Cutting stainless steel, even by professionals, presents a challenging task: it is strong, resistant to corrosion, and difficult to work with. Whether big industrial works are being carried out or small DIY jobs are being done, acquiring knowledge of cutting techniques with the appropriate tools is paramount to scoring a neat, efficient, and safe cut. This guide will walk you through the principal methods and tools needed for cutting stainless steel, so you can comfortably wield experience and precision in the process. In this article, we will discuss all aspects of tool choice, from manual to power tools, and proper safety measures when cutting stainless steel, so that you will know how to cut them as though you’ve been doing it for some time. Learn here which methods suit your needs and how to execute them well.

Understanding Stainless Steel

Stainless steel is an extraordinarily adaptable and sturdy alloy built mainly from iron, chromium, and other elements-with the composition varying from grade to grade, commonly nickel or molybdenum. What distinguishes stainless steel is its resistance to corrosion, developed through the formation of a thin chromium oxide layer that acts as a barrier against rust and staining. Stainless steel is employed for a plethora of construction, manufacturing, and household purposes and is classified into several grades (like 304 or 316) depending on the environment in which it is to be used and the end function. Inaccuracies related to the steel affect the methods of cutting, the choices of tools to be employed, and ultimately the whole success of the task.

Properties of Stainless Steel

- Corrosion Resistance

Cutting stainless steel is resistant to corrosion, building a thin layer of chromium oxide on the surface, which is self-restorative. The ability of corrosion resistance differs according to the grade, the austenitic stainless steels (such as 304, 316) providing the best corrosion resistance in aggressive environments such as marine or chemical exposure.

- Strength and Durability

With its mechanical strength, the stainless steel can resist high stress from mechanical forces without deformation. Its tensile strength will generally span an interval between 515 MPa and more than 1,000 MPa, depending on the grade and heat treatment applied to it.

- Thermal Resistance

Stainless steel retains its strength and resistance to oxidation at very high temperatures. Grade 304 and 310 are used for heat-resistant services, with 310 being capable of service up to 1,150°C (2,102°F), although this is intermittent.

- Low Temperature Toughness

Some stainless steel types, especially austenitic ones, remain ductile and tough down to extremely low temperatures. Thus, they are suitable for cryogenic service.

- Workability

It can be shaped through rolling, bending, welding, and machining. Notably, grade 304 and its close variants are probably the best grades for forming and welding.

- Hygiene

The smooth, non-porous surface of stainless steel restricts dirt and bacteria from accumulating and hence is considered a suitable material in the food-processing, healthcare, and pharmaceutical industries.

Types of Stainless Steel

|

Type |

Key Characteristics |

Common Applications |

|---|---|---|

|

Austenitic |

High corrosion resistance, non-magnetic |

Kitchenware, construction, dairy tanks |

|

Ferritic |

Magnetic, moderate corrosion resistance |

Automotive parts, industrial equipment |

|

Martensitic |

High strength, moderate corrosion resistance |

Cutlery, surgical tools, turbine blades |

|

Duplex |

Mix of austenitic & ferritic characteristics |

Chemical plants, pipelines, shipbuilding |

|

Precipitation-Hardening |

High strength, corrosion-resistant |

Aerospace, nuclear applications, industrial fittings |

Applications of Stainless Steel

- Construction and Architecture

For structural components, cladding, and roofing applications where emphasis is laid on durability, and elegance, stainless steel is deployed in the applications of construction. It is used to construct bridges, monuments, and high-rises due to its excellent resistance to environmental conditions and maintenance requiring time. About 20% of stainless steel produced is said to be utilized in the building and construction industries.

- Automotive Industry

Being impervious to extreme heat and corrosion, stainless steel is used largely in vehicle exhausts, catalytic converters, and decorative trims. Advanced grades such as duplex stainless steels are therefore also employed in structural components of EVs to promote safety and weight efficiency. The automotive sector consumes about 10% of stainless steel worldwide.

- Healthcare and Medical Equipment

With an inert surface and ease in sterilization, stainless steel is ideal for instruments, surgical tools, and implantable devices in the medical field. It is further used in hospital furniture, MRI scanners, and implantable screws. Precipitation-hardening stainless steels are, in particular, highly regarded for their properties combining strength and biocompatibility.

- Food and Beverage Processing

Stainless steel, along with its hygienic qualities and resistance to acidic and alkaline food product substances, is used in dairy tanks, brewing equipment, and industrial kitchens. Its smooth surface prevents bacterial growth and lends itself to easier cleaning. About 35% of stainless steel consumption is attributed to this industry.

- Chemical and Petrochemical Industry

The chemical industry utilizes duplex stainless steel in the construction of tanks, pressure vessels, and pipelines. Its resistance to chlorides and acidic environments is its primary asset in aggressive chemical applications. Fertilizer production, caustic soda, and hydrocarbon processing facilities are the big players.

- Energy and Power Generation

Tools for Cutting Stainless Steel

- Angle Grinders

Equipped with high-grade abrasive discs, angle grinding can be a versatile and potent cutter of stainless steel sheets or rods.

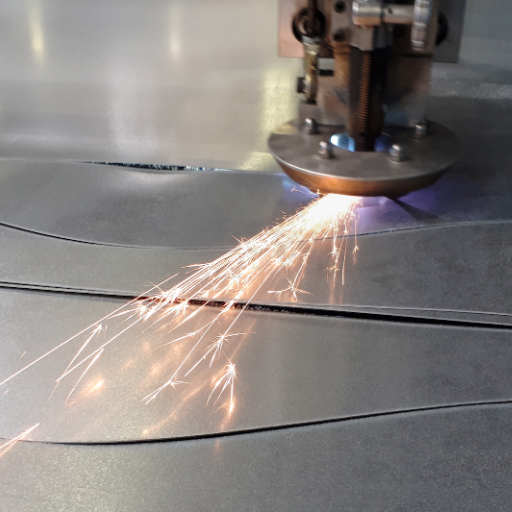

- Plasma Cutters

For speed and precision, plasma cutters will perform wonders on intricate pattern design or thick sections of stainless steel.

- Circular Saws with Carbide Blades

Band saws give fine cutting results using carbide-tipped blades made explicitly for stainless steel.

- Band Saws

Band saws fitted with bi-metal bands provide measure cutting on parts and are suitable for intricate shapes and large workpieces.

- Laser Cutters

Overview of Cutting Tools

The nature of stainless steel defines the tools that will cut it, so we have to determine different factors before cutting operations to fulfill precision and maximum efficiency. Hardness and thickness of the workpiece being cut largely influence the selection of a tool, as the harder types of stainless steel usually require stronger tools, such as carbide-tipped or bi-metal blades, which can stand more wear. Heat dissipation from the cutting zone is always an issue; stainless steel, with its low thermal conductivity, allows heat generation and causes distortion in the absence of a proper cooling method or tool setup.

To ensure top cutting output, speeds and feed rates pose a significant factor for the work involved. For example, low speeds normally do not allow tool overheating or unnecessary stresses on the material, whereas high-speed settings can be used to boost production levels, especially when advanced tools like a laser cutter are involved. Applying a good cutting fluid or lubricant is also required to reduce friction for easier cutting action. For artwork or project types that require blocking of burrs from a tool increase, unpacking on such tools will lessen time in post-treatment while preserving the material intact. These counteract tool selection with minor process adjustments to ensure the precision as well as the effectiveness of selected tools during the working of stainless steel.

Choosing the Right Tool for Different Thicknesses

When choosing tools to deal with stainless steel of varying thicknesses, a few critical factors should be addressed so as to achieve optimum tool performance and maintain material integrity. For thin sheets, fine-tooth saws or high-speed steel (HSS) blades with close-tooth spacing are suggested. These maintain clean edges with just a little danger of distortion or tearing.

For medium-thickness stainless steel, carbide-tipped blades or plasma cutters offer a good compromise between speed and accuracy, making them suitable for precision cuts with minimal wear on the equipment. Variable-speed controls for cutting machines can also be adjusted to change speed with the thickness of material for greater accuracy.

Heavy-duty means such as industrial plasma cutters, with adequate water flow and power rating, or high-frequency laser cutting systems, are preferred for deep penetration when working with thick stainless steel plates. This guarantees that the application is executed with several thermal resistances and adequate power to ensure good results in the hardest applications. It is good practice, especially during cutting, to use suitable cooling and/or lubrication systems to minimize heat and prevent warping of the material or degradation of the cutting tool.

Using Power Tools vs. Manual Tools

|

Parameter |

Power Tools |

Manual Tools |

|---|---|---|

|

Efficiency |

High, saves time and effort |

Lower, requires more physical labor |

|

Precision |

High, consistent accuracy |

Depends on user skill |

|

Portability |

Limited by power source dependency |

Highly portable |

|

Maintenance |

Requires frequent maintenance and care |

Low maintenance requirements |

|

Cost |

Higher initial investment |

Generally lower initial cost |

|

Skill Requirement |

Requires training for advanced usage |

Basic skills usually sufficient |

|

Versatility |

Suitable for specialized, complex tasks |

Ideal for simple tasks |

|

Energy Consumption |

Requires electricity or fuel |

No external energy required |

|

Safety |

Proper handling essential to avoid injuries |

Fewer safety risks but can strain physically |

|

Operational Speed |

Fast and efficient |

Slower, controlled manual effort |

Cutting Techniques for Stainless Steel

- Laser Cutting

Laser cutting can cut shapes with a very high degree of precision and is ideal for all intricate shapes. It is best for thin and medium-thick sheets of stainless steel and produces an edge that is both smooth and burr free.

- Plasma Cutting

Plasma cutting is the choice for thicker stainless steel plates that need to run fast. It, however, tends to leave rough edges that require finishing.

- Waterjet Cutting

A waterjet is a high-pressure stream of water mixed with an abrasive. It gives fine precision, and it never heats the material, so there’s no distortion.

- Mechanical Cutting

How to Cut Thin Stainless Steel Sheets

- Laser Cutting

Laser cutting is indeed among the most appropriate methods for this material. The use of modern CO2 or fiber lasers provides outstanding precision, especially for intricate designs or tight tolerances. Stainless steel thin sheets are perfectly reacting to laser cutting as the smaller the heat-affected zone, the lesser the distortion generated. Nitrogen-assisted gas application is popular with great results to keep the edge clean and free of oxides.

- Waterjet Cutting

Waterjet cutting is still considered the best for cutting thin stainless steel, for it does not entail risks of heat distortion. With the inclusion of abrasives in the waterjet stream, the power for cutting is increased, giving a smooth finish even to the most complicated patterns. This method is especially helpful where a great deal of precision is required and the integrity of the material must be maintained.

- Plasma Cutting

Generally, plasma cutters work primarily to cut thicker metals. Hence with adequate care and fine adjustment, these plasma cutters can be used for thin stainless steel. Thin sheets require low-amperage settings to lessen heat input. High-quality plasma cutters with fine-cut consumables are instrumental to ensure very little surface roughness during cutting.

- Shearing

- Manual Tools

Tin snips or metal cutting shears can be used for smaller scale projects. These are best for lighter gauge stainless steel cuts and require minimum assembly. The accuracy depends on the ability of the operator, and sometimes even after cutting, one might have to manually remove burrs from the edges.

- Rotary Tools or Dremels

Rotary tools have a great variety for cutting or shaping smaller sections with metal-cutting rotary bits. Although slower, such methods become necessary while carrying out finer details, as well as custom modifications.

Techniques for Cutting Thick Stainless Steel

- Plasma Cutting

Plasma cutters perform the best while working with thicker thicknesses of stainless steel. This is because an electrically conductive arc of plasma is generated that melts and cuts through the material almost instantaneously. They produce clean cuts and practically have no heat-affected zones, which makes it a preferred method for working with stainless steels on an industrial scale. In fact, a plasma cutter with higher amperage can deal with quite thicker gauges, sometimes even over 1 inch (25.4 mm).

- Water Jet Cutting

Water jet cutting refers to the production of an intense stream of water, mixed with abrasives, which cut metals with great precision, producing edges that are smooth, with no heat being introduced, which can compromise the steel’s structural integrity. This kind of processing gains more advantage when working with thick stainless steel as it avoids thermal distortions – most important for precision engineering applications.

- Oxy-Fuel Cutting with Special Additives

Oxy-fuel cutting for stainless steel is, in general, not suitable, primarily due to the chromium oxide layer on stainless steel. Yet, the inclusion of iron powder additives can enable a cutting action. This type of cutting is less costly for thick stainless steel, yet one has to have competent operators, and it tends to be less accurate than plasma or water-jet cutting.

- Laser Cutting with Higher Wattage

Highly advanced, high-wattage laser-cutting systems cut thick stainless steel at high levels of accuracy. Being a melting and vaporization process, the method leaves clean and precise edges but mostly just less-thick gauges compared to plasma or water jet cutting. Also, the method requires a strictly controlled working environment.

- Mechanical Sawing

Using Saws vs. Grinders for Cutting Stainless Steel

|

Criteria |

Saws |

Grinders |

|---|---|---|

|

Cutting Speed |

Moderate, dependent on blade type |

Fast, efficient for quick cuts |

|

Precision |

High with proper blade |

Moderate, may require added stabilization |

|

Material Thickness |

Effective for thick stainless steel |

Works for moderate to thin materials |

|

Edge Finish |

Clean cuts with less burrs |

Rougher edges, burrs may require removal |

|

Tool Wear |

Blades last longer with proper use |

Discs wear faster and require replacement |

|

Flexibility |

Limited to straight or fixed-angle cuts |

Highly flexible, suitable for curved lines |

|

Noise Level |

Lower compared to grinders |

Noisy, may require hearing protection |

|

Dust and Sparks |

Minimal dust, no sparks |

Produces both dust and sparks |

|

Skill Requirement |

Moderate skill for accurate cutting |

Moderate to high for controlled operation |

|

Portability |

Less portable, often requires stable setup |

Highly portable, handheld operation |

Safety Measures When Cutting Stainless Steel

- Wear Appropriate Personal Protective Equipment (PPE): Always put on your safety glasses to save wayward sparks and debris. Using gloves will protect your hands from heat and also from the loudness, depending on the tools being used.

- Ensure Proper Ventilation: The cutting process of stainless steel produces fine dust particles. If possible, use the system that has dust extraction to cut on its own or assure a good ventilation environment to minimize inhalation.

- Secure the Material: Stabilize the stainless steel using clamps to avoid it from moving when being cut; this will guarantee a precise and safe operation.

- Inspect and Maintain Tools: Keep the tools checked by any wear, and always make sure that they are in good working condition. Not to use damaged or blunt tools so as to minimize the risk of accidents.

- Avoid Excessive Heat: Cutting of stainless steel generated excess heat which can damage either the material or the tools. Use a cooling method to cool the cutting activities or stop periodically and apply cutting fluids when necessary.

- Adhere to Manufacturer Guidelines: Follow the instructions for safe use and operation given by the manufacturer for best results and safety.

Personal Protective Equipment (PPE)

Proper usage of Personal Protective Equipment (PPE) really is vital for safety and worker compliance concerning occupational standards when cutting stainless steel. Some important PPE includes the following:

- Safety Glasses or Goggles: Prevent lens from metal shards, sparks, and debris from injuring one’s eyes in the cutting operations. One should use assumed impact-resistant ANSI-approved eyewear.

- Protective Gloves: Heat-resistant gloves hold the ability to protect the hand from temperature burns developed in the cutting process. Cut-resistant gloves present an additional level of safety while handling sharp edges.

- Hearing Protection: The power tool for noise generation has an intensity of above 85 dB while cutting stainless steel, which may damage one’s ears. The operators must use industrial-rated earplugs or earmuffs.

- Respiratory Protection: Cutting processes such as grinding or welding can release harmful particulates and fumes. The respirator selected should have a proper filter like N95 or P100 to protect one from inhalation hazards.

- Flame-Resistant Clothing: Sparks from the cutting of stainless steel will ignite any flammable material. Thus, flame-resistant overalls or long-sleeved clothing will greatly reduce the risk of such burns and injuries.

- Steel-Toe Safety Boots: Protecting the feet from an occasion of things dropping on them, especially in an area where there are heavy materials or tools.

In correct use, PPE equipment decreases the risk of any workplace injury or accident and also meets regulatory standards to further promote efficient and safe working conditions.

Safe Handling Practices

The very foundation of working safely in the workplace requires good handling of stainless steel material or heavy tools. In general, materials should always be stacked securely and orderly to preclude any accidental shifting or falling, both of which may cause injury or equipment damage. In instances when workers are lifting heavy objects, proper lifting techniques should be employed; bending at the knees and using the legs to carry the load, as opposed to using the back, which only exacerbates the risk of musculoskeletal injuries.

Expert Tips for Cutting Stainless Steel

- Use the Appropriate Tools

Pick the cutting tools that are specially designed for steel cutting, like a plasma cutter, an angle grinder with a cutting wheel, and a bandsaw blade specifically for stainless steel. Such tools are designed to be able to punish a steel material.

- Ensure Proper Cooling

By use of coolant-lubricants, or sometimes by a spray of water, we want to develop a ‘cool’ culture during cutting, hoping that it will prevent material warping or damage to the tool.

- Secure the Material

Clamp the stainless steel to the workstation very firmly, keeping vibrations down and preventing accuracy eroding or tool wear.

- Work at the Correct Speeds

Wear the tools at the speed listed in the manual or brochure. This consideration helps develop lower temperatures for better cutting. Never apply heavy pressure on the tool as it will harm the material and tool.

- Maintain Blade Sharpness

Use sharp blades or cutting edges, and replace dull ones. Dull tools generate friction, excessive heat and give lesser accuracy.

- Follow Safety Protocols

Safety goggles and gloves are wearable along with hearing protection. A number of hazards, such as flying debris or sharp edges, may be created from the process of cutting stainless steel, so it is crucial to practice using good safety gear.

Avoiding Common Mistakes

- Neglecting Material Compatibility

Tools rated for specific materials will either struggle or outright refuse to work on incompatible substrates. Blades that are not rated stainless steel may provide an uneven cut and wear the tool prematurely. Always check what a tool is rated for and be sure of the compatibility.

- Applying Excessive Force

Increased force may result in deformation of the material being plated, premature wear of the cutting tool, or even outright destruction of the cutting machine. The art of precision cutting lies in using sharp tools, the correct settings, and steady feed rates-the opposite of brute force.

- Overlooking Cooling and Lubrication

High-friction cutting processes generate a lot of heat that reduces accuracy during cutting and might cause warping of the material or damage to the blade. Cooling systems or cutting fluids need to be employed in their applications to maintain an ideal temperature and extend the life of the tool.

- Ignoring Equipment Maintenance

Poor maintenance of tools or machinery will result in inaccuracies in operation, malfunctions, and alerting one to hazardous conditions. Detect signs of wear during inspection, perform maintenance as necessary, and verify proper calibration of cutting equipment.

- Skipping Trial Cuts

Without doing test cuts on the scrap material, errors may occur that would spoil the entire workpiece. A quick trial cut allows adjustment for tool settings, blade speed, or technique prior to the final cut on the actual material.

Maintenance of Cutting Tools

Reference Sources

1. Abrasive Water Jet Cutting Process of Stainless Steel

- Key Findings: The study analyzed the effects of cutting speed on surface roughness in abrasive water jet cutting of stainless steel. It was found that lower cutting speeds improved surface quality, especially in the lower zones of the cut. The process capability index (PCI) was used to evaluate the quality of the cut.

2. Energy Consumption in Turning Hardened Stainless Steel

- Key Findings: The study proposed using resultant cutting force to calculate energy consumption during the turning of hardened stainless steel. It highlighted that higher cutting speeds and feeds reduced energy consumption while maintaining low surface roughness and tool wear.

3. Thrust Forces in Drilling AISI 316 Stainless Steel

- Key Findings: Cryogenically treated drills significantly reduced thrust forces compared to conventionally treated drills. Artificial Neural Networks (ANNs) and regression models accurately predicted thrust forces based on cutting parameters.

Frequently Asked Questions (FAQs)

Q: What tools are best for cutting stainless steel?

A: When it comes to cutting stainless steel, the right tools are essential. A circular saw equipped with a metal cutting blade is ideal for straight cuts, especially in sheet metal. For thinner stainless steel sheets, a diamond saw blade or cutting disc can be very effective. If you’re cutting stainless steel pipes or rods, a band saw or a miter saw designed for stainless can work well. In addition, using cutting oil can help to lubricate the blade and ensure a clean cut, preventing damage to the material.

Q: How can I cut thin stainless steel sheets?

A: Cutting thin stainless steel sheets can be done effectively using several methods. A high-speed circular saw with a fine-toothed blade is one way to cut thin stainless steel quickly and accurately. Alternatively, using a hand-held angle grinder with an appropriate cutting disc can achieve similar results. It’s important to maintain a steady hand to ensure a straight cut line. If you’re looking for a more manual approach, metal snips can also be used for thinner stainless, but this method may require more effort.

Q: What are the cutting techniques for stainless steel?

A: There are various cutting techniques that can be employed for stainless steel, depending on its thickness and the desired precision. For thicker stainless steel, using a plasma cutter or laser cutter is recommended as they can cut through without damaging the material. For sheet metal, a table saw with a blade specifically designed for cutting metal can provide clean cuts. When dealing with stainless steel rods, a band saw is a popular choice. Always ensure you are using the right blade and techniques to prevent any heat buildup that can affect the integrity of the steel.

Q: Can I use an angle grinder to cut stainless steel?

A: Yes, an angle grinder can be effectively used to cut stainless steel, especially for small projects or pieces of stainless steel that are hard to cut with traditional saws. It is crucial to use a cutting disc that is designed for stainless steel to achieve the best results. This tool can quickly cut through various thicknesses of stainless steel, whether it’s in sheet form or as rods. However, caution should be taken to avoid overheating the material, which can lead to warping or damage.

Q: What are the best practices when cutting stainless steel?

A: To achieve the best results when cutting stainless steel, follow several best practices. Always ensure you are using the right blade or disc designed for cutting stainless steel, as this will minimize wear and tear. It’s advisable to apply cutting oil to lubricate the blade and keep the cut line cool. A steady hand and careful measurement are essential to maintain accuracy, especially when cutting longer pieces of stainless steel. Additionally, using clamps to secure the material can prevent movement and ensure a clean cut.