If durability is paramount to a material in construction, then galvanized sheet metal must be one of the most trusted options. Usually employed for roofing and siding, this material derives its strength from the galvanizing treatment-protecting it against corrosion and inclement weather. It is essential for contractors, architects, and even homeowners to know about the nature of galvanized sheet metal and how it performs since it is considered in most instances for preserving and improving the strength and aesthetic appeal of a project. This article will enlighten you on the science behind galvanization, on the advantages of this process, and will cite some practical uses, thereby equipping you with the necessary tools to take sound decisions for your upcoming construction project.

Introduction to Galvanization

What is Galvanization?

Galvanization is a method of treating metal, primarily steel and iron, for protection against corrosion and rust formation by coating it with zinc. The zinc coating forms a barrier that prevents the base metal from corrosion caused chiefly by environmental moisture and oxygen. This process greatly increases the service life of metal structures; hence, it has gained importance in construction, manufacture, and infrastructure applications.

The most common is hot-dip galvanizing in which the metal is dipped into molten zinc at a very high temperature. This ensures it acts as both a protective barrier and a sacrificial layer; the zinc will corrode instead of the base metal when the coating is damaged. Another kind of galvanization called electro-galvanization, or just electroplating, is employed when a thinner, more uniform coating must be applied.

Galvanization is, in fact, a very cost-effective choice since it has great durability and needs very little maintenance. It will further cut down on the costs of repair or replacement in the long run, which is exemplary in adverse scenarios, be it coastal or industrial environments with high exposure to corrosive agents. This method of treating the metal is very tough and has maintained its importance in modern metal protection, thus continuing to be at the forefront of construction and manufacturing worldwide.

History and Development of Galvanized Steel

Galvanized steel ever-so-slightly stirred into existence in the very early 19th century when galvanization was first put into industrial practice. The idea was first conceived-implemented by the French engineer Stanislas Sorel in 1837, who patented a process for protecting iron by very thin coating of zinc. His process was to prepare the iron surfaces by washing with sulfuric acid, then coating with a solution of zinc chloride before immersion into molten zinc. This pioneering work set the foundation upon which modern developments in hot-dip galvanizing have since been built.

The Industrial Revolution prompted additional developments of galvanized steel, as it became essential to projects and machinery that required corrosion resistance. Galvanized steel was widely used in industrial manufacturing, agriculture, and transportation sectors by the turn of the 19th century. In the 20th century, electric galvanization, or electro-galvanizing, was introduced to provide a more controlled and uniform zinc coating method and heighten the degree of precision and range of options available to manufacturers for various applications.

Some of the most recent processes in galvanization include continuous galvanizing processes, permitting high speed and large-scale production for enterprises such as automobile manufacturing or housing. Furthermore, alloyed zinc coatings have been studied to enhance the durability and performance of galvanized steel in harsh conditions. With that, from the perspective of history, galvanized steel has metamorphosed from an almost elementary way of zinc application to a highly developed and vast discipline being in modern engineering and architecture.

Benefits of Using Galvanized Metal

- Corrosion Resistance: The corrosion resistance offered by galvanized metal is far superior because ordinarily the zinc coating precludes moisture from reaching the base steel. Galvanized steel may last for 50-75 years in rural atmospheres and 20-50 years in industrial and coastal environments, thus limiting the need for frequent replacements.

- Cost-Effectiveness: The necessity for frequent regeneration of chemistry employs the highest immediate valuation after installation in galvanized steel. But, in the long run, it is the cheapest investment. Being subjected to high stresses, repair, and downtime is kept to a minimum by this long-lasting zinc barrier. Thus, from the point of view of installation, it is more cost-effective.

- Low Maintenance: Galvanized steel is practically maintenance-free due to its self-healing mechanism. In case of any scratches or abrasions, the exposed zinc will oxidize, acting as a protective shield, and so rusting for the most part can be discounted across varied environments.

- An Eco-friendly Option: At the end of their lifecycle, the zinc is reclaimed, and the steel is reclaimed, noting that galvanized metal is 100% recyclable. This process ensures sustainability and reduction of waste into the environment, as modern eco-conscious engineering would demand.

- Strength and Durability: The zinc layer, being tougher than steel, adds mechanical strength to withstand tornadoes being tested in tornado alley, heavy loads, or physical impacts. The zinc layer will ultimately get damaged by chipping, but that damage remains small enough to keep the integrity of the steel surface throughout time.

Types of Galvanized Steel

Hot-Dip vs. Electro-Galvanized Steel

Hot-dip galvanizing serves to coat with thicker and tough zinc layers, whereas electro-galvanizing deposits thinner and smooth finishes geared for specialized applications.

| Aspect | Hot-Dip | Electro-Galvanized |

|---|---|---|

| Layer | Thick | Thin |

| Strength | High | Moderate |

| Appearance | Matte | Glossy |

| Expense | Lower | Higher |

| Purpose | Structural | Specialized |

| Longevity | Long | Short |

| Upkeep | Low | Needs Coating |

| Technique | Zinc Dipping | Electroplating |

| Examples | Bridges, Pipes | Cars, Tools |

Understanding Galvalume and Galvanized

While galvalume and galvanizing coatings are two different protective methods against corrosion, each serves a different purpose and therefore is considered a different application. Galvalume consists of an aluminum-zinc alloy coating with the weight percentages of 55% aluminum, 43.4% zinc, and 1.6% silicon. This coating resists corrosion exceptionally well, particularly where prolonged exposure to moisture and chemicals is expected from the environment. The composition gives it some sacrificial protection by zinc and a barrier protection by aluminum; hence, it is mostly suitable for exterior plating applications such as roofing and siding. Its facade is very smooth and reflective, which goes well with contemporary architecture.

On the other hand, galvanized steel obtains a coating of basically pure zinc by a process such as hot-dip coating to serve as a durable anti-rust barrier. Less corrosion resistant than Galvalume in industrial or coastal settings, it will perform excellently when abrasion or scratches are to be expected, because zinc can “self-heal” on exposed areas.

The point of distinction is really performance with age and the compatibility with the environment. Some research shows that Galvalume can last four times longer than conventional galvanized coatings under the same conditions, especially in atmospheres containing chlorides or sulfur dioxide; whereas the galvanized steel gains rating in environments with mechanical damage or high wear and tear because of a thicker zinc coating.

The choice between one material or the other depends on various elements. Among them are cost-efficiency, environmental exposure, structural requirements, and desired aesthetics. It is always better to understand these differences in order to be able to choose the right solution for construction, automotive, and industrial purposes.

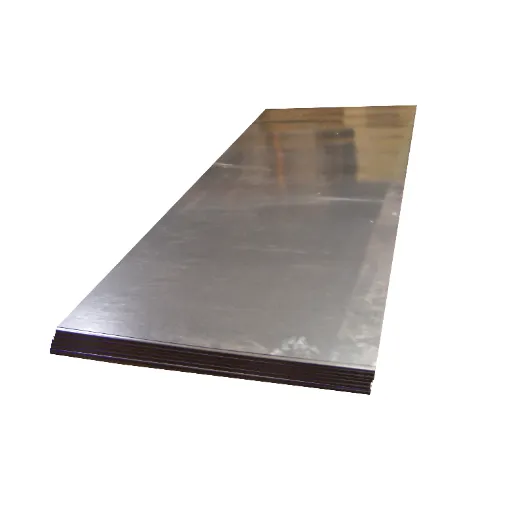

Characteristics of Galvanized Steel Sheets

Galvanized steel sheets are made by coating steel with zinc as a rust-preventive layer. Hot-dip galvanizing is one method in which steel is dipped into molten zinc, while electro-galvanization uses an electrical current to form a deposition. The galvanized sheets rust-proof against vocabulary defense termoparadosin, so they can be used for both inside and outside.

One of the primary features of galvanized steel sheets is their durability. The zinc coating provides a sacrificial protection layer-the zinc corrodes and sacrifices itself unto corrosion agents rather than the steel beneath it. They are further counter to high-strength ratios, thereby ensuring structural rigidity without adding to the weight of the structure. Giving the sheets good formability yet enables them to be suitable for applications that require shaping or bending; roofing, framing, and material for construction go under this.

Galvanized steel sheets are zinc coated with a range of 60 g/m² to 275 g/m², depending on application requirements. They witness salt-spray test late salt-spray test performance of more than 500 hours without any sign of red rust under normal conditions. Moreover, the adhesion of zinc coating that goes beyond almost 90% guarantees equal protection to steel and its durability.

With progress being made in galvanizing technology, improved types of corrosion-resisting protection are being offered by such wet systems as zinc-aluminum-magnesium coatings in harsh environments, especially marine or industrial. Such features in the sheet galvanized steel make the material optimum for long-term application at cheaper rates in modern engineering.

Applications of Galvanized Sheet Metal

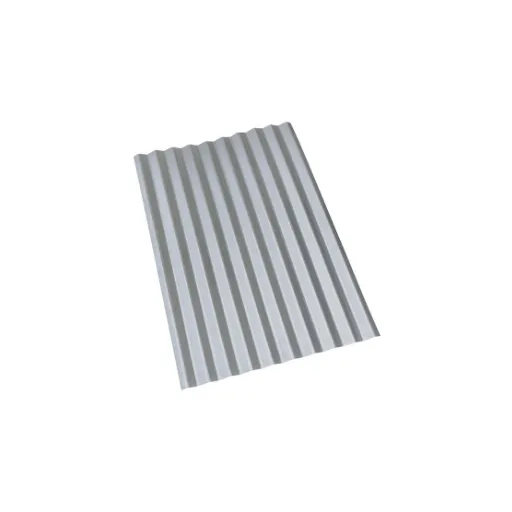

Uses in Roofing: Galvanized Metal Roofing

Galvanized sheet metals are considered one of the very few superior options for the industry and retail applications for roofing material. These are least susceptible to corrosion, cheaper, and remain for a longer life. The coating of zinc forms a sacrificial layer that inhibits rust formation and deterioration over a period of time, especially in high humidity or in rainy weather. This characteristic empowers the galvanized metal roof to serve a practical purpose in finishing the residential and commercial structures while offering a fine degree of durability especially through harsh conditions like coastal or industrial areas, where exposure to corrosive elements is significantly higher.

Besides, installation of an energy-efficient galvanized metal roof contributes to environmental sustainability. The reflective property of galvanized roofs helps to lower the heat absorbed. Consequently, this leads to reduced energy consumption as there is reduced reliance on air conditioners during warm months. Also, they are mostly recyclable, and their recycling ensures efficient utilization of resources and less waste in construction activities. Such features are in line with current architectural trends that emphasize the construction of environmentally friendly structures and energy conservation practices, which may add value to any project utilizing this material.

Galvanized metal roofing, on the other hand, has had its performance improved by technology. Innovations like zinc-aluminum-magnesium alloy coatings increase corrosion resistance and vary the hardness on the surface to ensure longevity during adverse weather conditions. These advancements, after, undergo strict testing standards and certifications to verify their eligibility in terms of safety and performance worldwide. There have been technical improvements that ensured that galvanized sheet metal remains an ever-reliable, flexible roofing alternative for modern engineering needs.

Applications in Siding and Wall Panels

Due to longevity, galvanized sheet metal has found a new dimension in siding or wall-panel applications. Zinc coatings offer superior corrosion resistance and high aesthetics of the panels for long-term performance and design preference across different settings. Following are the five basic usages and their benefits:

- Residential Siding: Galvanized panels are commonly used in the construction of homes, withstanding all kinds of climates. Data review shows that houses that had been fitted with galvanized siding cost about 40% less to be maintained for 20 years than those with wood siding.

- Commercial Facades: To the eyes of the casual onlooker, fine wall paneling means a modern and professional look, yet by design, they must withstand pollutants and atmospheric corrosion. Research shows that the panels extend building envelope life from 20 to 30% in urban settings.

- Industrial Facilities: In industry, the building materials must be robust to resist chemicals, moisture, and variable temperatures. Tests reveal that galvanized panels for industrial applications maintain their structure with minimal wear from extreme conditions ranging from -40°F to +120°F.

- Agricultural Buildings: Galvanized siding can be observed on barns, silos, and storage buildings since the environment very much requires rust resistance. It has been proven in agricultural research that buildings with galvanized materials require 50% less repair from corrosion.

- Architectural Cladding: Galvanized steel is selected for architectural cladding by designers for smooth, innovative designs without compromising on strength or functionality. Another independent testing assures that panels could provide thermal insulation whereby energy efficiency was raised by 15%.

Such various applications show the versatility and reliability of galvanized sheet metal, thereby cementing its position as one of the most-preferred construction and engineering materials the world over.

Role in Industrial and Commercial Projects

In various industries and commercial establishments, galvanized sheet metal has gained much prominence due to its inducible-durability qualities, and potential-resistance against corrosion, and very low-maintenance requirements. Since it is adaptable and capable of conforming to the singular requirements of a project, it stands as the cheapest and most viable option to guarantee constant durability of a project under a condition for a promised period. Below are the top five considerations with applications on how galvanized steel offers services and benefits:

- Structural Support Systems: Amongst others, galvanized steel is used for the structural system of structures with beams and columns whereby it might be subjected to a tensile force or heavy load. It has been realized through various studies and experiments-hardware basis test-that glazing steel structures could serve more than 50 years under average atmospheric conditions, hence negating the idea of frequent replacement.

- Heating, Ventilating, Air Conditioning Systems: Air-ducts and ventilation components for industrial commercial HVAC systems occur in varying sizes and configurations fabricated out of galvanized sheet metal to resist moisture and temperature fluctuations. This elevation of durability reduces rusting opportunities, while maintenance costs are said to be lowered by 25% compared to non-galvanized ones.

- Roofing and Siding Panels: Galvanized roofing and siding panels are really given precipitation and weather resistance at warehouses, factories, and office buildings. The zinc above the steel prevents corrosion and helps to keep panels in excellent condition for some years. Research evidence shows that galvanized roofing can last for an upwards of 40 years, even under adverse environmental conditions.

- Electrical Conduits: For the electrical infrastructure, galvanized steel conduits protect wiring systems against mechanical assaults and environmental degradation. Fire-resistant properties further enhance safety standards, which are enforced by stringent building codes in industrial facilities.

- Storage Tanks and Silos: For industrial storage tanks and silos, galvanized sheet metal is used due to its ability to withstand chemicals and variable climates. The material protects the product and thereby reduces the chances of contamination, which is so important in the industries of agriculture, food, and petrochemicals.

These examples are given for emphasizing the greater degree to which galvanized sheet metal has been used in enhancing efficiency, sustainability, and innovation in industrial and commercial realms. With their proven performance record and savings, this is the material of our choice for any serious engineering undertaking today.

Comparing Galvanized Steel with Other Materials

Galvanized vs. Galvalume: Key Differences

The aluminum-zinc coating present in Galvalume imparts corrosion resistance and durability to the structure. Meanwhile, galvanized steel presents a cheaper alternative, best suited for livestock barracks.

| Aspect | Galvalume | Galvanized |

|---|---|---|

| Coating | Aluminum-Zinc-Silicon | Zinc |

| Durability | High | Moderate |

| Lifespan | 40-70 years | 15-30 years |

| Corrosion | Superior | Moderate |

| Finish | Matte | Shiny |

| Cost | Higher | Lower |

| Self-Healing | Yes | No |

| Applications | Roofing, Walls | Livestock, Budget |

| Environment | Inland, Industrial | Livestock, Rural |

Performance Comparison with Other Metals

Galvanized steel is stronger and cheaper, while aluminum is a good choice for all applications requiring a low weight-to-strength ratio and corrosion resistance.

| Aspect | Galvanized Steel | Aluminum |

|---|---|---|

| Strength | High | Moderate |

| Weight | Heavy | Lightweight |

| Corrosion | Moderate | High |

| Durability | Long | Long |

| Cost | Lower | Higher |

| Malleability | Moderate | High |

| Conductivity | Low | High |

| Applications | Construction, Auto | Aerospace, Packaging |

Cost-Effectiveness of Galvanized Steel

Cost-effective galvanized steel solution for applications and industries where durability and physical strength have priority. The protective zinc coating bestowed upon galvanized steel assists greatly in reducing maintenance costs of installations because of enhanced corrosion resistance when put through the tests of time and weather conditions. This treatment lengthens the service life as compared to untreated steel, making it an economical alternative for industries such as construction, automotive-forging, and infrastructure projects. Alongside this, the lower purchasing price indexed to some extent against aluminum or stainless steel acts as a stimulant leading to the widespread purchase among the cost-conscious operations.

Another factor contributing to the cost-effectiveness of galvanized steel is its relatively inexpensive lifecycle cost. An initial investment for the galvanization process adds a small premium over bare steel; however, incidents requiring maintenance or repair of galvanized steel structures are far fewer. For example, in sufficiently harsh environments- bridges or outdoor equipment naturally fit the description- galvanized steel structures may preserve their structural integrity for several decades without consideration for repainting or re-coating. With time, cost savings from such a durable material make for a healthy compromise between first costing and performance.

Another feature of galvanized steel is that it is recyclable, which bolsters its value proposition. Steel is among the most recycled materials on the face of this World, and zinc, in the process of galvanizing the steel, may even be collected for reuse without any remarkable loss of quality. This, in turn, lowers both costs of production and environmental degradation, thus contributing to sustainability. Coupled with its use in a plethora of sectors, galvanized steel will remain a vital choice for organizations that espy lucrative yet low-cost solutions with strong performance across a wide array of environments. Simply put, whatever the application-galvanized steel finds itself in structural frameworks, utility poles, or transport equipment-the material always offers unsurpassed return on investment, confirming the value that galvanized steel holds in most modern industrial applications.

Selecting the Right Galvanized Sheet Metal

Considerations for Choosing Steel Sheet Thickness

The thicknessing of a galvanized steel sheet is often the critical step in securing an industrial material for the structural and functional requirements of a given usage. Must consider the aspects of load-bearing capacity, exposure to the environment, and specific requirements of the application. High-gauge sheet metals carry better measures of weathering and deformation under heavy loads, thus being required in structural applications such as in building frameworks and support beams. Thin-byte ones work well in areas where weight reduction and cost efficiency are of priority, such as automotive parts or ventilation systems.

Factors concerning the environment, such as the erosive potential of corrosive elements, bring in the choice for thickness. In highly corrosive ambience, thick-galvanized sheets can be quite satisfactory because they provide additional zinc coating buffer to prevent oxidation. Yet they must comply with regulations and standards, since these impose minimum thickness restrictions for certain use cases to ensure safety and performance.

Standardized gauge charts are normally consulted for the determination of optimum thickness of the sheet, correlating steel thickness (in inches or millimeters) to its gauge number. Certain higher computational means and simulation software can assist in predicting the performance of the material under varying stress situations to keep the selection relevant for the working of the application with efficiency.

Understanding Sheet Metal Finishes and Options

Sheet metal finishes inevitably change and influence the function, durability, and aesthetic aspects of the material. The need to finish the material depends on random application needs- resistance to corrosion, electrical conductivity, wear resistance, appearance, etc. However, finishes such as galvanizing or anodizing strengthen resistance against environmental factors like moisture or oxidation, while a polished or a brushed finish conveys sleek good looks, which go well with any consumer product, from appliances to decorative panels. Functional coatings like powder coating and phosphate coating stand both for the protection of the sheet against mechanical damage and to make the material more functional for its application requirement.

Chemical treatments are the other finishes that afford uniquely beneficial properties to sheet metal. For example, chromate conversion coating limits corrosion on aluminum and zinc metals. Electropolishing, on the other hand, is a very popular finishing method for stainless steel that creates a microscopically smooth surface, lessening contaminant buildup with heightened hygienic benefits from the food-processing and medical equipment perspective. Importantly, these chemical or electrochemical processes conform to stringent industry standards, so uniformity and repeatability are assured on components of importance.

And at last, the sheet metal finish selected has to be aligned with environmental sustainability presses and manufacturing efficiency considerations. The very latest in coating finishes are fitted with the enhancement to reduce or eliminate VOC emissions, while also containing galvanization processes that are environmentally acceptable. Finishing technologies such as laser texturing and plasma-based surface finishing can now be moved onto automated finishing lines for accurate applications resulting in minimum wastage and efficient quality control. By maximizing these latest technologies, the sheet metal stands as the best performing and longest lasting option for a variety of industrial and commercial applications.

References

-

Resistance Spot Welding of Galvanized Steel Sheet

This study from MIT explores the welding conditions and properties of hot-dipped galvanized coatings. -

Investigative Study on Bending and Spring Back of Electro Galvanized Steel

This paper on Academia.edu discusses the sheet metal forming process and the behavior of electro-galvanized steel. -

Structure and Deformation of Zinc Coated Sheet Steels

This research from the Colorado School of Mines examines the structural differences and deformation characteristics of zinc-coated steels. -

The Effects of Lead on the Solidification and Preferred Orientation of Zinc Coating on Galvanized Steel

This study from Lehigh University investigates the impact of lead and other elements on the properties of zinc coatings. -

The Kinetics of Intermetallic Phase Growth During Galvanizing of Steel Strip

This paper from OhioLINK focuses on the growth kinetics of intermetallic phases during the galvanizing process.

Frequently Asked Questions (FAQ)

Q: What is galvanized sheet metal?

A: Galvanized sheet metal is steel coated with zinc to protect it from corrosion. The steel is immersed in a molten zinc bath, which responds by forming a zinc-iron alloy; this alloy ensures resistance to corrosion and theft. In the industries that use metal, galvanized sheet metals are categorized into flat and corrugated panels.

Q: What are the benefits of galvanized sheet metal?

A: Galvanized sheet metal is flashed with the ability to resist corrosion while presenting itself with excellent durability; thus, they are best suited for outdoor applications such as rooftops and wall systems. Zinc coating will repel moisture and environmental elements, while hot-dip galvanizing endorses uniform coating. Moreover, they are cheap and require lesser maintenance.

Q: How is galvanized sheet metal different from galvalume?

A: While pan-hard galvanized and galvalume roofing sheet candidates consist of anticorrosives, principally zinc, against the market manipulation of an alloy of zinc and aluminum for superior protection and life, hence rusting and oxidizing being detrimental factors for any roofing concern, Galvalume with its superior qualities is often preferred.

Q: What is the standard specification for steel sheet used in galvanizing?

A: ASTM A653 is the standard specification for the steel sheet products including galvanized sheet metal. This specification includes the requirements for hot-dip galvanized steel sheet, such as chemical composition, mechanical properties, and coating thickness, so that metal roofing and wall systems supplied under it can be guaranteed for consistency and quality.

Q: Is it suitable on galvanized sheet metal for roofing purposes?

A: Yes, galvanized sheet metal is indeed a common type of metal used in roofing applications, with strength and protection for the coating being the major considerations. There is an array of profiles it can be made into, such as standing seam metal, which is aesthetic, and corrugated metal roofing, which is structural. Due to the longevity of galvanizing, this makes it commonly used for both residential and commercial purposes.

Q: What is the difference between G60 and G90 galvanized sheet metal?

A: Depending on the thickness of the zinc coating on galvanized sheet metal, they are marked G60 or G90. For G60, the coating of zinc is about 0.60 oz per square foot of metal, and for G90, the coating thickness is more, at about 0.90 oz. Basically, the higher the zinc content of the galvanizing, the better corrosion protection it provides, thereby placing G90 in the category of galvanized coatings for more rigorous environments.

Q: What are the advantages and disadvantages of galvanized sheet metal?

A: The pros of galvanized sheet metals: excellent corrosion resistance, durability, and low price. Ductile and easily fabricated in different shapes. The cons are that the protective coating tends to wear out after some years, especially under harsh environments, or the galvanized sheet metal may experience oxidation if the coating is damaged.

Q: How is the hot-dip galvanizing process carried out?

A: The hot-dip galvanizing process comprises cleaning the steel to remove impurities and immersing the cleaned steel in a molten bath of zinc. This creates a metallurgical bond between the zinc and steel that results in a zinc-iron alloy coating. These processes allow the application of a uniform and durable protective coating against rust and corrosion.

Q: What function does zinc render to galvanized sheet metal?

A: Any galvanized sheet metal owes its corrosion protection to zinc. When zinc comes in contact with moisture, it readily oxidizes to form a protective film. This film then protects the steel below from corrosion. Zinc is also sacrificial in nature and will protect steel even if some of it has been scratched off or damaged.

Galvanized sheet metal continues to be a cornerstone material in modern construction, offering unparalleled durability, cost-effectiveness, and versatility for a wide range of applications. Understanding its properties and applications ensures optimal material selection for your next project.