Stainless steel of the medical grade has significance in the modern world; it is widely used for the making of a variety of surgical tools, surgical implements, and medical instruments. Its unique features, including high corrosion resistance, high strength, and biocompatibility, make it workable in areas where superior safety and accuracy are required. The employment of high-quality stainless steel guarantees that surgical instruments can tolerate intense cleaning procedures, retain their form after being subjected to harsh circumstances, and reduce the chance of unwanted side effects in patients. In this article, the important features of medical grade stainless steel are discussed together with its classification and how it is very essential in the development of surgical and medical phenomena.

What is Medical Grade Stainless Steel and Why is it Important?

Medical-grade stainless steel is the alloy used in producing surgical equipment, pharmaceuticals, and any type of medical tool. A few of the key properties of medical grade stainless steel include the alloy’s strength, anti-corrosive abilities, and biocompatibility, which prevents any contamination of the surgical equipment and, in turn, increases patient safety. The durability and flexibility of the medical equipment can mostly be attributed to the careful control of the alloy’s composition, which requires nickel and chromium. This specific alloy is important for the healthcare sector as it is used to manufacture surgical tools, implants, and many types of medical devices.

Key Properties of Medical Grade Stainless Steel

- Corrosion Resistance

Surgical tools are often implanted in the human body, which makes it essential that they do not corrode in environments that contain bodily fluids; they also face the threat of oxidation and are subjected to sterilization. Additionally, medical-grade stainless steel also has the ability to resist aggressive cleaning agents; hence, it is perfect for this situation. This specific strength of medical grade stainless steel can be attributed to chromium which covers the base layer of the material to protect it from oxidation.

- Biocompatibility

Due to its nontoxicity, this metal alloy has the potential to eliminate the threats of an allergic reaction. Moreover, it can be praised for its low chances of being rejected, as it is specially crafted to limit negative immune reactions, thereby reducing the chances of an immune rejection after the alloy has been implanted in the body.

- Mechanical Strength

Looking at the industry-serving grade stainless steel, which has structural strength, it can easily handle the mechanical stresses triggered in the administration of surgical instruments or orthopedic implants while being in use. Due to its great tensile strength and elasticity, it stays in place well even under stress for a long period in various operations where critical factors are concerned.

- Flexibility and Ductility

One of the fundamental properties of materials is ductility, as it allows the material to be shaped or bent when forming it into complex medical tools and devices without weakening if the tool and device are deemed to be complex. Ductility also ensures that thin-walled needles or highly designed surgical devices can be made without worrying about the device’s performance.

- Sterilization Compatibility

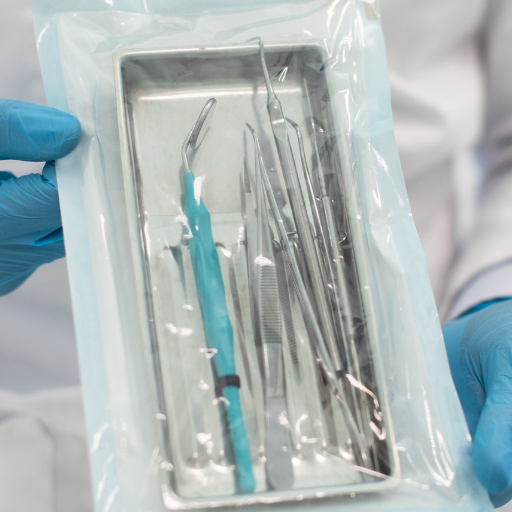

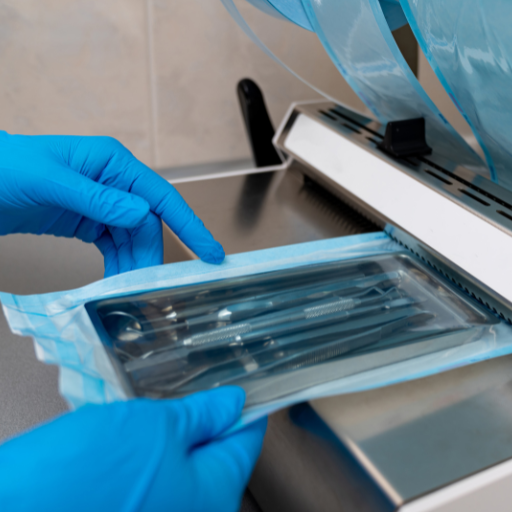

The properties of medical-grade stainless steel can actually endure repetitive sterilization that may include chemical cleaning, autoclaving, or other high-temperature treatments, so there is no degradation to its properties. This makes it easier for surgical instruments and devices to be used, as there is enhanced hygiene in place.

- Non-Magnetic Options

Some varieties of medical stainless steel, such as austenitic, are strongly non-magnetic, which allows for its use in MRI-grade devices. It doesn’t interfere with the work of magnets, which makes it compatible with imaging devices.

- Surface Finish Availability

Processes such as electropolishing are used to finish the devices, making them less prone to contaminants, such as bacteria. This makes it easier for the stainless steel to be cleaned and last longer. Additionally, having a smooth, shiny surface reduces the risk of foreign contaminant deposition.

Medical Applications

In a broader context, exporting a medical-grade stainless steel vertical band saw has never been more important. Due to its highly porous structure and temperature-sensitive properties, stainless steel is ideal for medical applications. Its corrosion resistance is beneficial in the survival of surgical instruments, implants, and devices that are in contact with bodily fluids or are further sterilized. The metal is inert to biological tissues, preventing unfavorable reactions with implant tissues or prosthetics. Also, the material can endure extreme pressure, allowing it to practice critical medical instruments. Such characteristics are vital in ensuring that the hardware meets strict hygiene, safety, and performance parameters.

How Does Medical Grade Stainless Steel Differ from Regular Stainless Steel?

What makes medical grade stainless steel different from stainless steel is that it is made to have enhanced features suitable for medical use. Its enhanced chromium and molybdenum contents give it effective corrosion resistance, which protects it from being destroyed when body fluids and various forms of sterilization are used. Moreover, medical-grade versions are of a higher grade and meet stricter standards in terms of quality, ensuring biocompatibility and eliminating unnecessary elements with potentially adverse effects. The finishing works, e.g., electropolishing, are also more specific, resulting in a smooth, non-porous surface that controls the risk of disease-causing bacteria. All these characteristics make medical grade stainless steel appropriate for use in critical clinical situations.

Composition Differences

16% and above is the chromium content of medical stainless steel. It serves to improve corrosion resistance. It might also have molybdenum which has a range in content from 2 to 3 percent, and this helps in pitting and crevice corrosion erosion when exposed to the chloride environment. Others, such as 316L, have low carbon content, which is to reduce carbide precipitation in welding. This leads to improved durability and structural integrity. Medical alloys have traces of nickel in a range of 10 to 14 percent and it is to increase tensile strength and ductility. In this way, the components can withstand repeated stresses and shear forces without failing. These very small differences in chemical composition are very important in satisfying the mechanical and biological aspects in medical use.

Corrosion Resistance Comparison

The corrosion resistance of medical grade stainless steel is stronger than that of stainless steel due to the difference in their alloy composition. It is enriching to note that adding molybdenum enhanced the corrosion resistance to pitting and crevice corrosion, making it applicable to saline or body fluid environments. Also, it can be observed that a surface with high chromium content also possesses a stable passive oxide film, which exposes itself in the presence of oxygen, subsequently assisting the surface in preventing oxidative damage. Lesser carbon grade variants, such as 316L stainless steel, reduce the risk of intergranular corrosion after welding. All these factors conclude that medical-grade stainless steel is appropriate for a healthcare facility’s harsh and corrosive environment.

Specific Requirements for Medical Applications

- Biocompatibility: Any material used in medical applications should never result in undesirable biological responses. This means that medical-grade stainless steel can be used in such situations because the material does not show toxicity or leach harmful ions, making it suitable for body contacts.

- Mechanical Strength: The material needs to have high tensile and yield strength to withstand the stress and loading conditions. Because of its high durability, stainless steel allows numerous mechanical forces to act simultaneously. This means it can be employed in orthopedic implants or surgeries as tools.

- Compatibility with Sterilization Procedures: Medical-grade stainless steel surfaces often need to be sterilized after every usage, especially in steam, high temperature, highly corrosive chemicals, and other harsh environments. Such harsh environments do not tarnish or disintegrate stainless steel, enhancing the success rate of medical devices after they are sterilized and making them reusable.

- Resistance to Wear: Surgical instruments and joint replacements carry out rubbing and also get rubbed against throughout use. Because of the highly tough properties associated with external wear and tear stainless steel material can withstand damage to its surface and remain usable for longer periods.

- Non-Magnetic Characteristics: For imaging applications such as MRI scans utilizing non-magnetic materials, doctors use stainless steel, which does not affect magnetic fields. This trait prevents any faulty imaging equipment from working.

- Surface Treatment: Thorough polishing of stainless steel, which is applied in surgical procedures, is necessary since having a visual defect increases the risk for bacteria to grow and become an infection or a hospital-related infection. Coupled with low roughness, polished stainless steel reduces the possibility of bacteria contamination in a clinical environment, making it safer for patients.

What Are the Most Common Types of Medical Grade Stainless Steel?

The dominant types of medical stainless steel are the 304, 316, and 420 stainless steel alloys. Surgical-type stainless steel is widely used across the globe because of its ease of fabrication and resistance to corrosion. Type 316 is high in molybdenum making it useful as it increases the resistance to pitting and crevice corrosion in saline and chloride environments. Type 420 is martensitic steel that is high in hardness and retains its high wear resistance after heat treatment, making it ideal for surgical instruments. All of these types are characterized by their mechanical properties, corrosion resistance, and their relevance to the specific end-use medical purpose.

304 Stainless Steel: Properties and Uses

Austenitic steel, type 304, is an alloy of iron with 18-20% chromium and 8-10.5% nickel as well as small percentages of manganese, silicon and carbon. Its properties appoint it to have outstanding corrosion-resisting ability and, therefore, becomes a great candidate for surgical instruments, implants, and medical devices. It has a tensile strength between 515 mp and 1035mp which makes it incredibly durable and offers excellent structural integrity even after multiple sterilizations. The alloy features excellent formability and weldability, allowing for more intricate geometric shapes to be made without compromising performance.

Also, 304 type stainless steel, when used for longer periods, can retain oxidation resistance up to temperatures around 870 Celsius (1598 Fahrenheit). In its annealed condition, it is non-magnetic which can be helpful in cases where there is a need to not interfere with magnetic fields. Its resistance to pitting and crevice, though, is moderate, and therefore, it is not advisable for use where there is prolonged exposure to high concentrations of chlorides or saline conditions. It is instead best suited where general corrosion resistance and mechanical reliability are more critical for use, such as surgical instruments and structural parts of operating booths. It is beneficial since it would not allow the corrosion products to shed off as tissue is biologically aggressive.

316 and 316L Stainless Steel: The Gold Standard

316 and 316L stainless steels are well known for their corrosion resistance characteristics and thus are generic in usage in places where there is exposure to corrosive agents and harsh condition common use. Both grades contain molybdenum in quantity such as 2 – 3%, which is likely to impede a good deal of pitting and crevice corrosion under the influence of chloride environments such as seawater and industrial chemicals. The main difference between the two is the amount of carbon in the alloy; 316L is lower in carbon (not more than 0.03%) and, therefore, less likely to experience carbide precipitation during welded fabrication, thereby making it most appropriate for application where corrosion resistant welded or high stressing parts are required.

The tensile strength of the 316 and 316L stainless steels is between 515-620MPa and their yield strength is around 205 MPa. In addition to this, their temperature performance is fairly good as they can absorb intermittent service temperatures of up to 870, and during continuous service, they can withstand temperatures of around 925 degrees Celsius. These characteristics are beneficial in numerous areas that are sensitive, like the marine environment, equipment used for chemical processing, as well as implants within the biomedical environment, where stability as well as elimination of wear and tear is needed. Additionally, since both of them are non-magnographic when heat is treated, they find applications in areas where a magnetic effect has to be avoided.

Other Grades Used in Medical Applications

- 420 Stainless Steel. The 420 grade of this martensitic stainless steel is a type that is known for its high carbon and good hardness after heat treatment. Cutting tools such as surgical scalpels, and other dental instruments that are known to cut well, are made using this grade as it sustains sharp edges, as well as possesses a high wear resistance. However, it should be noted that this grade is weaker in terms of abrasion resistance than austenitic grades.

- 17-4 PH Stainless Steel: This steel is often described as a precipitation-hardening grade. It possesses high strength, corrosion resistance, and rather good toughness. 15-17.5% of chromium and 3-5% of nickel are usually alloys in it, and it is most often used for devices like medical implants, dental instruments, and specific surgical instruments with high wear resistance and precision machining ability.

- Nitronic 60: This steel is excellent for galling properties and wear resistance, making it a high-performance stainless steel. The combination of 8-9% manganese and 16-18% chromium enables the steel to work under conditions of extreme pressures. This means that it is capable of withstanding high friction, which is why it is suited for the joints used in joint implants.

- 440C Stainless Steel: Another high-carbon, martensitic grade, 440C is engineer-preferred because of its excellent hardness and strength after heat treatment. Medical cutting tools, surgical scissors, and most precision instruments requiring sharp edges and strong, durable sides can be made from it since it is commonly used in medical tooling production.

- Cobalt-Chromium Alloys: Although not completely made of stainless steel, this combination has significance in the medical field. It has the best biocompatibility and improved corrosion resistance, which allows its use in medical implants—artificial joints, dental, and heart valves—that are meant to be long-lasting. The alloys have up to 30% chromium in them, which is why they are able to survive biological conditions.

How is Medical Grade Stainless Steel Manufactured?

The steel used to create medical instruments is of the highest quality possible. Making a metal of such high quality and strength requires going through an electric arc process involving alloy elements like nickel, chromium, and iron ore. This process is done with extreme precision as it is the crucial part and component of making this metal. After the steel is made, it is forced to roll, where it will then need to be forged again and formed as rods or pieces. Constant purification eliminates any chance that steel rust or corrode in any way as it is being made stronger. Finally, the process ends once the quality control manager ensures it passes all tests put forth by the governing body.

Raw Material Selection and Processing

The raw materials used to manufacture steel are a crucial element that determines the quality of the final product. These are high-purity iron ores, low residual scrap steel contaminants, and alloys with useful properties of chromium, nickel, and molybdenum. Fe content in an ore should typically exceed 62% while in scrap steel, the residuals of copper, tin, and phosphorus should be less than 0.15%. Other stainless steels contain from 10 to 20% chromium regarding the final composition.

These raw materials have to be treated properly to control their composition and microstructure. For instance, the carbon content was controlled during the refining stage with final carbon concentration varying between 0.02%-1.5%, depending on the steel grade. Also, the processes of slagging reduce the content of sulfur and phosphorus to a level lower than 0.03%. Therefore, it can be expected that the steel that is produced would conform to even very high-performance specifications for applications in medical devices as high strength and biocompatibility, as well as resistance to wear, are necessary.

Quality Control Measures

The steel-making industry uses quality control measures, which include testing and various processes to monitor that the target is met. These measures include chemical composition analysis, where advanced spectrometry techniques verify the material compositions within specified tolerances. The physical features of the materials are assessed through tensile, impact and hardness tests which check their strength and ductility attributes under different conditions. Non-destructive testing techniques like ultrasonic and radiographic inspections are employed to characterize the steel and identify potential internal flaws without causing any damage to the structural integrity of the steel. Furthermore, process calendars and real-time supervision systems control temperature, pressure and chemical events to maintain uniformity of production batches. Documentation and traceability systems further address the issues of transparency as well as accountability of the whole production life cycle to ensure that the output is of the standard required or above.

Sterilization and Finishing Stages

The steps of steel sterilization and finishing involve sophisticated processes that improve the materials’ surface and internal structural features. Sterilization is usually done by applying heat, such as during heating and soaking or during quenching (steel is heated to a certain degree and then bombarded by steel balls or by water). Impurities form in such heat treatment and are removed, improving steel’s structural molecular composition. This process is usually accompanied by peracid degreasing and pickling, in which hydrochloric acid or alkaline cleansers of controlled concentration ranges are employed in removing surface contaminants for best results.

The finishing phase’s aim is achieved by modifying the surfaces and internal specs to the level of the requirements, which could be aesthetic in nature or actual physics, such as dimensional accuracy. Usually, shots are blasted to remove residual or dependant scales, and the mechanical use of polishers is able to achieve a beautiful skin. There is also the use of coatings. For instance galvanization is a useful coating in preventing corrosion. The dimensional tolerances during this stage are usually intended to be in micrometers to meet the requirements of applications. All the aspects of the working procedures, right from chemical treatments to mechanical ones, are done within strict regulations to conform to ASTM or ISO standards outlined in the industry to ensure the production of strong and reliable steel materials.

What Are the Main Applications of Medical Grade Stainless Steel?

Stainless steel instruments are recommended for many surgical procedures. Some common and widely used stainless steel surgical instruments include scalpels, joint replacement implants, forceps, dental implants, and even stents. These instruments can withstand a lot of stress and pressure, remain intact while in the body, and do not rust or corrode.

Surgical Instruments and Tools

- Scalpels: These ultra-sharp stainless steel cutting blades are designed to cut through any material or tissue. They come in multiple types and shapes with different sizes to cater to various surgical needs.

- Forceps: Forceps are specially made tweezer-like instruments that allow a surgeon to hold or grip the tissues requiring surgical procedures. Because they are made of stainless steel, they help sterilize the working area and keep it free of rust.

- Retractors: These are used to keep body tissues or organs away or pushed back, making the working area even more accessible. They are designed to be long-lasting and utilize stainless steel as a material when placed under excessive mechanical force.

- Needle Holders: Instruments that securely grip a surgical needle and assist in the suturing of tissues, therefore providing precision and stability to the surgeons

- Scissors: Included in the categories of dissection scissors and operating scissors, surgical scissors assist with cutting sutures or tissues with minimal damage to the tissues. The blades of surgical scissors are made of sharp, rust-free metal so they can be used effectively.

- Hemostats: Clamps that are utilized to secure or pinch blood vessels or tissues in order to limit the bleeding during surgical operations. The metal in these tools are stainless steel, making them resistant to corrosion and allowing them to last for a very long time while staying clean.

- Curettes: Slim scraping instruments that have a scoop-shaped tip for scraping the tissues in delicate treatments that need precision and careful debridement.

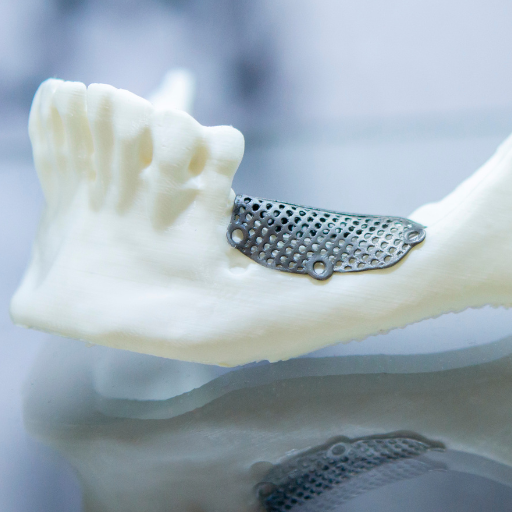

Implants and Prosthetics

- Orthopedic Implants: Titanium or stainless steel plates, screws and rods are known to be orthopedic implants as they support or completely substitute for damaged bones while also being biocompatible with no risks of the body rejecting them.

- Dental Implants: Implants are surgically embedded in the jawbone by drilling them with titanium or zirconia. They replace tooth roots and encourage integration, making them a very reliable solution for people who no longer have teeth.

- Cardiac Pacemakers: Small devices placed in the chest to correct abnormal heart rhythms. A pacemaker basically consists of two main parts: a generator that generates electrical impulses and a lead that transmits them through the function of the heart tissues.

- Cochlear Implants: Electronic devices that are placed inside the ear to help patients suffering from severe hearing loss regain their sense of hearing. Colonizers of human societies contain a microphone, speech processor, transmitter, and an electrode array that directly sends stimuli to the hearing nerve.

- Joint Prosthetics: Surgical prosthetic implants for human joints replacement such as hip prosthesis, knee prosthesis, and shoulder prosthesis. Such implants contain ceramics, metals, and high-density plastics, which perform functions of natural girdles and also last over a lengthy period.

- Breast Implants: These devices, filled with silicone or saline, are used in cosmetic or reconstructive breast surgeries. Their key goal is to appear realistic while still meeting safety and structural values.

- Spinal Implants: Instruments like rods and screws or cages for the surgical stabilization of the spine or in the course of spinal fusibility for deformity, trauma or degenerative conditions. They are made of titanium alloys, which ensure mechanical reliability and are biocompatible.

- Vascular Stents: They are arterial and venous stents, essentially tubular frame structures placed to help open veins and arteries in the case of their treatment. They tend to be made up of non-reactive metals that support the stent’s ability to function within the vascular system for longer and while being flexible.

Medical Equipment and Devices

- Electrocardiogram (ECG) Machine: ECG machines measure and document the electric activity of the heart. These machines are instrumental in diagnosing arrhythmias, heart disease, and heart attacks, among other cardiovascular diseases, since they take accurate data on the part to be analyzed based on the electrons placed on the skin of the patient’s body.

- Infusion Pump: These devices aim to provide a constant amount of fluid, either blood, medicine, or food, through a patient’s blood system. These practice devices are very important in medical practices as they ensure every little thing is done carefully without complications.

- Defibrillators: Any patient that has had a sudden cardiac arrest can be saved through the use of this device which essentially electric shocks the heart to make it pump blood again. It is effective in saving a person’s life by ensuring that there is a sustainable heartbeat and comes in manual form as well as AED for professionals and normal users.

- Dialysis Machines: These devices are for patients with kidney failure. According to the term, they cleanse the blood by getting rid of unwanted elements, fluids, and toxins while keeping the electrolytes in balance. This helps the body maintain homeostasis by taking over the regulating functions of the kidneys.

- Equipment Used in Medical Imaging: This includes devices like X-ray machines, CTs, and MRIs that capture radical images of the body’s internal organs. These pieces of equipment are vital diagnostic tools that require no invasive procedures in medical practice as they assist in detecting diseases, injuries and other…

- Mechanical Ventilators: These are manufactured devices that are meant to help or replace healthy breathing in situations where a person cannot breathe relatively well on their own. Such machines define critical care and surgical services by facilitating oxygen supply and breathing in a controlled manner.

- Robotic Assisted Surgery: These sophisticated robotic devices aid in performing surgeries with minimal body invasion. With robotic capabilities, such surgeries are endowed with motive precision, control, and flexibility, enabling more successful results and quick patient recovery.

- Monitors for patients: Multi-parameter Systems that continuously and automatically record and visualize vital parameters like heart rate, blood pressure, oxygen level, and temperature in real time. These are important devices in critical care sections of the hospital, such as ICUs.

- Ultrasound Devices: This is a type of imaging equipment that does not involve radiation-exposing imaging techniques. Ultrasound uses high-frequency sound waves to form images of internal organs, such as during pregnancy or any functioning organ.

- Oximeter: A small device that determines oxygen level saturation within blood. It helps track the patient’s respiratory condition in several clinical and home environments.

How Does Surgical Steel Compare to Other Medical Metals?

Steel that is used in surgical procedures, also known as “surgical steel” is a form of stainless steel that finds its use in medical applications because of its advanced resistance to rust, compatibility with organisms, and strong mechanical properties. The welding of titanium and stainless steel makes surgical steel much more resistant to corrosion than titanium while being as far stronger than titanium, making it a suitable metal for instruments and implants that will undergo stressful conditions. On the other hand, titanium has an advantage when it comes to being lightweight and being biocompatible more in the long term due to a lower chance of sensitization. Compared with cobalt-chromium alloys, surgical steel is optimal for implants because it is relatively cheap to process. However, cobalt-chromium alloys can provide greater shear and wear resistance. Each implant needs a different type dynamic and specific strength depending on patient sensitivity and operating conditions.

Comparison Between Surgical Steel and Titanium

Titanium and surgical steel are among the widely used metals in the medical industry, but there are a lot of differences in terms of applications and properties. As most Obviously steel composition has a high yield strength of about 290 MPA particularly 316L Stainless steel along has greatly enhanced wear resistance, this enables surgical implants and instruments that are constantly in mechanical stress to function. It also demonstrates notable corrosion resistance in the majority of biological environments. Its downside is that it is denser than titanium, with an average density of 8 g/cm³, this attached with other components may contribute to the increase of weight of equipment’s.

Whereas titanium is lightweight and versatile in handling the ionization caused by allergic reactions, its average density is about 4.5 g/cm³, meaning about half that of surgical steel. On the other hand, the yield strength nab is between 485 mpa- 830 mpa (Grade 5 of Titanium Alloy); this formation indeed provides enhanced usage regarding the mechanical load bearing. Also, titanium makes a passive oxide layer on its interface, protecting it from corrosion, possibly encouraging ion release that carries allergy.

Though titanium is a lightweight and high-performance option for long-term implants, titanium is still favored over surgical steel, especially in easy machining cases. It all comes down to the client’s requirements in terms of the mechanical characteristics of materials that will suit their needs and the costs involved.

Surgical Steel vs. Cobalt-Chromium Alloys

Cobalt-chromium is a popular metal combination for use in dental and medical implants due to its high strength and wear resistance qualities. Roughly, their density is between 8.3 grams/cm³ and 9.2 grams/cm³, which is comparable and slightly above the range for surgical steel. This allows cobalt-chromium alloys to have an increased level of strength, but on the downside, this contributes to the overall weight of the devices. The tensile strength of these alloy steels is substantial enough to allow them wider functionality for many implants, with average figures being around 1000 MPA, and their yield strength being above 450MPA.

With regard to issues of corrosion resistance, cobalt-chromium alloy has a strong passive oxide layer like titanium oxide, which increases the prevention of pitting and crevice corrosion in a biological environment. However, the potential for hypersensitivity to cobalt or chromium can be troublesome especially considering that these metals provide a range of specific anti-allergic benefits. These alloys were reported to have better wear properties than surgical steel, so they would have longer service lives in joints, prostheses, and other frictional surfaces.

Economically, cobalt-chromium alloys are more expensive and difficult to machine than surgical steel. Nevertheless, their remarkable mechanical features and biocompatibility make them the preferred materials in critical medical applications where load and wear resistance are necessary. Generally, the choice between cobalt-chromium alloys and surgical steel must be based on the functional requirements and the economical aspects of the medical device or implant being produced.

Advantages and Limitations of Surgical Steel

Surgical steel is one of the most common metals used in the medical and industrial fields due to its unique features. One of its key benefits is its corrosion resistance because chromium usually ranges between 10.5% and 12% or more. This feature assists surgical steel in avoiding rust and corrosion degradation on exposure to moisture or body fluids. Its hypoallergenic nature also reduces the chances of allergens and can be used in implants and as body piercings. Its mechanical properties, such as tensile strength and hardness, depend on the grade of surgical steel. For instance, 316L is a relatively common grade of surgical steel known for its relatively excellent strength and ductility.

Muscle memory is an important physical ability that evolves with repetitive motions. However, surgical steel has constraints. It is susceptible to scratching or wear and tear during prolonged use. As a result, its surface characteristics and performance may be affected, especially when tolerances are very close. More so, although its biocompatibility is good on average, some of its grades may contain low concentrations of nickel, forming a potential risk for nickel allergy patients. Finally, owing to its alloying elements and processing conditions, the production cost of surgical steel could be more than the other kinds of stainless steel, which could limit its use in bulk applications.

Reference sources

Frequently Asked Questions (FAQs)

Q: What is medical-grade stainless steel and why is it important in modern medicine?

A: Medical-grade stainless steel is a specialized type of stainless steel that meets specific standards for use in medical applications. It’s crucial in modern medicine due to its corrosion resistance, durability, and biocompatibility. This type of steel is used in the manufacture of medical instruments, implants, and equipment, ensuring safety and reliability in healthcare settings.

Q: What are the common grades of surgical stainless steel used in medical applications?

A: The most common grades of surgical stainless steel are 304 and 316 stainless steel. 316 stainless steel, particularly 316L (low carbon), is widely used due to its excellent corrosion resistance. 304 stainless steel is also used in some medical applications. Other grades like 420 and 440 stainless steel are sometimes used for specific instruments requiring high hardness.

Q: How does the chemical composition of medical-grade stainless steel differ from regular stainless steel?

A: Medical-grade stainless steel, particularly 316L, has a higher nickel content compared to regular stainless steel. It also contains molybdenum, which enhances corrosion resistance. The carbon content is kept low (typically below 0.03%) to prevent carbide precipitation and maintain its austenitic structure. This composition ensures better performance in medical environments compared to carbon steel or regular stainless steel.

Q: What are the main applications of medical-grade stainless steel in the medical industry?

A: Medical-grade stainless steel has numerous applications in the medical industry, including: 1. Surgical instruments (scalpels, forceps, etc.) 2. Implants (bone plates, joint replacements) 3. Medical equipment (operating tables, IV stands) 4. Dental instruments 5. Laboratory equipment 6. Sterilization containers 7. Needles and syringes These applications leverage the material’s strength, corrosion resistance, and ease of sterilization.

Q: How does 304L stainless steel compare to 316L for medical applications?

A: Both 304L and 316L are austenitic stainless steel grades used in medical applications. However, 316L is generally preferred for more demanding medical uses. 316L contains molybdenum, which gives it better corrosion resistance, especially against chlorides found in body fluids. 304L is still suitable for many medical instruments and equipment but is less resistant to certain types of corrosion compared to 316L.

Q: What properties make medical-grade stainless steel suitable for surgical instruments?

A: Medical-grade stainless steel is ideal for surgical instruments due to several key properties: 1. Corrosion resistance: Withstands repeated sterilization and exposure to bodily fluids 2. Durability: Maintains sharpness and structural integrity 3. Non-reactive: Doesn’t cause allergic reactions in most patients 4. Easy to clean and sterilize: Smooth surface prevents bacterial growth 5. Strength: Allows for thin, precise instrument designs 6. Non-magnetic: Important for MRI compatibility in some cases These properties ensure the safety and efficacy of surgical procedures.

Q: Is cutlery grade stainless steel the same as medical-grade stainless steel?

A: No, cutlery grade stainless steel is not the same as medical-grade stainless steel. While both may be corrosion-resistant, medical-grade stainless steel meets much stricter standards for purity, composition, and performance. Cutlery grade steel (often 420 or 440 series) is designed for durability and edge retention in food applications, whereas medical-grade steel (like 316L) is engineered for biocompatibility and resistance to more aggressive environments. Medical applications require higher-grade materials to ensure patient safety and instrument longevity.

Q: How is medical-grade stainless steel tested and certified for use in medical applications?

A: Medical-grade stainless steel undergoes rigorous testing and certification processes to ensure its suitability for medical use: 1. Composition analysis: To verify the correct balance of elements 2. Corrosion resistance tests: Including pitting and crevice corrosion tests 3. Mechanical property tests: For strength, hardness, and ductility 4. Biocompatibility tests: To ensure no adverse reactions in biological environments 5. Surface finish evaluation: To meet cleanliness and smoothness requirements 6. Compliance with standards: Such as ASTM F138 for surgical implant applications Certification often involves third-party testing and documentation to meet regulatory requirements.