AA 3004 (EN AW-3004) Aluminum Alloy Sheet

Top AA 3004 (EN AW-3004 Aluminum Alloy Sheet Manufacturer in China

The AA 3004 Aluminum Alloy Sheets are considered premium, non-heat-treatable alloys of the aluminum manganese family, with magnesium for strengthening purposes. Because it possesses excellent corrosion resistance, medium strength, and superb formability, this alloy is broadly applicable.

Discover high-quality AA 3004 (EN AW-3004 aluminum alloy sheet products here.

Home » Aluminum Alloy Sheet » AA 3004 (EN AW-3004) Aluminum Alloy Sheet

-

Characteristics of 3004 (EN AW-3004) Aluminum Alloy Sheet

- Improved Strength: Slightly stronger than 3003 aluminum alloys due to magnesium additions of 0.8 to 1.3%.

Outstanding - Corrosion Resistance: Strongly resistant to atmospheric corrosion and unsuitable for chemical environments, making it an excellent choice for outdoors and industrial products.

- Good Forming: Good drawing and forming characteristics make it suitable for designs with complex shapes.

- Lightweight: Its low density, 2.72 g/cm³, makes it a strong candidate for weight-sensitive applications.

- Easily Weldable: The alloys can be welded easily by any standard welding method, including TIG and MIG methods, with 1100 or 4043 filler alloys.

- Not Heat-Treatable: Resists conventional heat treatment and is strengthened only by cold working, rendering it essentially stable during storage.

- Application Areas: Able to be used in packaging, construction, industrial machinery, and consumer goods because of its versatility.

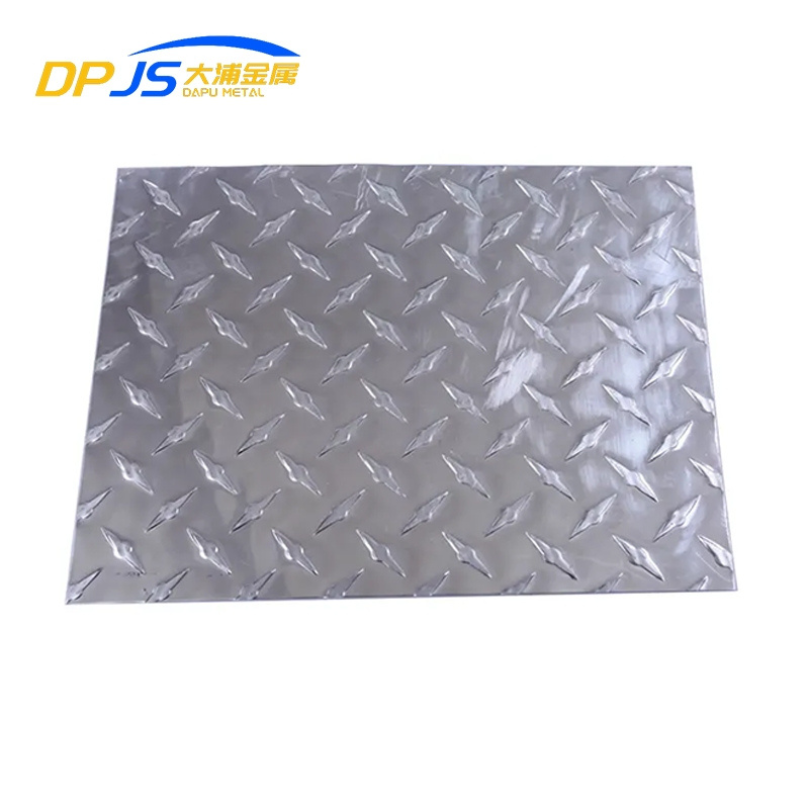

- Finish Options: Available in mill, paint, or stucco embossing finishes to give the product both cosmetic and better performance features.

AA 3004 (EN AW-3004) Aluminum Alloy Sheet Technical Specifications

| Element | Composition (%) |

|---|---|

| Silicon (Si) | 0.30 max |

| Iron (Fe) | 0.70 max |

| Copper (Cu) | 0.25 max |

| Manganese (Mn) | 1.0 - 1.5 |

| Magnesium (Mg) | 0.8 - 1.3 |

| Zinc (Zn) | 0.25 max |

| Others (each) | 0.05 max |

| Others (total) | 0.15 max |

| Aluminum (Al) | Remainder |

| Property | Value (H34 Temper) |

|---|---|

| Tensile Strength | 220 MPa min |

| Yield Strength | 180 MPa min |

| Elongation | 5% min (in 50mm) |

| Brinell Hardness (HB) | 55 HB min |

| Shear Strength | 140 MPa min |

| Fatigue Strength | 90 MPa min |

| Modulus of Elasticity | 69 GPa |

| Property | Value |

|---|---|

| Density | 2.72 g/cm3 |

| Melting Point | 645–655°C (1193–1211°F) |

| Thermal Conductivity | 160 W/m·K |

| Electrical Conductivity | 40% IACS |

| Thermal Expansion | 23.4 µm/m·°C (20–100°C) |

| Specific Heat Capacity | 0.900 J/g·°C |

- ISO: AlMn1Mg1

- UNS: A93004

- EN: AW-3004 / AlMn1Mg1

- JIS: A3004

Common Applications of AA AA 3004 (EN AW-3004) Aluminum Alloy Sheet

Packaging Industry

Construction and Architecture

Industrial Equipment

Consumer Goods

-

AA 3004 (EN AW-3004) Aluminum Alloy Sheet Customization

In addition to the usual stock, we offer full-service processing and can produce AA 3004 (UNS A93004) Lightweight Aluminum Sheets to your own special requirements.

- Custom Dimensions: We offer precision cutting and shearing services tailored exclusively to your length, width, or shape requirements.

- Thickness Range: Thin aluminum sheet for lightweight applications or heavy-duty sheets.

- Surface Finish: Choose from mill finish, painted finish, or stucco embossing for aesthetic and functional purposes.

- Processing Services: Custom value-added processing services including bending, welding, CNC machining, punching, and fabrication into ready-to-install components.

Contact our technical team today for a custom fabrication consultation to develop the ideal solution for your project!

Contact Us

Depending on the superior quality of materials, your project can be considered successful. We provide quality-assured AA 3004 (EN AW-3004) Aluminum Alloy Sheets, capable of living up to the exacting industry standards for effectiveness and durability. Partnering with us means that you can use our vast inventory and superior processing facilities to meet your exact needs-from standard stock to highly customized components. Thus, we deliver not just a product but a promise for equal measures of quality and reliability in your most rigorous applications.

Send your inquiry to our expert team for a no-obligation, competitive quote and material consultation. We are there for you in discussing your technical requirements and tailoring solutions for you with the best pricing and most timely delivery. Let us enable an easier procurement process for you and fulfill your project perfectly with all the help it deserves. GO AHEAD WITH YOUR INQUIRY NOW to get top-end materials!

Latest Articles ※