Structural Steel

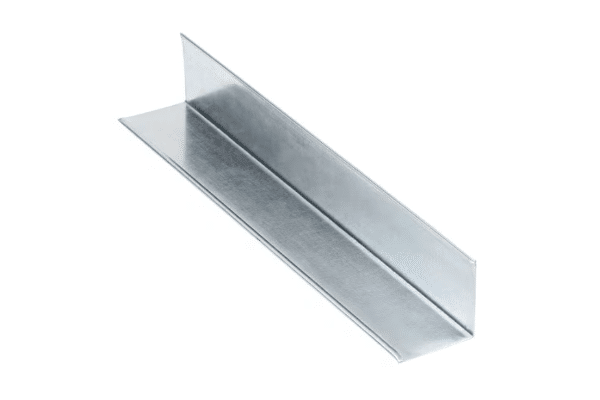

Angle Iron (L-Bar)

Equal & Unequal Leg Configurations

The versatile structural backbone for industrial framing, bracing, and support. Available in standard lengths or custom cut-to-size with precision tolerances.

Choose Your Configuration

Angle iron is defined by the length of its two legs. Select the profile that fits your structural requirements.

Equal Angle

Symmetrical Legs (Leg A = Leg B)- Geometry Perfect 90° Symmetry

- Typical Sizes 20x20mm to 200x200mm

- Stress Distribution Balanced / Uniform

Unequal Angle

Asymmetrical Legs (Leg A ≠ Leg B)- Geometry L-Shaped Asymmetry

- Typical Sizes 100x75mm, 150x90mm etc.

- Mounting One wide face for attachment

Example: "4 x 3 x 1/2" means one leg is 4 inches, the other is 3 inches, and the steel is 1/2 inch thick.

Engineered for Every Environment

Select the right grade based on your project's exposure to moisture and load requirements.

Carbon Steel

ASTM A36The industry standard. High strength, easy to weld and drill. The most cost-effective choice for indoor structures.

Galvanized

A36 + Hot Dip ZincCarbon steel dipped in molten zinc. Provides a rugged, sacrificial coating that prevents rust for decades.

Stainless Steel

AISI 304 / 316LMaximum corrosion resistance with a clean, sanitary finish. 316L is recommended for marine use.

Aluminum

6061-T6Lightweight (1/3 weight of steel) with good corrosion resistance. Ideal where weight savings are critical.

Engineer's Insight: A36 vs. A572-50

Standard angle iron is typically ASTM A36 (36,000 psi yield). For heavy structural projects requiring higher strength-to-weight ratios, request ASTM A572 Grade 50 (50,000 psi yield). We stock both, but A36 is the default for general use.

Critical Applications Across Industries

From supporting skyscrapers to organizing warehouses, angle iron is the unsung hero of structural engineering.

Construction & Lintels

Used extensively as lintels to support brickwork above doors and windows, or as diagonal bracing in steel frames.

Structural Support

Racking & Shelving

The primary component for heavy-duty pallet racks and mezzanines. Punched angle allows for adjustable shelf heights.

Modular & Adjustable

Machinery Bases

Provides a rigid, vibration-resistant frame for motors, generators, and heavy industrial equipment.

Rigidity

Utility Towers

Galvanized angle iron is bolted together to form lattice towers for electricity transmission and telecommunications.

Wind ResistanceStock Dimensions

Stocked in standard 20ft (6m) and 40ft (12m) lengths. Custom cut-to-size available.

Equal Leg Angles

Most Common| Size Range (Inch) | Thickness Range | Weight (lbs/ft) |

|---|---|---|

| 1/2" x 1/2" | 1/8" | 0.38 |

| 1" x 1" | 1/8" - 1/4" | 0.80 - 1.49 |

| 2" x 2" | 1/8" - 3/8" | 1.65 - 4.70 |

| 3" x 3" | 3/16" - 1/2" | 3.07 - 9.40 |

| 4" x 4" | 1/4" - 3/4" | 6.60 - 18.50 |

| 6" x 6" and larger | 3/8" - 1" | 14.90 - 37.40 |

Unequal Leg Angles

Specialized| Size Range (Inch) | Thickness Range | Weight (lbs/ft) |

|---|---|---|

| 2" x 1-1/2" | 1/8" - 1/4" | 1.44 - 2.77 |

| 3" x 2" | 3/16" - 1/2" | 3.07 - 7.70 |

| 4" x 3" | 1/4" - 1/2" | 5.80 - 11.10 |

| 5" x 3" | 1/4" - 1/2" | 6.64 - 12.80 |

| 6" x 4" | 3/8" - 3/4" | 12.30 - 23.60 |

| 8" x 6" and larger | 1/2" - 1" | 23.00 - 44.20 |

Need a size not listed? Download our Full Size & Weight Chart (PDF) or contact us for custom rolling.

Ready-to-Install Services

Don't waste time cutting on-site. Let us process your angle iron to exact specifications.

Precision Saw Cutting

Band saw cutting to your exact length requirements with tight tolerances (±1/16"). No scrap metal waste at your job site.

Punching & Slotting

Pre-punched round holes or elongated slots for bolted connections. Ideal for shelving, racks, and adjustable frames.

Priming & Galvanizing

Apply Red Oxide primer for temporary rust protection, or Hot-Dip Galvanize post-fabrication for maximum longevity.

Specialty: 45° Miter Cuts

Building a frame? We can miter cut angle iron ends to a perfect 45-degree angle, making your corner welding fast and square.

- Clean Edges: Deburred and ready to weld.

- Perfect Fit: Creates a tight 90° corner.

- Custom Shapes: Notching and coping also available.

Figure: 45° Miter for Corner Frames

Common Questions

Technical answers to help you select the right structural angle.

Which grade is best for outdoor use?

Standard A36 carbon steel will rust quickly outdoors. For outdoor projects, we recommend Hot-Dip Galvanized Angle (A36 dipped in zinc) for the most cost-effective rust protection. For marine environments or superior aesthetics, choose 316 Stainless Steel.

What is the load capacity of angle iron?

Load capacity depends on the span length, support method, and orientation (leg up or leg down). Please contact our engineering team for a specific Load Table based on ASTM A36 specifications. Do not guess on structural loads.

Is it hard to drill holes in angle iron?

No. A36 Low Carbon steel is relatively soft and easy to drill with standard HSS (High-Speed Steel) bits. However, stainless steel (304/316) is much harder and requires cobalt bits and slow drilling speeds to prevent work-hardening.

What is the difference between Hot Rolled vs. Cold Rolled?

Most structural angle is Hot Rolled (HR), which has a rougher "mill scale" surface and rounded corners inside the L-shape. Cold Rolled angle is rarer, has sharper corners, tighter tolerances, and a smooth shiny finish, usually used for furniture or display cases.

Pro Tip: How to Measure Correctly

Always specify dimensions in this order: Leg 1 Length × Leg 2 Length × Thickness.

Example: A "2 x 2 x 1/4" angle has two legs that are each 2 inches long, and the steel is 1/4 inch thick.