Sheet metal is an immensely versatile material that supports numerous industries in various areas, including construction, automotive manufacturing, appliance production, and more. Among the various types of sheet metal, 18-gauge sheet metal is renowned for its balance of strength, weight, and workability. But what makes 18-gauge sheet metal the best seller, and how does it compare to other gauges? This article will explore everything related to 18-gauge sheet metal, including its size, properties, applications, and other key considerations for working with it. Whether you are a fabricator by trade, an engineer, or simply someone interested in this essential material, this will provide you with the in-depth knowledge to fully comprehend 18-gauge sheet metal and its modern manufacturing and design landscape.

Understanding 18-Gauge Sheet Metal

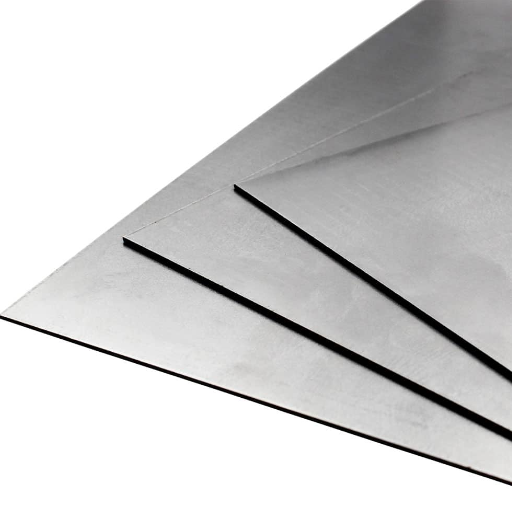

Generally, 18-gauge sheet metal refers to the thickness specifications witnessed in the industry. The 18-gauge steel has a thickness of 0.0478 inches (1.214 millimeters), and the aluminum has a thickness of about 0.0403 inches (1.024 millimeters). Thinness varies due to density differences present in these materials. It can be counted upon for striking a balance between durability and workability. Because of these criteria, 18-gauge sheet metal finds wide use in all preprocessing operations, where standardization of dimensional parameters helps in ensuring reliability in manufacturing and assures that said sheet metal will work uniformly with the majority of tools and processes in the industry.

What is 18-Gauge Sheet Metal?

A looming ambiguity surrounding the term “18 gauge” is an industry designation for a specific thickness of sheet material used primarily in sectors such as construction, automotive, and manufacturing. For steel, the measurement given corresponds to 0.0478 inches (1.214 mm), and for aluminum, it is approximately 0.0403 inches (1.024 mm). It duly stands at the force field-administration operational site where it must simultaneously keep up with its load and be somewhat workable for constructional purposes.

When comparing metal sheets, the strength-to-weight ratio is a big consideration in the manufacture of ductwork, roofing, and metal-fabrication industries, where it needs to be hard without being bulky. Thin-sheet metal, including 18-gauge, is made to go by the book so that working tools, welding processes, and many others go smoothly. These factors greatly contribute to its continued use due to its proven reliability and suitability for many differing operationally demanding situations.

Properties of 18-Gauge Cold-rolled Steel

- Thickness: 18 gauge cold-rolled steel has a 0.0478-inch (1.214-millimeter) nominal thickness that renders it just about perfect to maintain the balance between good strength and formability.

- Tensile Strength: About 50,000 to 70,000 PSI is the normal range of tensile strength. It is very much able to undergo heavy stress without experiencing deformation or loss of dimension.

- Yield Strength: The yield strength ranges between 30,000 and 50,000 PSI; therefore, it can stand the pressure itself is applied.

- Surface Finish: A smooth, polished surface was given by the cold rolling, which results in tight dimensional tolerances, making it good to look upon and ready for coating or painting.

- Corrosion Resistance: Uncoated cold-rolled steel lacks corrosion resistance and hence is usually galvanized or painted to increase corrosion resistance in corrosive environments.

- Weight: Weight stands at roughly 1.92 pounds per square foot, rendering it adequate for strength but not so heavy in applications where lightweight is a requirement.

- Hardness: Usually indicated through the Rockwell B scale, cold-rolled steel typically performs at an RB60 to RB85 rating, enough to give durability without being excessively hard or brittle.

Thickness and Dimensions Explained

Types of Steel Sheet Metals

- Cold-Rolled Steel Sheets

These sheets are processed at room temperature, resulting in an excellent finish on their surfaces and better tolerances. These sheets find their application in areas where the surface needs to be smooth and the dimensions precise, such as car panels and appliances.

- Hot-Rolled Steel Sheets

Being produced at higher temperatures, hot-rolled steel sheets are highly malleable and very easy to work with. They are far from precise when it comes to surface finish but are nevertheless largely preferred for construction and structural applications where high precision is not required.

- Galvanized Steel Sheets

Galvanized steel sheets, coated with zinc, offer excellent corrosion protection for applications outdoors, such as roofing, guttering, fencing, etc.

- Stainless Steel Sheets

Resistant to corrosion and exhibiting a nice finish, stainless steel sheets are used in food processing, medical equipment industries, and architectural industries.

Cold Rolled Steel Sheets

Cold-rolled steel sheets are manufactured through a process that involves passing steel through rollers below its recrystallization temperature. The effects of this operation are presumed to give a smooth surface finish, enhance dimensional accuracy, and improve mechanical properties such as tensile strength and hardness of steel. Cold-rolled steel sheets find their uses in almost every testing that needs precision, such as automobile panels, aerospace sheets, and home appliances. Furthermore, due to their smooth characteristics, the sheets are highly preferred in industries where they will be painted and coated later on. These sheets will range in thickness from 0.3mm to 3mm and will strictly follow all aesthetic and structural integrity parameters.

Carbon Steel vs. Mild Steel

|

Parameter |

Carbon Steel |

Mild Steel |

|---|---|---|

|

Carbon Content |

Higher carbon content, up to 2.1% |

Low carbon content, usually below 0.25% |

|

Strength |

Higher tensile strength |

Lower tensile strength than carbon steel |

|

Hardness |

Greater hardness due to higher carbon levels |

Relatively softer, easier to work with |

|

Ductility |

Lower ductility, more brittle |

Higher ductility, more malleable |

|

Weldability |

Difficult to weld |

Easier to weld |

|

Cost |

Generally more expensive |

More cost-effective |

|

Corrosion Resistance |

Poor, unless alloyed with other materials |

Poor, requires protective coatings |

|

Machinability |

Harder to machine due to brittleness |

Easy to machine, highly workable |

|

Applications |

Tools, knives, cutting-edge components |

Construction, general fabrication projects |

|

Magnetic Properties |

Magnetic depending on carbon composition |

Typically exhibits magnetic properties |

Thickness Variations and Their Significance

The thickness of a material plays a fundamental role in determining its mechanical properties, durability, and suitability for various applications. Usually, thick materials will be stronger and resist deformation, thus fitting the jobs of heavy-duty application, such as structural support and high pressure. Conversely, thin materials allow bending and are lighter in weight, which becomes imperative for automotive body panels, lightweight machinery components, etc.

Thickness could also affect thermal and electrical conductivity. For instance, thin conductive materials are usually used in electronic circuits in order to reduce the weight and enhance precision where thicker materials would be used to support higher current loads or serve as insulation under extreme conditions. In addition, a thinning of a material will significantly affect how welding, machining, processing speed, cost, and tool consumption occur.

Applications of 18-Gauge Sheet Metal

This gauge’s most broad use in industry medicine provides the balance between strength and flexibility. Some of the principal uses are:

- Automotive Manufacturing: This is used for body panels, brackets, and structural reinforcements as it is durable and easy to fabricate.

- Construction: In ductworks, roofs, and interior paneling where moderate thickness and greatest degree of structural integrity are maintained.

- Furniture Production: Often used in cabinet construction, desks, and shelving systems requiring strength and a smooth finish.

- Appliance Fabrication: Used for the manufacture of household and industrial appliances for things such as outer casings and support structures within.

- Artistic and Custom Fabrication: Used by metal fabricators and artists for decorative panels and sculptures.

Industrial Uses of 18-Gauge Steel Sheet

- Automotive Manufacturing

- Deliberately applied in the manufacturing of body panels, undercarriage components, and structural reinforcements.

- The design’s strength-to-weight ratio ensures the designs are lightweight and meet crash safety standards.

- Often used in the restoration of vehicles to recreate the original steel properties of classic models.

- Construction Industry

- Used in framing systems of modern buildings to provide structural integrity to ceilings, walls, and outdoor façades.

- Used in the fabrication of pre-fabricated panels for buildings and for concrete formworks, with good resistance to warping and corrosion when properly treated.

- HVAC Systems

- Great choice for air ducting systems and ventilation shafts thanks to high maintenance of proper airflow dynamics.

- The property of retaining resistance to temperature variations gives it top priority over industrial heating and cooling systems.

- Electrical Enclosures

- Fabricated into boxes for junctions as well as switchgear housings and control panel covers that protect against moisture and dust.

- Complies with the NEC (National Electrical Code) for material strength and fire safety.

- Industrial Machinery

- Used in the design of machine housings for conveyor systems and box parts for protecting internal parts of machines from physical damage and contamination.

- The property of the material allows it to be machined accurately in heavy-duty applications.

- Agricultural Equipment

- This is used in the manufacture of structural components of tractors, combine harvesters, and plows when mid-thickness is needed for durability and maneuverability.

- Ensures that when galvanized, it is resistant to environmental stressors such as chemical exposure and UV exposure.

Automotive Applications for 18 Ga Metal

Considered for best market implementation, with pounds per square inch resistance and tensile formations, it is utilized for a good balance of strength, light weight, and form that gives reliable structural support while allowing enough flexibility to incorporate intricacies designed into components. Below is the division of uses for the automotive application:

- Body Panels and Structures: This steel is extensively used in the manufacture of external body panels, including doors, hoods, and fenders. It is strong enough to resist impact and light enough to allow fuel efficiency. With an opposing thickness of 0.0478 inches, it practically provides a hard surface with a reduced possibility of denting or deformation.

- Chassis and Frame Components: 18-gauge steel is used by many manufacturers of vehicles in chassis construction, where its fine tensile strength affords a sturdy framework without adding too much weight to the vehicle.

- Exhaust System Components: When coated, galvanized, or black-metal treated, the 18-gauge steel finds application for use in exhaust pipes and mufflers. It needs to withstand high temperatures and corrosion effects from moisture.

- Reinforcement Structures: When it comes to reinforcement structures for crumple zones or other reinforcements that absorb energy during a collision, this metal is used for the greater protection of the occupants.

- Custom and Aftermarket Fabrications: Custom vehicle builders and aftermarket manufacturers use 18-gauge steel sheets in favored body modifications, grilles, and ornamentations because of their versatility and ease of machining.

Benefits of Using 18-Gauge Steel

- Strength-to-Weight Ratio

A sheet of 18-gauge steel provides an ideal compromise between strength and weight, enhancing strength properties with comparatively less weight.

- Cost-Efficiency

Choosing the standardized thickness reduces waste of materials and ultimately reduces production costs, hence being economical for the manufacturer.

- Ease of Machining

Its manageable thickness accommodates easy cutting, forming, and welding, referring to how manufacturing procedures are eased up, and then work output is enhanced.

- Corrosion Resistance

When coated and/or treated, 18-gauge steel is less prone to rust and other environmental damage; thus, it will last.

- Versatility

The 18-gauge steel can fit the widest applications from structural components to aesthetic features, carving room for many engineering and design requirements.

Durability and Strength of Mild Steel Sheet

Mild steel sheets hold top fame for their synthesis between strength and flexibility, with a myriad of uses in numerous industries. With quite an average tensile strength between 400 and 550 MPa, mild steel is strong enough to uphold any structure but is easily workable. With the increase in system durability, they can be worked with further using systems such as galvanization or coating to guard them against environmental factors like corrosion and mechanical wear. Moreover, mild steel has a fairly good degree of ductility, which means it resists absorption of mechanical load and dynamically responds to mechanical stress such that it does not fracture. Hence it is durable either in static or load applications, setting both. This combination of mechanical properties makes mild steel sheets an indispensable material in contemporary and industrial construction.

Versatility in Various Applications

Because mild steel sheets are versatile, they are essential materials used by many industries. Within the construction industry, mild steel is extensively used in structural frameworks, reinforcing materials, and roofing applications because of its high strength-to-weight ratio and reliability under different environmental conditions. Similarly, mild steel is the backbone in the automotive industry for vehicle chassis, body panels, and components of strength coupled with formability. Prime concern for mild steel beyond this is bulk manufacturing machinery and equipment that demand stringent tolerances and wear resistance. And, as fabrication technologies advance further, with laser cutting and CNC machining leading the pack, greater possibilities are being opened for mild steel to address highly specialized industrial needs in a robust and cost-efficient manner.

Cost-Effectiveness of Carbon Steel Sheets

Carbon steel sheets still remain one of the cheapest materials usable for numerous industrial applications. Their cheapness is an outcome of high availability, ease of production, and their ability to get recycled. Steel is known to be one of the most widely produced and utilized alloys in the world, and this has brought down the cost of its manufacture through economies of scale. Subsequently, developments in steel production, such as the electric arc furnace and continuous casting method, have made manufacturing cheaper by minimizing wastage and energy consumption.

Another factor that enhances the cost-effectiveness of carbon steel sheets is their exceptional durability and long service life. Their high strength-to-weight ratio allows them to resist stress and wear in harsher environments. Also, since they are easy-to-fabricate sheets, cutting, welding, and forming reduce the cost of labor in construction and manufacturing operations. Because they are also recyclable, this adds to environmental sustainability and provides an economic incentive by drastically reducing the material cost in the long run.

Working with 18-Gauge Sheet Metal

Grading for sheet metal considers the balance of strength and workability that 18-gauge sheet metal enjoys. Measuring approximately 0.0478 inch or 1.214 millimeters, this sheet is generally chosen to very few jobs where moderate strength with low weight is considered necessary; for example: HVAC ductwork, automobile panels, and some construction elements. It can be cut, formed, and welded with relative ease using standard tools, making the product relevant for both professionals and DIY enthusiasts alike. Also, its versatility and resilience ensure that it performs reliably in most situations – whether structural or decorative.

Cutting Techniques for Cold-Rolled Steel Sheets

- Mechanical Shearing: Best suited for straight cuts, mechanical shears provide high throughput and are best for bulk processing of cold-rolled sheets. It is an economical method and is the most common in industrial practice. However, it may cause slight deformation to either one or all edges of the cut, which may require secondary finishing.

- Laser Cutting: Laser cutting ensures unmatched precision, ideal in intricate design work or cuts needing tight tolerances. High-powered lasers make this cutting process give cleaner cuts with a lesser degree of thermal distortion, thereby making it highly preferred for applications requiring the ultimate accuracy standards- automotive or aerospace engineering, for instance.

- Plasma Cutting: This technique utilizes ionized gas to cut the material efficiently. Plasma cutting is versatile enough to cut thick cold-rolled steel sheets, though the process may induce a heat-affected zone (HAZ) that needs to be accounted for in structural applications.

- Waterjet Cutting: Waterjet cutting is the utmost cutting process when testing of thermally induced stresses is to be considered. It shoots down a very powerful stream of water combined with droplets of abrasive particles to support clean cuts without imparting heat stress or deformation. Waterjet cutting suits all applications requiring exact tolerances and luxuriant edge finishing.

Finishing Options and Surface Treatments

The finishing options and surface treatment methods play an important role in improving the performance, durability, and aesthetic aspects of the processed materials. The common methods of finishing include polishing, which increases surface smoothness and diminishes surface defects, and grinding, which fine-tunes surface finish for applications requiring close tolerances. To improve corrosion resistance and provide decorative appearance, electroplating and anodizing are the most commonly used finishing processes; the importance of anodizing lies mostly with aluminum alloys due to their ability to form a protective oxide layer.

Where surfaces are subject to aggressive conditions, powder coating-based finishes represent the ideal alternative due to their uniform thickness, hardness, and resistance to chipping, scratching, and fading, thus making the environment-friendly powder coatings an alternative to traditional paints in many industrial applications. Laser texturing is a relatively emerging technology facilitating the realization of complex surface patterns that match functionalities such as improved grip or friction control.

Reference Sources

-

The Performance of Adhesive-Bonded Thin-Gauge Sheet-Metal Structures:

- Key Findings: This study explores the use of adhesive bonding in automotive applications to reduce vehicle weight. Thin-gauge sheet-metal box-section beams were tested for torsional and flexural rigidity. Adhesive-bonded structures outperformed riveted or spot-welded beams in strength and rigidity.

-

Measurement of Friction Under Sheet Forming Conditions:

- Key Findings: This research developed a new test to measure friction in sheet forming processes, focusing on bending and tension. It analyzed frictional behavior across various materials, including steel and aluminum, under different conditions. The study found complex variations in friction coefficients but no significant changes with punch speed.

-

- Key Findings: This review highlights advancements in sheet-metal forming, including metallurgical improvements and innovations in tooling design. It discusses the impact of yield locus shape on strain distribution and the ability to form tapered shells using thinner gauges without interstage annealing.

Frequently Asked Questions (FAQs)

Q: What is the thickness of 18-gauge sheet metal?

A: 18-gauge sheet metal refers to a specific thickness measured in inches, which is approximately 0.048 inches or 1.214 millimeters. This measurement is part of the American Wire Gauge (AWG) system, which is commonly used to gauge metal thickness in various industries. The thickness of 18 gauge makes it suitable for a variety of applications, including automotive fabrication, construction, and general metalworking projects. It provides a good balance between strength and weight, making it a popular choice for both structural and decorative purposes. Additionally, 18-gauge sheet metal can be found in both cold-rolled and hot-rolled varieties, affecting its surface finish and overall properties.

Q: Where can I buy 18-gauge cold-rolled steel sheets?

A: You can buy 18-gauge cold-rolled steel sheets from various suppliers and online retailers that specialize in metal products. Many of these suppliers offer options to cut to size, allowing you to get the exact dimensions needed for your project. It’s important to check the specifications and properties of the steel, such as the finish and surface treatment, to ensure it meets your requirements. Additionally, local hardware stores or industrial metal supply shops may carry mild steel sheets in various gauges, including 18 gauge. Online platforms often provide a wider selection and competitive prices, making it easier to find the right product for your needs.

Q: What are the properties of an 18-gauge mild steel sheet?

A: An 18-gauge mild steel sheet has several important properties that make it ideal for a range of applications. It is known for its excellent weldability, ductility, and formability, allowing for easy fabrication into various shapes and designs. The mild steel’s low carbon content contributes to its malleability, making it suitable for automotive panels and other structural components. Additionally, 18-gauge mild steel sheets often have a smooth surface finish, which can be advantageous for aesthetic applications. When considering the properties of this material, it’s also essential to factor in its strength-to-weight ratio, as it provides sufficient strength without adding excessive weight to the final product.

Q: What are the common applications for 18-gauge steel sheets?

A: 18-gauge steel sheets are widely used in various industries due to their versatility and strength. Common applications include automotive body panels, appliance casings, and industrial equipment enclosures. In construction, they can be used for roofing, wall panels, and structural supports. The thickness of 18 gauge provides a good balance of durability and ease of handling, making it suitable for both lightweight and heavy-duty applications. Additionally, due to its fabrication capabilities, it is often used in custom projects where specific dimensions and designs are required. The variety of finishes available for 18-gauge steel sheets also allows for tailored solutions to meet aesthetic and functional needs.

Q: What is the difference between cold-rolled and hot-rolled 18-gauge sheet metal?

A: The primary difference between cold rolled and hot rolled 18 gauge sheet metal lies in the manufacturing process and resulting properties. Cold-rolled steel sheets are processed at room temperature, which results in a smoother surface finish and tighter tolerances. This type of steel is often used for applications requiring precision, such as automotive parts and decorative elements. In contrast, hot-rolled steel is processed at elevated temperatures, which can lead to a rougher surface and less precise dimensions. Hot-rolled sheets are typically used in structural applications where exact measurements are less critical. Understanding these differences is essential when selecting the appropriate type of 18-gauge sheet metal for your specific project.