Mild steel, being a highly versatile and commonly utilized metal across several industries, finds a great degree of flexibility between mechanical properties and economics. This is largely owing to the property of density, which while actually being a fundamental property, impacts the use and performance of the few materials for a specific engineering and manufacturing application. We aim to focus on technicalities regarding the density of mild steel, why this aspect is very much important, key advantages, and dating with practical scenarios. That said, whether you are a materials engineer, a student, or simply interested in knowing a bit about the basics of construction and fabrication, the post offers an authoritative overview of the importance of knowing the density of mild steel. Stay tuned as we proceed with unpacking the properties and applications of mild steel to further enrich your learning and decision-making on materials.

What is the Density of Mild Steel?

Being 7.85 g/cm³ or 7850 kg/m³, the density of mild steel directly correlates with how much mass of the material would be occupying a unit volume, making it quite a crucial parameter while deciding upon the use of the material in any kind of structural and industrial applications.

How is the Density of Mild Steel calculated?

The density of mild steel is determined by measuring its mass and volume, and then applying the formula:

Density (ρ) = Mass (m) / Volume (V)

An opposition between mass and volume is used to calculate mild steel density. The wilds are as follows: a balance, that is, the mass of the sample is weighed out with a precision of kilograms or grams. Volume is found geometrically for regular-shaped samples if the appropriate length of the object placed therein in meters and centimeters is known, for example, length, width, and height, or radius for circular cylinders, or through displacement methods for irregular shapes. The volume of fluid displaced equals the volume of the sample. Changes brought about by temperature and impurities make for some variations, and hence it is extremely important to fix the conditions at calculation time to enable all technical data to be referenced for engineering needs with confidence.

What is the typical density of mild steel?

The typical density of mild steel is about 7.85g/cm³ or 7850kg/m³. The density of steel varies a bit, depending on the alloy and its process of making, but most engineering and structural formulas mathematicize this ideal mean value. Depending on the density, mild steel is used primarily for its applications in the commercial building, automotive, and general manufacturing fields, where weight and strength are important.

Why is the density important in engineering?

Density is one solid property, which means it influences the selection of engineering materials and thus design optimization. As an example, in structural engineering, the density of a material determines load values and structure weight in stabilization, transportability, and foundation design. Density is essential in aerospace and automotive applications, too. Here, choosing low-density materials that exhibit sufficient strength would contribute to enhanced fuel efficiency and improved performance. Density, on the other hand, finds importance in fluid mechanics where it rules buoyancy, pressure distribution, and flow behavior. When the density of a material is known to the utmost precision, engineers can decide on the material’s suitability for the application, thereby making that choice on safety, performance, and standard compliance.

What are the different Grades of Mild Steel?

Mild steel is divided into grades on the basis of its composition and mechanical properties. Among the commonly known grades are:

- Grade A36: The most widely used grade for structural applications. It welds and machines well and has a reasonable strength and ductility.

- Grade 1018: Provides a very fine surface finish and is easy to machine, hence best suited for precision parts and mechanical components.

- Grade 1020: An increase in strength over 1018 while still having acceptable machinability and weldability.

- Grade 1045: It contains a high carbon content, thus more strength and hardness, suitable for parts with higher wear resistance.

- Grade EN8 (or 080M40): For shafts, gears, and areas where medium strength is required.

Most grades are designed for typical industrial types of work where their properties guarantee performance.

What defines mild steel grades?

Mild steels are thus classified on the basis of chemical composition, mechanical properties, and particular usage. Low carbon content, which ranges anywhere from 0.05% to 0.25%, is the principal characteristic by which mild steel is distinguished, as it lends the steel good ductility and weldability, also making it malleable. Moreover, tiny quantities of manganese, silicon, sulfur, or phosphorus could be present to impart or improve properties such as tensile strength, toughness, or surface finish. Variations in composition give rise to mild steel grades designed for operational performance in construction, machinery, or some generic fabric. Standards of the industry like ASTM or EN classification circle these grades further in respect to yield strength, tensile strength, hardness, or elongation characteristics so that they will all maintain certain measures of quality and be suited for their respective applications.

What are the properties of different mild steel grades?

- Yield Strength – The yield strength of regular mild steels ranges between 210 MPa and 350 MPa. High-grade steels, usually of stainless nature, tend to have higher yield strengths depending on the particular requirements of an application to resist heavy loading.

- Tensile Strength – The tensile strength of mild steels is generally between 345 MPa and 580 MPa. This characteristic is required in determining a material’s ability to resist tensile force before it actually fails.

- Hardness – The hardness of mild steel varies with its carbon content and processing. For instance, the lower carbon grades are more ductile but are less hard in comparison with higher carbon grades.

- Elongation – This is given as a percentage and refers to the stretchability before cracking. This usually varies from 10% to 25%. This particular characteristic is very important when a large deformation is required in the forming operation.

- Corrosion Resistance – Mild steel is generally considered as poorly corrosion resistant, but treatment processes such as galvanizing or alloying with elements like chromium can greatly improve on this resistance depending on where it is going to be used.

Compare the different grades of mild steel

|

Grade |

Carbon Content (%) |

Tensile Strength (MPa) |

Applications |

Key Properties |

|---|---|---|---|---|

|

Grades 1018 |

0.14-0.20 |

440-550 |

Shafts, gears, pins |

Good machinability, weldable |

|

Grades 1020 |

0.18-0.23 |

410-510 |

Automotive parts |

Tough, easy to form |

|

Grades 1045 |

0.43-0.50 |

570-700 |

Fasteners, bolts, axles |

Strong, moderate machinability |

|

Grades A36 |

≤ 0.29 |

400-550 |

Structural applications |

Cost-effective, weldable |

|

Grades C1015 |

0.12-0.18 |

390-490 |

Machine parts, general use |

High ductility, versatile |

|

Grades 1055 |

0.50-0.60 |

620-760 |

Cutting tools, sprockets |

High wear resistance |

How does the Density of Mild Steel compare to other Types of Steel?

Mild steel offers a density of around 7.85 g/cm³, akin to carbon steels and alloy steels in common, owing to their essentially iron-based structure. However, the differing addition of alloying elements between steel grades can constitute an influence on density; stainless steel may have, dependent upon the grade in question, densities ranging anywhere between 7.7 and 8.1 g/cm³ with reference to its higher content in alloys. Hence, the differences in densities are pretty negligible for various grades of steel, especially with regard to their selection for major applications in structural engineering.

What is the density of low-carbon vs high-carbon steel?

The density in the case of both low carbon steel and high carbon steel would show a slight variation because carbon content varies in them, and so does their microstructure. Low carbon steel consists of usually less than 0.25% carbon, whereas the density is around 7.85 g/cm³. This is due mostly to the presence of a pure phase of ferrite in the microstructure, which is of low density. In contrast, high carbon steels have carbon between 0.6% and 1.4% and could show marginally higher density, mostly in the range of 7.85 to 7.87 g/cm³; there occurs a slight increase in density due to the addition of cementite (iron carbide), a rather dense constituent that forms with the increase in carbon concentration. Although these slight variations in density exist, however, they can be determinants for some specific applications where exact material properties are required, such as in making tools or some other components wherein resistance against high wear is enforced.

What is the density of stainless steel compared to mild steel?

Generally, the density of stainless steels lies between 7.7 to 8.1 g/cm³, and it depends on composition. This is more by a little compared to mild steel with a density that normally varies between 7.85 and 7.87 g/cm³. The higher density of stainless steel could be attributed to the alloying elements such as Cr, Ni, and Mo that are heavier than Fe. For instance, an austenitic stainless steel such as grades 304 or 316 is of higher density owing to its high content of Ni and Cr. These density variations turn critical if weight becomes a crucial factor and the desired properties of the present material include considerations of corrosion resistance, e.g., marine, aerospace, and structural industries.

What are the Properties of Mild Steel?

Mild steel, also referred to as low-carbon steel, bears the characteristic of having a comparatively low carbon content of around 0.05-0.25%. There are a few properties characteristic of mild steel because of this composition:

- Ductility and Malleability: Being low in carbon, it is thus highly ductile and malleable, capable of being shaped and formed or welded with hardly any cracking.

- Tensile Strength: It does not possess a high tensile strength like that which is found in the high-carbon steels, but quite enough tensile strength for most structural and construction applications.

- Toughness: Able to absorb energy and resist impact without fracturing, mild steel is remarkably tough.

- Corrosion Susceptibility: Mild steel will rust and corrode, provided it is not intended to be protected by coating from corrosion, as compared to stainless steel.

- Cost-Effectiveness: It is the least expensive steel in the marketplace and hence suitable for use in bulk applications for which cost is important.

What is the tensile strength of mild steel?

Depending upon composition and method of manufacture, mild steels normally have tensile strengths between 400 and 550 megapascals (MPa). This means that the material can resist a maximum stress applied upon it in tension just before it yields to deformation or fractures. Being a mild steel, tensile strength is gained due to this relatively low carbon content, providing for a very well-balanced ratio between ductility and strength. This high tensile strength makes mild steel quite dependable as a material in many engineering applications such as structural elements and machinery parts. With further heat treatment and alloying, it could be enhanced further to withstand environments of a very demanding nature.

How does ductility vary with different grades?

External stresses greatly contribute to the ductility of materials according to grade, which is controlled by the aspects of chemical composition and the mode of manufacturing. For example, such steel grades as ASTM A36, with the least content of carbon, are highly ductile. It means that the material experiences a high degree of deformation before fracture. In contrast, higher carbon steels such as AISI 1045, while stronger and harder, become more brittle. Elements like manganese, nickel, or chromium influence the ductility to various degrees. Grades that contain such elements could have enhanced ductility without losing strength, such as stainless steel grades 304 that are fairly ductile and corrosion-resistant. Further enhancement of ductility can be made by processes such as annealing and controlled rolling, the first of which will optimize the microstructure and relieve internal stresses. An understanding of ductility versus grade is a fundamental prerequisite for the selection of materials where ductility requirements are in line with specific mechanical properties.

What are the Common Applications of Mild Steel?

Uses for mild steel include many diverse industries where affordability, weldability, and adequate mechanical properties are required. Common uses include:

- Construction: Used for beams, columns, and reinforcement for buildings and infrastructures by virtue of its strength and versatility.

- Automotive Industry: Utilized in car frames, panels, and other structural components for its durability and malleability.

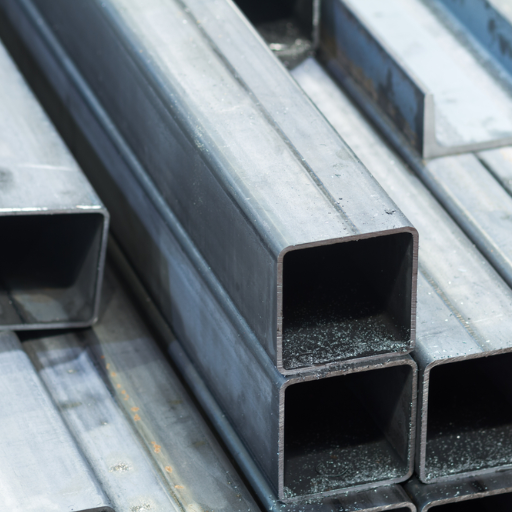

- Piping and Tubing: Frequently used for manufacturing pipes and tubes in plumbing, transportation of fluids, and gas systems.

- Machinery and Equipment: Used in the manufacture of industrial machines, tools for the agricultural sector, and machine parts.

- Household Items: Used in making furniture, appliances, and storage tanks since it is easy to fabricate.

Where is mild steel used in construction?

If the mild steel has duly gained acceptance, it must have been about its strength, and it is definitely strong, a little hard, brittle, and cheap. These properties of mild steel have found huge application in the construction industry. It is heavily used as the structural frame within beams, columns, and girders to give support or stability to buildings and infrastructures. Also, it is used for manufacturing reinforcing bars that will increase the tensile strength of concrete. Mild steel is also employed for roofing sheets, fencing, and staircases, where it can provide durability with ease of fabrication. Its weldability, malleability, and easy cutting make mild steel ideal for customized architectural designs and complex works. As a matter of development, improved protective coating and treatment for mild steel have stepped up its resistance to corrosion, thereby extending its useful life across various environmental conditions. All such characteristics describe how critically mild steel is positioned in the present world of engineering and construction.

What industries rely on mild steel?

Mild steel is a must-have product that finds application in a large number of industries, attributed to its versatility and affordability. In the construction sector, mild steel is employed in providing structural framework, rebar, and cladding systems due to its strength and adaptability. The automotive sector uses it for vehicle frames, panels, and engine components, owing to its ability to machine and capacity to withstand stress. The other major application includes oil and gas pipeline construction, manufacture of wind turbine components, and power generation systems in the energy sector, because of its durability and weldability. Manufacture of machinery, tooling, and other equipment involves mild steel to some extent, highlighting its contribution to industrial processes. This demonstrates how extensively mild steel is used in these different sectors and reveals the importance of a critical material worldwide in production and infrastructural development.

Reference Sources

-

Low-density steels

This study explores the development of low-density steels by substituting stainless steels with cheaper elements like Mn and Al. It discusses the advantages in density and cost-effectiveness.

Read more here -

The corrosion inhibition of metals by molybdate Part I. Mild steel

This paper investigates the role of molybdate in corrosion inhibition for mild steel, focusing on current density changes and passivation effects.

Read more here -

Dynamic strain ageing in mild steel

The research examines the relationship between nitrogen content and flow stress in mild steel, highlighting the impact of dislocation density at varying temperatures.

Read more here -

Corrosion studies on electrochemically deposited PANI and PANI/epoxy coatings on mild steel

This study evaluates the effectiveness of PANI/epoxy coatings in reducing corrosion current density in mild steel, especially in acid sulfate solutions.

Read more here

Frequently Asked Questions (FAQs)

Q: What is the steel density of mild steel compared to other types of steel?

A: The density of mild steel is approximately 7.85 g/cm³, which is similar to most other carbon steels, but this may vary slightly depending on the specific steel alloy and its carbon content. Generally, mild steel has a lower density compared to high-carbon steels which have a higher carbon content.

Q: What are the different types of mild steel according to the American Iron and Steel Institute (AISI)?

A: The AISI categorizes mild steel into several types, mainly designated by their carbon content. This includes low carbon steel (0.05% to 0.25% carbon), medium carbon steel (0.25% to 0.60% carbon), and high carbon steel (0.60% to 1.00% carbon). Mild steel is primarily recognized for its low carbon content, making it versatile for various applications.

Q: How does the carbon content affect the properties of mild steel?

A: The carbon content in mild steel significantly affects its mechanical properties. As the carbon content increases, the steel becomes harder and stronger but also less ductile. Mild steel is known for its balance of strength and ductility, making it suitable for welding and forming operations.

Q: What is the formula for density, and how is it relevant to mild steel?

A: The formula for density is Density = Mass/Volume. This is relevant to mild steel as it helps in understanding how the steel density can impact its weight and structural properties in various applications.

Q: In what applications is mild steel typically used due to its density and properties?

A: Mild steel is often used in construction, automotive, and manufacturing industries due to its high density and favorable properties. Common applications include structural beams, pipelines, and various components subjected to arc welding.

Q: How does heat treating affect the density and properties of mild steel?

A: Heat treating can alter the mechanical properties of mild steel by adjusting the microstructure. While the density may remain relatively unchanged, heat treating can increase strength and hardness, making it suitable for specific applications requiring enhanced performance.

Q: What is the common form of mild steel, and why is it preferred for various applications?

A: The common form of mild steel is structural steel, which is preferred due to its low cost, ease of fabrication, and good weldability. Its moderate density and strength make it ideal for buildings, bridges, and other infrastructure.

Q: What is the difference between mild steel and other steel types in terms of density and application?

A: The primary difference between mild steel and other steel types is its lower carbon content, resulting in a lower density and greater ductility. Unlike high carbon steels, which are harder and stronger but less ductile, mild steel is used in applications requiring formability and weldability.