Throughout the ages, when it comes to reliable and versatile materials, 304 stainless steel flat bars have been the most sought-after in practically every industry and application. Due to its great durability, corrosion resistance, and ease of fabrication, this stainless steel grade has made its name as the material of choice in construction, manufacturing, and design industries. So, what really makes 304 stainless steel flat bar special? Whatever your needs-whether a demanding project or just to keep an eye out for purchasing advice-this article will take you through the properties, common uses, and tips on sourcing this tried and trusted material. Read on to learn how a 304 stainless steel-flat bar has distinguished itself as a favorite among professionals and do-it-yourself enthusiasts.

Understanding 304 Stainless Steel

Composition and Properties

304 stainless steel is mostly composed of iron and contains consistent chromium and nickel additions: the key elements responsible for its better corrosion resistance and strength. Normally, it has about 18% chromium and 8% nickel, thereby getting the nickname 18/8 stainless steel. Trace quantities of other elements such as carbon and manganese are also present to increase the durability and ease of fabrication further.

The material is non-magnetic in the annealed condition but is well-known for a superior resistance to corrosion and oxidation when in the presence of moisture or acidic substances. The strength that it offers makes 304 stainless steel very adaptable and may be used across a broad range of temperatures for applications in food service, construction, and industrial machinery.

Another special property of 304 stainless steel is its workability. The material can be shaped, welded, or cut very easily without compromising its integrity and makes it good material for manufacturing. Combining strength with corrosion resistance and machinability means that 304 stainless steel flat bars will reliably perform in a variety of conditions in both heavy-duty structural applications and everyday commercial use.

Advantages of 304 Stainless Steel

- Corrosion Resistance: 304 stainless steel offers an excellent corrosion resistance over a wide range of environments that include moisture, acidic solutions, and many cleaning agents. This property finds its applications in marine, chemical processing, and food sectors where the resistance toward rusting and staining is of utmost importance.

- Durability: 304 stainless steel is highly tensile and able to resist wear and tear, making it a fairly tough material for structural as well as commercial application. It performs excellently well under different conditions, giving many years of useful service without frequent replacement.

- Fabrication: 304 stainless steel gives excellent machinability and welding and forming ways without loss of its structural integrity and skills; in other words, the metal can be fabricated into various shapes and sizes with flexibility for custom design and manufacturing processes.

- Temperature Resistance: It performs excellently at high and low temperatures. This substances types can withstand heat application of around 870–925°C (1600–1697°F) without any loss of mechanical properties and are suited for high-temperature applications like furnaces and heat exchangers.

- Hygienic/Non-reactive: It is non-porous and easy to clean, so it is used for hygienic applications, and it does not react with almost all food substances or chemicals; hence, it is highly preferred by food and beverage industry, medical industry, and pharmaceutical industry.

Comparison with Other Stainless Steel Grades

A comparison is carried out between 304 stainless steel and grades 303, 316, 201, 301, and 430 in terms of various properties such as corrosion resistance, machinability, cost, and specific types of applications.

| Grade | Corrosion | Machinability | Cost | Applications |

|---|---|---|---|---|

| 303 | Moderate | High | Medium | Nuts, bolts, gears |

| 304 | High | Moderate | Medium | Kitchenware, construction |

| 316 | Very High | Moderate | High | Marine, medical |

| 201 | Low | Moderate | Low | Kitchenware |

| 301 | Moderate | High | Medium | Automotive, aerospace |

| 430 | Low | Moderate | Low | BBQ panels, trim |

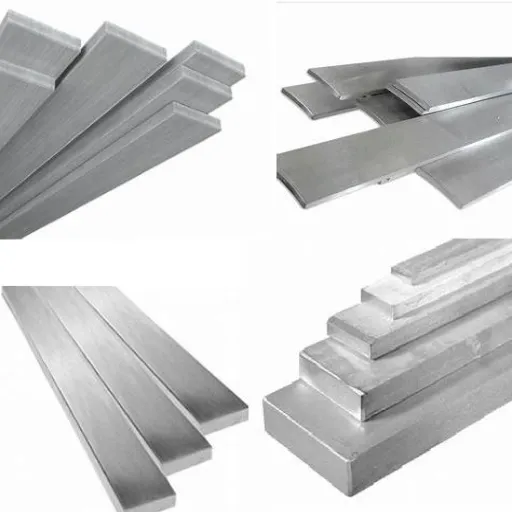

Features of 304 Stainless Steel Flat Bars

Dimensions and Thickness Options

304 stainless steel flat bars are produced in a wide range of sizes and thicknesses to meet the application requirements. Flat bars generally measure anywhere from 20mm up to 200mm in width, while thickness can be anywhere from 3mm to 20mm. This range caters well to industries such as construction, automotive, and food processing. In some instances, manufacturers modify the dimensions based on customer preference as surmounting the generic dimensions may allow more uses for a particular application or project.

Typically available in the standard length of 6 m, flat bars can be cut in custom lengths to minimize wastage and optimize the use of materials. With guaranteed accuracy in sizing, it allows ease in further fabrication plus welding, machining, or cutting operations. This makes it highly functional in manufacturing scenarios that require a sturdy yet nonferrous kind of material especially in an environment laden with moisture and chemicals.

While procuring 304 stainless steel flat bars, one has to gauge the thickness and dimensions that accommodate the intended use. For heavy-duty applications such as structural supports, select thicker and wider flat bars for better load-bearing capacity. Conversely, thin types are appropriate where there are light duties. This availability in different options justifies that 304 stainless steel flat bars have been one of the most sought-after products where balancing is concerned between durability, corrosion resistance, and customization.

Standard Lengths and Custom Sizes

Flat bars of 304 stainless steel are generally manufactured in standard lengths-specifically, any length falling within the range of 12 to 20 feet. These standard lengths cater to a lot of industries so much so that the procurement has to be straightforward for installation work concerning construction, manufacture, and industrial frameworks. Standard dimensioning chez permet will ensure less wastage of materials and enable smoother operations on the side of the industries. Not all building design corresponds with this standardization, though, causing an increase in demand for the custom measuring stainless steel flat bars.

Custom sizes provide solutions tailored to meet a unique need, be it non-standard dimensions, precision cutting, or specialized length required for a specific design or engineering purpose. Assisted by advanced manufacturing techniques and laser cutting technology, fabricators can offer products that meet high-quality standards while remaining completely true to specifications. Customization keeps the amount of scrap material to a minimum-demanding little secondary modifications in the installation-will save more time and resources in the long run.

Further, by combining custom and standard lengths, one attains the flexibility to reach the perfect compromise between ready and adaptable. Needless to say, suppliers too now provide value-added services such as shearing and polishing, pre-drilling, etc., to assist the widest spectrum of applications. This versatility signals the appropriateness of 304 stainless steel flat bars for use in varying industries, right from architecture to machinery manufacture. Therefore, their availability in standard size, together with the option of special dimensioning, makes them an essential material for present-day engineering and design work.

True Bar vs. Sheared Bar: Key Differences

Sheared bars are cut from plates and often differ significantly in tolerance, finish, and consistency, while true bars are milled in accordance with precise tolerances defining the profile in terms of cross section and controlled conditions of burnishing.

| Aspect | True Bar | Sheared Bar |

|---|---|---|

| Process | Milled | Plate-cut |

| Precision | High | Moderate |

| Surface | Uniform | Varied |

| Edges | Sharp | Rounded |

| Expense | Higher | Lower |

| Usage | Specialized | General |

Applications of 304 Stainless Steel Flat Bars

Construction and Structural Uses

304 stainless steel flat bars are highly valued in construction and structural applications because of their strength, durability, and level of corrosion resistance. Here are five notable applications:

- 1

Support Structures: 304 stainless steel flat bars are used as structural supports in buildings, bridges, and the construction of infrastructure on a large scale. The bars are ideal for load-bearing purposes because of their enormous strength and their high resistance to weathering. - 2

Reinforcements: These flat bars are used as reinforcements in concrete structures where durability and weather resistance are required enhancements for stability and longevity. - 3

Fabrication of Railings and Handrails: In fabricating the railing and handrails, stainless steel flat bars are used primarily because of their sheen appearance and high resistance to abrasion or corrosion; it is functional and decorative. - 4

Frames and Brackets: The flat bars are also used in manufacturing frames and brackets used in the support of various types of equipments and structural elements, with clean aesthetics, sturdy, and manufactured finish. - 5

Industrial Platforms and Walkways: Because of their strength and corrosion resistance, 304 stainless steel flat bars are considered suitable for industrial platforms or walkways in harsh environments such as chemical plants or marine installations.

These applications show the versatility and the importance of 304 stainless steel flat bars in various construction and structural disciplines.

Manufacturing and Industrial Applications

304 stainless steel flat bars remain immensely germane in manufacturing and industrial use for the sole reason of durability, corrosion resistance, and strength. Hence, the considered features make them indispensable in any industry. Below is an intertwined web of five common applications:

- 1

Food Processing Equipment and Machine Tool: Used widely for the manufacture of food-grade machinery and storage utensils due to the qualities of corrosion resistance and potential hygienic criteria. E.g., 304 stainless steel flat bars are applied in conveyor systems or perhaps in mixing tanks wherever sanitation rules must be observed. - 2

Pharmaceutical Equipment: Construing clean room equipment, sterile containers, and processing machinery because of the impossibility of chemical damage and easy sterilization. Thus product safety and strict regulatory standards are assured. - 3

Chemical Processing Plants: Chemically resistant to types of chemicals, acids, and varying environmental conditions, hence used in fabrication of tanks, valves, and piping systems in chemical manufacturing. - 4

Automotive Components: Used to manufacture the corrosion-resistant auto parts ranging from exhaust systems to structural reinforcements, thereby guaranteeing quality and longevity under the harsher working conditions involving heat and moisture. - 5

Marine Applications: The best choice for building ships, docks, and offshore platforms due to high resistance to saltwater and moisture common to the marine atmosphere. 304 stainless steel flat bars are commonly used for maritime structural support and fitting purposes.

These instances signify an adaptability and great significance of 304 stainless steel flat bars for one industrial application after the other, and, in doing so, fostering enhanced productivity and reliability.

Home and DIY Projects

304 stainless steel flat bars are industrially important and versatile materials used also in home and DIY applications. They possess the strength and durability against corrosion and ease of fabrication rendering them suitable for industrial as well as creative and practical household purposes. Here are five use cases for 304 stainless steel flat bars in home and gardening projects:

- 1

Furniture Frames: Constructed furniture frames provide long life and strength for table bases, shelving, or bed frames that echo minimalist styles of designs to come. - 2

Kitchen Countertop Supports: They provide counterweight support for heavy kitchen countertops, especially granite or marble weighing upon its classy looks. - 3

Decorative Metalwork: Considering its smooth finishing abilities, it’s excellent in the fabrication of customize decorative elements such as wall art, signs, or ornamental trims. - 4

Garden Structures: Builds for trellises, plant supports, or fencing for outdoor adaptation using weather resistance and rustproof qualities of these bars. - 5

Tool Racks and Storage: Create tool storage solutions or custom racks for the garage and workshops, which allow equipment to remain accessible and secure.

These are some applications that bring out the usefulness of 304 stainless steel flat bars in home and DIY projects-awe-inspiring creativity combining with practicality for enduring results.

Benefits of Using 304 Stainless Steel Flat Bars

Corrosion Resistance and Durability

The 304 stainless steel flat bars are famous for their extraordinary resistance to corrosion and durability, thereby making them the best option for various applications. Here are five facts and figures that establish their benefits:

- 🔧

Oxidation Resistance: 304 stainless-steel contains chromium, usually about 18-20%, and it forms an oxide layer on the surface that will prevent rusting and oxidation in even the harshest environment. - 💧

Performance in Moist Conditions: Due to high chromium and nickel content, this alloy provides resistance against moisture and is therefore an ideal choice for humid and wet environments without losing its structural integrity. - 🔥

Temperature Resistance: The alloy can resist deformation and corrosion to a temperature of about 1,500°F (815°C) and hence superb for higher heat applications. - ⚗️

Chemical Resistance: 304 stainless steel is best served against being attacked by numerous chemicals, namely acids such as nitric acid, alkalis, and salts, which guarantees long life separation in industrial and household environments. - 🌦️

Long Life for Outdoor Installation: By resisting weathering through UV rays, rain, and temperature fluctuations, 304 stainless steel will ensure prolonged durability for outdoor structures and installations.

These characteristics engender 304 stainless steel flat bars as a dependable, sturdy material in various project industries.

Versatility in Design and Functionality

304 stainless steel flat bars are essentially a highly versatile product, having an almost infinite adaptability for various uses and design requirements. This material stands as a perfect balance between strength, aesthetics, and ease of fabrication and a good choice for almost every project. Some of the major reasons why they are so versatile include the following:

- 🏗️

Architectural Applications: Often found in modern architectural architecture, 304 stainless steel flat bars adorn east in rails, frameworks, and decorative panels with their appearance and force. - 🏭

Industrial Equipment: Construction machinery and equipment, such as the conveyor belts and the support structures, where performance and safety call for materials that are especially abrasion-resistant and corrosion-resistant, see a great hire of these steel flat bars. - 🍽️

Kitchen and Food Processing: With notable hygienic qualities and corrosion resistance, 304 stainless steel are cultivated in the kitchens, making surfaces, utensils, and food processing equipment where there is food safety. - 🚗

Automotive and Transportation: In frame construction and other structural components, 304 stainless steel, because of its wear resistance and strength, helps build durable yet lightweight vehicles. - ⚓

Marine Applications: Being able to withstand the exposure to moist or saline environments, 304 stainless steel is heavily used for shipbuilding, docks, and other marine environments where corrosion resistance is of paramount concern.

Flexibility, availability, and environmental durability-all of these factors combined are the reasons why 304-grade stainless steel flat bars are still in growing demand in various industries.

Cost-effectiveness and Availability

When it comes to cost-effectiveness and widespread availability, 304 stainless steel flat bars offer numerous advantages. From these, five most important points will be presented below, highlighting their worth:

- 💰

Low Material Cost: Because 304 stainless steel is the perfect balance between price and quality, it is much more affordable than the other high-performance alloys. Being manufactured on a large scale and being obtainable globally helps to keep prices reasonably. - 🔧

Maintenance Cost Is Low: Corrosion- and weather-resistant quality will reduce repair frequency and replacement requirements, thus resulting in decreased long-term costs for industries where dependability is important. - ♻️

Recyclability: As 304 stainless steel is 100% recyclable and has an excellent demand of recycling material in the manufacturing processes, permuting to low costs and in support of sustainable practices. - 🌍

Global Availability: It is one of the widely used stainless steels, hence easily procurable in the international markets, which ensures the establishment of supply chains and further leads to reduction in lead times for industries dependent on it. - 🔄

Multi-functional Applications: Being versatile, it is used across construction, automotive, and marine industries, leading to cost efficiencies while manufacturing and procurement for the industries, which would otherwise be using different materials for the various applications.

All of these factors make 304 stainless steel flat bars a great option for money and readily available for various applications.

Purchasing Guide for 304 Stainless Steel Flat Bars

Factors to Consider When Choosing a Supplier

Reputation and reliability are the very first aspects I evaluate when choosing a supplier of 304 stainless steel flat bars. A credible supplier assures the highest quality of products and adherence to the promised time schedule, thus maintaining operational deadlines. I look into reviews, certifications, and perhaps testimonials from other clients to find out how credible a supplier is within the industry; very often, this can give an indication as to how committed they are to the delivery of dependable products and services.

The other important factor I would evaluate would be pricing and value for money. While low prices might seem attractive at first, I am happy to pay more for slightly higher-priced goods if I know for sure that I am dealing with a reputable supplier that will not compromise on product quality. Also, I take other facilities they might offer into consideration such as custom sizing, express delivery, or even application consultancy, as these greatly enhance the purchasing experience and contribute to reducing project costs.

Last, but not least, I look at the supplier’s stock and logistic capabilities. A supplier capable of providing a comprehensive range of sizes in 304 stainless steel flat bars and with quick turnaround times for stock requests is gold when it comes to carrying out large-scale or urgent projects. Being just confident that they can deliver project demand consistently and timely has also helped me gain confidence in meeting my longer operational requirements. Together, these things help him make well-informed decisions in choosing the right supplier.

Tips for Selecting the Right Specifications for Your Project

- 1

Assess the Project Requirements: Begin by thoroughly analyzing your project’s specific needs. Consider factors such as the intended application, environmental conditions, and required durability. For instance, if your project involves exposure to moisture or corrosive environments, opting for stainless steel grades with high corrosion resistance, like 304 or 316, is crucial. - 2

Understand Material Properties: Familiarize yourself with the physical and chemical properties of the materials you are considering. Tensile strength, hardness, thermal resistance, and machinability can directly impact the performance and lifespan of your project. Consulting material data sheets or industry standards can provide essential insights. - 3

Choose the Right Dimensions: Select the appropriate size, thickness, and shape of your materials based on the project’s scale and structure. Suppliers often stock a variety of dimensions, so ensure your choices align with both design plans and logistical considerations, such as ease of transport and assembly. - 4

Consider Industry Standards and Certifications: Always verify that the materials meet key standards and certifications relevant to your industry. Compliance ensures the quality and safety of your project while offering peace of mind that the specifications will meet desired performance metrics. - 5

Work Closely with Trusted Suppliers: Collaborate with suppliers who have a proven track record of reliability and expertise. They can provide valuable advice on material selection and availability, helping you make data-driven decisions without the drawbacks of relying on generic search results.

By applying these tips and working closely with experienced suppliers, you can confidently select the right specifications to meet your project goals efficiently and effectively.

References

-

ASCE Design Standard for Stainless Steel Structures

This document discusses various grades of stainless steel, including 304, and their applications in structural design. -

Research Machining Services – Purdue University

This resource provides details on stainless steel materials, including 304 grade, and their availability in flat bar forms. -

Ductility of 304 Stainless Steel Under Pulsed Loading

A study investigating the ductility and properties of 304 stainless steel under specific conditions. - Click here to read more.