Steel breaches its value threshold in the density property. Density, which refers to the mass per unit volume, is critical when dealing with steel. It is a widely used material for construction, engineering and other purposes. In this blog, I would elucidate every aspect of steel’s density that is essential for manufacturing and construction, including all of its implications and limits. Consider this an opportunity to broaden your knowledge to gain a competitive edge among professionals by understanding every technical detail of various fields. Density has numerous advantages, such as strengthening weight ratios, which in turn enhances product design and offers an array of options to select from different materials.

What is the Density of Steel?

Steel is regarded as having a density of 7.85 g/cm³ or 7850 kg/m³. It is important to note that these values are not absolute and may change slightly with the addition of other elements and alloys, however to an engineer this value will always be close enough for most standard applications. In addition, the precision of steel values in a model will have a direct correlation with its effectiveness as steel density is critical for weight, structure, and material functioning.

Definition and Importance of Steel Density

Steel density is important for many engineering and design processes because it impacts both functional and structural characteristics. In construction, the steel density directly influences calculations for the load-bearing and overall structural design for columns, beams, as well as reinforcements. Also, in manufacturing, knowing the precise density allows for estimating the weight of components which aids in proper assembly and balance in the machinery as well as in vehicles. In automotive and aerospace engineering where minimizing weight is critical, different grades of steel can be chosen depending on their density and highest strength to weight ratio. Moreover, in computational simulations for stress analysis, modeling accurately the density of steel is crucial for thermal conductivity studies and dynamic load tests which analyze performance under real world conditions.

Typical Values for Steel’s Density

Carbon steel typically falls within the 7.75 g/cm³ to 8.05 g/cm³ mark. Other types such as stainless steel will contain a greater variation owing to added alloys like chromium, nickel, and molybdenum which affect structure and weight. To engineers and designers small variances of weight do methamaticlly change effectiveness. To civil engineers these principles are required especially when a structure impacts load calculations and overall performance.

Comparison of Mild and Carbon Steel Density

Mild steel has a density of 7.85 g/cm³ and 7.87 g/cm³ which are within the same range as carbon steel. However, the carbon content along with other elements can change these values. A more common form of mild sterling is carbons with a percentage greater than 0.25% carbon. It is uniform, which is perfect for fabrication as well as for minimizing variables during physical testing requiring uniform material properties. Another form of steel is carbon, which takes the alloying material manganese and usually a carbon content between 0.3%-0.5%. Due to these complex differences in composition, advanced alloys of high strength carbon steels face changes to density along with shifting mass due to their high alloying content.

Mild and carbon steel illustrate how the small details regarding material density play a vital role in structural assessment, fabrication approaches, and optimal material selection. Taking construction as an example, the steel is suggested to be used in spaces that require a balance between ductility and uniform strength, however in spaces where high stress and wear is expected, carbon steel would be a better alternative. The engineering design stage is where these small details need to be taken account to ensure performance and build reliability.

What Are the Different Types of Steel and Their Density?

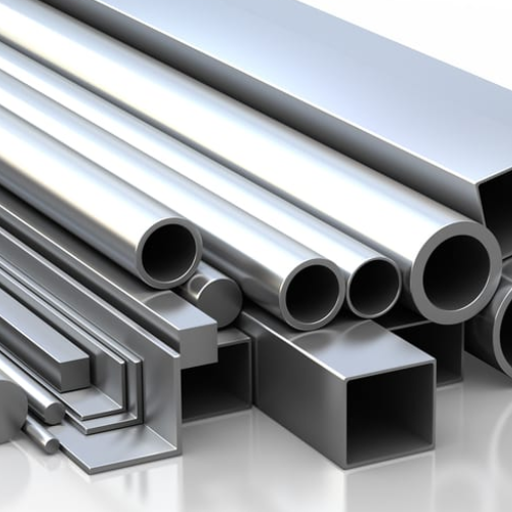

Steel can further be divided into subcategories which also influence its density:

- Carbon Steel

The density of carbon steel is a strong metric at 7.85 g/cmᶦ. It is a versatile metal and a widely used material because steel comes in various forms. The strength of the material can be catered to a specific use through hardening it and increasing ductility.

- Stainless Steel

Stainless steel has a density ranging from 7.75 g/cm3 to 8.1 g/cm3. Its uses are its corrosion resistance, making it ideal for stands exposed to high moisture or chemical environments.

- Alloy Steel

Alloy steels, specifically enriched with nickel and molybdenum, face dramatic changes in their composition based on their usage. Under testing conditions with high performance purposes, the steel density shifts to around 7.8 g/cm³ which makes it fluctuate depending on the chromium or other alloying elements.

- Tool Steel

Because cobalt and tungsten are sometimes added to tool steel to increase its hardness and heat resistance, it’s used in cutting and tool-making, having a density of 7.7 g/cm³ to 8 g/cm³.

- Mild Steel

Another alloy, sick steel, has lower carbon content and a density of 7.85g/cm³. Most favored for construction and manufacturing due to its ductility and weldability.

Alloying and chromium nickel or molybdenum may differ strength composition. This is why it is important to understand density variations for putting different types for steel engineering purposes.

Understanding Carbon Steel Density Variations

Like many other substances, carbon steel density is affected by several alloying elements, the amount of carbon, and heat treatment processes. Its density values usually seem to be between 7.75 and 8.05 g/cm³. High-carbon steel is one of the alloys with higher densities. This is because it often contains additional components like manganese which increase the steel’s density while also improving its hardness and tensile strength. Another example contains alloy steels which have additional chromium or nickel for better resistance to corrosion which also present small changes to the density.

Heat treatment, e.g., quenching and tempering, can change density indirectly by modifying the steel microstructure. Albeit the mass is the same, the phase composition, for instance, changing ferrite to martensite, can change static and dynamic stress, and load behavior, ultimately affecting internal stress. These details are especially important in the automotive and construction sector where mechanical performance and material efficiency are critical.

Mild Steel vs. High Carbon Steel Density

The mild steel and high carbon steel comparision showcase how the materials are made of mostly iron so the values are close together. Mild steel has a density of 7.85 g/cm³ while high carbon steel which has a carbon concentration from 0.6% to 1.5% is also estimated to have the same density as mild steel. Although chain in carbon concentration alters the density negligibly, the microstructure, hardness and tensile properties do change significantly.

The higher the carbon carbide concentration in a metallurgical structure, the stronger and harder the material is, and thus why high carbon steel is stronger compared to other types of steel. On the other side, mild steel is more easily shaped which allows for easier welding and manipulation of the material. These differences highlight the need for custom material grades based on precise engineering demands, especially from fabrication builders where weight, functionality, and strength have to be a closely assessed triangle.

Density of Alloy Steel and Its Implications

Alloy steel density can be between 7.7 and 8.0 g/cmᶦ, which is slightly higher than mild steel, commonly set at 7.85 g/cmᶦ. This can be due to components like chromium, nickel or molybdenum. The higher density of alloy steel results in better performance in certain applications. For example, in automotive or aerospace engineering where weight is reduced, an alloy with specific tailor-made compositions can provide the best blend of mechanical performance and material mass. On the other hand, in structural applications where weight bearing and rigidity are prioritized, added density improves performance, providing a better strength-to-weight ratio. For efficient utilization of material in engineering designs, precise density of specific alloy steel formulation is very important.

Why is Density Important in Selecting Materials?

An important factor about density in materiel selection is how it affects the weight, strength, as well as the efficiency of the final application. In most cases, lower density materials are more favorable when mass is important to enhance performance and fuel efficiency in such segments like aerospace or automotive industries. On the other hand, high density materials are useful in requiring durability and ability to properly resist heavy loads such as in structural supports and some kinds of machinery. This shows how the right density consideration improves functionality while reducing costs in designs.

Impact of Density on Durability

Choosing the right material can greatly impact the density of a structure or product and their overall durability. Steel and tungsten are the most frequently used high density materials due to their atomic structure tightly packed issue superior resistance to wear, deformation, and impact forces. This property makes them ideal for use in harsh mechanical environments and ballistic armor. Studies show that a steel density of roughly 7,850 kg/m³ allows for much greater load tolerance than aluminum which only reaches a density of 2,700 kg/m³.

Still, having a high density is not always beneficial as it can result in unwanted bulk and reduced efficiency, especially in moving systems. Composed of lighter parts and dense reinforcements, composite materials are being adopted more and more by engineers due to their advantageous strength-to-weight ratio. Materials like carbon fiber reinforced polymers illustrate how reinforced low-density components designed to enhance structural endurance while maintaining efficiency can prolong the life of systems in the performance-centric industries. These examples delve into how carefully weighing the implications of density and its perception drives modern engineering and manufacturing.

Role of Steel Density in Engineering Applications

Steel density is pivotal in determining its application in different engineering fields. Steel’s average density is around 7,850 kg/m³. This makes steel relatively easy to work with, and provides strength and durability. These features makes steel a fundamental material in the construction, transportation, and manufacturing sectors. The following information emphasizes important aspects of steel’s density alongside its applications:

- Structural Engineering

Steel is dense which improves its exceptional compressive and tensile strength and makes it useful for constructing sky scrappers, bridges and other large scale infrastructural projects. An example would be structural steel since it bears both tension and compression forces, it enables designers to implement cantilevered and highrise buildings.

- Mechanical Engineering

Mechanical systems such as geared machinery need certain components like gears, shafts, and bearings that are made of hybrid steels(non ferrous metals) that boast good density to make sure they last long and perform well under constant pressure or stress. The non ferrous alloys also soak up shocks which enable them to resist wear and tear while performing their mechanical functions.

- Automotive Industry

Having the correct alloy and chemical composition of Hybrid steels enables engineers to achieve their tasked vehicle weight. This is especially useful in ensuring better fuel economy, safety and efficiency of vehicles. With balanced structures, vehicles are able to carry high strength low alloy (HSLA) steel while reducing their weight for improved energy consumption and retention without compromising occupant protection.

- Defense Applications

Steel is used in the construction of tanks, weapons, and fortifications due to its protective traits and dense composition. For instance, steel is homogeneous armor (RHA), which is rolled and tailored for optimal protective hardness to safeguard against ballistics.

Engineering demands require alloy composition to be precisely controlled along with heat treatment processes. Steel’s properties and density can meet and are adaptable for tailored engineering expectations. Such versatility reinforces steel’s significance as one of the foremost materials utilized in modern engineering.

What is the Relative Density of Steel?

Commonly known as specific gravity, relative density steel rests between 7.75 and 8.05. In simple terms, this means under standard conditions steel is approximately 7.75 to 8.05 times denser than water. Depending on the alloying elements used, these values can change.

Definition of Relative Density in the Context of Steel

In regard to steel, relative density is understood as the comparison between the material’s density and the density of water at a specified temperature, which is usually 4°C, where water’s density is roughly 1000 kg/m³. This measurement which has no units portrays how dense steel is compared to water. For steel, which is measured to have a density between 7750 and 8050 kg/m³, its relative density is estimated between the values of 7.75 to 8.05. Elements such as carbon, chromium, nickel and manganese dictate the fluid state of the material. This can help during the designing process to determine requirements that involve sharp ratio of weight-to-strength, buoyancy of the material, or structures that bear loads.

Comparative Analysis: Steel vs. Other Metals

|

Property |

Steel |

Aluminum |

Titanium |

Copper |

Brass |

Magnesium |

|---|---|---|---|---|---|---|

|

Density (kg/m³) |

7750–8050 |

2700 |

4500 |

8960 |

~8500 |

~1738 |

|

Strength (MPa) |

250–2000 |

40–700 |

240–1100 |

200–400 |

200–550 |

180–290 |

|

Corrosion Resistance |

Moderate (varies by alloy) |

High |

High |

Moderate |

Moderate |

Moderate |

|

Thermal Conductivity |

50 W/m·K |

~235 W/m·K |

~22 W/m·K |

~400 W/m·K |

~120 W/m·K |

~150 W/m·K |

|

Electrical Conductivity |

Low |

Moderate |

Low |

High |

Moderate |

Low |

|

Machinability |

Moderate to difficult |

Easy |

Difficult |

Moderate |

Good |

Moderate |

|

Cost |

Low to moderate |

Moderate |

High |

High |

High |

Low |

|

Recyclability |

High |

High |

Moderate |

High |

High |

Moderate |

|

Applications |

Construction, automotive, tools |

Aerospace, packaging |

Aerospace, medical implants |

Electrical, plumbing |

Instrumentation, fittings |

Aerospace, lightweight parts |

Applications of Relative Density in the Steel Industry

Relative density, or specific gravity, is pivotal in assessing industrial grade steel’s relative usefulness for different applications. Assessing relative density enables industries to evaluate precision-calibrated parameters such as the efficiency of energy consumption, and the capability of bearing load, with particular readiness in demanding contexts. Outlined below are exact industrial applications of relative density in steel engineering.

- Automotive Industry

Customers in the automotive industry are always striving to increase fuel efficiency by a vehicle’s weight optimized because of advanced high-strength to weight ratio. For instance, Advanced High-Strength Steels (AHSS) Compared to other alternatives, their optimal strength to weight ratio allows emission reduction as well as compliance to regulatory standards achieved through reduction in mass of over 25% which makes vehicles emissions friendly.

- Aerospace Engineering

Maraging steels are used in aerospace applications and have critical specialization as they possess high strength to weight ratio; endowing improved payload capacities and enhanced fuel efficiency. In addition to offering superior strength and toughness, maraging steels retain reduced weight. When designing weight-critical structural components such as the fuselage and landing gear, relative density is key.

- Construction and Infrastructure

Skyscrapers, bridges, and tunnels are constructed using structural steel with tailored relative density. Optimizing the steel’s relative density enhances its material efficiency while conserving costs and preserving its load bearing capabilities. A case in point are lightweight steel alloys which make large scale transport and installation easier.

- Shipbuilding

Steels with a specific range of relative densities are widely used in the shipbuilding industry so that both strength and buoyancy can be achieved. Reducing fuel consumption is possible due to the vessel’s weight loss while maintaining low-density, high-strength steel upholding the structural integrity of the ship.

These examples strongly emphasize the role relative density plays as a characteristic property in the steel industry, having continuous impact on the design, functionality and performance of systems based on steel in different branches of industry.

How Does Carbon Content Affect Steel Density?

Because of its ability to change the microstructure of a metal, carbon content heavily influences the density of steel. Increased amounts of carbon will bond with iron to produce iron-carbide or cementite which is more dense than pure iron. Still, the overall effect on density is minor because carbon makes up a very small percentage of steel by weight. The ductility, strength, and hardness tend to shift in this order, with a greater amount of carbon content adjusting ductility downwards and hardness and strength soaring. Through all this, the change in density is minimal and often disregarded for most applications, not having a substantial impact.

Understanding Low vs. High Carbon Steel Density

Lower carbon steels using under 0.25% carbon by weight contain closer to 7.85 g/cmᶦ. Because of carbons minor influence this metric is consistent with pure iron. The slight difference in carbon content results in softer materials without shifting the density significantly. These products are mostly used in construction and automotive parts.

High carbon steel has a carbon content between 0.6% to 1.4%. This increases the density of iron-carbide (cementite), but only slightly. In most cases, it will remain around 7.85 g/cm³, much like how the added carbon increases density by a negligible amount. The primary differences that set high carbon steel apart is its increased hardness and brittleness, which makes it best suited for tools, cutting devices, and tools that are used for abrasion. Detailed studies show that while carbon does change the mechanical properties, it will only be affected by density as a secondary factor, which is mostly irrelevant in practical steel use.

The Relationship Between Carbon Content and Durability

The durability of steel is important with respect to its deformation and wear, and carbon percentage determines this alongside serving as a critical factor. With higher concentration of carbon, the hardness and tensile strength of steel improves with its iron carbide precipitate increasing. This also strengthens the lattice structure making it more resistant to plastic deformation. Steels with 0.6% to 1.0% carbon content demonstrate best in these characteristics, especially for high impact usage in automotive and construction industries.

Excess carbon will also hinder the toughness of the steel which will increase brittleness under static load. This seems to stem from the material’s inability to absorb energy before it fractures. To combat the drawback of increased brittleness under dynamic loads, high carbon steels undergo special thermal techniques such as quenching and tempering, which enhance toughness and improve strength. Current research in materials science has demonstrated precise adjustments of carbon levels accompanied with modern metallurgical methods will engineer steel with suitable durability for high demand environments.

Reference Sources

-

Application of Steel Slag Asphalt Mixture in Road Engineering: This study explores the use of steel slag, a by-product of steelmaking, in road construction. It highlights the material’s high strength, wear resistance, and bonding properties, which improve road durability and reduce environmental impact.

-

Vapor-phase Protection of Steel by Inhibitors Based on Salts of Higher Carboxylic Acids: This paper investigates the use of vapor-phase corrosion inhibitors (ChIn) for steel protection.

-

Resistance of Bacterial Biofilms Formed on Stainless Steel Surface to Disinfecting Agents: The research examines the resistance of bacterial biofilms on stainless steel to disinfectants.

Frequently Asked Questions (FAQs)

Q: What is the density of steel and how is it measured?

A: The density of steel is typically around 490 pounds per cubic foot or approximately 7,850 kilograms per cubic meter. It can also be expressed in grams per cubic centimeter, which is about 7.85 g/cm³.

Q: How can I calculate density for different steel grades?

A: To calculate density, you can use the formula to calculate density, which is mass divided by volume. For steel grades, you need to know the specific weight of the material and its volume to accurately determine the density.

Q: What factors affect the density of carbon in steel?

A: The density of carbon in steel is affected by its carbon content. Low carbon steel, which contains less carbon, will have a different density compared to high carbon steel, which has a higher carbon content. Generally, higher carbon content increases the density of the steel.

Q: How does understanding the density of steel help in construction?

A: Understanding the density of steel is crucial in construction, especially when designing steel beams and columns. It helps engineers calculate the load-bearing capacity and ensure that the materials used are appropriate for the structural requirements.

Q: What is the density of mild steel compared to plain carbon steel?

A: The density of mild steel is similar to that of plain carbon steel, typically around 490 pounds per cubic foot. However, variations may occur depending on impurities and other alloying elements present in the steel.

Q: Can the density of steel be altered, and if so, how?

A: Yes, the density of steel can be altered by changing its composition. Adding alloying elements or modifying the carbon content can impact the overall density, as well as the properties of steel.

Q: What is the importance of knowing the density of iron and steel?

A: Knowing the density of iron and steel is important for various applications, including manufacturing and construction. It helps in selecting the right materials and ensuring that structures are designed to handle specific loads effectively.

Q: How does the density of steel products vary between different applications?

A: The density of steel products can vary based on their intended application, such as beams and columns versus plates or sheets. Each application may require different steel grades, which can influence the overall density due to varying carbon content and alloying elements.

Q: What is the relationship between density and weight in steel?

A: The density makes it possible to determine the weight of steel products based on their volume. Knowing the density allows engineers and builders to accurately estimate weights, which is crucial for load calculations in construction.

Q: How can I convert density measurements from pounds per cubic foot to kilograms per cubic meter?

A: To convert density from pounds per cubic foot to kilograms per cubic meter, you can multiply the density in pounds per cubic foot by 16.0185, which gives you the equivalent density in kilograms per cubic meter.