Stainless steel is one of the materials that are frequently chosen in industrial, automotive, or construction projects due to its durability, as well as its ability to withstand corrosion and versatility. Among the different grades of stainless steel, 409 stainless steel sheets are the best choice in terms of price when it comes to applications with moderate corrosion resistance and very good thermal stability. However, what are the reasons that 409 stainless steel sheets price so much and what makes them the number one choice for the different industries? This article elaborates on the price factors, major uses, and spectacular benefits of 409 stainless steel sheets making it easier for you to take informed decisions concerning your projects. You are a manufacturer, contractor or design engineer; knowing these factors will assist you in uniting performance and budget wisely.

Overview of 409 Stainless Steel

What is 409 Stainless Steel?

409 stainless steel is another member of the ferritic family that mainly trusts its potential of being a good performer in terms of corrosion resistance, high-temperature strength, and cost-effectiveness. The most important part of its composition is the iron and chromium (approximately 10.5-11.75%), and the smallest fraction of titanium, whose participation impressively helps the steel to resist oxidizing and to be weldable. Unlike austenitic stainless steel, the 409 grade stainless steel is magnetic because of its ferritic structure. Also, it is recognized for its lower cost but still good quality in terms of durability and longevity.

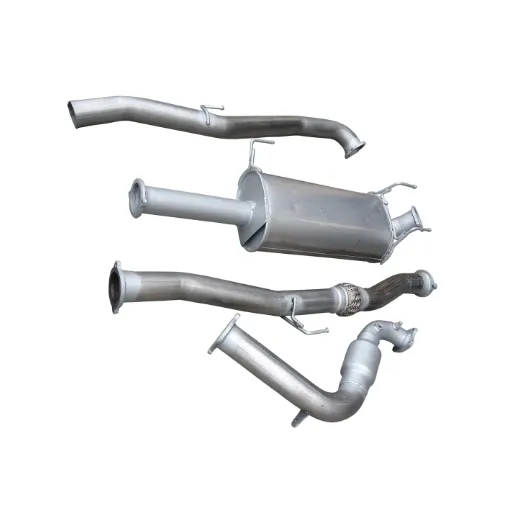

Besides that, its main role in the automotive industry is often to be an exhaust system, heat exchangers, and the construction of oxidizing control parts wherein high-temperature oxidation and moderate corrosion resistance are characteristics. Adequately balanced chromium prevents rusting in mild environments while titanium does not allow scaling even at peak temperatures. That is why 409 stainless steel is still the first choice of many industries due to its cost and wide-ranging applications.

Key Properties of 409 Stainless Steel

🛡️ Corrosion Resistance

Modestly resistant to corrosion in mild environments due to optimized chromium content. Appropriate for general-purpose uses and automotive and structural applications.

🔥 Thermal Stability

Titanium content helps fight scaling at high temperatures, making it ideal for automotive exhaust systems in high-heat areas.

💪 Strength and Durability

Excellent mechanical properties with enough strength for demanding applications. Very reliable under mechanical stress.

💰 Affordability

Major advantage is its price. Combines reasonable performance characteristics with low-cost production for mass production industries.

⚡ Weldability

Good weldability among ferritic stainless steels, allowing custom component fabrication. Proper heat treatment ensures optimal performance.

Comparison with Other Stainless Steels: 304 and 316

| Grade | Type | Key Features | Primary Applications | Cost |

|---|---|---|---|---|

| 409 | Ferritic | Moderate corrosion resistance, excellent thermal stability, magnetic | Automotive exhaust systems, heat exchangers | Low |

| 304 | Austenitic | Very high corrosion resistance, non-magnetic, versatile | Kitchen equipment, architectural components | Medium |

| 316 | Austenitic | Superior corrosion resistance with molybdenum, chloride resistant | Marine applications, medical devices | High |

When one associates 409 with the 304 and 316 classes, it is crucial to know chemical composition, corrosion resistance, and intended applications. 409, although being grouped with ferritic steels, has found a good balance of corroding resistance through the chrome content which still places the material considerably below 304 and 316 in aggressive environments. In fact, owing to its low cost and less thermal conductivity, 409 can be utilized especially for areas of automotive exhaust where the heat is extreme but cost-effectiveness is the main criteria. In contrast, 304 and 316 are mostly used for applications that require assurances against extreme conditions. Anyway, every material has its specific function and the choice of one should consider budget, environmental conditions, and functional requirements.

Current Trends in 409 Stainless Steel Sheet Pricing

Global Market Analysis

The price of 409 stainless steel sheets is determined by a mixture of global factors, including the availability of raw materials, the cost of production, and the demand from major industries such as the automobile industry. The data from industry reports and search trends reveal that there has been a growing interest in using stainless steel for exhaust systems and thermal application just because it is cost-effective to use such materials. On top of that, the movement in the prices of nickel and chromium, which are the main elements of stainless steel, also impacts the total price of the stainless steel market.

📊 Market Insights

The Asia-Pacific and North America areas continue to be the major sources for the world to demand these metals with lighter and more durable materials being the main reason for the energy-efficient designs.

The present search terms indicate that the inquiries for “affordable stainless steel sheets” and “best material for exhaust systems” are climbing, showing that the focus on the inexpensive and practical materials is continuous across various sectors, mainly in the automotive and industrial manufacturing.

Local Market Influences

There is a strong correlation between the local market trends and the consumer demand for materials that are both cost-effective and high performing. The increasing number of searches for “affordable stainless steel sheets” and “best material for exhaust systems” shows the preference for durable materials that offer quality and price. This indicates that companies should respond to this demand by obtaining materials that satisfy these requirements as well as developing their offer in accordance with the local economic situation. By meeting the two needs of price and quality, firms will be able to establish a strong presence in the local market.

Historical Price Trends

Looking into historical pricing shows a steady rise and fall of the cost of steel sheets over the past ten years, depending on factors like the availability of raw materials, global demand, and production costs. The increase in energy costs and supply chain disruptions in the past few years are among the causes of the high prices. The market research data shows a growing interest in “affordable stainless steel sheets” which leads to the conclusion that buyers are looking for reliable yet cost-effective options. This situation points out that the suppliers have to stay competitive by giving precedence to efficient sourcing strategies and transparent pricing that goes hand in hand with the consumers’ needs.

Factors Influencing 409 Stainless Steel Sheet Prices

⚙️ Raw Material Costs

The selling price of 409 stainless steel sheets is very much correlated with the price of its main raw materials, including iron, chromium, and nickel. Global supply chain and mining fluctuations together with political issues can result in changes of considerable extent in these materials’ costs.

Solution: Suppliers can use intelligent procurement models, take advantage of recycled materials where possible, and have strong bonds with suppliers to provide customers with less expensive quality while keeping costs stable.

🏭 Manufacturing Processes

Manufacturing plays a major role in determining market trends and consumer satisfaction. Modern workflows can significantly impact both quality and cost.

Strategy: Modernizing manufacturing workflows by incorporating state-of-the-art automation along with precision engineering and eco-friendly methods leads to efficiency in making products while being less of a burden cost-wise.

🚚 Supply Chain Dynamics

Supply chain dynamics can be adjusted to higher standards in terms of consumption and accuracy of market trends prediction. Companies can discover rising inclinations and regional differences in demand.

Approach: Using trend data helps review just-in-time inventory, supplier and distribution relationships, minimizing delays and achieving better forecasting accuracy.

Applications of 409 Stainless Steel

Common Applications

409 stainless steel is one of the most popular stainless steel grades in the industrial world, thanks to its excellent resistance to corrosion, low price, and durability. The automotive industry is the main application field; particularly in exhaust systems, catalytic converters, (which are one of the hottest parts in the exhaust system) and also in mufflers and tailpipes, where oxidation resistance is important.

Primary Application Areas:

- 🚗 Automotive Industry: Exhaust systems, catalytic converters, mufflers, and tailpipes

- 🌾 Agricultural Machinery: Equipment components requiring durability and corrosion resistance

- 🔥 Heat Exchangers: Industrial equipment handling high-temperature applications

- 🏗️ Construction: Structural elements benefiting from good welding and machining properties

- ⚙️ Manufacturing: Various industrial equipment and components

Niche Applications and Advantages

409 stainless steel still surprises us with new applications in different niche markets and one of the reasons is its cost-effective characteristics together with the corrosion resistance. For instance, in the automotive sector, it is being used more and more in lightweight cars that have to meet very strict emissions regulations and still be durable at the same time. The material’s ability to withstand high temperatures without scaling makes it an excellent option for energy-efficient manufacturing lines and waste heat recovery.

🌱 Emerging Green Applications

The material is quite easy to work with, letting designers use it in the renewable energy business, where for instance:

- Mounting systems for solar panels benefit from its long-lasting nature

- Structure of wind turbines get the benefit of its strength and durability

- Energy-efficient manufacturing lines and waste heat recovery systems

With continuous developments in material science, 409 stainless steel will become more and more in demand in green projects showing its timelessness in the eco-conscious market of today.

Heat Resistance and Corrosion Resistance

409 stainless steel is mainly appreciated for its remarkable heat resistance and moderate corrosion resistance; hence, it is extensively used for automotive exhaust systems and industrial applications. Recent reports indicate that the material’s strength to bear high temperature without much deterioration assures the life of parts made for hostile surroundings like catalytic converters and heat exchangers. In addition, the chromium in the alloy forms a layer that is more resistant to oxidation and rust due to the reduced permeability of the oxide layer. The combination of these properties along with its economical price, successfully positions the 409 stainless steel as the first choice of the industries that require the material to perform reliably during the thermal and corrosive stress cycle.

Buying Guide for 409 Stainless Steel Sheets

How to Pick a Trustworthy Supplier

The selection of a trustworthy supplier for 409 stainless steel sheets is a fundamental step in the battle for top-quality materials and prompt service delivery. The recent analysis and industry knowledge imply that the following factors should be the main considerations:

Essential Supplier Selection Checklist

1

Supplier Reputation

Probe into the supplier’s reputation via reviews on the internet, industry discussions, and customers’ remarks. A supplier that has been in the business for a long time and has good reviews is more likely to keep its promise in terms of quality and service.

2

Certifications and Compliance

Make sure the supplier follows the rules set in the industry and has certifications like ISO 9001. The supplier’s compliance guarantees both quality and traceability throughout the process of producing 409 stainless steel sheets.

3

Product Range and Inventory

A trustworthy supplier should provide a broad selection of sizes and thicknesses of 409 stainless steel sheets. Therefore, any specific project requirement can be met without delay.

4

Delivery and Logistics

Check if the supplier is capable of consistent and timely delivery. Reliable logistics are critical for projects with strict deadlines, and thus they are particularly important.

5

Transparent Pricing

Stock up on quotes to compare prices among various sources, thus preventing a situation in which you might pay more than what is justified. Be on the lookout for unexpected costs and make sure you know the total price before proceeding.

6

Customer Support

Not only does a reliable supplier provide good customer support, but they also offer technical help, answer questions quickly, and deal with complaints effectively.

The above steps combined with online tools like search engines can be very helpful in finding suppliers with great ratings and confirmed experience in the field. Spending time on this research really pays off, as you end up dealing with a supplier that is capable of efficiently satisfying your project’s requirements.

Tips for Purchasing Quality Sheets

💡 Smart Purchasing Tips

- Material is Key: Focus on the material composition. Look for body-safe, hypoallergenic materials that meet industry standards. Always verify material certifications.

- Verify Certification Labels: When choosing steel sheets, make sure to look for certification labels like ISO 9001, ASTM standards, or OEKO-TEX® that guarantee your sheets are manufactured according to quality standards.

- Check Reviews for Insights: Make use of search tools to find and read customer reviews and ratings for different suppliers. Be especially alert to durability, quality, and service comments.

- Consider Durability and Care: Buy sheets that meet your project specifications and do not require excessive maintenance. Read the technical specifications carefully to ascertain the expected lifespan.

- Price vs. Value: Quality sheets could mean a significant investment, but you should always weigh the factors of budget, durability, and performance against each other. Compare prices across multiple suppliers focusing on reputable brands.

Understanding Stainless Steel Plate Price Per Kg

The cost of stainless steel plates per kg gets derived based on different elements, which may vary according to market conditions and your specific requests. Below are the main factors responsible for the price:

📊 Grade of Stainless Steel

Stainless steel has different grades, 304, 316, and 430 among others, with each grade having its unique features. Higher grades like no. 316, which is highly resistant to corrosion naturally cost higher than lower grades per kilogram.

📏 Thickness and Dimensions

Plate thickness and size are the main factors that influence the overall price. Usually, larger and thicker plates are more expensive because of the amount of material that is needed.

📈 Market Demand and Supply

Prices are reflections of changes in global supply chains, new sources of raw material, and opening-up of markets. Recent shifts, such as changes in tariffs or costs of raw materials, can influence the price.

✨ Finish and Processing

Stainless steel plates usually come in different finishes – for example, brushed, polished, or mill finish. Additional processing adds to the final cost.

Frequently Asked Questions

❓ What are the determinants of the 409 stainless steel sheet price?

The valuation of the 409 stainless steel sheet is determined by a combination of parameters such as raw material prices, demand in the market, and thickness or gauge to be chosen by the buyer. The location of the supplier and the inventory available can impact freight and lead times, which in turn will have an effect on the final price. The surface finish and any coatings like that of aluminized or painted finishes would only add to the processing cost. The quantity ordered and minimum order requirements announced often yield volume discounts that bring down the unit price. Changes in currency values and the imposition of tariffs on steel imports can cause the prices to change over time.

❓ What way does thickness affect the price of 409 stainless steel sheet?

409 stainless steel sheets of thicker gauges are charged more for each sheet due to the reason that they are physically heavier and need more processing which in turn goes to the manufacturing and handling costs. Pricing of the standard gauges is done differently depending on the production runs and tool wear that affect the supplier’s pricing strategy. It is also possible that the heavier sheets have higher tensile strength and hence may need different fabricating techniques which will cost more in terms of labor. Getting thicker materials in bulk will enable one to lower the unit price through economies of scale. The surface finish and additional treatments can further modify the overall price independent of thickness.

❓ Is there a difference in price depending on the region where the 409 stainless steel sheet is?

Yes, local price variations are a result of supply chain, shipping costs, and regional tariffs or taxes. U.S. domestic suppliers may cut lead times and freight costs as compared to the imported material, thus, affecting the delivered price. Another reason for regional pricing could be the local market demand and competition among distributors as they can either offer price reduction or increase the price. The availability of certain surface finishes or coil versus sheet formats may differ regionally, thus, affecting the price. It is often overlooked that supplier quotes should include freight and handling to secure accurate comparisons.

❓ What ways do surface finish and coatings influence the price of 409 stainless steel sheet?

The choice of surface finish ranging from mill finish, brushed, or polished impacts the processing time and cost with the smoother or specialty finishes generally being more expensive. Besides, coatings such as aluminizing, painting, or passivation are subject to charges since they involve both materials and labor and the fact that some coatings also bring about improved high-temperature oxidation resistance or corrosion protection. The other secondary operations may also include slitting, cutting to size, or edge treatment that do add up to the final price. The suppliers may impose setup charges for special finishes or small custom runs. One can save even through choosing a finish that is compatible with their application needs as it will not only be economical but also performance ensuring.

❓ What are typical ordering considerations that affect 409 stainless steel sheet price?

Minimum order quantities, required lead times, and cut-to-size services, if needed, are among the ordering considerations and can all impact the price. Additionally, custom orders or short-run requests typically result in higher unit costs because of the setup and processing involved. Contract pricing or long-term agreements with suppliers can secure better rates and minimize exposure to market fluctuations. Payment terms and expedited order fees will also add to the overall cost. Always take into account packaging, freight insurance, and possible tariffs when you are preparing the budget for the purchase.

❓ How can I find the best market price for 409 stainless steel sheet?

Requesting multiple quotes from trustworthy suppliers is the first step to get the best market price. Compare the delivered costs that include the freight and handling for the different suppliers’ quotations. Keeping an eye on the commodity steel indices and industry reports will help you to get a grasp of the price trends and proper timing for making purchases. Total cost of ownership should include machining, surface treatment, and long-term durability, so do not only consider the initial sheet price. You can get a volume discount by negotiating or establishing a supply contract to stabilize the price. Verifying supplier certifications and checking lead times will ensure that you get reliable material at the best price.

Reference Sources

📚 ResearchGate Study

Study and Analysis of Welding of Dissimilar Metals 409 and 439 Stainless Steel

This research examines the TIG welding process for joining 409 and 439 stainless steels, focusing on improving corrosion resistance and performance balance.

📚 ScienceDirect Research

Experimental Studies on Single Point Incremental Sheet Forming of 409L Stainless Steel

This study experimentally analyzes the formability behavior of 409L stainless steel using both conventional and incremental forming techniques.

📚 SciELO Analysis

Study of Work-Hardening Rate Transient of AISI 409 Stainless Steel

This research investigates the mechanical behavior of AISI 409 steel under cold rolling, tensile, and shearing operations, focusing on work-hardening rate changes.