Stainless steel sits at the crossroads of engineering, manufacturing, and everyday convenience. Its reputation rests on an unusual blend of toughness, resistance to rust, and the uncanny ability to adopt finishes that range from mirror-smooth to industrial matte. Yet, the phrase stainless steel hardly pinpoints the material because hundreds of alloy recipes share that label. Curious buyers and seasoned specifiers alike can be bewildered by the sheer alphabetical soup. Two designations that often surface in conversation are the shorthand 18-8 and the fuller 304; many people speak as if they mean exactly the same thing. This article tries to clear away that fog. The goal is straightforward: set down what each grade is, what it contains, and how it behaves when pressed into actual service. No lofty rhetoric, just hard facts that engineers, shop-floor managers, and the naturally inquisitive can use with confidence.

What is 18-8 Stainless Steel?

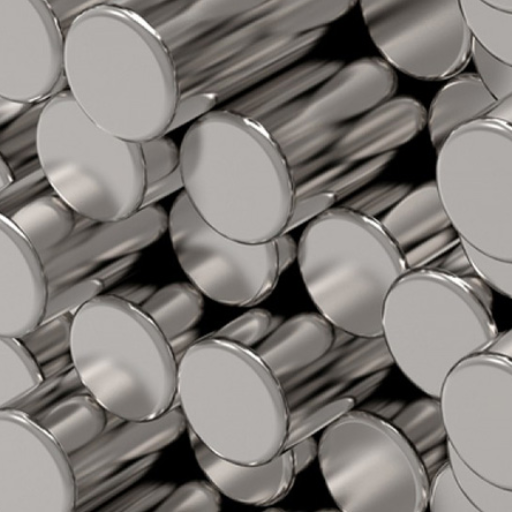

The technical moniker 18-8 pinpoints an open-ended family of steels boasting roughly 18 percent chromium and 8 percent nickel; steelmakers treat the figure as a suggestive guide rather than a fixed formula. Those two elements, chromium and nickel, bond with iron to form a durable oxide layer that blocks further oxidation. In plain English, that layer appears so quickly after manufacture that the metal looks usable almost straight off the mill floor. Commercial kitchens, medical gear, and mass-market appliances lean on that quick-protect feature because replacements can be costly if machinery rusts. Building plumbing, aircraft fasteners, and even the saddles that cradle guitar strings follow an identical impulse, albeit for mildly different reasons rooted in pressure, vibration, or simple style.

Composition and Characteristics of 18-8 Stainless Steel

Mechanical engineers frequently select 18-8 stainless steel because the alloy strikes a practical balance among strength, ductility, and resistance to rust. In laboratory testing, tensile strength usually falls between 515 and 862 MPa and yield strength measures between 205 and 310 MPa, with values varying according to work-hardening and heat-treatment procedures. Elongation often exceeds 40%, confirming that the steel can stretch considerably before pulling apart.

Toughness does not abandon the steel at either extreme of the temperature scale. Specimens remain tough at cryogenic lows and do not shatter or become brittle at the soaring temperatures seen in some aerospace missions. Hardness typically registers around 78 on the Rockwell B scale, so the alloy resists scratches and minor abrasion during everyday service. When engineers combine these mechanical traits with the alloy’s well-known immunity to pitting and general corrosion, the choice becomes clear for environments ranging from food processing to marine hardware. 18-8 stainless steel keeps showing up wherever industry demands enduring strength and reliable behavior in the presence of moisture or chemicals.

How Does 18-8 Stainless Steel Compare to Other Grades?

|

Grade |

Composition Highlights |

Strength |

Corrosion Resistance |

Applications |

Key Features |

|---|---|---|---|---|---|

|

18-8 Stainless Steel |

~18% Chromium, ~8% Nickel |

High |

Excellent |

Aerospace, cryogenics, food industry |

General-purpose, versatile |

|

~18% Chromium, ~8% Nickel |

Moderate |

Excellent |

Kitchenware, architecture |

Cost-effective, widely used |

|

|

316 Stainless Steel |

~16% Chromium, ~10% Nickel, Mo |

Higher than 304 |

Superior to 304 |

Marine, chemical processing |

High corrosion, chloride resistance |

|

430 Stainless Steel |

~16-18% Chromium, low Nickel |

Moderate |

Moderate |

Automotive trim, appliances |

Ferritic, magnetic properties |

|

202 Stainless Steel |

Low Nickel, high Manganese |

Lower than 304 |

Lower than 304 |

Household goods, containers |

Cost-efficient alternative |

|

410 Stainless Steel |

~13% Chromium, low Nickel |

High |

Moderate |

Cutlery, tools, machinery |

Hard, wear-resistant |

Common Applications of 18-8 Stainless Steel

- Food and Beverage Industry

Manufacturers reach for 18-8 stainless steel the moment they design fry pans, mixer housings, or the mobile tanks that shuttle soup through the process line. The alloy sits quietly, refusing to react with the food inside or impart any metallic hint of its presence.

- Medical Equipment and Instruments

Hospitals depend on the same grade for scalpels, orthopedic plates, and the clutter of carts that move from ward to sterilization room. Steam, chemicals, and dry heat bombard the tools, yet rust rarely finds a foothold.

- Chemical Processing

Chemical plants give 18-8 a workout inside pipelines, pressure vessels, and tanks that cradle acids or brines for days or even years on end. The metal laughs at low levels of oxidation and shrugs off most corrosive liquids that threaten lesser grades.

- Architectural and Structural Applications

Architects specify the alloy for curtain-wall systems, balcony railings, and structural trusses exposed to city smog and rainy weekends. The steel holds its finish long after the glass and painted carbon steel would fail.

- Marine Equipment

Boat builders use it for handrails, bait-well liners, and small fuel tanks, using the chromium-nickel blend to resist spray and humidity. Saltwater pounces instantly, but the alloy still outlasts cheaper steels in anything short of daily submersion.

Taken together, these stories explain why the world keeps inventing uses for 18-8 stainless. Few materials blend ease of fabrication, reasonable cost, and such broad immunity to the tricks that water, heat, and air play on metal.

What is the Difference Between 18-8 and 304 Stainless Steel?

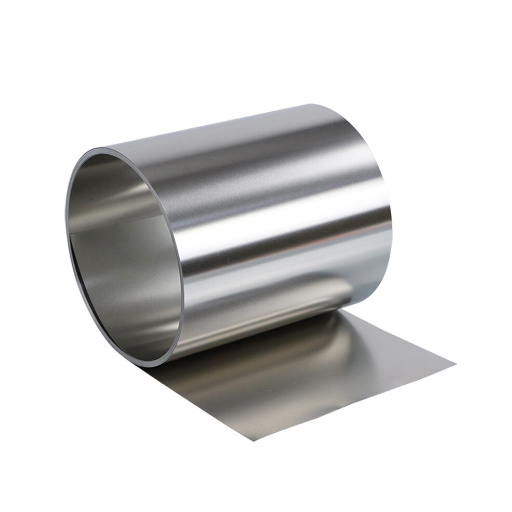

The catch-all term 18-8 stainless steel describes an alloy with approximately 18 percent chromium and 8 percent nickel, yet the phrase is loose enough that grades beyond 304 can slip into the conversation. Technically, 18-8 signals a general family of stainless steels rather than any one precise formulation. That broad categorization often confuses newcomers who assume the label pinpoints a single grade.

304 stainless steel narrows the picture by imposing tighter chemical and mechanical limits. Users find the grade indexed individually in specifications because it reliably reduces carbon content and clarifies yield-strength expectations. Engineers appreciate that uniformity, even if the steel shows up in practice tagged with the looser 18-8 label.

Comparative Analysis of 18-8 vs 304

Carbon shifts the conversation in meaningful ways. Unless specified otherwise, 304 keeps carbon capped at 0.08%; its low-carbon sibling 304L trims that figure to 0.03% to protect welded joints. Those small decimals enlarge the difference once heat and humidity start threatening intergranular corrosion.

Across most mechanical benchmarks, standard 18-8 stainless steel and grade 304 behave in almost identical ways, sitting together in the usual tensile-strength lane of 515 to 730 MPa. Elongation figures hover close to 40%, so engineers rarely worry about sudden brittle failure. Still, the grade 304 recipe, in particular its heavier slug of chromium and nickel, gives it a surprising edge when the atmosphere turns salty or laced with harsh chemicals. That attribute alone persuades food, medical, and marine fabricators to pay the small premium, because predictable behavior in corrosive service usually beats the wider 18-8 specification tolerances that sometimes sneak in unwanted surprises.

Strength and Durability: 18-8 vs 304

In practice, toughness and durability tilt ever so slightly toward 304, even if the two alloys start from nearly the same chemistry. Both can climb to take or leave a few hundred psi the 510 to 770-MPa plateau once polish, harden, or cryogenically tempering swing into the picture. Where stress cycles multiply, though, the added nickel-chromium cocktail in 304 digs in, cracks less often, and simply lasts longer under relentless flexing or vibration. That resilience turns out to be the quiet reason aerospace, pharmaceutical, and power-generation shops habitually reach for 304, trusting it will shrug off fatigue after the gauges stop blinking.

The familiar 18-8 formulation works perfectly for many routine jobs, yet the tighter chemistry of 304 stainless steel adds an extra margin of defense against rust and pitting. Field personnel often notice that the alloy survives extreme temperature swings and sudden pressure spikes without losing strength. Because 304 meets the latest ASTM and ISO benchmarks, maintenance engineers trust it to deliver predictable performance when public safety hangs in the balance.

What Are the Advantages of 304 Stainless Steel?

- Corrosion Resistance

The alloy commonly designated 304 stainless steel remains one of the engineering world’s first choices because of its remarkable immunity to rust and oxidation, even when humidity creeps well into a workspace. Sand, splash, or spill water on a finished part, and the invisible protective film keeps the base metal out of trouble.

- Durability

The material also tolerates mechanical stress better than many substitutes, so engineers often select it for load-bearing beams as well as lighter fixtures. From scaffolding to kitchen sinks, the steel blends strength, ductility, and weldability in one package.

- Versatility

Trades people appreciate the steel for another reason: it bends, cuts, and welds with minimal fuss. Shapes emerge quickly, whether the job calls for sink bowls, brewery pipe runs, or curtain-wall framing on a high-rise. Because of this workability, rotation among kitchen, factory, and construction uses is almost seamless.

- Hygiene and Cleanability

Cost is another advantage. While specialists’ grades are pricier, 304 delivers solid performance at a midmarket price point. Budget planners appreciate the combination of quality and economy.

- Cost-Effectiveness

Cost is another advantage. While specialists’ grades are pricier, 304 delivers solid performance at a midmarket price point. Budget planners appreciate the combination of quality and economy.

Corrosion Resistance of 304 Stainless Steel

Designers routinely reach for this grade because the chromium-nickel mix-seventeen or 18% chromium for every one and 8% nickel-grows a tight, dust-thin oxide skin the moment the surface is exposed. That shield thwarts clean-room acids, marine salts, and even the smudged tomatoes found in busy kitchens. Chemical plants, offshore vessels, and food-packing lines all tolerate stainless steel 304, so chances are the same steel will outlive the project.

304 stainless steel stands out for its remarkable toughness in the face of atmospheric rust. Urban air loaded with sulfur dioxide or seaside winds carrying chlorides hardly phase it. Engineers trace that resilience to the alloy’s nickel-chromium balance, which locks moisture out of the surface. Even at eye-watering spikes near 870°C (1598°F), and through endless rounds of thermal cycling, the metal does not droop or crack. Because of this durability, designers lean on 304 when they need a material that keeps working.

Common Industries Using 304 Stainless Steel

Varied industries pull 304 stainless in different directions, yet it keeps delivering. Food-and-beverage plants line processing vats and transfer lines with the grade because spills and caustic cleaners show no mercy. Medical inventory mirrors that choice; scalpels, sterilizers, and sometimes even implants echo the shine of hospital carts. The shared reason is hygiene. 304 brushes off microbes the way glass repels fingerprints, and the alloy endures the repeated wipes that keep those surfaces clean.

304 stainless steel has built a loyal following in construction for roofing skins, curtain-wall panels, and exposed framework, mainly because rain, sun, and salt cannot easily dent its finish. Chemical plants and refinery corridors stock the alloy in columns, heat exchangers, and bulk-storage vessels, trusting its simple chemistry to shrug off acids, sulfides, and other tough cocktails. Automakers and airframe builders likewise turn to the grade when they need exhaust tubing or backup ribs that must survive both soot and a searing fly-by-wire schedule. Such a varied biography shows why engineers rarely question whether to specify 304, it simply behaves.

What is the 300 Series Stainless Steel?

The 300 series stainless steel describes a large family of austenitic alloys admired for their all-purpose utility, strength, and immunity to corrosion. Each grade typically blends chromium with a sizable portion of nickel, elements that fend off oxidation and keep rust at bay. Grades most often referenced 304, 316, and, in specialized cases, 321 appear almost everywhere, from kitchen equipment to pressure vessels and surgical instruments. They have become especially trusted in mills, clinics, and any workplace where hygiene cannot be a secondary thought.

Characteristics of the 300 Series

- Corrosion Resistance

Corrosion resistance stands at the head of the 300 series resume, and that protection comes chiefly from the chromium and nickel content. Steels of this kind shrug off moisture, salt fog, and most mild acids, which is why piping, fasteners, and tanks made from these grades endure while less robust metals often fail.

- Austenitic Microstructure

Austenite crystals give the series its soft magnetic footprint, keep the pace through a wide sweep of temperatures, and continue to absorb shock without snapping, even when the thermometer drops.

- High Tensile Strength

Many engineers reach for the 300 series the moment heavy tensile strength becomes a priority. Strength values cluster between 515 MPa and 750 MPa, depending on the precise alloy and the finishing schedule, yet even the low end feels reassuring in a support beam.

- Weldability

Weldability is another hallmark feature; most 300-series alloys join easily because they do not require preheat or postheat treatment. Grades such as 304 and 316 keep their strength and resist rust even after intensive field welding.

- Non-Hardenability by Heat Treatment

Conventional quenching and tempering will not harden this family of steels, a limitation that practitioners quickly learn. Instead, the alloys gain toughness the old-fashioned way: repeated bending, rolling, or hammering induces a microscopic lattice shift known as work hardening.

Because of their combined resistance to corrosion, impressive strength, and pleasant machinability, the 300 series has settled comfortably in arenas as diverse as hospital equipment, offshore oil rigs, and urban construction.

Types of 300 Series Stainless Steel

|

Type |

Key Composition |

Properties |

Applications |

Other Notes |

|---|---|---|---|---|

|

301 |

Chromium, Nickel, Iron |

High strength, corrosion resistance |

Springs, automotive parts, conveyors |

Work hardening improves strength |

|

302 |

~18% Chromium, ~8% Nickel |

Excellent corrosion resistance |

Food processing, utensils |

Similar to 304 but stronger |

|

303 |

Added Sulfur or Selenium |

Improved machinability, moderate corrosion |

Screws, nuts, aircraft fittings |

Reduced corrosion vs. 304 |

|

304 |

~18% Chromium, ~8% Nickel |

High corrosion resistance, versatile |

Kitchenware, buildings, medical devices |

Most commonly used grade |

|

304L |

Low Carbon variant of 304 |

Improved welding properties |

Chemical tanks, welded structures |

Less carbide precipitation |

|

305 |

Higher Nickel content |

Non-magnetic, excellent formability |

Automotive trim, deep-drawn parts |

Low work hardening rate |

|

309 |

High Chromium, Nickel |

Heat and oxidation-resistant |

Furnace parts, kiln liners |

Withstands extreme temperatures |

|

310 |

High Chromium, Nickel |

Superior high-temperature performance |

Heat-resistant equipment, kilns |

Better than 309 at high heat |

|

316 |

Chromium, Nickel, Molybdenum |

Enhanced corrosion in chlorides |

Marine equipment, chemical processing |

Molybdenum adds resistance |

|

316L |

Low Carbon variant of 316 |

Low-temperature toughness, weldability |

Pharmaceutical, marine environments |

Used where welding is needed |

|

317 |

High Molybdenum content |

Superior pitting and corrosion resistance |

Pulp and paper, chemical industries |

Better chemical resistance |

|

321 |

Titanium-stabilized |

Excellent corrosion, intergranular resistance |

Aerospace, chemical processing |

Good for high temperatures |

|

347 |

Niobium-stabilized |

Strong against intergranular corrosion |

Aerospace, engines, chemical tanks |

Resists high heat and acids |

When to Use 316 Stainless Steel Instead of 304?

Select 316 stainless steel over the more common 304 grade whenever the working environment is relentlessly wet, salty, or chemically aggressive. The marine engineer who battles open oceans or a city transit manager who confronts truckloads of de-icing brines quickly learns that 316 will last longer with far less maintenance. Pitting, crevice corrosion, and unexpected red rust become far less of a headache. Another plus: strong acids and caustic bases leave 316 standing while 304 may begin to fail, especially after long exposure. Many research labs and medical-device manufacturers keep that property in mind when the number 316 appears on the order form.

Corrosion Resistance of 316 Stainless Steel

Corrosion-resistive performance rests upon elemental choices the steel mills make at the blender. Roughly 16-18% chromium, just shy of tarnishing the surface into a mirror, and 10-14% nickel give both alloys most of their toughness and shine. The decisive molecule, however, is the 2-3% molybdenum that fortifies the metal against small electrochemical attacks in nooks and crannies. Because seawater and heavily salted highways stage plenty of those attacks, 316 finds a natural home in marine winches, desalination piping, offshore drilling, and any system that must endure twenty-four seven contact with chlorides.

A thin, passive oxide film develops almost immediately on 316 stainless steel and keeps oxidation at bay. If the surface gets scratched, the layer reforms on its own as long as oxygen is around. Tests show that in chloride-rich water above 200 ppm, the added molybdenum in 316 gives it a clear edge over 304. That extra protection matters in the petrochemical sector, where pipes and valves face both heat and aggressive fluids almost nonstop.

Applications for 316 Stainless Steel

- Marine Environments: Marine hardware thrives on the alloys’ pitting resistance because ocean spray delivers chlorine at levels far beyond 200 ppm. Anchors, railings, and offshore platforms made from 316 show no serious rust after years submerged in salt water; many comparable metals break well before that milestone.

- Chemical and Petrochemical Industry: Chemical-processing plants depend on the grade for tanks and piping that must survive sulfuric acid for one hour and caustic soda the next. Laboratory studies report up to a 50% longer service life in 316 when exposed to strong acids, nodding to the molybdenum as the hero element. Heat exchangers run cooler and safer because leaks in the stainless walls take much longer to appear.

- Pharmaceutical and Food Processing: In the dairy plant or brewery, mixing tanks built from 316 stainless steel offer peace of mind, since the alloy does not react with milk proteins or hops. The same tanks survive daily clean-in-place routines with caustic detergents, allowing operators to maintain sanitary surfaces without replacing equipment every few years.

- Medical Instruments and Implants: Surgeons reach for scalpel blades and retractors made of 316 because the steel can be sterilized, bent into fine shapes, and still hold their edge through hundreds of procedures. Long-term studies indicate that joint implants crafted from the same alloy resist corrosion from synovial fluid, outlasting the biological tissue they were meant to support.

- Architectural and Construction Applications: Skyline condominiums often boast handrails that shimmer with a brushed finish; 316 stainless steel is chosen for its mirror-like look and stubborn refusal to pit when sea spray blows in from the harbor. Building inspectors note that even after a decade in a salt-laden city, the fasteners and cladding show barely perceptible wear.

The varied roles of 316 stainless steel, from pharmaceutical corridors to operating rooms and urban façades, prove that few materials combine endurance, hygiene, and aesthetic longevity so reliably. Engineers keep it on the short list whenever the service environment promises repeated extremes of heat, chemical attack, or biological exposure.

Reference Sources

-

All About 18/8 Stainless Steel: What it is and How it’s Used

This article provides an overview of 18/8 stainless steel, its composition, and its versatile applications. -

18-8 Stainless Steel: Composition, Uses & Comparison

A detailed analysis of the composition, applications, and comparisons of 18/8 stainless steel. -

Corrosion Behavior of 18/8 Stainless Steel and Nickel-Plated Medium Carbon Steel

This research investigates the corrosion resistance of 18/8 stainless steel in specific environments.

Frequently Asked Questions (FAQs)

Q: What is the difference between 18-8 and 304 grade stainless steel?

A: The main difference between 18-8 and 304 grade stainless steel is their chemical composition. Both grades are austenitic stainless steels, but 18-8 typically contains 18% chromium and 8% nickel, while 304 grade stainless steel is essentially the same composition, which is why they are often used interchangeably in various applications.

Q: Are 18-8 stainless steel fasteners suitable for food processing equipment?

A: Yes, 18-8 stainless steel fasteners are often used in food processing equipment due to their good corrosion resistance and ability to withstand harsh environments. This makes them ideal for applications where sanitation is crucial.

Q: What does the term ‘grade stainless steel’ refer to?

A: The term ‘grade stainless steel’ refers to the specific classification of stainless steel based on its chemical composition and properties. For example, 304 is a commonly used grade of stainless steel that is known for its corrosion resistance and durability.

Q: How does the corrosion resistance of 18-8 compare to that of 304 stainless steel?

A: The corrosion resistance of 18-8 and 304 stainless steel is quite similar, as they both belong to the same series of stainless steel alloys. However, 304 stainless steel may have slightly better corrosion resistance in certain environments due to its higher nickel content.

Q: Can 18-8 stainless steel be annealed?

A: Yes, 18-8 stainless steel can be annealed to improve its ductility and reduce internal stresses. Annealing is a heat treatment process that helps in cold working the steel and enhancing its properties.

Q: In what applications is 304 grade stainless steel commonly used?

A: 304 grade stainless steel is commonly used in various applications, including cookware, processing equipment in the food industry, and parts that require good corrosion resistance. Its versatility makes it a popular choice across multiple industries.

Q: What is the significance of the term ‘austenitic stainless steel’?

A: Austenitic stainless steel refers to a category of stainless steel that has a face-centered cubic crystal structure, which gives it excellent toughness and corrosion resistance. Both 18-8 and 304 grades fall under this classification.

Q: What are the benefits of using stainless steel fasteners over mild steel?

A: Stainless steel fasteners, such as those made from 18-8 or 304 grades, offer better corrosion resistance, higher strength, and durability compared to mild steel. This makes them suitable for use in harsh environments where rust and degradation can occur.

Q: How can I determine the grade of stainless steel for my project?

A: To determine the grade of stainless steel for your project, you can look at the chemical composition, consult with a material specifications database, or use tests like magnetic attraction or spark testing to identify the type of stainless steel being used.