Corrugated galvanized steel is the best option when it comes to materials for construction that last long, are versatile, and cost effective. Its characteristic wavy pattern and strong performance have led this material to be used in both residential and industrial projects for several decades. But what exactly makes it so popular? And why should it be considered for the next project? This complete guide will tell you everything you need to know—from its unique properties and benefits to practical applications and maintenance tips. It does not matter if you are a homeowner, contractor, OR simply curious about construction materials; this article will give you the necessary insights to help you take informed steps.

Introduction to Corrugated Steel

What is Corrugated Galvanized Steel?

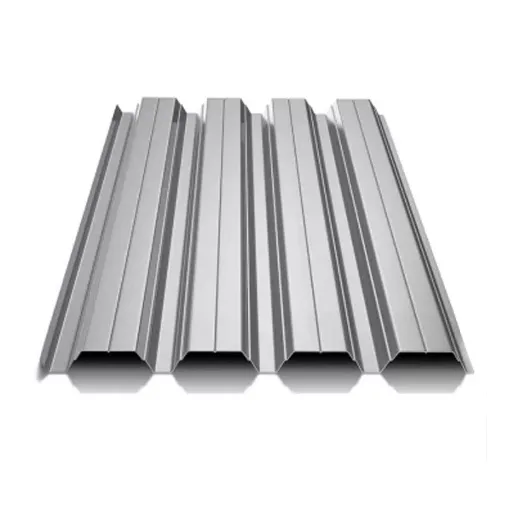

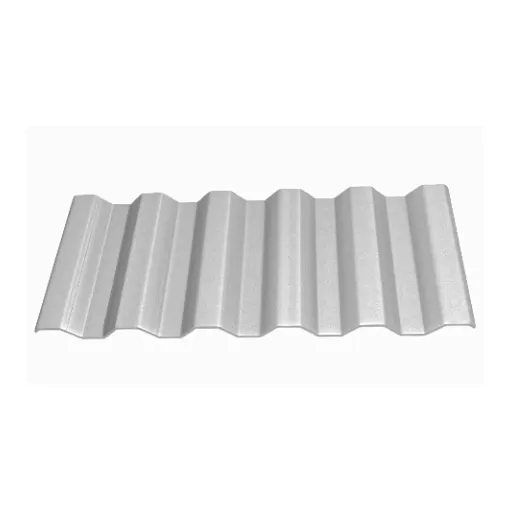

Corrugated galvanized steel is a special metal that most of the time is used in the building industry and factories because of its hardness and non-roughness to nature. It has a wavy pattern that apart from making it stronger also allows water, snow, and dirt to run off easily. This product is obtained from steel sheets which are then ridged by corrugation and coated with zinc for rusting and wear resistance in an environmental setting.

Zinc coating, which is also referred to as galvanization, is the main reason why corrugated galvanized steel lasts so long. The reason is that the zinc covering prevents steel from coming into contact with moisture and air which are the main causes of metal corrosion. This quality makes corrugated galvanized steel particularly outdoor and heavy-duty fit for use in roofing, siding, and fencing where it is necessary to endure extreme weather.

The fact that corrugated galvanized steel is not only versatile and cheap but also greatly appreciated. It has a small weight and easy to deal with which simplifies the installation as compared to other types of materials. On top of that, it has a good price and is easy to maintain thus it is an economical choice for both small and large industrial projects. With that mix of features, strength and long-lasting, corrugated galvanized steel has gained the reputation of a reliable material in different construction situations.

History and Development of Corrugated Metal

The first efforts in creating corrugated metal were undertaken during the 1820s by Henry Palmer, the architect and engineer of England. At first, the metal was made of wrought iron, and its pattern of alternating ridges and grooves, which, at the same time, accentuated its strength, was the reason behind the not so heavy and bulky materials not being used in the process. This milestone turned corrugated metal into the perfect material for roofs and coverings in buildings, hence, it swiftly got popular in factories and farms, particularly in those areas where metal goods usage was high or where metal goods usage was high or where they were in contact with the elements even more often than elsewhere.

During the last decade of the 19th century, the technological advancements in metallurgy made galvanized steel the standard metal for corrugated metal. Galvanization, a technique that applies a barrel of zinc onto the steel to make it resistant to oxidation, also improved the corrosion resistance of the steel, especially in wet or seaside areas. This technology enabled the manufacturers of corrugated metal to prolong the life of their products and to secure even more their position in the construction and infrastructure industries.

In fact, corrugated metal is still a building material widely used in modern architecture and engineering. The metal has been along its journey of development diversified to include varieties of aluminum and other alloys that are more than ready to take on a wider spectrum of applications. Its long-lasting nature combined with its flexibility and minimum upkeep has guaranteed its demand, along with that of the other metals used, for building and decorating in the case of residential, commercial, and industrial projects around the globe. These past events reveal the still significant role that corrugated metal plays in construction.

Key Features of Corrugated Steel Panels

The uniqueness of corrugated steel panels lies in their superior strength-to-weight ratio, which is one of the reasons they are favored in building projects that call for durability and structural integrity. The panels’ characteristically ribbed design offers not only strength but also resistance against bending and stress, thereby ensuring that the panels will perform effectively even in adverse weather conditions or under heavy loads.

Another important feature is their multi-functionality. The panels can be used in various ways, such as roofing, siding, and flooring. They come in a wide range of thicknesses, sizes, and finishes allowing the architects and builders to create designs that meet both the aesthetic and functional requirements. Modern panels are also available with coatings that offer protection against corrosion, UV rays, and moisture, thus making them fit for use in a wide range of environments.

The installation process is another significant reason why corrugated steel panels are so valuable. The material, that is lightweight, can be moved and installed with very little effort and time. This not only reduces costs but also the length of time the project will take. The ability to not just resist environmental wear and tear but together with these panels represent an economic and durable solution for both small and large construction projects.

Benefits of Using Galvanized Corrugated Metal

Durability and Strength of Steel Substrate

- ✓ Corrosion Resistance – The zinc coating applied to the steel prevents it from rusting and getting oxidized even in extreme environmental situations like heavy rain, snow, or coastal air with high salt content.

- ✓ High Tensile Strength – Steel substrates usually have tensile strengths that range from 50,000 to 70,000 psi which enables them to bear heavy loads and resist stress without getting deformed.

- ✓ Impact Resistance – The strong and durable structural design of the corrugated type gives it a better capacity for impact absorption and distribution thus making it a good option for physical wear and tear areas.

- ✓ Longevity – Galvanized corrugated metal is expected to have a life span of over 50 years if kept in rural areas and around 25 years in places with industrial or coastal environmental conditions, all that with very little maintenance.

- ✓ Temperature Tolerance – Steel does not lose its strength even when exposed to very high or low temperatures thus being a reliable material in such varying climates and conditions.

Corrosion Resistance and Protection from Elements

A major feature of galvanized corrugated metal that sets it apart is its unmatched ability to resist corrosion, which means it will be functional for a long time even in very badly affected by corrosion places and situations. The application of zinc coating during the galvanization process is the main reason for this resistance as it forms a barrier through which moisture, air, and other corrosive elements cannot penetrate and thus won’t affect steel. Here are five important things to know about its corrosion resistance and protection:

- ● Zinc Coating Barrier – The zinc coating keeps moisture and oxygen away from the steel surface, which makes it very unlikely that rust is formed.

- ● Self-Healing Properties – In the case that the coating is scratched or damaged, zinc can still save the steel underneath by giving itself up through a process called galvanic action.

- ● Protection in Humid Environments – Galvanized metal is able to withstand the conditions in areas with high humidity, and it will not suffer from problems like condensation-induced corrosion which takes very long to happen.

- ● Resistance in Saltwater Conditions – Whereas unprotected steel gets eaten away very fast in coastal or marine environments, you can consider that the lifetime of galvanized metal is enhanced due to its reduced susceptibility to the salt-laden air affecting its structure.

- ● Prolonged Exposure Durability – It is capable of withstanding corrosion for prolonged exposure to changing weather, including intense sunlight, rainfall, or freezing temperatures, hence its suitability for outdoor applications.

The combination of these features makes it very difficult for galvanized corruated metal to be unworthy, even under the toughest conditions.

Cost-Effectiveness of Metal Roofing Solutions

The metal roofing solutions have multiple advantages in terms of cost that make them a great option for both residential and commercial areas. The following are the five major details that present their affordability and value over the long term:

- $ Durability and Low Maintenance Costs: Metal roofs have a lifespan of 40 to 70 years or even longer, which is significantly more than that of conventional roofing materials, such as asphalt shingles. This long-lasting quality brings about a big cut on the costs associated with replacements and their frequency.

- $ Energy Efficiency: Metal roofs can reflect about 25% of the solar radiant heat, which is cooling cost saving of up to 25%. Proper insulation and coatings allow significant savings on the necessary energy bills for both the home and business throughout the year.

- $ Recyclability and Environmental Impact: Metal roofs will be recycled entirely when they reach the end of their life cycle, and this is a common practice since they are also made of recycled materials themselves. Thus, the environmental pollution is minimized, and the costs from disposal and production of new materials are also reduced in the long run.

- $ Lightweight Installation: Metal roofs being light in weight come with the advantage of putting less pressure on the building’s frame which means that the construction and reinforcement costs may be reduced during the installation process.

- $ Insurance Premium Discounts: The roofs made of metal are considered to be so resistant to fire, wind, and hail damage that many insurance companies will offer you a discount on your premiums. These cuts can mean considerable savings over the course of the years.

The combination of these elements guarantees that the metal roofing solutions are not only inexpensive initially but also good investments for the future in terms of cost savings.

Common Applications for Corrugated Metal

Metal Roofing in Residential Construction

Metal roofing is becoming increasingly popular due to its longevity and aesthetic appeal. Homeowners are choosing corrugated metal roofing not only for durability but also for its energy efficiency. Corrugated metal can resist corrosion and withstand extreme weather conditions, from heavy snow to high winds, making it ideal for residential use. Additionally, corrugated metal sheets provide excellent water runoff, preventing potential water damage or leaks. The variety of colors and finishes available today makes it possible to match any architectural style, adding a modern touch to traditional homes.

Siding Solutions for Buildings

Corrugated metal is also an excellent choice for siding on both residential and commercial buildings. Its versatility and sleek appearance make it attractive for modern architecture. The material provides a protective barrier against weather elements while requiring minimal maintenance. When used as siding, corrugated metal offers a clean, industrial look that appeals to contemporary design preferences. Furthermore, its resistance to pests such as termites or rot makes it a superior alternative to traditional wood siding.

Agricultural Buildings and Barns

Farmers and agricultural businesses rely heavily on corrugated metal for constructing barns, storage facilities, and livestock shelters. The material’s strength and durability ensure these structures withstand harsh conditions while protecting valuable equipment and animals. Corrugated metal buildings are cost-effective and require less upkeep compared to traditional wooden structures. The ease of installation also means these buildings can be erected quickly, minimizing downtime during busy farming seasons.

Industrial and Commercial Use

In industrial and commercial settings, corrugated metal is used extensively for warehouses, factories, and retail spaces. Its ability to span large areas without requiring extensive support structures makes it perfect for creating open floor plans. The material’s fire-resistant properties also add an extra layer of safety in commercial environments. Many businesses choose corrugated metal because of its affordability and the speed at which buildings can be completed, reducing construction time and costs.

Fencing and Security Applications

Corrugated metal fencing is a practical choice for both residential properties and commercial facilities. It provides security and privacy while being durable and low-maintenance. Unlike wooden fences that can rot or warp over time, metal fencing maintains its structural integrity for decades. The material can also be customized with different heights and styles to meet specific security needs. Industrial sites often use corrugated metal fencing to create secure perimeters around sensitive areas.

Cost Analysis and Budgeting

Material Costs and Pricing Factors

The cost of corrugated galvanized steel varies based on several factors. Gauge thickness is a primary determinant—thicker materials cost more but offer greater durability. Coating type affects price, with standard galvanized being most economical, while painted finishes or Galvalume coatings command premium prices. Panel length and width also influence cost per square foot. Market conditions and metal prices fluctuate, so timing your purchase can impact overall project costs. Generally, expect to pay between $1.50 to $5.00 per square foot for materials alone, depending on specifications.

Installation Cost Considerations

Professional installation costs vary by region and project complexity. Simple roof installations on new construction are most economical, while replacement projects requiring tear-off and disposal of existing roofing increase costs significantly. Complex roof geometries with multiple angles, valleys, or skylights require more labor and waste, raising installation expenses. Geographic location affects labor rates—urban areas typically have higher installation costs than rural regions. Budget between $3.00 to $8.00 per square foot for professional installation, though complex projects may exceed this range.

| Roofing Material | Material Cost (per sq ft) | Installation Cost (per sq ft) | Lifespan (years) | Maintenance Level |

|---|---|---|---|---|

| Corrugated Galvanized Steel | $1.50 – $5.00 | $3.00 – $8.00 | 40 – 70 | Low |

| Asphalt Shingles | $0.80 – $1.50 | $1.50 – $3.50 | 15 – 30 | Moderate |

| Standing Seam Metal | $3.00 – $7.00 | $5.00 – $12.00 | 50 – 75 | Low |

| Clay Tiles | $5.00 – $10.00 | $8.00 – $15.00 | 50 – 100 | Low to Moderate |

| Wood Shakes | $4.00 – $7.00 | $6.00 – $10.00 | 20 – 40 | High |

DIY vs. Professional Installation

Choosing between DIY and professional installation significantly impacts project costs. DIY installation can save 50-60% on labor costs but requires appropriate tools, skills, and safety equipment. For handy homeowners with construction experience, simple structures like sheds or small outbuildings make suitable DIY projects. However, residential roofing should generally be left to professionals due to safety concerns and the importance of proper installation for warranty coverage. Complex projects or multi-story buildings always warrant professional installation to ensure structural integrity and safety compliance.

Long-Term Value and ROI

While corrugated metal may have higher upfront costs than some alternatives, its long-term value is substantial. The extended lifespan means fewer replacements over a building’s lifetime. Energy savings from reflective coatings reduce cooling costs. Low maintenance requirements minimize ongoing expenses. Many buyers view metal roofing as a premium feature, potentially increasing property value. When calculating return on investment, consider the total cost of ownership over the expected lifespan rather than just initial installation costs.

Financing and Payment Options

Several financing options can make corrugated metal roofing more accessible. Home improvement loans offer fixed-rate financing specifically for renovation projects. Home equity lines of credit (HELOCs) provide flexible funding using home equity. Some contractors offer payment plans or financing through third-party lenders. Additionally, energy-efficient metal roofing may qualify for tax credits or rebates, reducing net costs. Research available incentives in your area and compare financing terms to find the most economical approach for your project.

Troubleshooting and Problem-Solving

Identifying Common Issues

Even with proper installation and maintenance, certain issues may arise with corrugated galvanized steel. Recognizing these problems early allows for prompt correction before they escalate. Common issues include loose or missing fasteners, which can be identified by visible gaps or rattling during wind. Water stains on ceilings or walls may indicate leaks at seams or penetrations. Unusual noises during temperature changes might suggest thermal expansion issues. Visible rust spots signal coating damage requiring attention. Regular inspections help identify these issues when they’re still minor and easily correctable.

Dealing with Leaks and Water Infiltration

Leaks in metal roofing typically occur at fasteners, seams, or flashing points rather than through the panels themselves. To locate leaks, trace water stains backward and upward from interior evidence—water often travels before dripping. Check fasteners for proper sealing and tightness. Inspect lap seams for adequate overlap and sealant condition. Examine flashing around chimneys, vents, and skylights for gaps or deterioration. Temporary repairs can be made with roofing sealant or tape, but proper long-term fixes should address the root cause and maintain the roof’s integrity.

Addressing Noise and Thermal Movement

Metal roofing can produce noise during rain, hail, or thermal expansion and contraction. Rain noise is primarily an issue with insufficient insulation or underlayment. Adding insulation board beneath the metal significantly reduces sound transmission. Expansion and contraction noises (popping or clicking) occur when temperature changes cause metal to move. This is normal but can be minimized by using appropriate fastening systems that allow controlled movement. Ensure fasteners aren’t over-tightened, which can restrict necessary expansion. Proper installation with adequate clips and spacing prevents most noise issues.

Preventing Oil Canning and Panel Distortion

Oil canning refers to visible waviness in flat areas of metal panels, creating an uneven appearance. While primarily aesthetic, it’s a common concern. This phenomenon results from stress in the metal due to manufacturing, handling, or installation. To minimize oil canning, choose panels with stiffening ribs or heavier gauges. During installation, avoid over-tightening fasteners and ensure panels aren’t forced into position. Proper substrate preparation and adequate support prevent many distortion issues. Understanding that some oil canning is inherent to metal’s nature helps set realistic expectations.

Managing Condensation Problems

Condensation forms when warm, moist air contacts the cold underside of metal panels, particularly problematic in temperature-controlled buildings. Proper ventilation is the primary solution—ensure adequate airflow between the roof deck and metal panels. Installing a vapor barrier on the warm side prevents moisture migration. Adequate insulation maintains consistent temperatures and reduces condensation risk. In agricultural or industrial buildings where humidity levels are high, additional ventilation or dehumidification systems may be necessary to prevent condensation-related problems.

Comparing Alternatives

Corrugated vs. Standing Seam Metal Roofing

Advantages of Corrugated:

- Lower material and installation costs

- Easier DIY installation for simpler projects

- Traditional aesthetic appeals to certain architectural styles

- Exposed fastener system simplifies repairs and replacement

Disadvantages of Corrugated:

- Exposed fasteners are potential leak points and require maintenance

- Less sleek appearance compared to standing seam

- May not be suitable for very low-slope applications

- Fewer color and finish options in some markets

Advantages of Standing Seam:

- Concealed fasteners reduce leak potential and maintenance

- Sleek, modern appearance highly valued in contemporary architecture

- Better performance on low-slope roofs

- Easier panel expansion and contraction accommodation

Disadvantages of Standing Seam:

- Significantly higher material and installation costs

- Requires specialized tools and expertise for installation

- Not suitable for DIY installation

- Repairs may be more complex and expensive

Galvanized Steel vs. Aluminum

Both galvanized steel and aluminum offer distinct advantages for corrugated applications. Galvanized steel provides superior strength and durability, making it ideal for areas with heavy snow loads or where impact resistance is important. It’s generally less expensive than aluminum and better suited for structural applications. However, aluminum excels in coastal environments due to superior corrosion resistance in saltwater conditions. Aluminum is lighter, which can reduce structural requirements but may be more susceptible to denting. The choice often depends on specific project requirements, environmental conditions, and budget considerations.

Metal vs. Traditional Roofing Materials

Comparing corrugated metal to traditional materials like asphalt shingles reveals significant differences in performance and value. Asphalt shingles cost less initially but require replacement every 15-25 years, making metal more economical over time. Metal’s durability far exceeds asphalt in wind and hail resistance. Energy efficiency strongly favors metal through its reflective properties. However, asphalt installation is more familiar to contractors, potentially simplifying finding qualified installers. For premium applications, clay or slate tiles offer comparable longevity to metal but at significantly higher costs and with much greater weight requiring additional structural support.

Galvanized vs. Galvalume Coating

The choice between galvanized and Galvalume coatings impacts performance and longevity. Galvanized steel features pure zinc coating, offering excellent corrosion resistance and self-healing properties when scratched. It performs exceptionally in most environments and costs less than Galvalume. Galvalume combines aluminum and zinc, providing enhanced corrosion resistance and better heat reflectivity. It excels in harsh coastal environments and offers slightly longer lifespan expectations. The aluminum component makes it more reflective, improving energy efficiency. For most applications, galvanized steel provides excellent performance, but Galvalume merits consideration in especially corrosive environments or where maximum energy efficiency is desired.

References

Corrugations

This source explains the structural benefits of corrugations in pipes, including stiffness and strength.

Flexural Properties of Corrugated Metal Roofing

This academic paper discusses the structural strength provided by corrugated shapes in steel or aluminum roofing.

Culvert Materials and Construction

This resource details the construction and materials of corrugated steel pipes, emphasizing their use in culverts.

Frequently Asked Questions (FAQ)

Q: What is corrugated galvanized steel?

A: Corrugated galvanized steel is a specific steel type that has a zinc coating, which is supposed to keep rust and corrosion away. The corrugated design not only looks good but also contributes to the strength and rigidity of the material, therefore making it suitable for many applications such as roofs, walls, and barns.

Q: How is corrugated galvanized steel produced?

A: Corrugated galvanized steel production is a process that begins with making carbon steel plates, these are then passed through a zinc bath at melting point. With this method, they get a strong and durable galvanized coating that is able to withstand the outdoors’ tough weather.

Q: What are the advantages of using galvanized corrugated sheet metal?

A: The use of galvanized corrugated sheet metal has a number of advantages such as longer life, not being affected by rust, and less cleaning and supervision. The fact that it is lightweight also contributes to its being a popular option in post-frame construction as it is easy to install.

Q: Can I get custom sizes for corrugated galvanized steel?

A: Yes, there are a lot of suppliers who sell corrugated galvanized steel that have custom options available. You are allowed to ask for widths, and lengths that are particular to you and even have designs that are special made for you so that they can fit right into your projects.

Q: What is the difference between galvanized and galvalume steel?

A: In the case of steel, the coating is zinc on galvanized, whereas, for galvalume, the coating is aluminum and zinc. The latter coating provides even better protection from corrosion and is usually more reflective, thus making it suitable for roofing applications such as galvalume roof panels.

Q: How do I request a quote for corrugated galvanized steel?

A: If you want to get a price offer for corrugated galvanized steel, either the supplier or manufacturer in your area should be contacted. The exact details of the metal products you need, such as size, quantity, and mode of delivery, should be given to them so that you get a correct estimate.

Q: What types of applications are best suited for corrugated galvanized steel?

A: Among the various applications, corrugated galvanized has roofing, siding, fencing, and agricultural buildings at the forefront. Its toughness and resistance make it suitable for both residential and commercial projects.

Q: Is corrugated galvanized steel environmentally friendly?

A: Corrugated galvanized steel is, in fact, environmentally friendly as it is recyclable and its long-lasting feature minimizes the replacements therefore less frequent replacements are required as a result- which reduces the overall carbon footprint thus contributing to sustainable building practices.

Q: How do I ensure efficient delivery of my corrugated galvanized steel order?

A: To make your corrugated galvanized steel order efficiently delivered, it is advised that you closely cooperate with your supplier in order to take care of the logistics. The delivery time should be confirmed, stock availability should be checked, and then any custom requirement you might have should be planned for ahead.

Q: What accessories are available for corrugated galvanized steel installations?

A: Fasteners, trims, and flashing are just the most common among the roofing galvanized steel installations’ accessories. The accessories not only help with the fitting but also the overall performance and aesthetics of the installation are enhanced.