Galvanized steel coils are crucial parts of galvanized steel strips and galvanized steel sheets in construction work, used in building ships and in creating appliances over other uses. It is highly valued because It is remarkably bestowed with enduring value, voracious versatility and resistance to corrosion. Whether possessing a building or operating in the automotive industry or in the world of pre fabricating tools, using reputable galvanized steel coils will change the quality of your works for the better and have a positive impact on their strength and durability. However, galvanized steel manufacturers can be exceptionally difficult to locate for your unique and separate requirements because of the overwhelming options available in the international market. This article aims to highlight some of the key considerations to take into account while getting a supplier for galvanized steel coils, point out the main challengers, and explain what sets them apart from the rest. By the end, you will have all the rounded information needed to make an educated decision that meets project needs and desired quality standards.

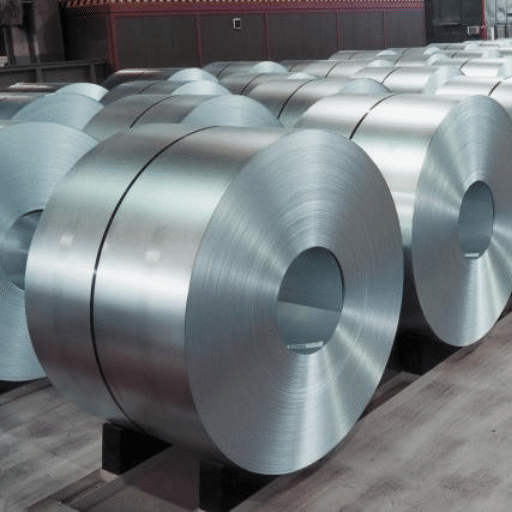

What is a Galvanized Steel Coil?

A galvanized steel coil is a steel sheet which is dipped into molten zinc or treated with the help of a direct current to coat it with a layer of zinc, protecting it from getting corroded and rusted. The raw steel is further galvanized, meaning dipped into slurry. Then, the newly formed zink layer acts as a barrier and an additional bolster against wear and tear as well as bad weather conditions for the steel. These steel coils are used all over for construction, in automobiles, and for industrial works as it is strong and last a long time even with bad treatment.

Understanding the Coating Process

One of the best ways to add a zinc coating to the surface of steel is through hot dip galvanization. The first step in hot dip galvanization is absolute surface cleaning. It consists of rinsing, degreasing, and pickling with acids to form a rust and oil free surface. After cleaning, the steel is suspended in an over 840°F acid bath before they are submerged for a chemical reaction with zinc. After zinc immersion, steel undergoes metallurgical reactions that form intermetallic compounds bound tightly to zinc.

Benefits of Galvanized Steel Coils

Sprayed galvanized, or simply galvanized steel coils, have a lot of useful characteristics of practical and economic importance for different fields of work due to the fact that it is strong, flexible, and durable. The greatest features of hot pre-galvanised steel is the zinc layer, which prevents the coil from rusting and acts as armor for the steel. This phenomenal protection greatly increases the lifespan of the steel, and lowers maintenance and repairs that would otherwise be required more frequently in hostile environments, like construction batons or infrastructure constantly in contact with the sea.

Moreover, the versatile applicability of galvanized steel coils like in construction, agricultural equipment, and automobile manufacturing makes it highly valuable. The coils provide strong structural integrity making them maintain impressive longevity while requiring minimal upkeep. This will help cuts down costs in the long run. Sustainability is also promoted as the zinc coating improves recyclability. In addition, modern galvanization methods improves precision in coating thickness which guarantees quality and reliability in performance across different industries.

Applications of Galvanized Steel Coil

In addition, The galvanized steel coil is widely used in fencing, irrigation and silo manufacturing, aiding in the construction for harsh conditions. Indeed, galvanized coils and galvanized strips are extremely helpful for a multitude of industries because they offer effortless pre-fabrication and inexpensiveness. One such demand is in the construction industry where their uses extend to roofing, siding and structural frameworks. Along with aiding in the aesthetic appeal, the zinc coating guarantees long lasting protection from wear and tear. Also, the versatility of the material makes it useful for use in residential as well as commercial infrastructure.

Furthermore, It plays a crucial role in the advancement of silos, fencing and irrigation equipment by serving as the most favorable material due to the extreme conditions. It is predominantly utilized by border protecting companies where the maintenance of territory is crucial. Most importantly, in the automotive industry, its role is remarkably breathtaking providing protection against rust while integrally holding the overall protection of the vehicle walls. Keeping in mind the customer satisfaction, the galvanized steel coil also significantly contributes by improving body cupping.

Developments within the past few years have increased the application of galvanized steel coil in the energy sector, especially in renewable energy where it is used in components of wind turbines and solar panel mounting systems. Such use guarantees the durability of equipment subjected to rigorous outdoor conditions. The adaptability and dependability of galvanized steel coil makes it a critical material within these primary sectors.

How to Choose a Reliable Galvanized Steel Coil Manufacturer?

- Quality Standards

Verify the manufacturer’s compliance with recognized quality standards like ISO certifications or ASTM specifications. Industry galvanized steel coils of high quality should display an even coating as well as high durability.

- Reputation and Experience

Check the manufacturer’s reviews and reputation history within the industry. Companies with a long-standing reputation usually class turn out positive products and service.

- Custom Capabilities

Look for a manufacturer who can meet your technical specifications, such as particular sizes and coating thicknesses, and can meet your appropriately tailored requirements.

- Delivery and Supply Chain Reliability

Check if the manufacturer has proven to consistently meet deadlines for large or repeat orders. Strong logistics and distribution networks are equally as important.

- Customer Support

Look for a company that offers the best response times for customer inquiries as well as post-sale support.

Considering these factors will steer you to a suitable galvanized steel coil manufacturer for your project requirements.

Top Coil Suppliers in the Industry

- ArcelorMittal

ArcelorMittal is one of the biggest steel makers in the world. They produce galvanized steel coils praised for their strength, uniformity and quality. The company achieves galvanization of higher value pretreated steel with superior protective coating due to advanced corrosion protection techniques. Other than being a trusted supplier for numerous commercial and industrial businesses, ArcelorMittal is known for providing innovative services and strict quality assurance compliance.

- Baosteel Group

A leading steel company in China, Baosteel is well-entrenched in the industry due to its modern production facilities and strong research and development arms. Their galvanized steel coils find broad application in construction, automotive, and household appliance manufacturing. Baosteel uses precision engineering and sustainable technology to satisfy the performance expectations of their customers around the world.

- Nippon Steel Corporation

Nippon Steel Corporation is the most important galvanized steel coils supplier in Japan. They are recognized for their premium steel products and their consecutive skilled manufacturing. By utilizing advanced technology, they ensure provisions of uniformity in coatings along with protection against corrosion. Their focus on innovation along with quality control allows them to be a leader in material supply across industries dependent on material reliability.

- POSCO

An international leader in steel manufacturing, POSCO is based in South Korea. Their subsidiaries manufacture galvanized steel coils with guaranteed surface quality, structural strength, and mechanical properties, due to usage of modern technologies. Alongside quality production, POSCO focuses on sustainable development and green business practices by using eco-friendly means to produce goods which comply with international standards and rigorous certifications.

With suppliers like these, companies are guaranteed a constant supply of standard and specialty galvanized steel coils that meet the highest standards. These partnerships foster business growth while maintaining quality standards.

Questions to Ask Your Galvanized Steel Coil Manufacturer

- For galvanized steel coils, what coating thickness and type exists?

In relation to your specific needs, knowing the specific corrosion resistance requirements and the coating thickness, like G60 or G90, is important. Also, what is the type of the coating; is it zinc or zinc-aluminum alloy and does it meet ASTM A653 or comparable industry standards?

- What are the specified dimensions and tolerances?

For corrosion resistance, precise questions regarding sheet thickness, width, and length must align with design specifications to mitigate waste. Manufacturers must also supply specific levels of tolerance like ±0.01mm, important for precision expectations in critical applications.

- What methods are used for quality control and testing?

Manufacturers need to address their testing methods for tensile strength, yield strength, elongation, and cross-cut adhesion of the coating. Product quality can be assured with ISO 9001:2015 and other quality management norm certifications.

- What are the mechanical properties of the coils?

Be sure to ask about the steel grade fueled the fire, ductility, and structural integrity, and operational environment suitability of the material. This includes more advanced specs, like asking about HSLA grades for demanding applications.

- Do they offer customizations or special coatings?

When determining a manufacturer, consider whether they can enhance UV protection or heat resistance if that’s what the project requires them to do. Enhanced project requirements can include additional coating options or altered chemical composition policies for the specific project.

- What is the lead time and delivery structure?

Ensure production time frames and delivery logistics are in-sync with your project to avoid misalignment. Batch production speed, stock levels, and shipping methods should be discussed and agreed upon, dealing with logistics in these areas.

Targeted questioning in this manner provides the information necessary for selection of a manufacturer whose functionality and standards fit the operator’s criteria.

What Are the Different Types of Galvanized Steel Sheets?

Galvanized steel sheets are categorized into two broad types depending on how they are made:

- Hot-Dip Galvanized Steel Sheets

An immersion into molten zinc creates a thick, protective layer on the steel, forming these sheets. This galvanized steel will be structurally sound and capable of enduring extreme outdoor environments because it offers excellent rust protection.

- Electro-Galvanized Steel Sheets

An electrolytic method is used with this type to add a protective zinc layer to the steel. Although the coating is thinner than those from hot dip galvanized sheets, it’s smoother and more uniform. For that reason, it is used in high precision applications such as automobile components and household appliances.

The decision to pick one over the other is usually dependent on the use of the product, expected conditions, and the needed finish. Both types perform reliably over a long period but differ in thickness, surface finish, applying smooth finishes, automotive parts, precision parts, and rough parts used in machines, etc.

Understanding Zinc Coating Types

Practically, the decision of which type of zinc coating to use is made based on the environmental conditions, mechanical exposure, and the visual appeal that needs to be achieved. For example, areas that suffer from high corrosion like coastal or industrial areas require thicker coatings which hot dip galvanizing provides because the zinc layer is thicker. On the other hand, regions with controlled exposure may prefer electro galvanized coatings because they are free from thicker obstructions and provide precise finishes.

Furthermore, the coatings and their corresponding durability suggest that the lifespan of zinc coatings is directly proportionate to the thickness of the coating. The common standard of hot-dip galvanized layers ranges from 45 to 85 micrometers. Hot-dip galvanized layers can last for decades depending on the exposure conditions. Electrogalvanized coatings, which are more detailed and smoother, also have a shorter measurement between 5 and 10 micrometers. Such coating measurement is ideal for automotive and electronic components.

The addition of zinc-aluminum-magnesium alloys to existing technologies of zinc coating is one of the emerging optimizations that are set to enhance performance. There are also other advanced coatings that increase corrosion resistance whilst reducing the number of coatings needed, therefore they would become more efficient in terms of material. To this end, determining the optimal conditions for the parameters taken into consideration such functional and environmental requirements will decide the essential framework for selecting the type of zinc coating.

Comparison of Low-Carbon Steel and Hot-Rolled Steel

One of the most popular materials utilized in industry is low-carbon steel or mild steel, hot rolled steel. Each of them has differences in properties, applications or even how they are manufactured. Dedicating part of its composition, low-carbon steel comes with a carbon content of 0.05% to 0.25%. This makes it easy to machine or weld, so low-carbon steel is most useful for applications that require high ductility like structural parts, mobile parts, and sheet metals.

Unlike low-carbon steel the manufacturing of hot-rolled steel starts with rolling the metal at extremely high temperatures (1,700 °F (927 °C) or over). If the metal has been recrystallized, it is then easy to reshape. This particular steel becomes integral in the production of large structural parts such as I-beams or railroad tracks, due to their improved malleability. Unlike other alternatives however, hot-rolled steel does not have a smooth outer surface or precise dimensions.

In comparison, low-carbon steel is more workably and is more precise for more delicate tasks. Hot rolled steel is used where the surface finish and the dimension does not need accuracy. Both materials are extremely useful across different sectors and the choice is based on the the mechanical properties, surrounding factors, and price.

What Are the Key Properties of Galvanized Steel Coils?

The durable and versatile, galvanized steel coils, have additional unique features. Steel’s tendency to rust in different environments is mitigated by a layer of zinc added to the steel which shields it from galvanized rust and oxidation. This coating also protects the material’s sturdiness further accenting the lifespan of the material and is thus safe for external usage. Moreover, galvanized steel coils have a high strength-to-weight ratio which provides structural integrity and stability while maintaining a reasonable weight. These steel coils also feature high formability, meaning to say, they can be produced and shaped into different fabricated products without losing their protective covering. Thus, they are perfect for construction work as well as in the automotive and appliance industries.

Corrosion Resistance and Durability

Galvanized steel coils have been fabricated for effective protection against corrosion and measures against moisture and pollutants by using protective zinc coating. The zinc layer does not only support the underlying steel, it also oxidizes sacrificially. For example, galvanized steel has a much slower rate of deterioration than non-galvanized steel counterparts during salt-spray, marine environment simulations tests. This makes galvanized steel ideal to sustain infrastructure exposed to sever weather conditions like bridges, utility poles and roofing systems. Additionally, other advancements in technologies for galvanization have restrengthened the uniformity and thickness of the coat, galvanization enhances resistance against localized such as pitting and crevice corrosion. With these features, the material proves dependable in industrial and residential constructions.

Mechanical Properties of Galvanized Steel

The mechanical properties of galvanized steel make it one of the most widely used materials in engineering and manufacturing. Its tensile strength is usually between 350 MPa and 550 MPa, depending on the grade and the host steel substrate. This makes sure that galvanized steel can endure considerable weight, without deformation or failure of any kind. The marshalling operation adds a zinc layer to the steel which will greatly reduce its likelihood of corrosion. Additionally, this material also provides a degree of ductility, meaning it can be bent and formed without losing the protective coating. Unlike other materials, this one possesses a remarkable adhesion surface meaning it can be done with great compatibility with welding, painting or any finishing needed. These mechanical traits, along with unmatched environmental stress endurance galvanized steel makes it a crucial material for applications that are needed to be reliable for a long time.

How Do Galvanized Steel Coils Compare to Other Steel Products?

Galvanized steel coils’ corrosion resistance is better than standard steel steel due to their galvanized wires which help protect the coils from the environment’s moisture and oxidation. In rough conditions, galvanized coils last longer than uncoated steel and untreated steel because galvanized coils require less maintenance. Though stainless steel is less susceptible to corrosion untreated steel is cheaper making galvanized steel a preferred option for many uses. Furthermore, galvanized steel coils can easily be painted and welded increasing their value in many industries. Products made from steel are usually more expensive, but products with steel tend to be priced cheaper. It is the combination of adaptability, affordability, and durability that sets them apart other steel products.

Advantages Over Traditional Steel Sheets

- Enhanced Corrosion Resistance

Galvanized steel sheets are coated with zinc to fill gaps where oxygen, moisture and other harsh factors could enter which significantly increases the likelihood of rust forming. Research shows that in rural environments, galvanized coatings seem to last over 50 years while in more industrial or coastal areas, the coatings last around 20-25 years.

- Lower Maintenance Requirements

Maintreatment and the reapplication of protective measures like painting are not required on galvanized steel sheets, as is the case with untreated steel sheets. This significantly saves on maintenance resources. Reduced lifecycle costs are incurred due to lower expenditures related to repairs, replacements as well as the need to resupply resources because of infrequent repairs needed on the zinc coated steel sheets.

- Improved Durability

For example, galvanized sheet steel is best suited for roofing due its exposure to extreme weather conditions like high humidity. It also holds up better for use in marine settings because the more extreme exposure to saltwater tend to degrade untreated steel rather quickly. This also makes the galvanized steel the better option for demanding applications.

- Cost-Effectiveness

The traditional steel sheets may incur a cheaper direct cost initially, however, the savings when compared to the lifespan of galvanized steel with lower maintenance needs make it more cost-efficient. This becomes increasingly beneficial for large-scale projects.

- Versatility in Applications

Due to their versatility, galvanized steel sheets are used for roofing, automotive components, and construction. Their ease of painting and welding adds to their functionality as compared to untreated steel sheets.

The above-mentioned reasons will further showcase how the industry is shifting towards galvanized steel sheets due to their unmatched value when balanced with price and cost efficiency, reliability, and performance.

Cost-Effectiveness of Galvanized Steel Coils

The economic practicality of galvanized steel coils arises from their long life, low servicing, and maintenance requirements, which make them beneficial for various industries. Galvanized steel coils are designed to take on minimal rust damage, reducing the need for frequent replacing, or additional protective coverings. This improves operational costs and enhances manufacturing efficiencies.

Moreover, the primary investment made in acquiring galvanized steel is mostly balanced out by the product’s overall value and building efficiency as it performs so well heaving enduring structural damages. Research suggests that galvanized coatings under specific environments can last 20 and up to 50 years untouched, untreated or unprotected, untreated products greatly lack this. Moreover, the ability to recycle galvanized steel reduces waste and enhances cost control and industrial sustainability objectives. All these factors aid in less tempered steel spindle elements construction adaption to infrastructure, manufacturing, and other pivotal industries.

Reference Sources

-

Comparison of models created for the prediction of the mechanical properties of galvanized steel coils

This study focuses on predicting the mechanical properties of steel coils before the galvanizing process, aiming to prevent production issues. -

Fault diagnosis and comparing risk for the steel coil manufacturing process using statistical models for binary data

This research uses statistical models to monitor and estimate the quality of galvanized steel coils during manufacturing. -

Corrosion behavior and failure mechanism of electromagnetic pulse welded joints between galvanized steel and aluminum alloy sheets

The paper examines the corrosion and failure mechanisms in welded joints of galvanized steel and aluminum alloys. -

Galvanized steel reinforcement: Recent developments and new opportunities

This article discusses the traditional and modern uses of hot-dipped galvanized steel, highlighting its long service life and potential applications. -

Review of modeling and simulation of galvanizing operations

This review explores modeling and simulation techniques for galvanizing operations, focusing on improving process efficiency.

Frequently Asked Questions (FAQs)

Q: What are galvanized steel coils and how are they used in related products?

A: Galvanized steel coils are sheets of steel coated with a layer of zinc to protect against corrosion. They are commonly used in a variety of related products, including roofing materials, automotive parts, and construction components.

Q: What is the difference between hot dipped galvanized steel and cold-rolled steel?

A: Hot dipped galvanized steel is coated with a layer of molten zinc to prevent rust, while cold-rolled steel is processed at room temperature to achieve a smoother finish and tighter tolerances. Hot dipped galvanized steel is often used for outdoor applications due to its corrosion resistance.

Q: How does the galvanization process affect the quality of galvanized steel coils?

A: The galvanization process enhances the durability and lifespan of steel coils by providing a protective layer that prevents rust and corrosion. High-quality products undergo a thorough coating process, ensuring a consistent and effective layer of zinc.

Q: Can you explain the role of Curtis Steel and MST Steel Corp in the galvanized steel industry?

A: Curtis Steel and MST Steel Corp are reputable manufacturers that specialize in producing high-quality galvanized steel coils and other steel materials. They provide a range of products, including hot dipped galvanized steel and flat rolled steel sheets, catering to various industrial needs.

Q: What factors should I consider when choosing galvanized steel coils from manufacturers?

A: When selecting galvanized steel coils, consider factors such as the type of steel needed (for example, hot dipped galvanized or galvannealed), the thickness of the coils, the manufacturer’s reputation, and the specific applications for the steel in your projects.

Q: How do galvanized steel coils compare to other steel products in terms of environmental impact?

A: Galvanized steel coils typically have a lower environmental impact than other steel products due to their longevity and corrosion resistance, which reduces the need for frequent replacements. The steel industry is increasingly focusing on sustainable practices, including recycling and reducing emissions during production.

Q: What are the applications of hot dipped galvanized steel in manufacturing?

A: Hot dipped galvanized steel is widely used in manufacturing applications such as the production of roofing panels, automotive components, and construction materials. Its corrosion resistance makes it ideal for long-lasting products exposed to the elements.

Q: Are there different grades of galvanized steel coils available?

A: Yes, there are different grades of galvanized steel coils available, which vary based on factors such as zinc coating thickness, steel type (like low carbon or multi-phase steel), and mechanical properties. It’s essential to choose the right grade based on your project’s specific requirements.