Galvanized sheet metal is a versatile and durable material utilized in several industries, ranging from construction to automotive manufacturing. One format most popularly used is the 4 x 8 sheet of galvanized steel, which is a fairly standard size that allows much versatility in its application. This article covers an in-depth exploration of this important material: factors which price it, uses for it, and benefits implicative. Whether you are a contractor looking at options for a project, a manufacturer seeking cost-effective alternatives, or a DIYer wanting to try out something new, this guide should provide you with the information needed for playing an active role in decision-making. Let’s find out why 4 x 8 galvanized sheet metal continues to be one of the most chosen materials for industrial and creative works.

Introduction to Galvanized Sheet Metal

What is Galvanized Sheet Metal?

Galvanized sheet metal is essentially steel coated with zinc, which acts as a sealant against corrosion and rust. Galvanization renders the steel more workable and durable, and it basically can be put in construction, fabrication, and all kinds of industries. The zinc layer acts primarily as defense against moisture, oxygen, and any biological agents that may cause its degradation.

The methods usually followed in the manufacture of galvanized sheet metals are hot-dip galvanizing and electro-galvanizing. Hot-dip galvanizing is the process of coating steel by dipping it into molten zinc, ensuring a very strong and uniform coating. Electro-galvanizing, in contrast, applies zinc through an electric current, giving rise to a rather thin coat. Both give birth to galvanized sheet metals but metallurgists discuss hot-dip galvanizing if extreme protection is needed at a reasonable cost against abrasive environments; otherwise, they discuss electro-galvanizing.

For applications such as roofing, siding, ductwork, automotive parts, and custom fabrication, galvanized sheet metal is used largely for its corrosion resistance and high strength-to-weight ratio. In addition, galvanized sheet metal provides an aesthetic value as it is visually clean and industrially finished and thereby presenting beauty in projects. These characteristics, plus affordability, make galvanized sheet metal flexible for a wide array of applications.

Importance of Galvanization

The galvanizing process provides the utmost protection to steel and iron to render their durability. The coating functions as a barrier, not allowing environmental factors such as humidity, rain, and pollution to stain the metal underneath, which is the chief cause of corrosion. Minimizing the formation of rust through galvanization, therefore, aids in maintaining the structural integrity of the materials, further lessening frequent repair or replacement.

Another advantage of the galvanizing process is that it is more economical. Even though the initial investment is usually greater than that of ungalvanized steel, the affordability in maintenance and replacements far exceeds this initial cost. Further, the maintenance of galvanized materials is very low because the zinc coating has the ability to regenerate on its own with time, covering slight scratches or abrasions for continual protection.

Sustainability is thus another facet of the galvanizing process. Galvanized steel being more durable eventually means lower material wastage in its lifecycle. Moreover, this choice is environmentally responsible as both steel and zinc used in this process are fully recyclable. This capability puts it in action in construction, transportation, and manufacturing industries to help build resilient infrastructure and resilient products that can withstand severe conditions.

Overview of 4 x 8 Size

The 4 x 8 size is a common industry term used mostly for materials such as plywood, drywall, and sheet metal. These dimensions specify a width of 4 feet and length of 8 feet, totaling an area of 32 square feet. Its popularity arises from practicality, as it aligns with most framing dimensions in construction projects and reduces wastage, not to mention ease of installation.

Perhaps the greatest advantage of having these dimensions is that they cater well to common building governing practices. For example, wall studs in residential and commercial construction are generally spaced apart 16 inches on center; therefore, material of this size would fit neatly without the need for undue cutting, thus saving time and labor. Also, the standard size guarantees uniformity in various applications, extending from floor installations to wall paneling.

In manufacturing and transportation industries, the 4 x 8 size finds application beyond the construction industry. It is suitable for handling and shipping due to its manageable dimensions, while adequate space or structural integrity is required for larger projects. Having such a wide variety, the 4 x 8 size ensures continued relevance and use and stands as a necessity across several industrial and architectural applications.

Types of Galvanized Steel Sheets

Gauge Options for Galvanized Steel

Galvanized steel sheets come in a wide range of gauges, varying to suit different industrial needs. The gauge of a steel sheet depends on its thickness, usually measured in either millimeters or inches; hence, the higher the gauge, the thinner the steel sheet. The common options for galvanized steel gauges range from 10-gauge, which is around 0.1345 inches or 3.416 mm in thickness, to 30-gauge, which is roughly 0.012 inches or 0.3048 mm in thickness. Depending on thickness, these sheets can be used in different ways-from structural to functional applications.

Thicker gauges, such as 10- to 16-gauge sheets, are used in load-bearing and heavy-duty situations such as construction beams, bridges, or industrial machinery. On the other hand, thinner gauges, such as 24- to 30-gauge sheets, are applied wherever lightweight materials are required for applications like HVAC ductwork or roofing or decorative panels. These measurements often differ in exact thickness by industrial standard specification, for example, ASTM A653, to maintain tolerance across production batches.

The choice of gauge depends on functional requirements but also cost, exposure, and life expectancy. Ideally, the choice is best for the suitable durability, structural integrity, and cost across several industrial, commercial, and architectural uses.

Common Uses of 4 x 8 Galvanized Steel Sheets

Construction Applications

Since this 4 by 8 galvanized steel sheet has high durability and corrosion resistance, it finds extensive applications in construction, including roofing, wall cladding, and structural members. The zinc oxides protect the steel from rusting for a much longer time even in the presence of moisture, making it a choice of both residential and commercial builders.

Automotive Parts

These sheets are used in the technique of manufacturing automotive components such as body panels, chassis parts, and underbody shields. The light material, together with strength and resistance to environmental degradation, increases the life of a vehicle and improves fuel consumption.

Industrial Usage

Industrially galvanized steel sheets form an essential part, as equipment and machinery are often exposed to corrosive aggressive atmospheres. They are used in the construction of ductworks, covers, and housings. Being corrosive-resistant and subjected to mechanical stresses during operation, these sheets ensure the equipment’s reliability for many years.

Farm Uses

Farmers and other agricultural businesses use galvanized steel sheets for barns, silos, and fencing materials. They are highly effective in resisting any wear occasioned by regular outdoor exposure to weather variations and cases of contact with soil or livestock.

HVAC

In heating, ventilation, and air conditioning, the 4*8 galvanized sheets for air ducts and housings are frequently used. The material resists surface wear from temperature fluctuations or possible exposure to moisture, thereby ensuring system efficiency and protection of the internal components.

Architectural Designs

Demand for 4 x 8 galvanized steel sheets in modern architectural designs is on the rise as an exterior finish, as well as for stylistic use. Designers creatively use these sheets for decorative cladding, facades, and interior accents, providing a touch of industrial style and a durable finish.

These 4 x 8 galvanized steel sheets, able to meet the most strict standards and specifications, have been proven reliable and versatile for many markets and different applications, carrying out a higher level of structural performance with respect to cost put in.

Comparison with Other Steel Types

Cost-effective and corrosion-resistant owing to the zinc plating, galvanized steel, however, is less durable and versatile compared with stainless and other steels.

| Key Point | Galvanized Steel | Stainless Steel | Carbon Steel |

|---|---|---|---|

| Durability | Moderate | High | High |

| Corrosion | Good with zinc coating | Excellent | Poor |

| Cost | Economical | Expensive | Affordable |

| Strength | Moderate | High | Very High |

| Maintenance | Low | Minimal | High |

| Applications | Construction, DIY | Architecture, medical | Heavy machinery |

| Aesthetic | Matte finish | Polished | Plain |

| Lifespan | Decades with care | Long-lasting | Shorter without treatment |

Pricing of 4 x 8 Galvanized Sheet Metal

Factors Influencing Pricing

Pricing 4 x 8 galvanized sheet metals involves several key variables working into both production costs and marketing system. The most important factors considered are raw material prices-that of steel, which varies with supply-demand cycles, geopolitical tensions, and commodities market trends. At the same time, whatever methods of galvanization are used, such as hot-dip or electro-galvanization, come into play-relative to energy consumed and zinc coating specifications-that will influence expenses.

Another big price influencer of the galvanizing treatment is manufacturing efficiency; here, my great friend, labor, and factory operations will make all the difference alongside constant technological evolution, being in line with cost control. The demand in specific markets, such as construction and automotive, has a direct influence on price. For instance, when it’s peak season for construction projects, prices increase.

Transportation and logistics expenses are also pivotal, for they depend upon the location of raw material suppliers and distribution networks. In the end, tariffs and regional trade policies also play a substantial role concerning the pricing mechanism, mainly in zones where imported sheet metal lands under tariff. These factors, put together, create a pricing structure that buyers in different industrial sectors must reconcile carefully.

Cost Comparison with Other Materials

Depending on its use and the lifecycle cost, galvanized steel offers a cheap alternative to stainless steel or aluminum.

| Key Point | Galvanized Steel | Stainless Steel | Aluminum | Wood |

|---|---|---|---|---|

| Material | Steel with zinc | Steel with chromium | Lightweight metal | Natural |

| Cost | Low | High | Moderate | Low |

| Durability | Moderate | High | Moderate | Low |

| Corrosion | Good | Excellent | Good | Poor |

| Weight | Heavy | Heavy | Light | Light |

| Maintenance | Low | Minimal | Low | High |

| Applications | Construction, fencing | Architecture, medical | Aerospace, DIY | Fencing, furniture |

| Lifespan | Decades | Long-lasting | Moderate | Shorter |

Durability and Maintenance of Galvanized Steel Sheets

Longevity of Galvanized Metal Sheets

The galvanized sheets are exceptionally durable as the zinc coating acts as a protective barrier against environmental factors such as moisture, air, and pollutants. The longevity of the sheets largely rests on the degree of exposure to the corrosive environment. Galvanized sheets generally have an extremely long lifespan. Earlier, these sheets lasted for 25-30 years in urban or coastal areas where the degree of humidity and pollutants would be high level. In contrast, these were expected to last for more than 50 years in rural areas characterized by very low exposure to harsh environmental conditions.

The factors influencing their longevity include the zinc coating thickness, the environment where the material is installed, and maintenance situations. The thicker the zinc coating, the slower the corrosion proceeds, thereby rendering the material’s working life longer. Also, galvanization protects even small scratches or abrasions through a self-healing mechanism called sacrificial protection, wherein zinc corrodes in preference to the underlying steel.

By means of advancement of galvanizing techniques, they are now made performing better and hence even more reliable for industries including construction, automobile production, and infrastructure. When properly installed and maintained, galvanized steel sheets are the best cost-efficient and durable option for even harsh environments.

Maintenance Requirements for Optimal Performance

To achieve the anti-corrosive properties and ensure that the product lasts for its intended use, proper maintenance of galvanized steel is required. Thus, periodic inspections need sequences to observe the building concerning early indications of corrosion, damage, or accumulation of contaminants on the surface. Immediate treatment is necessary for compromised areas like scratches and rust spots of a localized nature. The contaminants can be removed by cleaning with a mild detergent or an alkaline solution, provided these include dirt or salt deposits or any kind of pollution that can cause rapid corrosion if allowed to go on. Under no circumstances should abrasive methods of cleaning be used, for they can impair the zinc coating.

Though environmental exposure greatly affects the performance of a galvanized metal, particular in high humid areas, coastal ones, and those acidic industrial atmosphere, it is vital to reinforce the zinc layer with a periodical application of protective paints or sealants in installations carried out in such environments. Moreover, ensuring free drainage and ventilation around galvanized structures forbids the accumulation of water that could corrode the product barrier as time goes by. Finally, employing cathodic protection systems that are designed and installed in a specialized manner further lengthens the service life of the structure by opposing those electrical actions that worsen corrosion.

Studies performed for the industry also emphasize that no contact shall be permitted between galvanized steel and metals incompatible with it, such as copper or brass, since such contact could instigate galvanic corrosion in the presence of moisture. Likewise, during transportation and installation, the storage and handling procedures must be properly executed. Thus, keeping galvanized steel dry and preventing it from staying in prolonged contact with any wet or corrosive substances is a way of ensuring that the protective zinc layer works according to spec. Thus, with some methodical maintenance, in combination with intelligent material management, the service life and performance of galvanized steel would be well improved for use in their industrial and commercial shades.

Resistant Properties of Galvanized Steel

The galvanized steel stands with commendable corrosion resistance and hence is chosen for many environments, such as those supplied with moisture or chemicals bearing environmental conditions of alternating temperature. The protective coating of zinc that is depositioned by way of galvanization-Welding ensures a good barrier to resist the entry of oxygen and moisture to the steel substrate-materials. The zinc layer, in fact, serves well in cathodic protection should any small scratch or damage to the steel occur, thus, corroding in place of the exposed steel and keeping it viable for a long period.

Actually, quoted experimental data show galvanized steel capable of lasting for decades without excessive corrosion when exposed to rural, urban, and even industrial atmospheres. It has been suggested that, in an average atmosphere, zinc can corrode almost 1 to 2 microns per annum, thereby assuring long-term reliability. Galvanized steel has been employed satisfactorily under high humidity situations as well as in mildly acidic ones, as it is in marine structures, telecommunication towers, and agricultural applications.

These are further improved with some modernizations in galvanizing technology, such as alloyed zinc coatings, which improve performance under mechanical stresses and impact attacks coming also from chemical reactions. This increased performance from advances makes galvanized steel even more versatile and durable in response to modern construction and industrial needs.

Practical Applications of 4 x 8 Galvanized Sheets

Construction and Building Uses

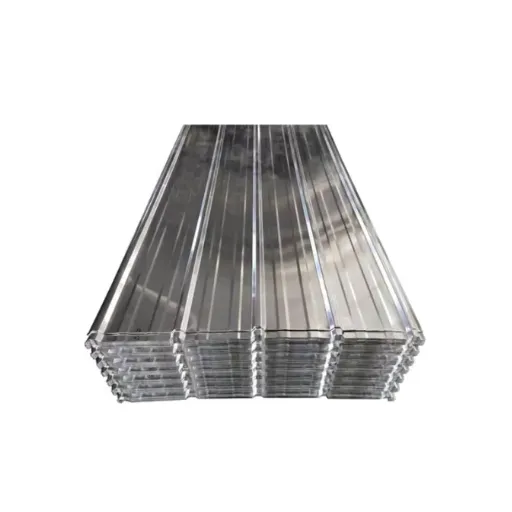

Roofing and Siding

Since it is corrosion-resistant, the galvanized steel sheet is widely accepted for roofing and siding. They create long-term protection against the weather elements, so they are apt for residential, commercial, and industrial buildings.

Structural Framework

These sheets find application in building frameworks such as beams and columns by virtue of their strength and durability. They can bear heavy loads and thus maintain the structural stability over time.

Drainage Systems

Galvanized steel sheets are used in gutters, downspouts, and water drainage systems because of their water-repellent nature, ensuring efficient water handling as well as preventing rust.

HVAC System

Galvanized sheets in the ducts and casings constitute a vital part of heating, ventilation, and air conditioning systems. Their anti-corrosive nature deposits much importance in the efficiency and longevity of these systems.

Fencing-Barriers

Galvanized steel sheets are perfect for durable fencing panels and barriers for both residential and commercial applications. With their sturdiness and weather resistance, the coating made them an outdoor product.

This application shows the 4 x 8 galvanized steel sheets to be very versatile and useful, placing them as an indispensable material for the construction and building industry.

Industrial Applications

4 x 8 galvanized steel sheets get considered for very many professional applications, being expected to be really durable, reasonably corrosion-resistant, and thus cheap. The five major industrial applications for these steel sheets are presented below:

Automotive Manufacturing

In the automotive industry, galvanized steel sheets are used to make car bodies and panels, chassis, and other components. The resistance to corrosion of the steel sheets helps to make the life of vehicles longer, even when placed in harsh environments.

HVAC

A galvanized steel sheet is also utilized in heating, ventilation, and air-conditioning ducting and structural components. Its resistance to moisture and rust guarantees it to have reliable performance for a prolonged lifetime.

Agricultural Equipment

A galvanized steel sheet is also used to make many structures of agricultural machinery and storage units such as silos and barns, thus securing them against environmental exposure and wear.

Containers and Storage Tanks

Industrial facilities use galvanized steel sheets for chemical containers and tanks for water and other materials. The zinc coating serves as a protective barrier against chemical damage, adding to durability.

Shipbuilding and Marine Equipment

Being excellent in corrosion resistance in saline waters, galvanized steel sheets are frequently employed for structural applications and marine equipment, such as docks and offshore platforms.

These cases show the importance of the galvanized steel sheets in industrial applications, with applications that call for durability and cost-effectiveness.

Paneling and Siding Options

Paneling and siding with galvanized steel sheets can be a perfect choice when one looks for everything versatile and durable in residential and commercial applications. With potential strength plus excellent corrosion resistance, these materials are best exterior coatings that can resist the onslaught of nature while standing tall in terms of structural strength. Galvanized steel paneling and siding are offered in different finishes so that they fit well with varying architectural styles.

I find that using galvanized steel for paneling and siding is a choice that is both practical and beautiful. This material promises longevity and requires very little maintenance in the long run, thereby saving money, effort, and time. From manufacturing plants to sleek residential designs, galvanized steel has been dependable for finishing design applications for numerous years.

Steel, especially galvanized steel, offers very practical use and style. With the creation of panels and sidings, one can think of a solution that is sturdy and looks beautiful when it weathers the exposures and in return adds value to the property.

References

- Friction Effects on the Formability of Electrogalvanized and Hot-Dipped Automotive Sheet Steel: This study explores the formability of galvanized sheet steels and the impact of friction during sheet metal forming processes.

- Structure and Deformation of Zinc Coated Sheet Steels: This research discusses the structure and deformation characteristics of zinc-coated sheet steels, including their applications in stamping operations.

- Resistance Spot Welding of Galvanized Steel Sheet: This paper examines the resistance spot welding process for galvanized steel sheets, focusing on the effects of welding cycles and material properties.

- The Effects of Lead on the Solidification and Preferred Orientation of Zinc Coating on Galvanized Sheet Steel: This study investigates the influence of lead on the solidification and orientation of zinc coatings in galvanized sheet steel.

- The Kinetics of Intermetallic Phase Growth During Galvanizing of Steel Strip: This research focuses on the growth kinetics of intermetallic phases during the galvanizing process of steel strips at high temperatures.

- Click here to read more.

Frequently Asked Questions (FAQ)

Q: What is a 4 x 8 galvanized sheet metal?

A: A 4 x 8 galvanized sheet metal is a flat sheet of steel of 4 by 8 feet, coated with zinc on its surface to protect against rusting and corrosion. This material is widely used in construction and manufacturing for its strength and ability to resist the environment.

Q: What are the common gauges available for 4 x 8 galvanized sheet metal?

A: The most common gauge used for 4 x 8 galvanized sheet metal is 22 gauge; however, depending on the requirements, a thicker sheet can also be used. Gauge steel varies in thickness and, therefore, in strength and for which projects it can be used.

Q: How is galvanized sheet metal different from corrugated steel?

A: Galvanized sheet metal is typically flat, while corrugated steel is shaped into ridges and valleys. Both can be made from 4 by 8 ft sheets, but corrugated steel is mainly used for roofing and siding due to strength and the ability to efficiently shed water.

Q: Can 4 x 8 galvanized sheet metal be cut to size?

A: Indeed, 4 x 8 galvanized sheet metal can be cut to size by plasma cutting, shearing, or welding. This assures precision for projects that require fittings or installations of specific dimensions.

Q: For which applications would 4 x 8 galvanized sheet metal serve best?

A: Construction materials, roofing, siding, and industrial uses are among the many applications for this metal. Since the galvanized metal is resistant to rust and corrosion, it is suitable for outside use and situations subjected to hail and other weather conditions.

Q: Is there any difference between hot dip galvanized and electro-galvanized sheet metal?

A: Hot dip galvanized sheet metal is offered zinc coating by dipping through the zincing process, providing a thicker tread of protection. In contrast, the electro-galvanized sheet metal is coated electro-chemically with a thin layer of zinc. Generally, workers claim that hot dip galvanized are able to resist corrosion longer and are suitable for harsher environments.

Q: What do the Z60 and Z90 ratings mean for galvanized steel?

A: Z60 and Z90 refer to the actual zinc coating weight on galvanized steel. Z60 has a coating of 0.60 oz/sq ft, whereas a Z90 has a coating of 0.90 oz/sq ft. Higher rating such as a Z90 coating provides greater anti-rust and corrosion protection, which is especially good for outdoor applications.

Q: How could I ensure proper adhesion when welding 4 x 8 galvanized sheet metal?

A: To properly weld galvanized sheet metal, the zinc coating should be removed from the areas to be welded. This could be done by grinding or sanding. It is also necessary to have proper ventilation systems for safety and to avoid exposure to fumes arising during welding.