If we take stainless steel, for instance, there is hardly a domain wide enough where this material is not usable. For instance, in building and even in medicine, this material can be found everywhere. But have you ever been curious about the intricate processes that occur when creating stainless steel? This review presents a comprehensive overview of stainless steel production, encompassing every step from obtaining the raw materials to the final polished product, which is unarguably equivalent to other types of metals due to its corrosion resistance. As we do this, we shall attempt to disentangle the jargon enveloping the ergonomic literature at the time-trade off and other economic, sociopolitical, or sociotechnical archetypes. Whether you belong to the technical field or not, whether you just want to know about the manufacturing of such a unique material, this text will help you understand how it should be.

Raw Materials for Stainless Steel Production

The process of stainless steel manufacturing commences by blending essential raw materials in specific proportions for the desired properties of the final product. These essential components are:

- Iron Ore – The core component and primary source of iron for stainless steel manufacturing.

- Chromium – A critical element used to provide corrosion resistance and make the steel “stainless.”

- Nickel – Enhances the material’s strength, toughness, and heat resistance.

- Carbon – Used in controlled amounts to improve hardness and strength.

- Molybdenum – Added to increase resistance to pitting and improve durability in harsher environments.

- Silicon and Manganese – Assist in the deoxidation process and improve strength and hardness.

- Recycled Scrap Metal – An eco-friendly, cost-effective way to reduce waste and provide a significant portion of the raw input material.

These materials are carefully measured and put together according to the specific grade and features of the stainless steel in production, a procedure that is of great help in the attainment of the same quality and proper running of the metal in the end.

Importance of Quality and Composition

The mechanical properties and behavior of stainless steel, including its corrosion resistance, are associated with the composition of its surface. Manufacturers are capable of producing stainless steels that meet the exacting standards and requirements of the industry through the intelligent use of alloying contents and through established production practices. For example, increasing the amount of chromium increases the corrosion resistance, making it suitable for such environments as in marine, medical, and manufacturing, whereas with nitrogen ,increasing the resistance to pitting and tensile strength.

Compare Common Raw Materials Used

| Raw Material | Characteristics | Applications | Key Properties |

|---|---|---|---|

| Iron Ore | Primary source of iron extraction | Steel production, alloy manufacturing | High strength, malleable |

| Chromium | Adds corrosion resistance | Stainless steel, coatings | Hard, corrosion-resistant |

| Nickel | Enhances ductility and toughness | Stainless steel, superalloys | Heat and corrosion resistance |

| Carbon | Strengthens iron for steel creation | Construction, tools, machinery | Improves hardness and strength |

| Manganese | Improves toughness and wear resistance | Steel alloys, batteries | Deoxidizer, enhances durability |

| Silicon | Acts as a deoxidizing agent | Ferrosilicon, electronic components | Thermal and electrical resistant |

| Molybdenum | Enhances high-temperature strength | Aircraft parts, energy industry | Withstands heat, tough |

| Vanadium | Improves steel wear resistance | Tools, automotive parts | High tensile strength, durable |

| Tungsten | Adds heat resistance and weight | Cutting tools, military applications | Extremely dense, temperature-stable |

| Aluminum | Reduces weight, corrosion-resistant | Aerospace, construction materials | Lightweight, non-corrosive |

| Copper | Provides excellent electrical conductivity | Electrical wiring, heat exchangers | Ductile, conductive |

Melting and Casting Techniques

Steel division into mats and quality improvements of the steel before using it. At the first stage, the raw material, comprising, among other ingredients waste steel material attracting high temperatures, is melted in suitable raw material melting equipment, an electric arc furnace (EAF). Strict measures are also in place to ensure that the as-recycled waste steel used is of no less a quality than the others. This is followed by the pouring of the molten and refined stainless steel into molds which have been supplied and connected to the EAF by a known sequence of operations. The molten metal in these ingots and slabs is molded into a shape that the metal is needed for in lightweight steel applications during the hours of the day. These shapes are fundamental for further processing, such as rolling or forging processes, to meet the drawing and property requirements necessary for specific industrial applications.

Electric Arc Furnaces Explained

An electric arc furnace (EAF) works by heating scrap metal or metallic ore using an electric source to create steel. This process begins with the loading of standard scrap steel or hot-briquetted iron (HBI) into the furnace. The chamber contains carbon and/or graphite electrodes that create very high localized temperatures by conducting electricity through narrow arcs that are intended for melting above 3000°F (1650°C). In modern times, induction furnaces are designed to be highly versatile, catering to various materials with the goal of minimizing waste through increased energy efficiency.

These electric arc furnaces are also known as primary steel recycling methods, with a focus on scrap utilization by eliminating the traditional iron primary input. Moreover, these furnaces can, by and large, save 60-70% of heat energy compared to other steel making furnaces. This has a significant advantage in reducing carbon emissions from industry.

The most important technological developments over these recent years can be linked to introducing strategies related to designing and/or improving processes, including systems for control of these processes. This is particularly important activity in the context of the prevailing technocratic perceptions of intelligence. Electric arc furnaces are especially effective in the field of steel production, offering pollution-free operations, both economically and ecologically, provided certain modern technological provisions have been implemented.

Alternative Melting Methods

Non-electric arc furnace (EAF) alternative melting approaches are garnering considerable attention due to the benefits associated with energy conservation and environmental friendliness. One of the methods that has been adopted for usage in the global steel manufacturing era is Induction Furnace Technology. This technology uses electromagnetic energy waves to generate heat source making it unnecessary to burn raw materials. This helps reduce greenhouse gas emissions. Melting by electric induction is particularly effective for treating high-alloy metals in terms of precision in temperature and contamination level.

An equally topical example of advanced engineering technology is Plasma Arc Melting, which utilizes extremely high temperatures generated by ionized gas (plasma) to melt various types of metals. The advantage of this technology is in view of the ineffective recycling of largely impure metals in particular. Furthermore, it is clear that the primary objective of global decarbonisation, as stated in state objectives, is to achieve zero carbon emissions across every city. To address this, hydrogen plasma reduction processes will be implemented to replace conventional carbon reduction techniques in steel industry sensors, thereby rectifying the situation. Additionally, in relation to this, Hydrogen Plasma Reduction is said to hold the potential of achieving a greatly reduced or zero emission CO2 protocol inside the steel industry.

Casting Processes in Steel Mills

For producing high-quality steel, production routes containing casting processes are vital in order to enable the pouring of the molten metal into a solidified semi-finished product such as billet, slab, bloom, etc., which is then processed to give finished steel. The most prominent method nowadays is continuous casting, which has almost completely replaced the previous method of ingot casting due to its superior production efficiency and higher product quality. This technique primarily involves pouring molten steel into a water-cooled mold and then allowing it to cool as it progresses through the system. In the meantime, the steel is extracted from the mold and post-loaded with the liquefied steel, thereby providing continuous production. This method also enables the cutting down of production losses and time and thereby helps in ensuring even the last product in corrosion uniformity of its metallurgical structure. Such management is particularly effective in achieving the best results and solutions in the system of technical-process parameters and subjacent equipment functioning mainly thanks to the state-of-the-art automated and process control systems.

Forming Processes in Stainless Steel Manufacturing

Rolling

It is universally known that rolling is one of the most effective ways used to sanitize stainless steel. It is the method by which stainless steel is passed through heavy sheet rolling mills to produce flat sheets, strips, or other shapes. This method can be applied at various stages of the process. Hot rolling aims to increase ductility and control shape, whereas cold rolling focuses on surface finish and strength. Both of them are important for producing materials applicable to various industrial fields.

Forging

Hammering is the deformation process in which the stainless steel is reshaped under compressive forces. The main features of this process are the strengthening of the product, as well as the grain refining of the material. In the future, most high emphasis applications like the aviation industry, oil and gas, and the automobile industry will adopt imaginative thickenings of stainless steel that have been forged in their construction.

Extrusion

Extrusion involves plunging naval brass with a fixed cross-section, e.g., pipes or I-beams, through a die. It is especially useful in elaborated shapes and shows very precise results. It is usually applied in the manufacture of the parts research needed in construction and technology.

Drawing

Drawing is a technique typically applied in the production of metal wires, tubes and sticks by means of pulling metal through a specific drawplate. Developed for micrometry and repetitiveness, it is often utilized for building the materials necessary in industries such as medical and electronics and communication.

Hot Rolling Techniques

In metalworking, hot rolling is a technique used to roll iron or steel products or any other metal product, over and over again when the metal is hot, i.e., in temperatures exceeding its recrystallization point, in the neighborhood of 1100 and 1250 degrees Fahrenheit. Such temperature has an effect on the metal, and the latter becomes weaker, thus resulting in its ease of workability, with little or no work hardening taking place. There is a great advantage of this process when one needs large quantities of uniform metal sheets, plates, or even ship sections manufactured. Many recent developments in the hot rolling processes include the introduction of computer-aided systems and devices in order to incorporate automatic rolling control, thereby raising working speed, reducing per-ton material cost, and improving the attained surface quality of the product. The design of the latest hot rolling mills has also included multiposition temperature control instruments, which make it possible to control programmed as well as real phase changes, leading to a consistent distribution of grain boundaries. This has indicated that hot rolling is an inevitable technique within such industries as automotive, shipbuilding, and civil engineering, where high strength as well as cost effectiveness are the dominant drivers.

Cold Rolling Techniques

Cold rolling is the most important process used in metal processing that is carried out at or near ambient temperatures to guarantee high dimensional cleanliness, high state of stress (small residual stress), high surface or great coefficients of friction and limited mechanical properties. Unlike hot rolling, it is unwinding that does not allow for a temperature high enough so the effect of re-crystallization softens the material by removing the strain and leaving only the cold work in place. It is normal for the material to be compressed and thinned more than once in sections of a motive rolling mill with each stand in the train squeezing the section smaller than the previous one. Widespread advancements in rolling mills for cold rolling, like automated thickness control systems, in-line ultrasonic flaw detectors, and adaptive control systems, have tremendously increased the productivity and quality of the rolling process. Further, lubrication and cooling systems play a significant role in the cold rolling process by minimizing friction and heat, thereby sustaining dimensional precision and preventing the work piece from heat damage. The cold rolling process is highly accurate, with tight dimensional tolerances and excellent surface finishes, making cold-rolled steel ideal for electronics, automotive, and precision engineering products.

Other Forming Processes

In addition to the cold rolling process, a variety of fabrication procedures are typically employed in various sectors, not limited to achieving predetermined state-of-the-art performances. In particular, hot working is a process in which metals are formed at elevated temperatures to improve their toughness or to control their residual stress after cold working. This technique is most suited for the production of larger components or intermediate products of foundry nature. One more metalworking method, where the metal is squeezed out of a die in order to produce objects with a uniform cross-section, is called extrusion. Extrusion is an advanced process that is best suited for the tough complex shapes and quality appearing components of aviation and construction material. Analogously, forging changes the form through putting the metal under pressure, ensuring high strength as well as wear resistance that is ideal for the robust components such as gears, shafts and con rods.

Heat Treatment in Stainless Steel Production

The technique of heat treatment is the most important in the steel production process, as it affects and improves the properties, resistance, and strength of the metal. Such heat vision techniques can be divided into the following parts: annealing, hardening, and tempering. Annealing of such steels is performed by heating to a particular temperature and thereafter chilling very slowly, which results in repairing faults and increasing ductility. Hardening, on the other hand, is performed with the aim of increasing the strength of the steel, and cooling is very fast, generally using either water or oil as coolants. The last process, that is, tempering, changes the hardness or strength of the steel by reheating it to a lower temperature, immediately after it was hardened. These operations are maintained under strict control in the course of background treatment to achieve the required objectives in the industrial implementation of stainless steel.

Role of Heat Treatment

One of the most important undertakings in the field of metal science is the heat treatment process. This is particularly critical with stainless steel. The engineers can manipulate the microstructure of the material to suit the desired end state effectively by controlling the variables such as temperature, rate of heating, cooling technique and duration. For instance, it is inevitable that the process of annealing enhances ductility and relieves stresses to a level that ensures the material can undergo deformation without fracturing at the point of fabrication. On the other hand, hardening through quenching forms a martensitic structure that enables the rise in mechanical strength and wear resistance of the steel.

Progresses in recent times in heat treatment technology highlight the importance of computational modeling and automation in optimizing parameters. Manufacturers can enhance their energy savings and reduce carbon emissions by utilizing these systems to maintain uniform mechanical properties in the heat-treated object. Additionally, several studies have demonstrated the importance of alloying elements and heat treatment conditions for carburizing, as the levels of carbon and exposure to oxidizing gases can significantly impact the effectiveness of the procedure. What cements this approach even more is that such accuracy is very essential, making heat treatment the basis of production of high functional materials like alloys in all sectors of the economy, including but not limited to aviation and motor-vehicle segment.

Achieving Desired Mechanical Properties

Perfecting the mechanical characteristics of a substance requires a split second of processing coupled with the right environmental conditions to match. More specifically, tempering, quenching, and annealing are some of the environmental aspects that are controlled heavily so as to give a defined level of hardness, strength, and ductility of the materials in concern. For example, quenching is a technique that employs a rapid rate of cooling, often using cooling media such as oil, water, and air to maintain the microstructure in a HARDENED state. This is often followed by tempering, a process that suppresses brittleness and provides a harmonious blend of both strength and ductility.

In recent literature on materials properly, it can be noted that the property of the finally treated material, such as wear resistance and surface treatment, can be significantly improved through the modification of the chemical composition, in particular, the inclusion of specific alloying elements such as manganese, chromium, and molybdenum. Furthermore, novel models and real-time process control of heat treatment processes have been implemented such that engineers can model and adjust their designs with more accuracy than was previously possible. This ensures that different materials comply with the strict requirements of various available applications today, especially accomplishment of works in extreme conditions, such as when serving in building, aircraft, and energy sectors, etc.

Different Heat Treatment Methods

| Heat Treatment Method | Description | Key Parameters | Applications |

|---|---|---|---|

| Annealing | Softens material, improves ductility. | Temperature, cooling rate | Metal forming, machining |

| Normalizing | Refines grain structure, enhances toughness. | Heating above critical temp. | Structural components, automotive |

| Hardening | Increases strength and hardness. | Quenching medium, high heating | Cutting tools, heavy machinery |

| Tempering | Reduces brittleness after hardening. | Tempering temperature, duration | Springs, shafts |

| Case Hardening | Hardens surface, keeps core soft. | Carbon/nitrogen additives, depth | Gears, bearings |

| Quenching | Rapid cooling to fix structure. | Cooling medium, speed | Engine parts, knives |

| Stress Relieving | Reduces residual stresses. | Controlled heating and cooling | Welded structures, cast components |

| Precipitation Hardening | Improves strength via fine particles. | Aging temperature, time | Aerospace, power turbines |

| Induction Hardening | Surface hardening with electromagnetic fields. | Frequency, power density | Shafts, gear teeth |

| Cryogenic Treatment | Enhances wear resistance and durability. | Subzero temperature, duration | Tools, high-performance parts |

Finishing Processes for Stainless Steel

Different operations like grinding, polishing, shot blasting, and so on, are also basic in the fabrication of stainless steel components, and their roughness, surface finish, and visual appeal are a recognition of certain applications. There are various ways to obtain a perfect finish on stainless steel, But some of the most popular are:

- Polishing: Enhances the smoothness of the surface and overall appearance of the stainless steel in a manner that helps in reducing surface corrosion in crevices. This is often done using abrasives such as varying grit sizes.

- Passivation: Used to remove any traces of paint, oil, or other foreign materials from stainless steel. Additionally, the stainless steel is said to be passive, meaning some impurities or defects have been removed. It can also involve chemical treatments like citric acid or nitric acid passivation.

- Electropolishing: Electrolysis, otherwise labelled as electropolishing, is a technique which incorporates an electrochemical approach at microscopic level to qualify and remove materials on a surface to ensure a cleaner, less corrosive and more appealing surface.

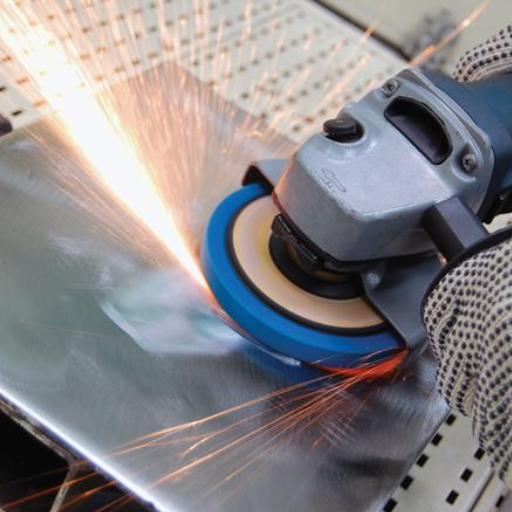

- Grinding: Eliminate the surface defects, joints of the weld and the traces of gas cutting. It can also be a rough finish before the detailed finishing of the workpiece.

- Bead Blasting: This is also known as precision blasting, which is used to increase the surface texture grades in all areas on which cleanliness is required while maintaining the appearance of steel and resisting electrolyte corrosion.

Most of the time, the specific characteristic that defines the stainless steel and affects the selection of the process is the ease between functions and after finishing.

Surface Treatments for Durability

Making sure that stainless steel lasts long, involves the use of innovative measures such as advanced surface treatments that increase the strength and life of stainless steel in challenging conditions. The most widely used of these advanced treatment methods are passivation, electropolishing, and physical vapor deposition (PVD) processing, each providing certain benefits:

- Passivation: An effective procedure that rubs off all the unwanted iron impurities and other contaminations off the steel’s top coat in a measured way to create a strong enough layer of chromium oxide. This transparent layer is called a passive film and it significantly increases its resistance level against corrosion, especially in difficult environments such as sea or industrial.

- Electropolishing: Considered mostly as a controlled surface treatment process in that it polishes away a uniform surface thickness of material in order to eliminate wave like underwater crater-like structures or contamination. Thus the remodeled surface becomes so shiny and less rough meaning there will be reduced friction while still controlling corrosion and bacterial activities.

- Physical Vapor Deposition (PVD): The conception of Physical Vapor Deposition (PVD) is an innovative, advanced coating technique where a thin layer of hard material is deposited on the stainless steel surface. As a result, PVD is known for providing scratch and wear resistance features as well as the ability to increase the resistance of steel to heat and chemicals depending on the type of coating put on.

When these treatments are not wrongly practiced, they give services for a longer life of the stainless steel products with minimum conformity to the accepted, another important aspect of which is performance and dependence of engineering structures. It is one of the biggest concerns in the design and use of aircraft, medical equipment, and food because of the need to ensure the sterility and structural reliability of materials in these sectors.

Aesthetic Finishing Techniques

Aesthetic finishes such as brushing and debossing in stainless steel seek to increase the aesthetic appeal of the surface and its touch impression to meet the needs of the different sectors. Such finishes consist of mechanical finishes like polishing and brushing which are commonly employed to give a decorative aspect to the surface while at the same time ensuring an additional benefit. For the facades and interiors, for example, untiring fingering and scratching of the finish can spoil the effectuation of the other surfaces; you will require brushed finishes or antispatter agents.

Moreover, specialized processes like e-polishing provide microscopic polishing of material after which the shining and mirror-like surface obtains properties that are rust-proof. Techniques of finishing and coloring, like, for example, PVD (physical vapor deposition) coating, provide an opportunity to paint stainless steel in vivid colors which are protected against most factors undermining the existing advantages of the metal – strength and wear resistance. Careful selection of every coating system is carried out in such a way that each method of tiling and grouting complies with the strict criteria set for the specific uses of the finishes.

Reference Sources

1. Influence of Cryorolling on Properties of L-PBF 316L Stainless Steel

- Key Findings:

- Laser Powder Bed Fusion (L-PBF) technology was used to produce 316L stainless steel, followed by cryorolling and heat treatment.

- Cryorolling at cryogenic temperatures (77K) significantly enhanced the mechanical properties, including yield strength and tensile strength, compared to ambient rolling.

2. Thermal Treatment of Stainless Steel Dusts for Leaching

- Key Findings:

- Stainless steel production generates flue dusts containing zinc, which is challenging to recycle due to the presence of zinc ferrites.

- Thermal treatment with sodium hydroxide (NaOH) and potassium hydroxide (KOH) improved zinc recovery in acid leaching, achieving up to 91% recovery for certain dust samples.

Frequently Asked Questions (FAQs)

Q: What is the actual process to manufacture stainless steel and its corrosion resistance?

A: Many operations take place in manufacturing stainless steel, for example, melting, pouring, and forming. First, the raw material is loaded into an electric arc furnace, which may or may not contain Argon gas to enhance melting. The metal, having been melted, is then poured into molds to form ingots, which are subjected to rolling at high temperatures to acquire the final shape. The corrosion resistance of stainless steel occurs mainly because of the chromium which helps in forming an oxide layer called the barrier, a chemically inert surface blocking oxide film. According to this, different grades of stainless steel have different proportions of the protective elements against corrosion and rust, such as austenitic and ferritic stainless steel.

Q: How stainless steel created to grade wise?

A: Stainless steel manufacturing is a compound process of making the alloy. It is achieved by controlling the carbon content and the presence of any other alloying element of the primary alloy at the time of melting; for example, in the making of steel plates more attention is given to chromium and nickel, while in the production of grade 316 steel type molybdenum is added for better corrosion resistance. The process of developing this product also includes a step of annealing which facilitates the manipulation of the surface. Each modified alloy has properties by which it is classified for a particular end-use thereby guaranteeing the production of good products meeting industry standards.

Q: What types of stainless steel are produced in steel mills?

A: There are quite a few types of stainless steel that are produced in steel mills. Some materials include austenitic, ferretic, and duplex stainless steel grades. Chromium and nickel are just 2 elements used to make alloys. Austenitic stainless steel such as 304 and 316 stainless steel is very particular about being rust corrosion-resistant and thus has found preferred use in the food and chemical industry. Ferritic stainless steel, which contains some nickel, is used in such applications as automobiles. And, in addition, duplex stainless steel is a high strength stainless steel that yields the advantages of both austenitic and ferritic stainless steels especially in regards to pitting corrosion resistance. The authors say that a whole series of stainless steels is developed and specially produced on the basis of its specific properties for each industrial application.

Q: What are the impacts of manufacturing on stainless steel properties?

A: Stainless steel and its intrinsic composition are enormously affected by the manufacturing procedure. Expressed as an equation, the quality of stainless steel greatly depends upon its strength, stress change, hardness, ductility and corrosion resistance depending on the use of the material. For instance, the pipeline shooting is produced as sheets, which are then subjected to heating prior to rolling to assist in the provision of the materials into deeper corners. Since annealing does make its microstructure finer, the materials show better mechanical characteristics when elongated and subjected to lower strain. The recrystallization effect whose temperature occurs in a material is dependent upon the internal stress calculated through apparent strain or true strains. Its process of manufacture when unchanging could greatly cause a variation on the product; thus, stamping where each operation is controlled must not be skipped or hastened by a manufacturer during production.