinating area of materials science that challenges conventional beliefs about electrical conductivity. While metals are typically considered good electrical conductors, a curious group of materials exists that defies this classification. The article provides a comprehensive examination of the theory of non-conductive metals, their unique properties, the factors that hinder conductivity, and how these metals are utilized in modern technology. Whether you are a materials engineer, an electronics enthusiast, or just someone with a little curiosity about this intriguing topic, this article will make you well-versed in such unconventional metals. So unroll the curtains and uncover the science and innovation that has kept this specialty field progressing.

Defining Non-Conductive Metals

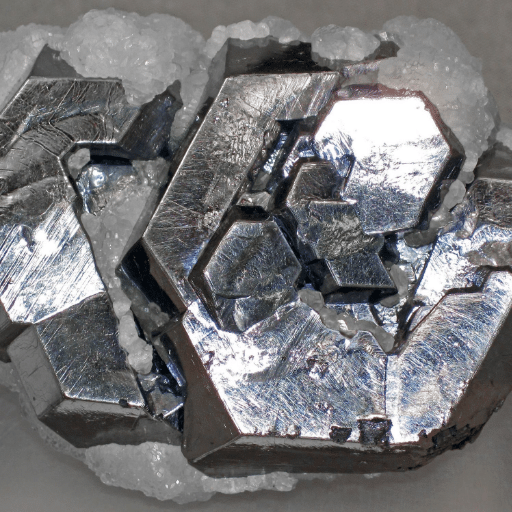

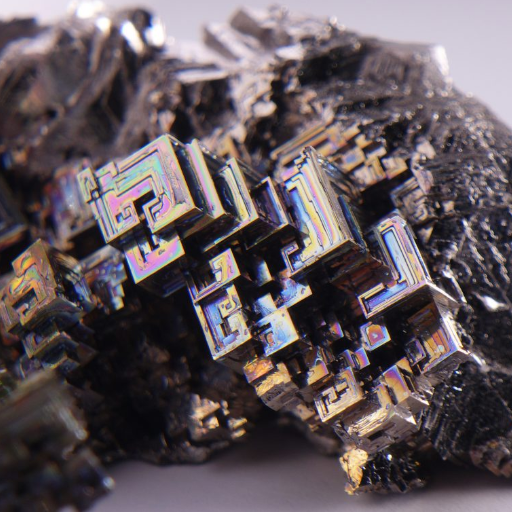

Non-conductive metals or poor conductors in generic engineering are metals that, by nature, do not possess much electrical or thermal conductivity compared to the more commonly conductive metals such as copper or silver. This limited conductivity is due to several reasons related to the atomic structure of such metals, which do not allow the free movement of the electrons. Some of the alloys and metals considered non-conductive include bismuth and tungsten, as these electrifying resistors find use in heat insulation or in situations where controlled electrical resistance is desirable. These metals, therefore, play the very important role of aiding certain special industries, including aerospace, electronics, and medical devices, in attaining particular performance characteristics.

What is a Non-Conductive Material?

An insulator or a non-conductive material is one that cannot conduct electricity efficiently because there are no free electrons within its atomic structure to facilitate the conduction of current. These materials are highly resistant to electricity, and they prevent any undesired flow of current in any system they are part of. Some of the common materials that fall into this category include rubber, glass, ceramics, and some plastics, which are mostly used to insulate components and to enhance safety features of various circuit designs. Nonconductive materials have industrial applications in electric power transmission, where they serve as insulators, and in electronics as coatings or packages to protect equipment from electrical interference. Thanks to their dielectric properties, they have no alternative in an environment that needs electrical insulation and energy conservation.

Characteristics of Non-Conductive Metals

- High Electrical Resistivity

Non-conductive metals show extraordinarily high values of electrical resistivity, usually far greater than classic metals like copper with a resistivity of 1.68 × 10⁻⁸ Ω·m. To take an example, bismuth’s resistivity is approximately 1.29 × 10⁻⁶ Ω·m at room temperature.

- Thermal Stability

Temperature often does not have a bearing on the insulating behavior of many of the non-conductive metals, thereby providing stable performance in operationally fluctuating thermal environments.

- Corrosion Resistance

Owing to the inertness and oxidation resistance levels of non-conductive metals, beryllium oxide-coated alloys are employed widely in aggressive environments where corrosion could otherwise degrade most common materials.

- Density and Machinability

Low to moderate densities coupled with machinability from a range of technical requirements is the feature with which some non-conductive metals such as titanium oxides or zirconium alloys can be tailor-made.

- Dielectric Strength

By being able to form oxides or compounds of high dielectric strength, these non-conductive metals shall be suitable for applications such as capacitors or electrical barriers. For example, aluminum oxide (Al₂O₃) has a dielectric strength of around 9.8 MV/m.

Comparison with Conductive Materials

|

Property |

Non-Conductive Materials |

Conductive Materials |

|---|---|---|

|

Electrical Conductivity |

Very low or negligible |

High, enables current flow |

|

Thermal Conductivity |

Generally low, retains heat |

High, dissipates heat efficiently |

|

Material Composition |

Oxides, ceramics, polymers |

Metals, alloys, graphene |

|

Dielectric Strength |

High, ideal for insulation |

Low to moderate, not suitable for insulation |

|

Corrosion Resistance |

High in many oxides, durable |

Varies, often prone without protective coating |

|

Density |

Light to moderate, depending on composition |

Often higher, depending on metal/alloy type |

|

Mechanical Strength |

Ranges from brittle (ceramics) to flexible (polymers) |

Typically strong, with high load tolerance |

|

Applications |

Insulators, capacitors, barriers |

Wires, connectors, heat exchangers |

Scientific Properties of Non-Conductive Metals

Conventional conductive metals are separable from one another through certain distinct properties exhibited by non-conductive metals or, in a better sense, are metals exhibiting poor conductivity. These materials, in the majority of cases, are keenly resistive because of their internal atomic arrangements that disallow electrons from free movement. The main characteristics are:

- Electrical Resistivity: Usually way too large as compared to conventional conductive metals, hence a less good electrical application.

- Thermal Behavior: The thermal conductivity typically gets better than that of ceramic and polymer, but less than that of metals of extreme conductivity, i.e., copper or silver.

- Corrosion Resistance: Many non-conductive metals resist corrosion, especially in their oxidized form, such as titanium or chromium oxides.

- Applications: Such materials with peculiar attributes find application in highly specialized fields as coating materials or protective barriers or specialized structural members with least electrical interaction.

Electrical Conductivity and Resistivity

In reality, electrical conductivity and resistivity are basic occurrence properties that influence how materials interact with an electrical current. Conductivity refers to the ability of a material to permit electric charge to flow and is given in Siemens per meter (S/m), while resistivity stands for its opposition to such flow and is given in Ohm meter (Ω·m). These two are reciprocally related: a high-conductivity material will have low resistivity and vice versa.

Metals like copper, silver, and aluminum are known for being good conductors of electricity with the presence of free electrons in the atomic arrangement, for conducting high-voltage transmission and electronic circuits. On the contrary, higher resistivity-based materials (such as non-metals and some alloys) are much sought after for their application in insulation and resistance to ensure restricted current flow. For the sake of example, pure copper has high conductivity; room temperature measurements put the value near \(5.96 \times 10^7\) S/m; semiconductor silicon, in comparison, has a resistivity value of approximately \(2300 \, \Omega·m\), interestingly indicating the controlled nature of its electrical specs.

Temperature shows another factor affecting these properties. For metals in the conduction regime, the resistivity increases with increasing temperature, as electrons scatter more with vibrations of the atomic cores. Whereas in semiconductors, the resistivity reduces with increasing temperature, a crucial attribute for the working of the electronic devices themselves. Thus, a thorough knowledge of these changes would direct the design of materials and systems for optimum electrical use in all industries.

Thermal and Electrical Conductivity Explained

Thermal and electrical conductivity processes are intrinsically linked at the atomic level in most cases, especially in metals. The mechanistic base lies in free electrons transferring heat and electrical current transmission. The Wiedemann-Franz law states that the ratio of thermal conductivity (k) to the electrical conductivity (σ) in metals is directly proportional to the temperature; in fact, this implies that highly electrically conductive metals often have high thermal conductivity.

Examples being copper and silver, having high electrical conductivity being renowned for their utmost thermal conductance, prove more efficient than any other metals to be used in heat exchangers and electronic components. This is less true with non-metallic materials or semiconductors, where lattice vibrations (phonons) carry heat and are independent of electrical conduction paths.

Real-World Applications of Non-Conductive Metals

- Cryogenic Insulation Systems

Non-conductive metals, such as those of the titanium family, are mainly used in cryogenic environments because the metals lose their conduction property at temperatures below zero. This loss of conduction property makes them useful as thermal barriers in cryogenic facilities for storing and transporting liquefied gases like LNG (Liquefied Natural Gas). For the record, titanium has a thermal conductivity listed as 21.9 W/m·K, considerably lower than that of standard conductive metals such as copper.

- Aerospace and Defense Applications

The non-conductive metals are utilized in aerospace thermal shielding and for structural parts. Titanium, with its strength and non-conductivity, enhances the performance of aircraft components, especially those exposed to extreme temperature variations. For instance, titanium alloy Ti-6Al-4V is the preferred alloy for insulating critical engine components.

- Electronic Substrate Manufacturing

Non-conductive metals find their use in the manufacture of insulating substrates for semiconductors and microelectronics. High-resistance materials such as specialized titanium alloys are selected to provide layers that prevent short circuits yet allow for heat dissipation. This is especially essential in high-performance computers and in the manufacture of commercial advanced microchips.

- Thermal Insulation in Energy Systems

- Medical Implants and Devices

These metals, owing to their biocompatibility and low thermal conductivity, are also employed in medical applications such as pacemakers, bone plates, and joint replacement. In this field, titanium is extremely successful in providing strength and negligible thermal interference, thus assuring its compatibility with the human body.

- Specialized Industrial Machinery

Use in Electronics and Electrical Components

Low-conductivity metals assume critical roles in the manufacturing of cutting-edge electronics and electrical components by limiting heat transfer and providing electrical resistance to their specific applications. For example, resistors consisting of nickel alloys provide dependable performance even with temperatures and ensure the long-term stability of the circuit. Certain alloys, such as beryllium copper, are also applied in connectors and switch gear because they offer medium conductivity, excellent mechanical strength, and corrosion resistance-the perfect properties required for harsh environments.

Silicon and gallium arsenide, with their very low conductivity, are kind of regulars in the arena of semiconductor technology, having been used for many years to take advantage of their peculiar electrical behavior, which is needed to handle tight thermal load requirements of smaller and more powerful devices. Moreover, thermocouples often rely on the pairings of dissimilar low-conductivity metals for accurate temperature measurements; a must-have for industrial control systems and scientific instrumentation. As their use proceeds to extend, these technologies pave the way for downsizing, energy efficiency, and higher reliability of modern electronic systems.

Applications in Aerospace Engineering

In aerospace engineering, the application of advanced materials is intended to enhance the performance, durability, and safety of a structure. Thermally, management systems utilize high-conductivity materials to dissipate heat from engines, avionics, and other critical components, which are designed to operate under the most extreme conditions. Composite materials that are low in weight, such as carbon fiber-reinforced polymers, are being utilised extensively to reduce weight without compromising on the structural integrity, and this in turn raises fuel efficiency and payload capability. In manufacturing propulsion systems, advanced ceramics and heat-resistant alloys are, by and large, highly valued on account of, inter alia, the superb resistance to thermal and sheath stress produced under the action of high speeds for a long period. The magnitude of these materials in contemporary aerospace designs lies in making planes and spacecraft lighter, faster, and reliable enough to meet ever-increasingly stringent performance norms.

Medical Equipment and Non-Conductive Materials

The entry of non-conductive materials in medical instrumentation has sparked a metamorphosis with regard to safety, reliability, and good patient outcomes. Nonconductive polymers and ceramics are used for their insulating properties, making them useful in devices such as MRI, defibrillators, and ECG. They can block any kind of interference for sensitive circuits to make them perform diagnostic and therapeutic functions with precision.

Currently, the non-conductive synthetic materials were used to feed implantable devices of pacemakers and neurostimulators, where insulation was needed to prevent electrical leakage from adjoining tissues. Also, with an increased integration of non-conductive materials for the making of lighter, stronger, and corrosion-resistant parts, it is increasingly occurring in portable medical equipment. Thus, this shift toward advanced non-conductive materials is in line with the trends in highly miniaturized and high-performance health-care engineering.

Common Non-Conductive Metal Alloys

Non-conductive metal alloys are specially crafted materials that restrict electrical conductivity without compromising strength, durability, and wear resistance. The following are some of the popular non-conductive metal alloys:

- Tantalum Alloys

Tantalum alloys are favoured in medical devices regarding non-conductivity, where corrosion resistance and biocompatibility are in demand.

- Titanium-Based Alloys

Titanium alloys, especially those alloyed with aluminum and vanadium, exhibit excellent non-conducting properties while remaining lightweight and greatly strong in tension.

- Beryllium-Copper Alloys

Though generally considered conductive, beryllium-copper alloys may be treated to reduce their conductivity, placing them in a special category for use in electronics or very fine instrument housings.

- Aluminum Oxide-Coated Alloys

Advantages of Using Non-Conductive Alloys

- Electrical Insulation

Non-conductive alloys serving efficiently as electrical insulators are needed in various applications. For example, aluminum oxide-coated alloys with a surface resistivity as high as 10¹² ohms will provide great assurance against electrical interference due to touch in sensitive applications.

- Corrosion Resistance

Most non-conductive alloys, notably beryllium-copper when treated, give high resistance to corrosion. This gives them suitability in harsh environments such as marine or industrial settings where one is apprehensive over the degradation of materials.

- Thermal Stability

Specific non-conductive alloys, such as ceramic-coated metals, are able to withstand high temperatures, with an operational endurance beyond 1000°F (538°C), which is essential to the aerospace, automotive, and high-performance industrial machinery.

- Mechanical Strength and Durability

They maintain mechanical properties despite their lack of conductivity. For instance, these advanced non-conductive aluminum alloys can hopefully surpass tensile strength over 400 MPa, thereby supporting heavy-duty applications.

- Lightweight Properties

Examples of Non-Conductive Alloys in Industry

- Aluminum-Silicon Alloys in Electronics

These aluminum-silicon alloys find broad application in electronic housing mainly for their excellent non-conductivity and high thermal stability. Their corrosion resistance and capacity to endure thermal cycling make them apt for protective casings of high-performance computing systems and communication devices.

- Magnesium-Based Non-Conductive Alloys

Magnesium alloys with non-conductive coatings are used in aerospace applications for lightweight structural components. The mechanical strength of the alloys is balanced with the insulation properties so that they can work optimally in environments with high electromagnetic fields.

- Titanium Alloys for Medical Applications

Certain titanium alloys, surface-treated for enhanced non-conductive properties, are used for medical devices and implants. Providing biocompatibility, electrical insulation, and excellent mechanical properties, they are suitable for MRI-compatible implants and surgical instruments.

- Copper-Beryllium Alloys in Energy Systems

Creating Non-Conductive Materials

Non-conductive materials, or such, are electric insulators that are fabricated mainly by the exploitation of compounds that quite naturally resist electric current. These are some of the strategies:

- Material Selection

Basic materials such as ceramics, glasses, and some polymers exhibiting their respective natural insulation behavior or electrical resistivity are chosen. These materials are all major insulators with very high resistivity and very low conductivity.

- Specialized Coatings

Such measures include an insulative coat, for instance, an epoxy resin or silicone-based compound, applied onto an otherwise conductive core to realize non-conductive performance. The latter is typically adopted for components in high-voltage environments.

- Composite Engineering

Computer polymer-based non-conductive polymers combined with reinforcements, for example, glass fiber or carbon fiber, result in an advanced composite. These composites are designed to ensure electrical insulation and, at the same time, furnish other properties required, especially thermal resistance or mechanical strength, which apply to any application occasion.

This way, materials are able to fulfill demanding requirements for applications in various industries, including electronics, power supply, and medical technologies.

How to Make a Metal Non-Conductive?

- Electroplating with Insulating Materials

Electroplating is a process of covering a metal surface with a thin coating of an insulating material such as plastic or ceramic by placing the metal in an electrolyte bath through which deposition of the insulating layer takes place, helped by an electric current. This is mostly used in the electric components where conduction has to be avoided.

- Anodizing with Non-Conductive Coatings

Anodization creates a layer of oxide on the surface of the metal in a controlled fashion. The oxide layer thus formed serves as a good insulating medium and also improves corrosion resistance and durability of the metal. This method for creating an oxide layer is widely employed in the fields of aerospace and consumer electronics.

- Powder Coating with Non-Conductive Polymers

In powder coating, layers of thermoset or thermoplastic powder are applied to the surface of metals and cured under dry heat. These polymerized coatings are completely non-conductive; they are also aesthetically pleasing, resistant to weathering, and commonly utilized in automotive and industrial machinery.

- Application of Insulating Epoxies or Resins

Epoxy and resin coatings are sprayed or poured onto surfaces as liquid films and allowed to harden to form solid non-conductive layers. Such coatings are very helpful in scenarios wherein there is a need to encase or protect small electrical components, or to seal off areas susceptible to environmental degradation.

- Surface Oxidation Through Chemical Treatment

Future Trends in Non-Conductive Materials

The arena of non-conductive substances is greatly evolving in response to the rising demand for premium insulating materials in electronics, aerospace, and renewable energy sectors. Trend of note includes that of hybrid materials wherein conventional polymers are combined with nanomaterials, such as graphene oxide or boron nitride nanosheets, to enhance thermal threat and mechanical strength while preserving superior dielectric properties.

The rise of bio-based non-conductive materials is yet another player in this arena. Eco-conscious researchers are turning their attention to plant-based polymers and biodegradable composites aimed at furnishing a green alternative to conventional insulation materials without compromising their strength or performance. Such advancements go hand in hand with global efforts to lessen their environmental footprint while catering to the steeply increased use of non-conductive components in green technologies like electric vehicles and wind turbines.

Reference Sources

-

“Volatile corrosion inhibitors for ferrous and non-ferrous metals and alloys: A review”

- Key Findings: This study reviews the use of volatile corrosion inhibitors (VCIs) to protect metals like iron, zinc, and aluminum from corrosion. It highlights the formation of protective films on metal surfaces as a primary mechanism for corrosion prevention.

- Read the paper

-

“Cathodic delamination of polymer coatings from metals. Mechanism and prevention methods. A review”

- Key Findings: The study examines the mechanisms of cathodic delamination in polymer coatings on metals. It compares the efficiency of conductive and non-conductive coatings, finding that non-conductive coatings often perform better in preventing delamination.

- Read the paper

-

“Photopolymer-metal Composites Based on Metal Foil Deposition on Additive Manufactured Substrates: An Overview”

- Key Findings: This paper explores the deposition of metal coatings on non-conductive substrates using additive manufacturing techniques. It discusses the potential applications of this process in creating advanced composites.

- Read the paper

Frequently Asked Questions (FAQs)

Q: What are non-conductive materials and how do they differ from conductive materials?

A: Non-conductive materials are those that do not allow the flow of electric current, unlike conductive materials, which are characterized by their ability to conduct electricity efficiently. Metals are generally considered good conductors of electricity, but certain alloys can be engineered to be less conductive. For example, materials like glass fiber and ceramic are known for their electrical resistance and are often used in applications where insulation is needed. The resistivity of a non-conductive metal can be significantly higher than that of common metals like copper or aluminum, making them suitable for specific uses in electrical applications.

Q: How is the conductivity of metals measured and what affects it?

A: The conductivity of metals is typically measured in siemens per meter (S/m) and is influenced by factors such as temperature, impurities, and the material’s structure. Pure metals like silver and gold exhibit the highest electrical conductivity due to their valence electrons being free to move. However, when non-metal impurities are introduced into a metal alloy, they can disrupt the flow of charged particles, decreasing conductivity. Additionally, as temperature increases, some metals may retain their conductive properties while others may become less conductive, affecting their performance in electrical circuits.

Q: What are some examples of non-conductive metals used in applications?

A: While the term “non-conductive metal” may seem contradictory, certain alloys can exhibit non-conductive properties under specific conditions. For example, alloys that contain transition metals with higher resistivity can act as insulators when used in electrical applications. These materials are often found in circuit boards or as coatings to prevent unwanted electrical conduction. Additionally, metals that have been treated to enhance their non-conductive characteristics can be utilized in environments where electrical isolation is crucial, ensuring safety and reliability in devices.

Q: How does the thermal conductivity of silver compare to that of non-conductive materials?

A: Silver is known for having the highest thermal and electrical conductivity among pure metals, making it an excellent choice for applications requiring efficient heat and electricity transfer. In contrast, non-conductive materials, such as glass fiber, exhibit low thermal conductivity, preventing heat transfer. This characteristic is beneficial in applications where insulation is necessary, as it helps maintain temperature control. While metals conduct heat and electricity effectively, non-conductive materials serve essential roles in safeguarding against unwanted thermal and electrical flow, thus complementing the properties of conductive metals in various applications.

Q: Can non-conductive metals be used in electronic devices?

A: Yes, non-conductive metals, particularly those engineered as alloys with specific impurities, can be effectively used in electronic devices. These metals may be employed in areas requiring insulation or protection against electrical interference. For instance, non-conductive coatings on metal components prevent electrical conduction, enhancing safety in devices where exposure to electricity is a concern. Additionally, materials like glass fiber are increasingly integrated into electronic designs, providing structural integrity while maintaining non-conductive properties. This combination allows for the creation of safe and efficient electronic systems.