What is Aluminum Passivation?

Understanding the Importance of Aluminum Passivation

Passivation is the chemical procedure that improves the corrosion resistance of metals, such as aluminum. In the case of aluminum, passivation involves the creation of an oxide layer on the surface of the metal. When aluminum is exposed to oxygen, it forms a thin aluminum oxide layer that is stable and prevents further oxidation or degradation of the underlying aluminum.

Key Benefits of Aluminum Passivation:

- Extended component lifespan

- Protection against various forms of corrosion

- Maintenance of mechanical properties in harsh environments

- Environmental benefits through reduced material replacement needs

- Cost-effective long-term solution

How Aluminum Passivation Works

Passivation of aluminum is a chemical treatment that enhances aluminum’s corrosion resistance. Aluminum naturally reacts with air to create a thin, protective layer of aluminum oxide on its surface. This oxide layer is chemically inert, limiting further oxidation and protecting the metal underneath from moisture, pollutants, and chemicals.

Under typical conditions, the passivation process is self-sustaining because the oxide layer is self-healing. Passivation can be optimized through controlled processes like anodizing, which thickens and uniformizes the oxide layer by immersing aluminum in an electrolytic bath and energizing it with current.

Comparison: Aluminum vs. Stainless Steel Passivation

| Key Point | Stainless Steel | Aluminum |

|---|---|---|

| Weight | Heavier | Lighter |

| Corrosion Resistance | High resistance | Moderate resistance |

| Process Type | Acid-based | Conversion coating |

| Primary Applications | Industrial, medical | Aerospace, electronics |

| Galvanic Risk | Slower corrosion | Faster corrosion |

Benefits of Aluminum Passivation

Improved Corrosion Resistance

The passivation process allows aluminum to form a protective oxide layer that significantly enhances its corrosion resistance. This stable oxide layer prevents the underlying aluminum from reacting with moisture, oxygen, and other corrosive chemicals. Compared to untreated aluminum, passivated aluminum maintains its structural integrity even over extended periods under harsh conditions.

Enhanced Durability and Performance

Passivation is crucial for developing products that can resist corrosion and last longer. Research indicates that passivated aluminum shows close to 70% reduction in corrosion rates, extending the material’s life considerably compared to non-passivated metal.

Applications in Various Industries

Aerospace Engineering

- High strength-to-weight ratio performance

- Increased resistance to environmental factors

- 25% increase in operational uptime

- Reduced maintenance intervals

Automotive Manufacturing

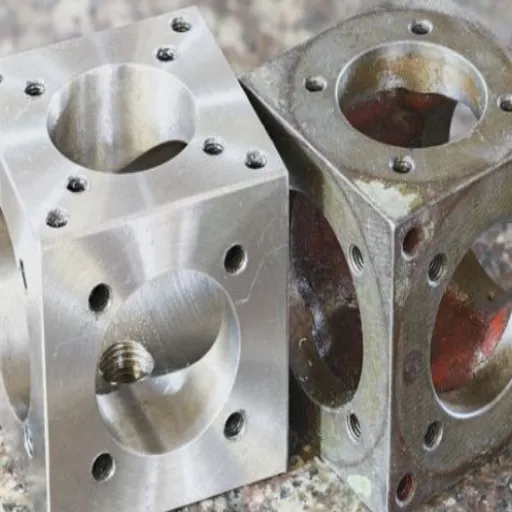

- Used in engine blocks, body panels, and heat exchangers

- Up to 40% improvement in product life

- Enhanced resistance to road salt and high humidity

Construction and Infrastructure

- Structural components like frames, roofing sheets, and cladding

- 30% reduction in repair and refurbishment costs over 20 years

- Extended structural integrity periods

Electronics

- Heat sinks, connector housings, and circuit boards

- 20% enhancement in thermal management efficiency

- Improved reliability under harsh environmental conditions

Marine Applications

- Boat hulls, offshore platforms, and underwater pipelines

- 60% increase in service life in saltwater environments

- Minimized downtime and maintenance costs

Processes Involved in Aluminum Passivation

Step-by-Step Guide to Passivating Aluminum

Step 1: Surface Preparation

Clean the aluminum surface with alkaline or acid-based agents to remove contaminants like oils, dirt, and oxidation. The choice of cleaning agent depends on the specific application.

Step 2: Rinsing

Rinse with deionized or distilled water to remove cleaning solution residues. This prevents interference with subsequent chemical reactions.

Step 3: Etching

Treat the surface with an acidic solution (such as nitric acid) to remove the topmost oxide layer and modify the microtexture for better passive layer formation.

Step 4: Applying Passivation Solution

Immerse or treat aluminum with a passivation solution containing chromates, phosphates, or non-chromate alternatives like zirconium or silane chemistries.

Step 5: Reaction Timing

Maintain aluminum in the passivation bath for a measured period (typically 20-40 minutes) with strict temperature and time control.

Step 6: Final Rinsing

Rinse with deionized water to remove residual chemicals without disturbing the newly formed oxide layer.

Step 7: Drying and Inspection

Dry using air knives or controlled ovens, followed by quality inspection using XRF analysis or salt spray testing.

Factors Affecting Passivation Quality

- Surface Preparation: Critical cleanliness requirements – inadequate cleaning can reduce passivation efficiency by about 40%

- Chemical Composition: Variations in pH, concentration, and stabilizers significantly impact oxide layer quality

- Alloy Composition: Different aluminum alloys require specific passivation methods

- Environmental Conditions: Humidity and airborne particles can interfere with the process

- Post-treatment Handling: Proper storage and handling maintain coating effectiveness

Common Methods: Anodizing vs. Chemical Passivation

| Key Point | Anodizing | Chemical Passivation |

|---|---|---|

| Materials | Aluminum | Stainless Steel & Aluminum |

| Process | Electrochemical | Chemical cleaning |

| Purpose | Oxide layer creation | Contaminant removal |

| Corrosion Resistance | High resistance | Enhanced resistance |

| Applications | Aerospace, electronics | Medical, industrial |

Challenges in Aluminum Passivation

Common Issues Faced During the Process

- Inadequate Contaminant Removal: Grease, oils, or oxides interfere with uniform passive layer creation

- Chemical Composition Control: Deviations from specified pH values or incorrect ingredient ratios

- Environmental Factors: Temperature and humidity fluctuations affecting chemical reactions

Solutions to Overcome Passivation Challenges

- Environmental Controls: Cleanroom or humidity-controlled chambers

- Real-time Monitoring: pH and spectrophotometric analysis of solutions

- Automation: IoT technologies for continuous process variable monitoring

- Material-Specific Protocols: Tailored procedures for different aluminum alloys

- Regular Maintenance: Periodic equipment calibration and maintenance

Recent Advancements in Aluminum Passivation Technology

Emerging Techniques and Innovations

- Hybrid Sol-Gel Coatings: Combining organic and inorganic components for enhanced protection

- Ion Implantation: Subatomic surface modification for improved pitting resistance

- Environmentally Friendly Techniques: Cerium and lanthanum-based conversion coatings

- Advanced Modeling: Machine learning algorithms with finite element analysis

Industry Trends

- Shift toward chromium-free passivation solutions

- Integration of AI and machine learning for predictive performance

- Development of hybrid organic-inorganic coatings

- Focus on lightweight materials for automotive and aerospace

- Investment in nanostructured coating research

Frequently Asked Questions (FAQ)

References

- Binghamton University: Mechanism of Formation of the Aluminum Passivation Layer – Discusses the formation of bilayer oxides in aluminum passivation

- University of California, Riverside: Surface passivation of bare aluminum nanoparticles – Studies SAM coatings for aluminum passivation against oxidation

- Penn State University: Passivation and stabilization of aluminum nanoparticles by plasma-enhanced chemical vapor deposition

- Oak Ridge National Laboratory: Understanding the dissolution and passivation of an aluminum electrode – Passivation in electrocoagulation systems

- PubMed: Selective aluminum passivation for targeted immobilization – Selective passivation methods for specific applications