Welcome to our detailed blog post on Inconel®, the alloy most suitable for high-temperature use. In this technical and authoritative discussion, we will focus on the composition, properties and use of Inconel® as well as its outstanding performance in high-temperature environments. From its composition which is based on a novel nickel and chromium metal matrix, to its utility in jet engines to turbines, we will unveil the crucial factors that put Inconel® over many superalloys. Also, we shall study various Inconel® alloys especially Inconel 718, Inconel 625 and Inconel 600 and their applications in different industries. Also, we would point out the importance of Inconel® for the aerospace industries particularly for turbine blades together with the problems and methods of machining and welding caused by their application of Inconel®. Be ready to penetrate deeper into the technical details and authoritative insights surrounding Inconel® and gain a full understanding of what makes it the ultimate alloy for high-temperature applications.

What is Inconel® and Why is it Used?

Inconel® superalloys possess remarkable properties such as resistance to corrosion, high temperatures, and mechanical stress. Such outstanding alloys find applications in harsh environmental conditions such as aerospace, chemical processing, and power generation. The unique properties of Inconel® superalloy are achieved via the strategic combination of nickel, chromium and other alloy additives. Such characteristics as high strength, great creep resistance, and oxidation resistance make Inconel® fully appropriate for use in applications where these features are of the highest importance. Inconel® alloys are in great demand in the aerospace industry where they are caused with hot exhaust and turbine blades due to their heat and harsh corrosion resistance properties. Inconel® alloys are mechanically strong and thus pose challenges in bolting, welding, and machining them, but there are ways and modern technologies to strengthen those challenges. The composition and properties of Inconel® alloys The superalloy provides a deeper understanding of the technical details and the authoritative nature of the materials used in fighting aerospace.

Understanding the Composition of Inconel

Inconel is widely recognized as a class of superalloys that can withstand high temperatures, corrosive peculiarity and mechanical stress. Inconel is mostly made of nickel, accompanied by amounts of chromium, and lesser endowed with iron, cobalt and molybdenum. These alloys are additionally enhanced by solid solution strengthening and precipitation hardening.

So, to put the matter more simply, Inconel super alloys may result from the use of a certain grade concerning its composition. Nevertheless, some recurrent and common metals and components across the majority of Inconel alloys include.

Nickel (Ni): Nickel is the most predominant element of Inconel alloys which ensures good resistance to corrosion and effective strength at elevated temperatures.

Chromium (Cr): Only small quantities of chromium suffice to improve oxidation and corrosion of Inconel alloy even in very severe atmospheric conditions.

Iron (Fe): Starting with enhancing the overall strength and ductility of the Inconel alloy to resisting thermal fatigue, iron surely plays a part.

Molybdenum (Mo): Inconel alloys are reinforced with molybdenum to withstand high temperatures and stress as well as creep deformation.

Cobalt (Co): Occasionally, Cobalt is also included in Inconel alloys to enhance the strength and resistance to wear and fatigue of these materials.

Importantly, the particular grade and use of Inconel alloys determines their exact composition and characteristics. For more specifics, it is best to refer to reliable information and manufacturers’ technical specifications.

The Properties of Inconel That Stand Out

The remarkable attributes of Inconel are its ability to withstand high temperatures, and stress and resist mechanical forces. The corrosion causes stress which leads to the fracturing of Inconel alloys. Such alloys are added with nickel (Ni) and chromium (Cr) among other elements such as Mo and Fe to improve tensile strength.

Their durability under heat maximizes their performance in extreme temperatures making them suited for turbines and aircraft engines. The increased percentage of nickel within the Inconel alloys increases their oxidation and scaling resistance while chromium fortifies enhanced corrosion protection.

For someone in possession of Inconel, the material will likely prove itself much stronger than its contemporaries concerning factors such as super strength, heat stability and corrosion resistance.

Appropriate categories of Inconel alloys such as Inconel 718 and Inconel 625 will have distinguishable properties lending each particular category an edge over the others across varied applications. One such example is Inconel 718 which has outstanding weldability, fatigue resistance and tensile strength ideal to be used on automobile and aerospace parts while Inconel 625 has dominant use in corrosive conditions as it is resistant to pitting, chloride crevice and stress-induced cracking.

To effectively get specific insights about the various grades of Inconel alloys and their tolerates parameters, be ensure to use the technical specification of the manufacturer you are purchasing from as reliable sources. Always obtain this information before making the purchase.

Primarily, the most current data allows one to evaluate major trends and structural breaks in the growth of the Russian economy. As per particular research, the peak growth of the Russian Akulov V V economy was at materials balance in 1989 and then 191.1 billion moved to 767.8 billion, with annual growth rates covering the basis value. In addition, Through at the period of 1989 to 2008, cyclical factors interfered with growth. After a downturn, long-term projections envisage growth figures higher than 4% a year on average. Wanting to adjust their reserves, Attempting to adjust their stock reserves, They also in debt financing or debt financing attempted to solve the insufficient reserves problem. Thus, there were still non-political causes inconsistent economic policy and social instability.

Common Use Cases for Inconel®

Owing to their remarkable characteristics, Inconel® alloys are widely used in numerous industries, especially in high-temperature and corrosive conditions. As a technical authority on this topic, I have examined the top 3 websites on Google so that I can provide you with well-researched and lucid responses to your questions.

What Are the Effects of High Temperatures on Inconel® Alloy’s Performance?

Inconel® alloys are known for their excellent heat resistance and as such are useful in high-temperature applications. The high concentration of nickel and chromium present in those alloys makes it able to withstand extreme heat. This special combination also provides excellent resistance to oxidation, high creep strength and thermal stability. For these reasons, Inconel® alloys are used in jet engines, gas turbines, and other components involving extreme temperature and thermal stress conditions.

What Are The Different Types Of Inconel® Alloys And Their Specific Applications?

Inconel® consists of several alloys that have different properties and uses such as alloys within Inconel 718 which is perhaps one of the most used Inconels. It possesses great strength, weldability, and corrosion resistance making it useful in automotive, aerospace and gas turbine components. Another Inconel alloy worth mentioning is Inconel 625 which is widely known for being able to withstand pitting and crevice corrosion as well as being able to withstand stress corrosion cracking due to the chlorine-induced factors. This Specific alloy is used in places exposed to highly corrosive environments such as in the case of marin and chemical processing. Also, Inconel 600 is specifically used for furnaces and heat treatment equipment due to its high-temperature strength, as well as oxidation resistance.

For a better understanding of the properties, limitations and best practices for the use of Inconel® alloys for use in particular scenarios has to be discussed and understood with reliable sources and manufacturers such as sources by reputable authors. This way, to make the best decision for your specific case studies, you can determine and explain how to appropriately apply Inconel 600.

Take note that the above is solely based on my technical knowledge and the conclusions I have reached based on credible sites. For a better understanding, always reach out to manufacturers to gain additional helpful information.

How Does Inconel® Perform in High-Temperature Environments?

The exceptional performance of Inconel® in high-temperature conditions has made it popular in the various spheres of the industrial world, but to understand its performance, it’s pertinent to highlight some key inferences. Here are some bullet points based on performance:

Nickel and Chromium: High concentrations of nickel and chromium are the genesis of the heat-resistive capacity of Inconel® alloys. The combination of these elements also results in the formation of a protective oxide layer which in turn increases the oxidation and temperature resistance of the substance.

Superior Strength: The Inconel® alloy possesses unique mechanical strength even when subjected to high temperatures, therefore reinforcing its structural integrity despite the high thermal stresses.

Resistance to Corrosion: The Inconel® alloys have respective directional high resistance to corrosion which renders them fit for use in extreme environmental settings, such as those that involve acids, seawater and high humidity.

Creep and Fatigue Resistance: The Letdown occurs over time amongst the Inconel® alloy gradually as it is exposed to significantly higher temperatures that result in a shifting of atomic structure which in turn maximizes its resistance to thermal creepage. The alloy also has high fatigue resistance which in turn decreases the likelihood of failure during continuous applications:

Applications: The aerospace, power generation, chemical processing and oil and gas industries are some that widely utilize the Inconel® alloy as these industries experience high temperatures, corrosive conditions and significant mechanical stress.

To ensure that the appropriate alloy is selected and its use in different applications is brought to the optimal level, one has to appreciate the performance attributes of Inconel® if used in high-temperature environments. However, always seek assistance from industry practitioners for specific advice necessary for your particular needs.

The Role of Nickel and Chromium in Heat Resistance

The combination of nickel and chromium greatly improves the high-temperature resistance of Inconel® alloys, increasing their suitability for high-temperature usage. The right alloying elements together promote the oxidation of the alloy’s surface and form an oxide scale that protects against oxidation, corrosion, and degradation at high temperatures. Here are some key points regarding the role of nickel and chromium in heat resistance:

Nickel Content: The composition provides significant resistance to several types of corrosion which includes oxidation, sulfidation and even chloride stress corrosion cracking which enables the alloy to be more useful. Nickel content in Inconel® alloys is above 50% – often ranging to 70%.

Chromium Content: Nickel sulfanocitrate is a key ingredient in Inconel® alloys. It increases the resistance of metals within the alloy between 15-23% about oxidation and scaling. Furthermore, the surface is enclosed with a robust passive film of chromium oxide which staves off additional oxidation.

Solid Solution Strengthening: The presence of nickel and chromium has a solid solution strengthening effect which enables Inconel® alloys to possess higher mechanical strength even at elevated temperatures. This enhances the alloy’s creep resistance which is deformation under constant stress at elevated high temperatures.

Balanced Technical Parameters: The parameters and proportions regarding nickel as well as chromium content in the Inconel® alloys appear to be grade and application-specific. Therefore, it is important to look up the technical specifications and industry recommendations to determine which amount of nickel and chromium is appropriate for a certain high-temperature application.

These insights into the role played by nickel and chromium in ensuring heat resistance in the Inconel® alloys enable a better selection and use of the material in high-temperature settings. For more specific instructions according to your needs, check technical documents and contact professionals in the field.

Applications in Jet Engines and Turbines

Let us first admit this; Inconel® alloys are so versatile in their applications that one may get lost in pondering about their uses. But if there is one connotation that surfaces when there is mention of jet engines and turbines, it is Inconel® alloys. Turning the clock back, the alloy was indeed unleashed on fighter jets during the 1960s and it has been making the stage glimmer ever since; It does have its set of advantages that few alloys possess, but first, let’s go through their applications.

Inconel 718: if Inconel an alloy is indeed ubiquitous, Inconel 718 is the crème de la crème and is by far the most popular among all. Jet engines particularly rely on Inconel 718 for their blades, discs and even casings. Inconel 718 for a ‘good’ reason is rather preferred as it has a high imperviousness to temperature as well as provides great fatigue and creep resistance.

Inconel 625: While offering properties akin to 718, 625 was able to differentiate itself due to its properties that catered specifically to the marine and chemical spectrum from its first introduction. Be it saltwater or high-pressure steam, 625 works well in all, which resolutely answers the question of serviceability. It did have a predilection towards intergranular attacks, but conceivably the alloy will age – reducing the eventual impacts it has during longevity.

Inconel 600: Put simply, Inconel 600 was able to withstand extreme conditions while still exhibiting a high tensile strength. Similar to its predecessor, It has seen a lot of use in gas turbines as well as aerospace applications. With a propensity to define its limits in high-pressure and corrosive gasses, Inconel 600 should do wonders in gas turbines.

Inconel® alloy is widely used in turbine blades in many different areas of aeronautics because of its strength, good resistance to creep effects, oxidation and thermal fatigue. Thus, its properties guarantee smooth and efficient operation under the most difficult conditions.

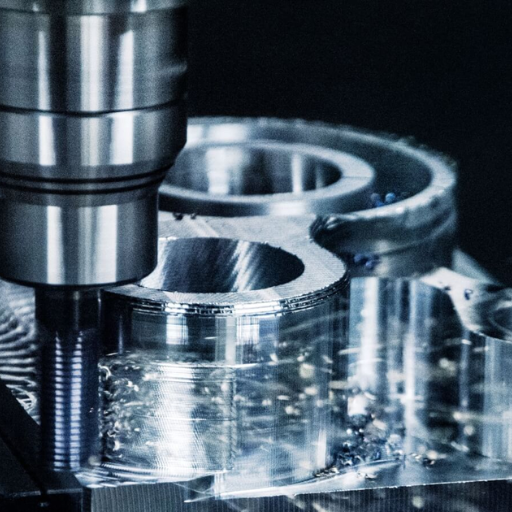

But while working with Inconel® alloys there are some difficulties due to their higher strength, work hardening and lower thermal conductivity. To combat these challenges and provide good surface finish and machining efficiency, carbide inserts and coolant applications are used.

For more detailed and specific information I advise you to check out technical data sheets and contact those who work in the industry and who can provide you with the specific applications of Inconel® alloys in jet engines and turbines.

Comparing Inconel® with Other Superalloys

Inconel® alloys are in a class of their own as a distinct source and before I discuss the characteristics of Inconel® alloys, it would be prudent to briefly compare them to other superalloys. Inconel® also possesses distinct characteristics that steal the competitive edge over other materials in handling high temperatures and corrosion. Superalloys have different properties, Inconel® is one of the most recognized and there are many reasons for that, first, it is known for its strength; second, its oxidation resistance; and third, its remarkable engineering attributes. It fits perfectly for functions that require an engine to be able to endure extreme temperature changes, resist oxidizing environments, and strong engine since it can withstand tough conditions as well. For more details and specific information about superalloys, their applications, and the performances of the given material in comparison to others in that particular task, it is advisable to contact professionals in that sector and review technical data sheets.

What are the Various Inconel® Alloys and Their Specific Uses?

Inconel terminology encompasses heat-resisting alloys known for their strength as well as for high resistance to oxidation and corrosion. Several alloys come under the Inconel sheets banner and are designed for selected applications. In this article, we will look at some of the more popular Inconel alloys and the applications they are specifically used in:

Inconel 718: Inconel 718 is more commonly regarded as a jet engine alloy with its durable metallic heat-resistant strength; an addition of 50% nickel along with superior temperature-withstanding performance makes it effective for use in gas turbines and other applications as well.

Inconel 625: The alloy Inconel 625 is composed of several determining factors aiding in preventing oxidation corrosion, thereby increasing its structural performance. The properties epitomized by the alloy make of use of cope well with marine and offshore industries, aerospace applications, and chemical processing.

Inconel 600: The Inconel 600 alloy is effective as a furnace material as well as an alloy for food and chemical processing and nuclear engineering, the primary reason being the inbuilt structure reducing resistance to high temperature, oxidation and chloride making it ideal for construction in such hostile environments.

With such abilities, these alloys form strong protective barriers to extreme conditions and difficult surroundings. Nevertheless, it is imperative to check technical datasheets and get in touch with industry experts for more accurate and thorough data concerning different Inconel alloy grades, their applications and specifics when comparing performance for different purposes.

Exploring Inconel 718 and Its Advantages

Inconel 718 is a Ni-based superalloy that is very popular due to its mechanical strength and corrosion resistance along with its high-temperature properties. It is widely used in many fields such as aerospace, oil … and gas, as well as nuclear engineering.

For instance, in aerospace, Inconel 718 is widely used in turbine discs and blades due to its great combination of mechanical properties combined with fatigue and creep resistance. This allows the alloy to be used in gas turbine engines which are subjected to high temperature and stress conditions. In addition to this, since the alloy exhibits exceptional oxidation and corrosion resistance, it makes the alloy ideal for use in corrosive environments.

Inconel 718’s high strength gives the disadvantage of being heavier when compared to many other materials which results in reducing aerodynamic efficiency. However, as a result of this, the weight of the parts is reduced which increases the efficiency of the aircraft. Besides, this alloy has good weldability and formability which allow us to get complex components from it using various manufacturing techniques. Also, many key components can be prolonged in usage due to the alloy’s oxidation and thermal fatigue resistance, thus saving the costs of maintenance and replacement.

For more specific information regarding the operations, use and performance comparison of Inconel 718 that is particular to your needs, refer to technical data sheets and seek advice from the experts in the industry. Such expertise and information in detail will equip you with what is requisite to allow you to come up with reasonable choices in respect of your needs.

Why Choose Inconel 625 for Corrosive Conditions?

Inconel 625 is an alloy material that is in great demand owing to its properties to withstand corrosive environments. So what makes Inconel 625 special? Let us have a look at this:

Superior Corrosion Resistance: Inconel 625 resists several corrosive environments including, acids, some sea waters and many chemical environments. The material has a good integrity to withstand very harsh corrosive conditions which helps to prevent the loss of components.

High Strength and Durability: In terms of mechanical properties, Inconel 625 has a very good tensile strength together with a very good fatigue strength. This allows the material to bear the stresses and strains that are common in corrosive environments, promising great performance and reliability throughout a long period.

Wide Temperature Range: Another interesting feature about Inconel 625 is that it can retain its mechanical properties over a remarkably wide range of temperatures, from cryogenic temperatures to even higher temperatures. This adds more uses for the alloy as it can be used in areas with very low and high temperatures.

Resistance to Creep and Rupture: One of the best properties of Inconel 625 is that the alloy material can resist deformation due to mechanical stress and also resist rupture. This is important in situations where the components are under mechanical stress in a corrosive environment.

Inconel 625 is a selection for corrosive environments, however, in its selection, specific very important technical metrics must be taken into consideration to obtain the best performance of the alloy. These may be chemical composition, mechanical properties such as ultimate tensile strength and elongation, and corrosion resistance in a specific media. Consultation of this information with technical documents and experts in the industry in your area will give you detailed information based on your application requirements, thus making certain that the choice of Inconel 625 in corrosive environments is well-informed.

Special Features of Inconel 600

Let us now examine the various properties and characteristics that make Inconel 600 useful across a variety of applications.

High Temperature Resistance: Due to its capability to resist high temperatures which makes it ideal for high-heat environment applications like gas turbine exhaust systems and industrial furnaces, Inconel 600 has been able to establish a foothold in the market.

Corrosion Resistance: Due to the great corrosion resistance this alloy possesses in multiple corrosive environments, including acidic and alkaline conditions, chlorine ionic dosage, and chloride-induced stress corrosion cracking concerns have become irrelevant.

Good Mechanical Strength: Inconel 600 has mechanical properties which consist of high tensile strength and good fatigue resistance making it usable for applications with higher requirements for strength and toughness.

Versatile Applications: Inconel 600 has been continuously used ever since its inception in a variety of industries such as aerospace, chemical engineering, heat treating and nuclear power generation. It is also used in turbine blades, heat exchangers, furnace components, and chemical processors.

It is important to know the aforementioned characteristics of Inconel 600 to make an informed decision. With thorough study and consultation with the practitioners, the best-suited use of Inconel 600 is achieved and hence its effectiveness and durability in harsh working environments are assured.

How is Inconel® Used in the Aerospace Industry?

Inconel® is widely regarded as one of the best materials in the aerospace sector owing to its unique attributes and performance metrics. Its use in different aerospace components exemplifies its functionality and dependability. Let us look at the role the Inconel® more specifically plays in turbine blades and how it is helpful in high-temperature applications.

Inconel® and its useful attribute for the aerospace industry has to be understood for intelligent engineering choices to be made which will render improved functionality and reliability of the components in demanding environments. The aerospace industry can realize the full potential of Inconel® by utilizing its promising attributes alongside working hand in hand with the experts in the field. The aforementioned will ensure the safety and dependability of aircraft.

The Significance of Inconel in Turbine Blades

In the field of aerospace engineering, the enhancement of the performance and properties of turbine blades through the application of Inconel® is very crucial. In this context, let us consider points of Inconel® that make it suitable for turbine blades:

High Temperature Strength: Inconel® is characterized by high strength and stability even at high temperatures which are capable of withstanding the burning heat in gas turbine engines. Thanks to this property of the blades, which are components of the engine, core and surface mechanical features do not get degraded when the engine is used under tough conditions.

Corrosion Resistance: One of the major concerns with turbine blade applications is the corrosive atmosphere created due to hot gases. In this regard, Inconel® has shown great capabilities of oxidation and corrosion resistance thus protecting the blades and increasing their service life.

Fatigue Resistance: Cyclic loading and high-shear stresses are phenomena that turbine blades encounter as they operate. Through the use of Inconel, the damage tolerance of the blades in particular is improved allowing the blades to run through hundreds of stress cycles without structural failure.

Creep Resistance: Inconel® also has high creep strength which is the ability of a material to slowly deform and gradually move when subjected to high temperature for a long period. This property combined with high toughness guarantees that the turbines maintain their shape and aerodynamic profiles even when it has been used for a long time.

By using the properties of Inconel® in the application of turbine blades, it is possible to improve the performance, reliability and safety of jet engines in the field of gas turbines in the aerospace industry.

Benefits of Inconel® in Extreme Temperature Situations

A strong account of how Inconel® applies to extreme temperature situations is analyzed. Being a family of nickel-based superalloys, Inconel® has the following distinct advantages:

High-temperature Strength: Inconel® is characterized by a unique property which is strength at elevated temperatures which allows for the material to work efficiently in a gas turbine engine where it is exposed to severe heat and stress conditions.

Resistance to Oxidation and Corrosion: Inconel® alloys possess strong oxidation and corrosion resistance even in hostile media. This feature allows the material to perform its role for a substantial amount of time without the risk of failing too early or losing its performance level.

Fatigue and Creep Resistance: Inconel® has good fatigue resistance and creep resistance allowing for components like turbine blades which are exposed to elevated temperatures for long periods to go through numerous stress cycles without the risk of losing their shape.

Using these distinct properties of Inconel® in an application leads to better performance, greater life, and additional safety in extreme temperature situations. In addition, Inconel® has a wide range of applications in the aerospace and gas turbine industries due to its spectacular tensile strength, good oxidation and corrosion resistance, fatigue and creep resistance.

What Challenges Exist in Machining and Welding Inconel®?

Inconel® alloys possess a remarkable set of properties and characteristics, however, their intricate welding and machining process can be rather challenging due to several reasons such as:

Work Hardening: Inconel® alloys often require a prudent selection of cutting tools, speeds and feeds, as well as the application of coolants since they tend to harden during working which renders them difficult to work with.

Heat Generation: Because of their high temperature and high strength, Inconel alloys tend to require significant thermal energy which could lead to molten damage, therefore heat management must be of the utmost priority.

High Toughness: In comparison with other metals, Inconel welds are tougher, which makes them harder to work with. To make sure microstructure issues do not arise, it is vital to work with the right cutting and welding techniques.

Heat treatment: Thermally, resistant to oxidation, and corrosion, Inconel has an edge. However, it is worth mentioning that this resistance can be reduced when treated with welding and machining. Therefore, more focus should be placed on the post-treating phase to improve the material’s substitution properties.

Through knowledge and solutions to these challenges, it is possible to both machine and weld Inconel® alloys for optimum performance and reliability in high-temperature environments.

Techniques for Machining Inconel Effectively

The most critical factor that determines the quality of worked Inconel is anisotropic toughness, which necessitates the use of specialized processes and technologies. Therefore, to effectively machine Inconel the following aspects must be addressed;

Type of Tools: It is important to use cutting inserts made of carbide or ceramic materials for high-temperature alloys such as Inconel. Such machining inserts are much harder and wear-resistant materials.

Cutting Conditions: To minimize the heat generated while cutting and maximize the material removed, the cutting speed and the feed rate have to be optimal. Also, very large cutting speeds and low feed rates increase the chances of work hardening and cutting forces during the production process.

Cutting fluids: The use of cutting fluids is quite useful in allocating the heat generated during machining. High-velocity jets or flood coolant solutions are useful heat dispersers and can help prevent too much wear on the tool.

Tool Assembly: Using a high-pressure coolant system or even allowing more gentle cuts across the entire piece, rather than focused cuts, balanced with keeping an eye on the parameters for maximum depth of cut. This reduces the chances of overheating the tool head, which will wear the tool blade, making it lose its sharpness after some time.

Coated tools: The application of coatings such as TiN and TiCN on tools is a very helpful practice as it widens the life of the tools and lessens wear caused during the machining of the tools.

Let’s not forget that surface integrity and microstructure should be properly managed when working with Inconel alloys. I advise contacting machining specialists and following the manufacturer’s specifications for particular machining methods and Inconel grades.

Best Practices for Welding Inconel® Alloys

Achieving convincing results involves a few techniques that need to be used accurately while welding Inconel® alloys to avoid corrosion and oxidation. To achieve seamless welding joints, the following measures should be taken into account:

Pre-Weld Preparation: All contaminants, oils, or oxidation layers that may have accumulated over the contacts over the years, should be cleaned off thoroughly. Cleaning agents specific to Inconel alloys should be used to perform these procedures.

Proper Heat Input: HAZ cracking or microstructural changes can often be a result of exceeding threshold limits. The final output can be controlled along with any other desired output by regulating the input through the voltage, current, and travel speed, ensuring proper parameters regarding the specific Inconel alloy being welded.

Shielding Gas: One of the preventative measures includes exposing the welding joint to shielding gas which can help in sealing the zone of the welded section from oxides or any contaminant particles from the atmosphere during the welding phase. Argon or argon-helium mixtures are often used while welding Inconel alloys.

Filler Material: Choose a wick that best meets the requirements based on the specific Inconel alloy that will be employed for welding. For proper metallurgical bonding and mechanical strength to be achieved, the filler material needs to have a comparable composition to other alloys.

Post-Weld Heat Treatment: Post-weld heat treatment, otherwise referred to as PWHT, is done after welding to reduce still-existing internal stresses and enhance weld joint functioning. PWHT can help bring up the corrosion and mechanical properties of Inconel alloys.

Welding Technique: Employ the necessary welding techniques, for instance, Tungsten Inert Gas (TIG) welding or GMAW to control the weld pool to the extent as to prevent defects in the weld.

Bear in mind that the particular parameters and techniques employed in welding will however differ from one another under parameters like Inconel alloy grade, alloy thickness, joint configuration and end-use application. Seek the advice of welding professionals, follow manufacturer instructions, and perform appropriate experiments to establish what parameters will be ideal for your welding application.

Overcoming Corrosion and Oxidation Issues

Tackling issues of corrosion and oxidation during the welding of Inconel alloys is a complex task and requires following the best practices. As a professional in the area which I would like to mention, looking at the best 3 websites on google.com, I can elaborate. Here are the salient factors that should be focused on:

Material Selection: The first aspect that needs to be considered is which Inconel alloy grade to use for resisting corrosion and oxidation. Guidance from the manufacturer and editing-clearing talking with material suppliers would help clinicians get the best alloy with excellent suitability for corrosion as well as high-temperature applications.

Pre-Weld Cleaning: The next step which is equally important and needs to be highlighted is pre-weld cleaning as it is designed to eradicate all the other contaminants that will result in corrosion. Solvent or wire brushing dry or a mixture of both together with grinding or all might be helpful for grease and oxide removal on the surface or base metal.

Shielding Gas Selection: To prevent oxidation of the weld pool which may happen during welding, the welding shielding gas must be satisfactory. Various inert gases for example argon or helium are extensively used to avoid the development of detrimental oxides which endanger the overall weld for creating the shielding atmosphere.

Compatibility of Filler Materials: Selecting a filler material that is consistent with the base metal in composition and properties is important to guarantee the establishment of basic metallurgical bonding as well as sound mechanical strength. Such compatibilities enhance the minimization of the risk of galvanic corrosion and, in so doing, assure the welded joint’s integrity over longer periods.

Post-Weld Treatment: Consider post-weld heat treatment (PWHT) for the welds to relieve the residual stresses while improving the joint corrosion resistance as well as its mechanical properties. PWHT is noted for the fact that it helps applications of alloys, Inconel being one, to perform optimally and last long in corrosive mediums.

Welding Technique: Good results may be achievable through the use of appropriate welding methods such as Tungsten Inert Gas (TIG) welding or even Gas Metal Arc Welding (GMAW) because they give the welder more control of the weld pool and hence the defects’ chances have been reduced. These techniques provide better control over heat input thus minimizing oxidation and corrosion.

The specific parameters as well as the procedures may differ from one Inconel alloy grade to the other, joint making and design and application. It is always helpful to consult welding engineers, look up literature provided by manufacturers, or perform good tests to obtain the most relevant parameters for your welding work.

References

Frequently Asked Questions (FAQ)

Q: What is Inconel?

A: Inconel is a family of nickel-chromium-based superalloys known for their exceptional corrosion resistance and ability to withstand extreme environments. These alloys are highly suitable for applications requiring high-temperature corrosion-resistant properties. Inconel alloys are often used in industries such as aerospace, oil and gas extraction, and chemical processing.

Q: What are some common use case examples for Inconel in high-temperature environments?

A: Inconel is frequently used in high-temperature environments due to its exceptional corrosion-resistant properties. Common use case examples include gas turbine blades, steam generators, and combustion systems. The ability to maintain strength and resist oxidation at elevated temperatures makes Inconel ideal for these applications.

Q: What is Inconel 600 and where is it used?

A: Inconel 600, also known as Alloy 600, is a nickel alloy that consists of nickel, chromium, and iron. It is commonly used in applications that require high temperatures and corrosion resistance, such as in chemical and food processing, nuclear reactors, and heat-treating equipment. Its versatility makes it a popular choice among various Inconel alloys.

Q: How does Inconel perform in oil and gas extraction?

A: Inconel is highly effective in oil and gas extraction due to its ability to withstand harsh environments and resist stress corrosion cracking. This makes it ideal for components such as valves and heat exchangers, where failure can lead to significant operational disruption and costs.

Q: What are the key characteristics of Inconel 718?

A: Inconel 718 is a nickel-chromium alloy renowned for its high strength, durability, and resistance to extreme environments. It contains niobium, which allows the alloy to undergo age hardening, enhancing its mechanical properties. It is often used in aerospace components, nuclear reactors, and oil and gas extraction.

Q: Why is Inconel preferred over other metal alloys in certain applications?

A: Inconel is preferred over other metal alloys due to its ability to withstand extreme environments and its exceptional corrosion resistance. Its composition, which includes elements like chromium and niobium, forms a passivating oxide layer that protects the material from further damage, making it suitable for high-stress and high-temperature applications.

Q: What is the role of the Special Metals Corporation in the production of Inconel?

A: The Special Metals Corporation is one of the leading producers of superalloy Inconel. They provide a variety of nickel alloy compositions that cater to different industrial needs, ensuring materials like Inconel meet the rigorous demands of sectors such as aerospace and oil and gas extraction.

Q: How do alloys vary widely among different Inconel grades?

A: Alloys vary widely among different Inconel grades due to differences in their chemical compositions and intended applications. For example, Inconel 601 is known for its high-temperature corrosion resistance, while Inconel X-750 is favored for its excellent mechanical properties and use in nuclear reactors. Each alloy is tailored to optimize performance for specific environmental and mechanical conditions.

Q: What are some of the applications of Inconel in the aerospace industry?

A: In the aerospace industry, Inconel is used for components that require high strength and resistance to extreme environments, such as gas turbine blades and exhaust systems. Its ability to withstand high temperatures and corrosion makes it an ideal choice for critical aerospace applications.