Magnetism has been a mystery that made humans wonder since a long time ago, which led to many inventions and the part of physics that we call technology today. But the question still remains: what are the characteristics of magnetic materials and what is the reason that some metals have stronger magnetic properties than others? Nature offers us magnetite and the advanced metallic alloys that are used today for high-tech applications in the still very much fascinating and intricate world of magnetism, which is nothing else than a mix of science and art. This piece of work unveils the science of magnetism by investigating the properties of the most magnetic materials along with their secrets. It does not matter if you are a science lover or just want to know more about the invisible forces that cause changes in our environment; come with us through the interaction of physics and materials in this magnetic phenomenon.

Types of Magnetism in Metals

Ferromagnetism Explained

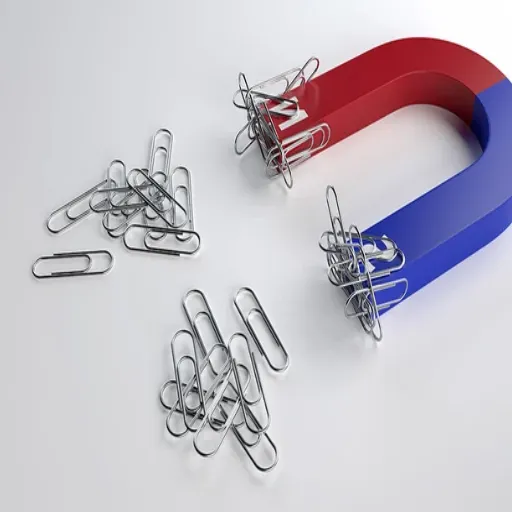

Ferromagnetism is a trait that is mainly seen in certain metal types like iron, cobalt, and nickel, which turn out to be very good in the magnet aspect. The magnetism of such metals results from the atomic magnetic moments all being in the same direction, thereby reinforcing each other and forming a magnetic field. High retention of magnetism even after the withdrawal of the external magnetic field is a characteristic trait of such materials, so they make perfect candidates for the permanent magnets.

The source of ferromagnetism are the electron spins mainly through quantum mechanical interactions among the electrons. When the atomic spins of a group align, then a magnetic domain is created. The situation of ferromagnetism arises when these domains get together and are aligned with the external magnetic field. This alignment appears naturally in the case of ferromagnetic materials because their internal structure is such that it favors a stable and strong magnetic state.

The use of ferromagnetic materials is not only extensive but also very important for the modern technology. They are utilized in the cores of electromagnets, transformers, and electric motors, where strong magnetic characteristics are improving efficiency and performance. Moreover, they are founding supporters of data storage devices, where the ability to retain magnetization is utilized for writing and reading information on hard drives. Consequently, ferromagnetic materials remain to be a main player in the technology advancement of various industries.

Paramagnetism vs. Diamagnetism

Unpaired electrons are characteristic of paramagnetism, which is also the main reason for the attraction to magnetic fields, whereas diamagnetism is accompanied by paired electrons and the opposite action, i.e., a magnetic field repulsion.

| Property | Paramagnetism | Diamagnetism |

|---|---|---|

| Electron State | Unpaired | Paired |

| Magnetic Effect | Attracted | Repelled |

| Field Retention | No | No |

| Examples | O₂, Fe²⁺ | Zn, N₂ |

| Cause | Net spin | Spin cancelation |

How Metal Composition Affects Magnetism

The properties of magnetism in a material are largely determined by its metal composition. Different metals and their atomic structures dictate the extent of their interaction with the magnetic field. To illustrate, ferromagnetic materials like iron, cobalt, and nickel are very magnetic since the atomic structure is such that they can easily line up with each other resulting in the formation of large magnetic domains. Depending on their specific composition, the alloys made up of these metals might boost the magnetic strength even more.

In contrast, some metals are weak or have imperceptible responses to the magnetic fields. Copper and gold, for example, which are the classic diamagnetic materials, very slightly repel the magnetic fields owing to their electronic configurations. Such elements do not possess unpaired electrons and hence cannot form any magnetic domains at all resulting in their being so weakly magnetic. There is a similarity with the case of paramagnetic materials, such as aluminum and magnesium; these elements are subject to a slight positive magnetic attraction, but the magnetic effect is so weak that it does not allow them to be permanently magnetized.

Finally, the alloying of certain elements is one of the ways in which the magnetic properties of a material can be modified for industrial use. For instance, iron silicon alloy has an increased magnetic efficiency suitable for transformers and rare earths like neodymium can be used to make very strong magnets for advanced technologies. So, the composition of metals not only determines their response to magnetic fields but also is an important factor in material science and engineering.

Most Magnetic Metals: A Closer Look

Nickel: Properties and Uses

Nickel is one of the metals that are highly prized for their magnetic and multipurpose properties, being around in a variety of industrial applications. With an incredible resistance to corrosion, nickel is frequently alloyed with other metals to enhance their properties. Nickel can be described as a metal that is silvery-white in color, lustrous, and atypically ductile. Thus, it can easily be shaped or formed. Though nickel is not as strong magnetically as iron or cobalt, its melting point and stability secure its position in certain industries.

Nickel has innumerable applications but one of the most significant ones is the manufacturing of stainless steel, where nickel plays the role of further upgrading strength and corrosion resistance. What’s more, nickel is one of the main components in the production of superalloys, which can withstand high temperatures and harsh environments such as the jet engine. Relays and memory devices, owing to its magnetic properties, are among the many places where nickel finds applications, thus solidifying its position in both traditional industries and cutting-edge technology. Also, due to their durability and aesthetic appeal, nickel is widely used as a coating material in items such as coins, batteries, and cookware.

Nickel is a vital contributor to the growth of renewable energy resources and sustainable development. The metal is an ally in the making of rechargeable nickel-cadmium (NiCd) and nickel-metal hydride (NiMH) batteries that are used to power various devices from home electronics to electric vehicles. The increasing demand for nickel in line with the transition to green energy technology is particularly focused on its use in the production of lithium-ion batteries for electric cars. Such a shift in demand is an indication that nickel continues to play an important role in bringing about greener technologies. Despite being a metal that is readily available, nickel mining and refining processes inflict environmental damage, thus making the search for eco-friendly extraction methods and recycling processes critical for future use.

Cobalt: Characteristics and Applications

Cobalt is one of the top-tier elements that are characterized by thermal and corrosion resistance besides its high strength and durability. It is a shiny and metallic-looking element that is silver-gray in color and has a variety of applications in different areas due to its properties. Cobalt is mainly found in ores mixed with other metals, and it is also one of the vital elements for technological advancements in the modern world. Cobalt has a role in the following five applications:

Battery Production

In the manufacture of lithium-ion batteries, Cobalt is considered a major component. These batteries are commonly used in electric cars, laptops, and mobile phones. Besides using Cobalt to boost up the energy density, its other important feature is stability which makes it quiet crucial for the battery’s performance.

Superalloys

Cobalt is one of the main ingredients of superalloys that are typically used in the manufacturing of jet engine and gas turbine parts. The tough alloys can stand high temperatures and rough conditions and are thus indispensable in aerospace and power-generating industries.

Catalysts in Chemical Processes

Cobalt is a catalyst for different chemical reactions such as petroleum refining and synthetic material production. The chemical reactions taking place with the help of Cobalt are very much efficient and sustainable.

Magnets

Cobalt is part of the manufacturing process for the strongest magnetic materials like samarium-cobalt magnets. Such magnets are used in electric motors, windmills, and medical imaging technology, among others.

Pigments and Coatings

Cobalt compounds are known for their use as pigments in the production of blue shades in ceramics, glass, and paints, and so on. In addition, alloys of cobalt used in coatings increase the wear resistance of the coated material while at the same time decreasing corrosion thus prolonging the life of the material.

The above-mentioned applications are the ones that highlight the importance of cobalt not only in the automotive and electronic industries but also in the technology of tomorrow. The management of cobalt resources needs to be carefully done as the demand keeps on increasing.

Rare Earth Metals and Their Unique Magnetism

Rare earth metals, comprising a total of 17 elements including the lanthanides, scandium and yttrium, are most often recognized and praised for their impressive magnetic properties. Neodymium, samarium, and dysprosium are among those that get special attention due to their capacity to make strong permanent magnets. For instance, neodymium magnets are the strongest ones that can be found on the market and are thus of great importance to high-performance motors, electric vehicles, and wind turbines. The peculiarities of these elements’ electron configurations are the reason for such an extreme level of magnetism as well as for their excellent aligning of magnetic moments.

The great amount of rare earth metals that are needed in modern applications reveals their essential place in the technological innovations. Apart from magnets, these metals have found their way into various places such as electronics, lasers, and even sophisticated military systems radar and missiles. One of the uses of dysprosium that has to do with its property of keeping high-temperature magnets strong is wind-powered energy generators. On one hand, rare earth sector is rich in the elements that are essential for renewable energy generation including but not limited to wind power or solar power, and on the other hand, it faces the challenge of securing/obtaining sufficient supplies due to production being highly concentrated in some parts of the world with China being the largest producer, hence giving rise to the geopolitical and economic implications.

To continue with the innovations and create responsible supply chains, material recycling, and rare earth alternatives are getting increased attention from researchers. Steps towards recovering these elements from obsolete electronics and industrial waste are being taken which reduces dependence on mining and at the same time addresses the environmental concerns. In addition, new materials giving lesser dependence on rare earths are being developed as a result of material science progress. These promising ventures together with the policies that support and promote ethical sourcing are necessary to make up for the ever-increasing demand for rare earth metals without compromising sustainability and resource availability in the long run.

Magnetic Alloys and Their Applications

Creating Stronger Magnetic Alloys

The creation of stronger magnetic alloys has turned into a major area of focus in material science, especially since the industries are looking for such materials that have the best magnetic performance. The researchers have been able to boost the magnetic powers of the materials by adding the rare earth elements neodymium, samarium, and dysprosium into the alloy compositions, and taking advantage of their high anisotropy to bring about superior coercivity and energy density. These alloys are necessary for the applications where there are small and very efficient magnetic systems, like electric motors, wind turbines, and high-tech sensors among others.

Newly developed methods in nanostructuring and grain boundary engineering have played a major role in the improvement of the performance and reliability of magnetic alloys. A case in point is the technology involving nanocomposite materials where the different phases have different magnetic properties. This has helped to achieve the right magnetic alignment while the eddy current losses have been reduced. Moreover, the researchers have shown that the microstructure of alloys becomes better by the addition of trace elements like cobalt and boron, leading to better temperature stability and resistance to demagnetization. The field is witnessing such developments where the innovations of the chemical, thermal, and mechanical processing are coming together.

In a bid to attain the goals of sustainability and cost-efficiency, the researchers are looking into new compositions that would cut down on the use of rare earth elements while the magnetic strength is not reduced in any way. The researches are being carried on iron-nitride compounds and other non-rare-earth-based systems which have so far shown quite a lot of potentials to take over. On top of that, computer simulations and machine learning models are being put to the task of predicting ideal alloy configurations, which in turn allows for a faster discovery process. The confluence of these technological tools with advanced manufacturing techniques like the ones used in 3D printing is anticipated to bring about a transformation in the design and production of magnetic alloys in the near future.

Applications of Magnetic Alloys in Industry

Magnetic alloys have become unavoidable materials for many manufacturing sectors, thanks to their exceptional properties such as the ability to maintain a certain magnetic state and High resistance plus heat tolerance. They are present in a variety of industries, with each industry taking advantage of the particular characteristics of these materials for essential operability and performance improvement. Below are the major industrial applications of magnetic alloys:

Electric Motors and Generators

Magnetic alloys especially those made with rare-earth elements like neodymium-iron-boron (NdFeB) and cobalt-samarium (SmCo), are heavily utilized in electric motors and generators. Their extremely high magnetic product leads to the development of very small and highly efficient systems. To give an example, NdFeB magnets play an important part in wind power and electric vehicle motor production whereby an estimated 96% of all EVs have such magnets in their drivetrain systems.

Transformers and Inductors

Silicon steel and iron-nickel alloys, which are soft magnetic alloys, possess low coercivity and high permeability making them perfect for use in transformers and inductors. They are simultaneously being energy efficient and reducing losses, thus power transmission and distribution being the ideal place for them. Modern transformers well over 99% efficiency have become possible mainly due to the magnetic alloy technology used.

Data Storage Devices

In hard disk drives (HDDs) especially, magnetic alloys are very important in data storage technologies. Media recording layers made of thin films of magnetic alloys such as cobalt-chromium-platinum (CoCrPt) are used so that data can be stored at high density. The current trend in HDDs is to get storage densities of more than 1 terabyte per square inch, a position reached largely due to changing magnetic alloy compositions.

Magnetic Resonance Imaging (MRI)

High performing magnetic alloys are indispensable in superconducting magnets that are used in MRI machines. The alloy of NbTi (Niobium-Titanium) and Nb3Sn (Niobium-Tin) stands out as the best for its ability to conduct at very low temperatures with high cryogenic giving thus the creation of very strong and stable fields that have the required strength for imaging.

Sensors and Actuators

Magnetic alloys, including amorphous and nanocrystalline materials, are frequently utilized in sensors and actuators. These devices enjoy the alloys’ high sensitivity to magnetic fields and rapid response times. Applications stretch from automotive systems, for instance, anti-lock braking systems (ABS), to sophisticated industrial automation and robotics, where precision and reliability are of utmost importance.

The use of magnetic alloys in these industries highlights their essential role in the progress of technology and industry today. Meanwhile, informing research work and creating environmentally friendly substitutes are still the main activities driving innovations in these critical areas.

Case Studies: Successful Uses of Magnetic Alloys

1. Magnetic Alloys in the Motors of Electric Vehicles (EVs)

The application of the magnetic alloy that was the subject of successful development is particularly noticeable in the creation of high-performance electric vehicle (EV) motors. Rare-earth alloys, notably neodymium-iron-boron (NdFeB), are the mainstays of the manufacturing of the permanent magnets for EV engines because of their remarkable energy density and magnetic power. This bigger development not only allows the designers to create motors with reduced weights but also to provide a highly torque and accelerated performance. For instance, the Model 3 motor of Tesla utilizes NdFeB alloys that play an important part in the motor’s efficiency and performance. Along with that, researchers have come up with different compositions that are of low-quality rare-earth element and thus rely on rare-earth elements less, which is a progressive step forward for this application.

2. Wind Turbine Generator with the Highest Efficiency

Magnetic alloys are also one of the most significant and practical applications in the area of wind turbine generating units. Direct-drive systems of the modern wind turbines are sometimes built with permanent magnets of samarium-cobalt (SmCo) or NdFeB, wherein the former methods are sometimes more energy efficient than the latter ones. So, these magnetic materials are not only good in terms of energy efficiency but also, in being reliable in very tough conditions, since they are thermally stable and corrosion resistant when compared to others. For example, the technology of the offshore wind turbines has made use of these magnetic alloys in such a way that even under very adverse weather conditions, they have been able to guarantee high performance, along with the long-lasting nature and operational efficiency of the alloy.

3. Medical Imaging Technology Using Magnetic Alloys

Alloys that are magnetic are the main characters in the process of the best medical imaging systems that we have like the magnetic resonance imaging (MRI) machines. A high-quality superconducting magnet that is made from niobium-titanium (NbTi) or niobium-tin (Nb3Sn) is producing the extremely strong magnetic fields for the purpose of the high-resolution imaging. These alloys have superconductor-like properties at cryogenic temperatures and, therefore, serve as the basis for imaging diagnostics that are very precise and dependable. Therefore, the process of innovating the magnetic alloy formulation has not only made MRI technology that is safer but also more available in the healthcare systems across the globe.

It could be argued that each case study gives an excellent example of the universal need for magnetic alloys in different areas of high-impact applications. The gradual improvement and evolution of these materials have somehow become a direct supporter of technologically advanced and sustainably developed modern industries.

Non-Magnetic Metals and Their Properties

Identifying Non-Magnetic Metals

Non-magnetic metals are those which have no significant magnetic response under the influence of a magnetic field. Such metals have their atomic structure in a way that there are no unpaired electrons, which are the ones determining the magnetic properties. The most common non-magnetic metal examples are aluminum, copper, lead, zinc, and gold.

Aluminum is, for instance, the lightest, corrosion-resistant, and hence the most widely used in industries like aerospace and construction. Copper is the most used conductive metal and its versatility is the reason behind its main application in electrical wiring and electronics. Lead, although more toxic than other metals, is still very important for applications such as radiation protection and production of batteries. Zinc is used to protect steel and iron products from corrosion through galvanizing. Gold, due to its ductility and resistance to tarnish, is very much used in electronic devices and luxury items.

The situation with non-magnetic metals is that even though they are usually thought of as having the same properties, new material science has revealed that their behavior can be very different under high-frequency magnetic fields. This property is one of the reasons they are used in electromagnetic shielding applications where materials such as copper are very effective. Knowing the special characteristics of the non-magnetic metals, the engineers and the researchers are able to choose the right material for highly professional applications in industries that include telecommunications, medical technology, etc.

Applications and Importance of Non-Magnetic Metals

Non-magnetic metals are indispensable in different industrial sectors because of their distinctive attributes such as high resistance to magnetic fields, superb electrical conductivity, and prevention of oxidation. These features make such metals great to be used in places where magnetic interference must be suppressed in order to keep the electronic devices working at their best and the environments secure and reliable. Listed below are the significant five applications of non-magnetic metals with an in-depth explanation of their respective importance:

Electromagnetic Shielding

Copper and aluminum, which are non-magnetic metals, are mostly used for shielding against electromagnetic radiation and protecting electronic equipment from being affected by the external electromagnetic fields. As a case in point, copper shields are capable of eliminating 99% of EMI (Electromagnetic Interference) in telecommunications and aerospace systems, thus making the signals clean and safe for operating.

Medical Imaging Technology

Non-magnetic metals are very important to the making of MRI (Magnetic Resonance Imaging) machines. Titanium is one of the non-magnetic materials that are used in MRI systems because of its ability to withstand the strong magnetic fields used in the imaging process. Its use results in the production of clear diagnostic images free from distortion or interference.

Precision Instrumentation

Instrument of high accuracy, particularly in scientific investigation and laboratories, frequently use non-magnetic metals like brass or bronze as their primary materials. These metals offer magnetic protection thereby giving accurate readings and safe measurements in areas such as the spectroscopy and analytical equipment.

Maritime Applications

Non-magnetic and corrosion-resistant metals like aluminum and brass serve dual purposes in shipbuilding and underwater vehicles—firstly, they create one’s signature in the magnetic field less detectable and secondly, they do not interfere with the navigation systems. For instance, in the navies, brass is employed for making propellers and fittings so as to cut down the magnetic signature of the ship.

Energy Systems

Non-magnetic metals are the backbone of the industries engaged in energy supply. Aluminum, to mention one metal, enjoys widespread use for power lines and transformer parts since it is a good conductor and light in weight. Its magnetic susceptibility being low means that its application is more efficient particularly in high voltage situation leading to a decrease in power losses.

The various applications highlight the strategic necessity of non-magnetic metals in the areas of technology and fields of science. Their capability to deal with the challenges of modern technology while countering the issues brought about by magnetic fields makes them continually important in providing solutions of the highest quality in the industrial area.

Detecting Non-Magnetic Metals with Metal Detectors

The non-ferrous metals like aluminum, copper and titanium that are not having magnetic properties at all, need highly advanced and accurate methods for their detection. The idea behind the working of modern metal detectors is the creation of a fluctuating electromagnetic field. When such a field comes in contact with a non-magnetic metal that is conductive, the metal gets energized, which in turn induces current flows (called eddy currents). Then the current flows produce an electromagnetic field that is paralleled to the one created by the detector and this is why it is called the ‘receiver’. The detector’s receiver coil or sensor can then determine how much conductivity was presented, and in addition, the size, shape and position of the metal play a vital role in the entire process of detection.

The proactive use of multi-frequency systems in metal detection technology has greatly increased the precision and quality of detection of non-ferromagnetic metals. These systems provide the metal detectors with the capability to assess several frequencies at once, which makes it much easier to tell apart the different kinds of materials. Furthermore, the implementation of pulse induction technology has led to a significant increase in the performance of metal detectors in difficult situations, such as those with high mineral content that absorb the signal, since it allows the signal to penetrate much deeper. Data algorithms are also of great assistance as they filter the signals and process them to get the specific signatures of non-ferrous conductive metals isolated.

The business areas of non-magnetic metals detection include recycling, security, and industrial manufacturing. For example, in recycling centers, advanced detectors are used to scan and process aluminum and copper from the mixed waste streams which helps in making the process faster and saving the materials that could otherwise get lost. Airports and security also use similar types of detectors but for different purposes like spotting the threats posed by non-ferrous materials while keeping the number of false alerts in such situations low. With the developments in technology, one can say that soon AI and machine learning will take the detection to a level where it won’t be a problem at all to reliably identify a non-ferrous metal even in a very complex case.

The Future of Magnetic Metals and Alloys

Innovations in Magnetic Material Science

Magnetic material science has made great strides, which are the reason for the revolutionary changes in different industries, especially in energy, electronics, and healthcare. There is a higher level of research that has been put into the study of nanostructured magnetic materials, which have more advantages like higher coercivity, better thermal stability, and lesser eddy current loss. The new materials are leading to the production of high-efficiency transformers, stronger electric motors, and generator units that are lightweight and are all part of the eco-friendly energy solutions. Additionally, the soft magnetic composites that have better magnetic permeability are being customized to meet the requirements of modern high-frequency applications.

One of the most remarkable advancements in innovations is the use of magnetic alloys whose properties can be tuned through exacting compositional alterations. To illustrate, amorphous and nanocrystalline alloys are extremely efficient in cutting down core losses, which in turn makes them very busy in energy-saving applications. Moreover, the new techniques in additive manufacturing have made it possible to produce magnetic materials in complex shapes with specific magnetic properties. This has paved the way for miniaturized but very functional devices like sensors, medical implants, etc. where the precision of size and magnetic behavior is of utmost importance.

In the near future, the study of magnetic materials is closely linked with the computer modeling and artificial intelligence methods. The use of these tools allows for the prediction and optimization of the properties of the magnetic material before any physical model is made, thus, coming up with a very fast and efficient innovation process. Also, the combination of magnetic materials with new technologies that are coming up such as quantum computing and spintronics could change the whole scenario of the next generation of data storage and processing capabilities. Researchers are not only creating technologies that are magnetic material based but also have sooth far-reaching implications for modern society, by constantly evolving magnetic material science.

Potential Future Applications of Magnetic Metals

In my opinion, the future uses of magnetic metals are to be very varied and they can change the world of many industries for good. One of the main areas of energy where magnets will really help the most is production and storage. Engineers are already using magnetic materials to create powerful wind turbine generators and also to make devices that control nuclear fusion through magnetic confinement. So if these metals are used mainly to boost the efficiency and cut the energy wastage, they will be the ones doing the switching to the more sustainable energy systems. Moreover, the magnetic refrigeration technology is also the ground-breaking application that the development has come up with to be the very plus of non-energy-consuming methods of cooling.

The other good way is in the medical field, where magnetic metals could come up with the most accurate and least invasive methods of medical treatment. The great thing is that cancer patients receiving magnetic nanoparticles for hyperthermia treatments and drug delivery do not undergo surgery, as they are going to be directed to certain body areas only, and the side effects are also going to be minimal. In addition to this, the application of magnetic materials in imaging areas like advanced magnetic resonance imaging (MRI) systems, improves diagnostic accuracy and lowers the time for scans.

The use of magnetic materials in the configuration of faster and more reliable communication is of great significance for the future of data and electronic technologies. Interest in the development of storage and processing devices powered by magnetic materials has been increasing due to their low energy consumption and fast speed, which are the main advantages of spintronics technology. On the other hand, the advanced superconductors that are being made through the use of magnets and the shielding of electromagnetic waves have the potential to make the next generation of electronics more durable and trustworthy. Taking all these technological improvements into consideration, the future of magnetic metals seems to be very bright as they not only will be the backbone of current technologies but also will be there to explore the new tech avenues.

Challenges in the Development of New Magnetic Alloys

The creation of new high-performance magnetic alloys is not only a scientific but also an economic puzzle at the same time. The difficulty of the situation is mainly about getting the perfect combination of properties of the materials that are to be used, among which are the magnetic power, thermal stability, and corrosion resistance. It is important that the alloying elements are extremely carefully selected and optimized so that these properties will still be present even after changes in operating conditions. For example, when rare-earth elements like neodymium or dysprosium are added to the mix, the magnetic power can go up significantly, but at the same time, there are supply chain vulnerabilities created because of their limited availability combined with the high cost of production.

In addition to the above, the techniques from manufacturing are another great challenge besides the above-mentioned ones. Techniques such as powder metallurgy and rapid solidification might offer some new ways of overcoming the existing issues, but plenty of controls need to be in place because otherwise, defects that are not supposed to be there will develop and degrade the magnetic properties. All these demands have their negative consequences on the availability of suitable alloys since lots of constraints depend on the demand for small, high energy-density components that require perfect performing alloys at the miniaturized scale for the handling of heat dissipation without compromising that. One of the areas that need development is computational material science and nanoscale engineering, and any further developments in these areas will be very beneficial as they will facilitate predictive design and experimental validation of new alloy compositions.

At the same time, the environment is a matter of concern, as the materials used in high-performance magnetic alloys extraction, processing, and disposal can be significant sources of ecological damage. One of the tasks of the researchers will be to find out the most eco-friendly ways to get and recycle the most important elements with the least lifecycle emissions possible. These challenges are so extensive that the involvement of scientists from different fields is a must if we want to get good cooperation between materials experts, engineers, and production or even more so, the whole industry.

References

- MetalsCut4U: Discusses various magnetic metals, including iron, cobalt, nickel, and others, highlighting iron as the most magnetic metal on Earth.

- Wikipedia – Magnetite: Explains that magnetite is the most magnetic of all naturally occurring minerals, providing scientific context.

- Reddit – Materials Science: A discussion in the Materials Science community about magnetic properties of metals, including steel.

- Click here to read more.

Frequently Asked Questions (FAQ)

Q: What is the most magnetic metal?

A: The most magnetic metal is iron, recognized for its powerful ferromagnetic qualities. Under the influence of a magnetic field, the atoms of iron get aligned, thus producing a strong magnetic effect. There are also metals like nickel and cobalt, which have considerable magnetism.

Q: What are ferromagnetic metals?

A: Ferromagnetic metals refer to those materials which can be permanently magnetized and show great magnetism. The group consists of iron, nickel, and cobalt. The arrangement of their atoms makes it possible for the magnetic dipoles to line up, thereby increasing their magnetic characteristics.

Q: Are there metals that can be magnetized?

A: Definitely, on the list of metals that are capable of being magnetized are iron, nickel, and cobalt. The reason for this is that these metals possess unpaired electrons which are responsible for the formation of a magnetic field when the metals are in the presence of an external magnetic force.

Q: What are non-magnetic metals?

A: Non-magnetic metals do not show any magnetism and that includes gold and aluminum among others. Their atomic makeup is such that alignment of magnetic domains is very difficult hence making them immune to magnetic forces.

Q: How do metals like steel showcase magnetism?

A: Steel is regarded as a magnetic material because it is made of iron, the most important ferromagnetic metal. By controlling the arrangement of the steel’s magnetic domains, steel can become magnetized which is why it is applied in different areas.

Q: What is the significance of magnetic properties in alloys?

A: An alloy’s magnetic properties are determined by the alloy’s composition. The presence of ferromagnetic metals such as iron and nickel in the mix produces strong magnets whereas the inclusion of non-magnetic metals like aluminum results in little or no magnetism at all.

Q: What are the three different forms of magnetism?

A: Ferromagnetism, paramagnetism, and diamagnetism are the three forms of magnetism. Strong magnetic power is characteristic of ferromagnetic materials like iron, while on the other hand, paramagnetic materials have a tendency to weakly attract magnetic fields. Materials that are classified as diamagnetic, such as copper, are not only repelled by magnetic fields but also regarded as non-magnetic.

Q: What is the function of rare earth metals in magnetism?

A: Neodymium and samarium are among the rare earth metals that possess very high magnetic strength. A combination of their specialized crystal structure and exceptional remanence enables them to produce extremely powerful permanent magnets, thereby becoming necessary in a range of tech applications.

Q: Is it possible for metals to be attracted to magnets?

A: The answer is a yes, the metals that attract magnets are of the ferromagnetic type namely iron, nickel, and cobalt. The reason behind this is their ferromagnetic nature which facilitates the alignment of magnetic dipoles and thus a strong interaction with external magnets is established.